Engine base capable of meeting multiple installing requirements at same time

A technology of motor base and installation method, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., and can solve problems such as waste of funds and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

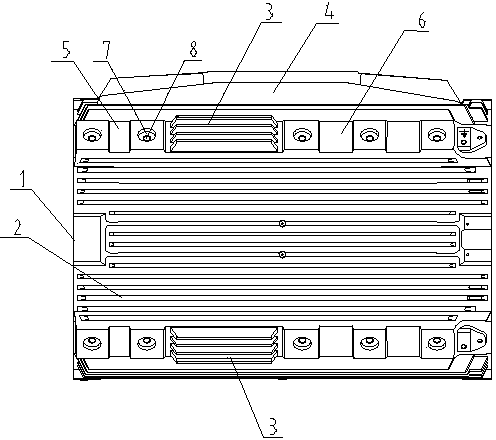

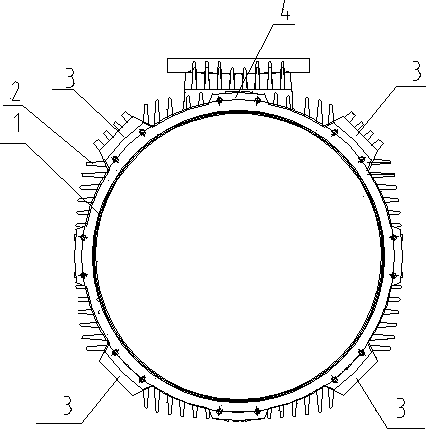

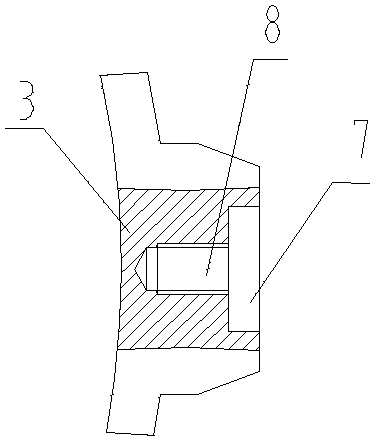

[0020] as attached figure 1 , attached figure 2 and attached image 3 As shown, a motor base that can meet the requirements of multiple installation methods at the same time includes a cylindrical base body 1 with heat dissipation ribs 2 evenly distributed on the base body, and four axial reinforcements uniformly distributed on the peripheral surface of the base body. The rib 3 is provided with an outlet hole 4 on the frame body between the two reinforcing ribs, and the reinforcing rib 3 is respectively provided with a front bottom angle mounting surface 5 and a rear bottom angle mounting surface 6, and the front and rear bottom angles At least two upper positioning counterbores 7 are arranged on the installation plane, and threaded counterbores 8 are arranged in the upper positioning counterbores.

[0021] as attached Figure 10 As shown, the moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com