Method for integrally supporting coil inner paper tube of transformer

A technology of integral coil and support method, which is applied in the field of transformers, can solve the problems such as the inner layer of the coil going up and affecting the quality of the product, and achieve the effect of convenient disassembly of tooling, reduction of repeated operations, and simple and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the present invention will be further described by embodiment

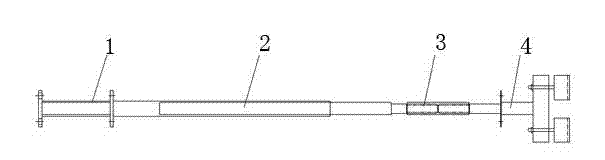

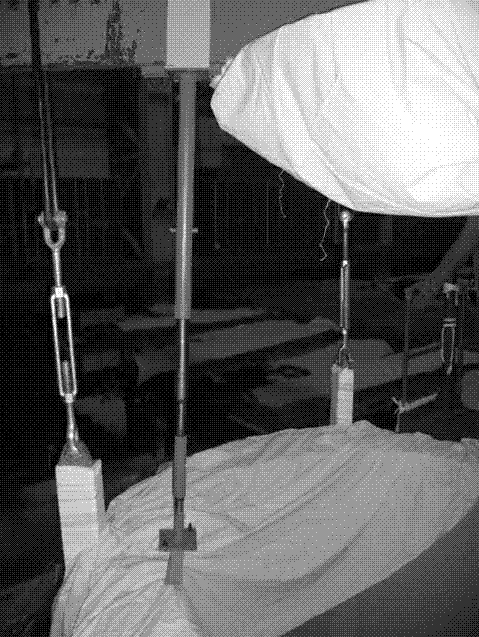

[0010] A method for supporting a paper tube in an integral coil of a transformer, comprising the following process steps: ① Using special tooling, the tooling is composed of a clamping part 1, a lead screw insertion part 2, a screw thread buckle 3, and a support shaft 4, and the clamping One end of the part is a compression flange, and the other end is connected to the plug-in part of the screw through the flange. The plug-in part of the screw includes two parts: the plug-in structure and the screw structure. There is a lead screw thread buckle, the lead screw structure is connected with the support shaft, and the end of the support shaft is provided with two rotatable supports; ②The compression flange of the tooling is fixedly connected with the cantilever of the coil lifting tooling, The overall length is adjusted through the tooling plug-in structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com