LED lamp with inserting type wire outlet position waterproof structure

A waterproof structure and LED lamp technology, which is applied in the direction of air-proof/waterproof devices, components of lighting devices, lighting devices, etc., can solve problems such as uneven force, poor connection strength, and weak tensile capacity of clamped wires , to achieve the effect of ensuring waterproof sealing, ensuring tensile strength and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

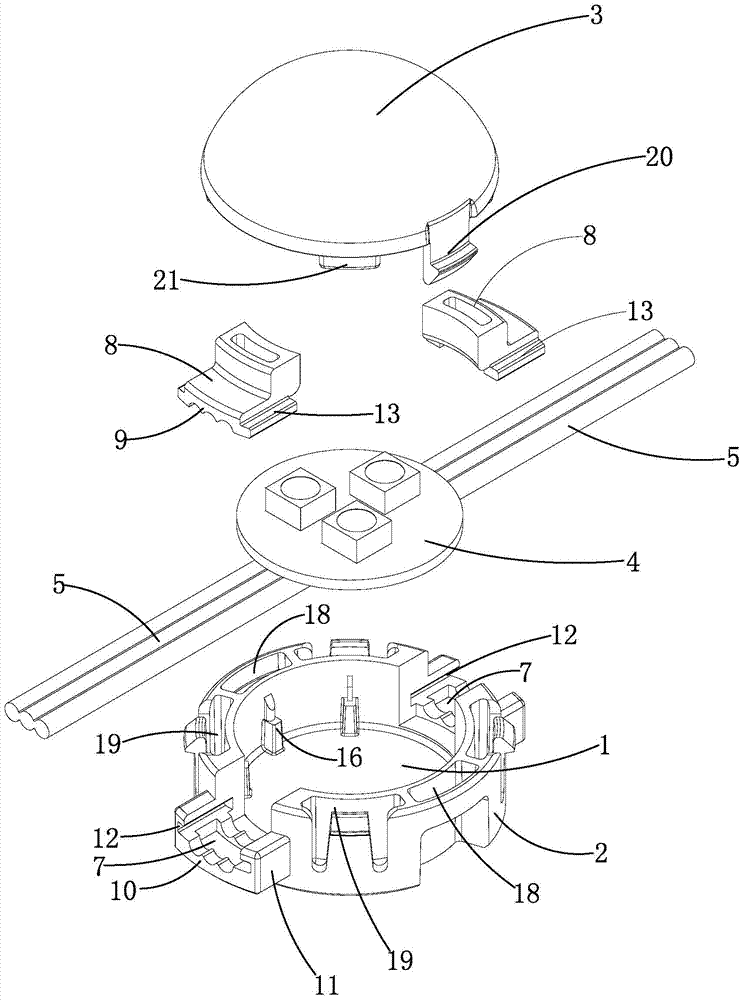

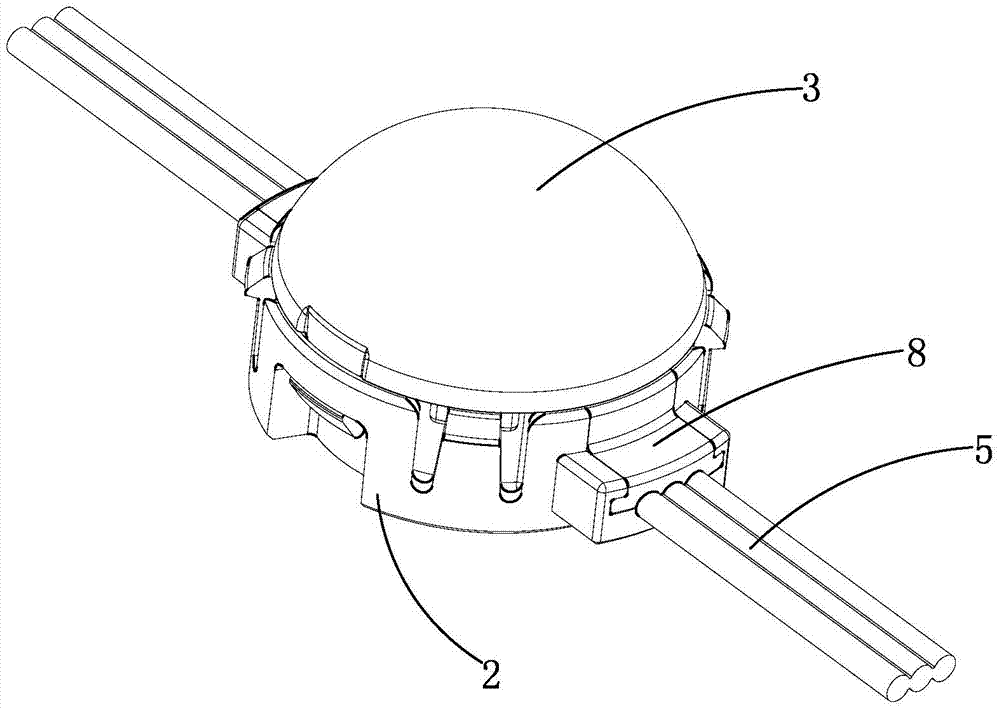

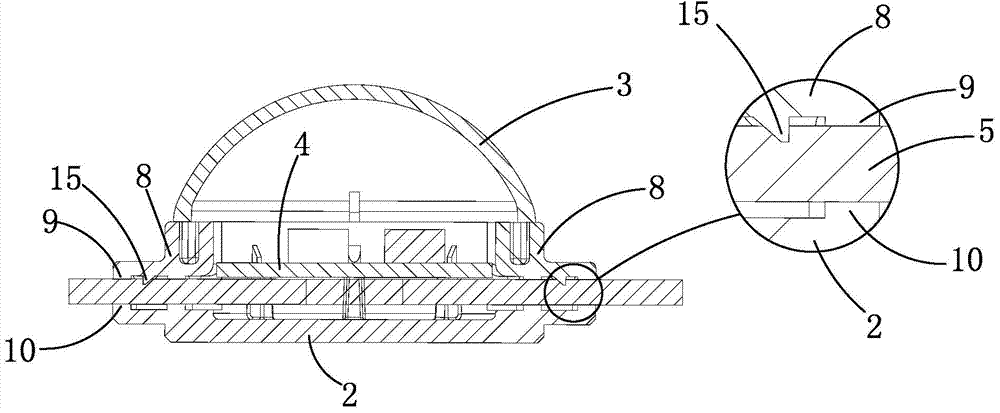

[0021] Such as figure 1 , 2 The shown LED lamp with a plug-in outlet position waterproof structure consists of a base 2 with a cavity 1, a cover 3 installed above the base 2, and an LED embedded in the cavity 1 of the base 2. The LED lamp board 4 is composed of a wire 5 extending out of the base 2, and the base 2 is provided with an outlet waterproof structure 6 matching the extension path of the wire 5, and the outlet waterproof structure 6 includes a wire outlet 7 opened on the side wall of the base 2 and a slider 8 correspondingly inserted and connected in the wire outlet 7, and the bottom surface of the wire outlet 7 and the bottom surface of the slider 8 are respectively provided with matching upper The thread 9 and the lower thread 10 are tightly clamped by the upper thread 9 and the lower thread 10 that coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com