Material initial damage assessment method based on fracture quantitative inversion and numerical analysis

A technique of initial damage and quantitative analysis, applied in the direction of analyzing materials, testing the ductility of materials, measuring devices, etc., can solve problems such as large errors and inability to meet needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] Taking the TA15 titanium alloy electron beam welding sample as an example, the evaluation process of the initial damage is given:

[0109] (1) Using a smooth fatigue sample, carry out a fatigue test under constant amplitude spectrum

[0110] Smooth bar-shaped sample, the middle section of the sample is electron beam welded. Test conditions: Stress ratio R=-1, the maximum stress is 500MPa, the fatigue test is carried out under the constant amplitude spectrum until the sample breaks, and the fatigue test fracture is obtained. The total life of the test is 114500 cycles.

[0111] (2) Using the fracture quantitative analysis method, the expression of the crack growth rate curve is obtained

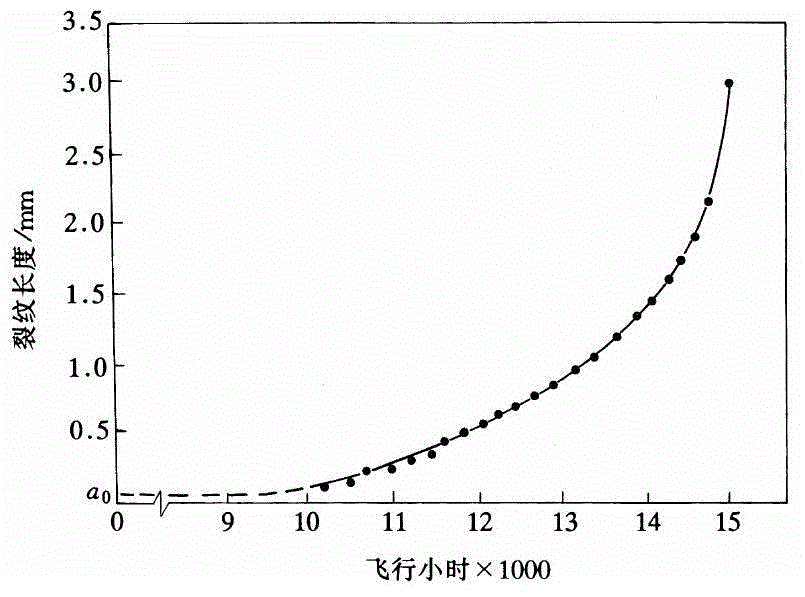

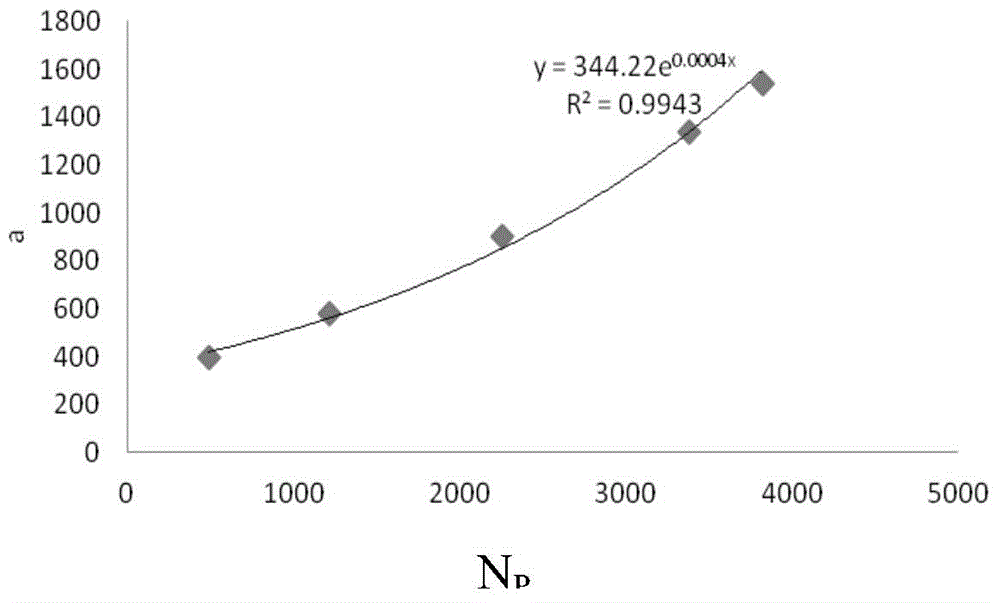

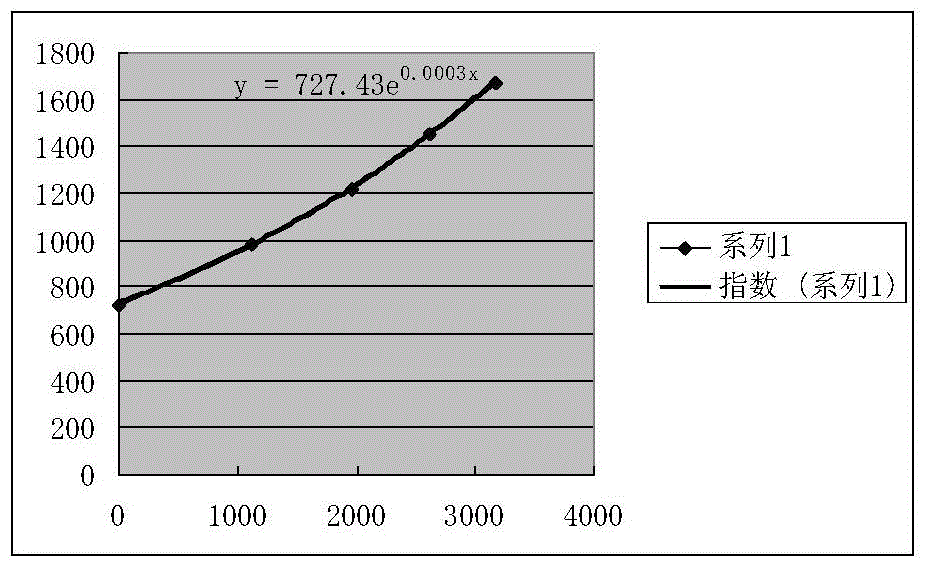

[0112] The macroscopic morphology of the obtained fatigue fracture is shown in Figure 8 , the fatigue strips in the fatigue extension zone on the fracture see Figure 9 , on the fracture surface of the fatigue specimen, starting from the crack source area, along the main crack propa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com