Switchgear cabinet for tool-less floor panel mounting

A switchgear and baseplate technology, applied in substation/switch layout details, electrical components, electrical equipment structural parts, etc., can solve the problem of easy loss of clamping parts and clamping bolts, and achieve the effect of simplifying installation or disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

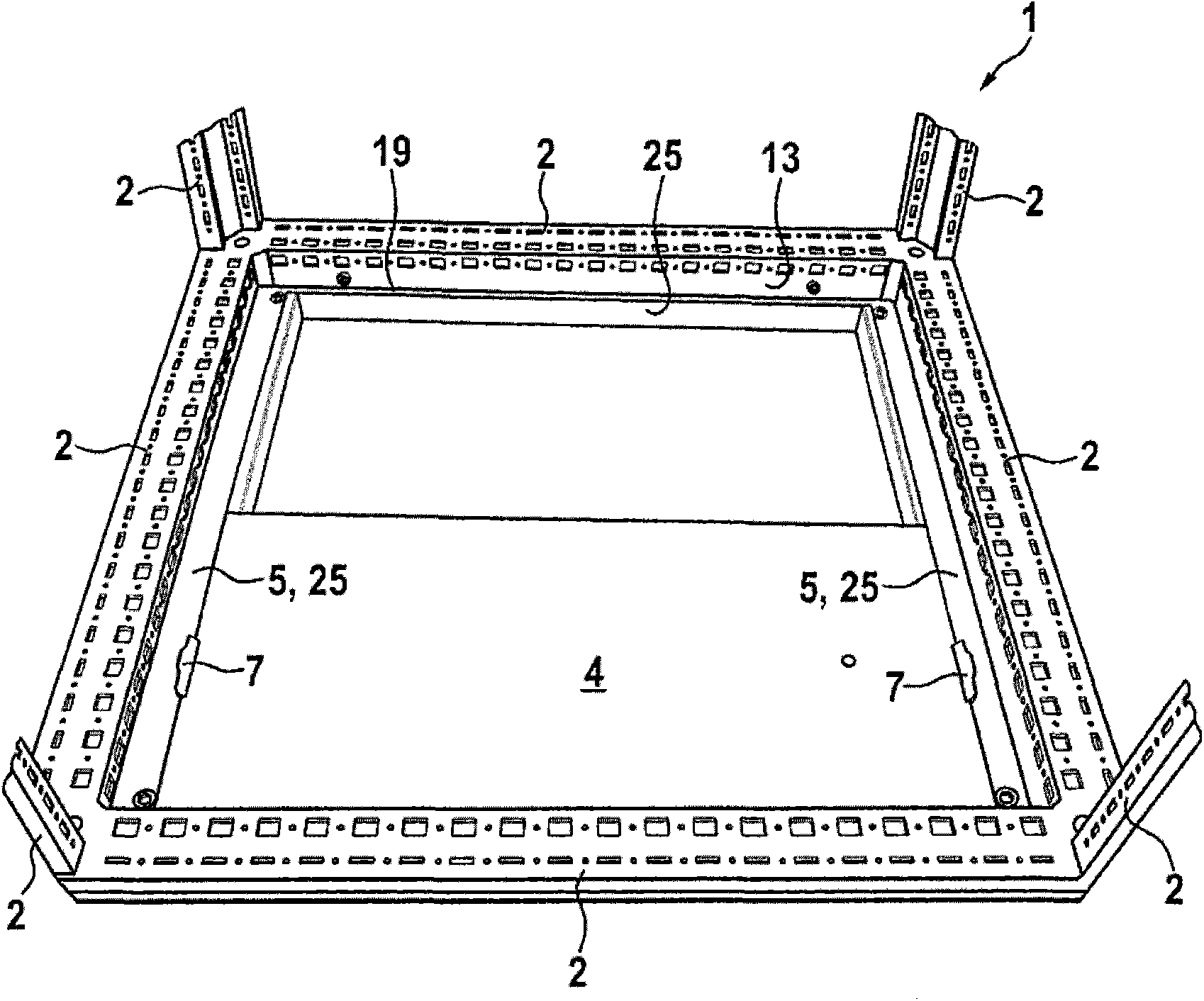

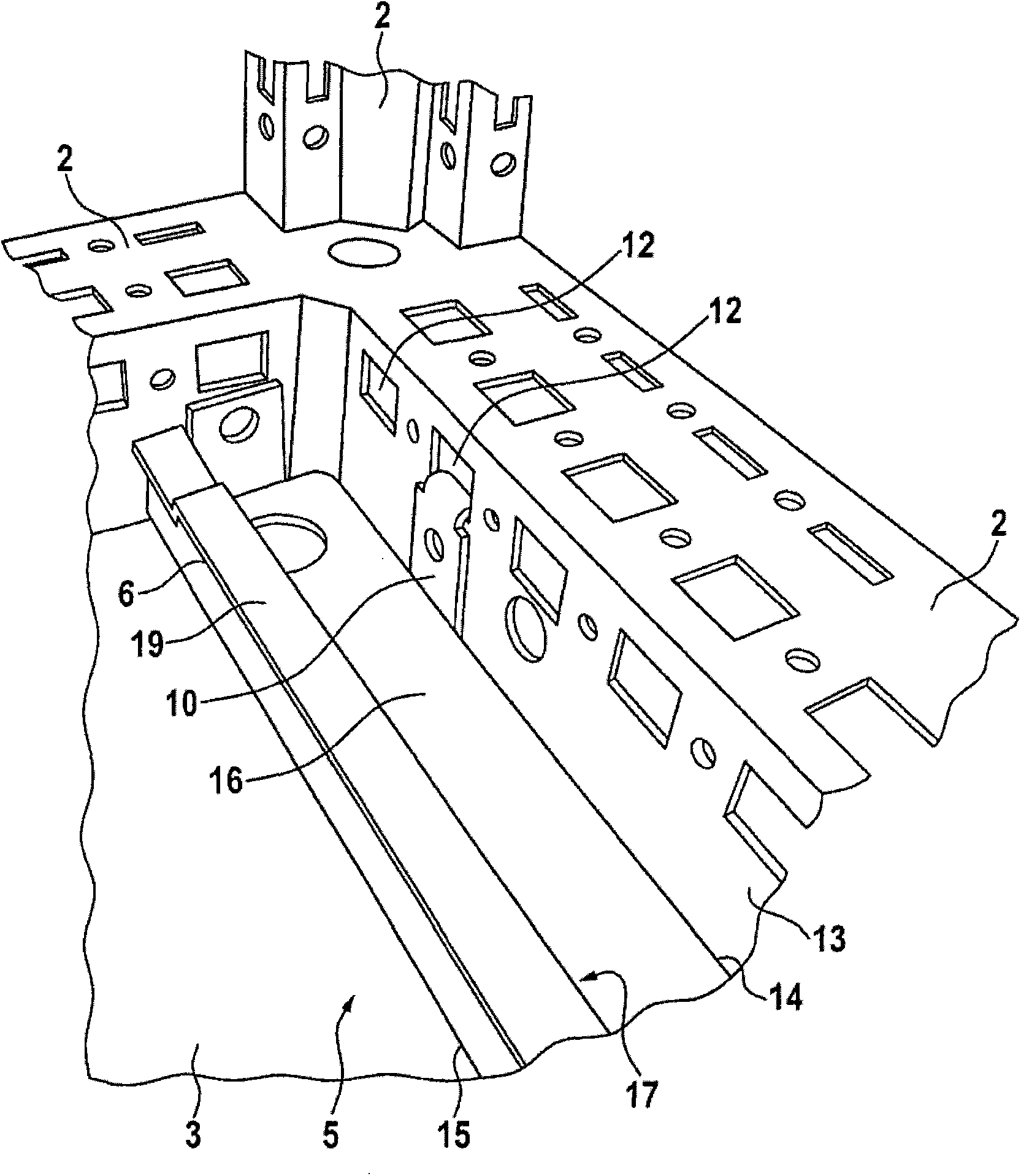

[0029] figure 1 A preferred embodiment of the present invention is shown. In this embodiment, the mounting rail 5 is provided by a bottom groove 25, wherein the mounting rail 5 is composed of two opposite frame members of the bottom groove 25. The two frame members of the bottom groove 25 that provide the mounting rail 5 are connected to each other through the other two frame members arranged perpendicular to them, so that the bottom groove 25 forms a substantially right-angled frame. The frame arm 2 is designed as a hollow profile, wherein the bottom groove 25 has at least one fixed connecting piece extending vertically through the opening to the inside of the hollow profile. The fixed connecting piece is bolted to the vertical profile surface 13 of the frame arm 2. The bottom plate 4 is frictionally connected with the mounting rail 5 by means of a locking member 7 arranged on the mounting rail 5 opposite to each other.

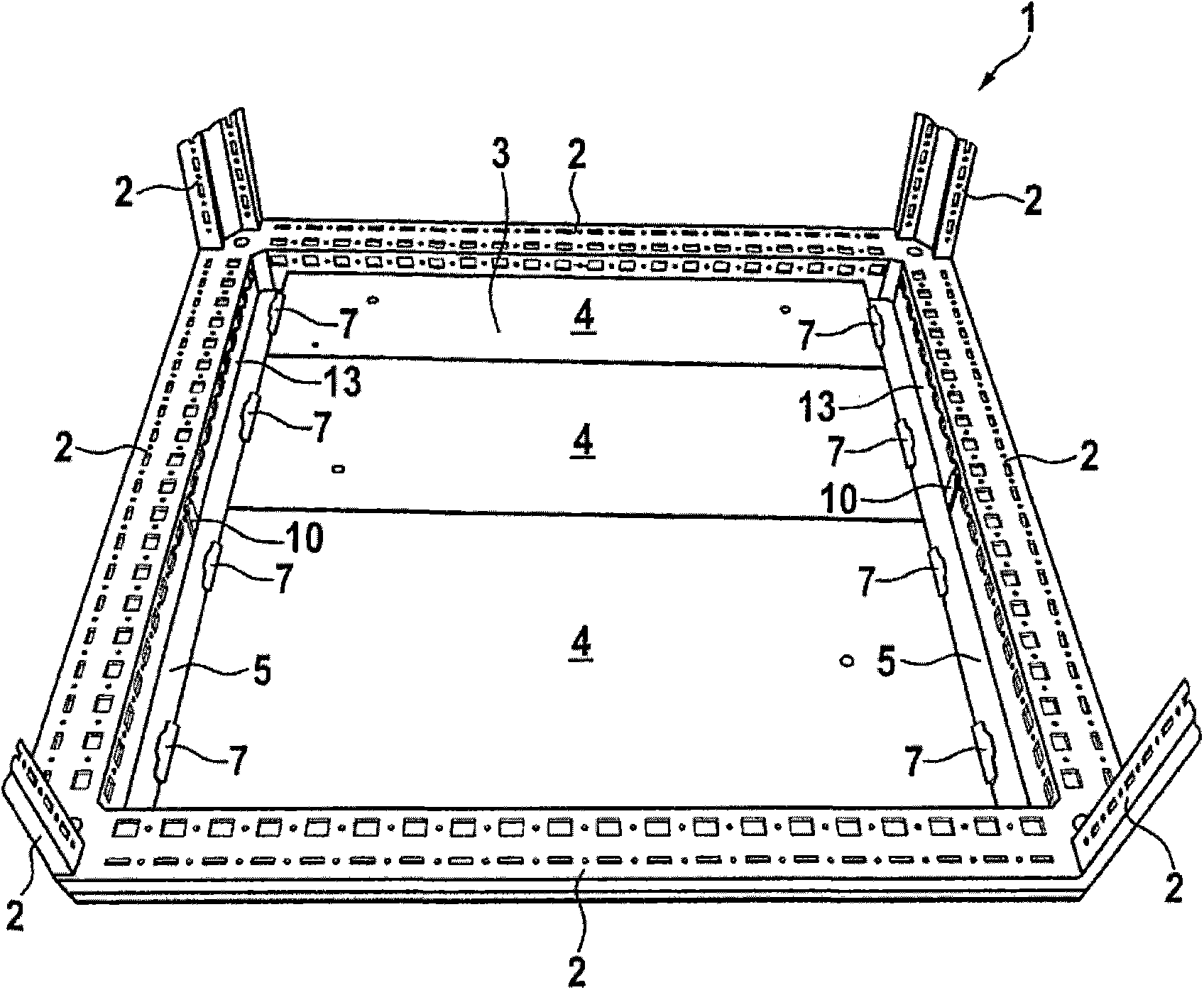

[0030] figure 2 The frame of the switch cabinet 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com