Quick lifting method for online drawing rotor of large motor

A technology for large motors and motor rotors, applied in the manufacture of stator/rotor bodies, etc., can solve problems such as low efficiency, many jacking times, and high cost, and achieve the effect of overcoming defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is further illustrated below by specific examples.

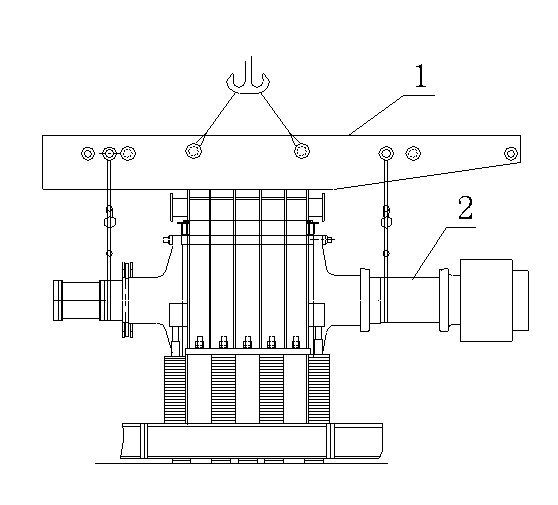

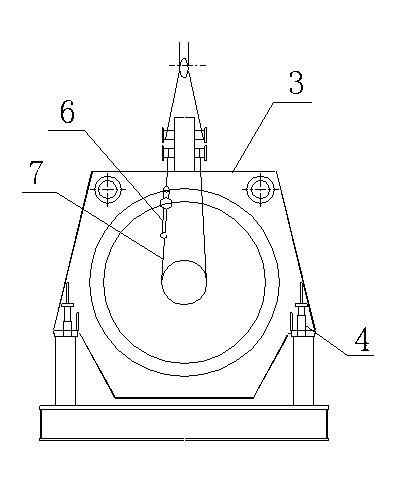

[0020] Such as figure 1 , figure 2 Shown:

[0021] A fast jacking method for online rotor extraction of a large motor, comprising the following steps:

[0022] Step 1. Remove and lift the universal joint shaft of the motor;

[0023] Step 2. Dismantling of electrical lines and instruments;

[0024] Step 3. Remove the upper cover and the upper tile of the bearing housings at both ends of the motor, remove the motor cover and accessories, and remove the motor stator anchor bolts;

[0025] Step 4. Remove and lift the motor encoder, thrust bearing and accessories;

[0026] Step 5: Assemble the motor to the long shaft;

[0027] It also includes a rotor suspension beam 1, an inverted chain 6, a steel cable 7 and the following steps,

[0028] Step 6: Lift the rotor beam 1 with a crane, set the rotor beam 1 on the top of the motor stator 3 and level it, then hang 6 chains and steel cables 7 on bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com