Films for transmission media

A membrane pump, working membrane technology, applied in the direction of pumps with flexible working elements, liquid variable capacity machinery, machines/engines, etc., can solve problems such as limited service life, and achieve the effect of improving installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

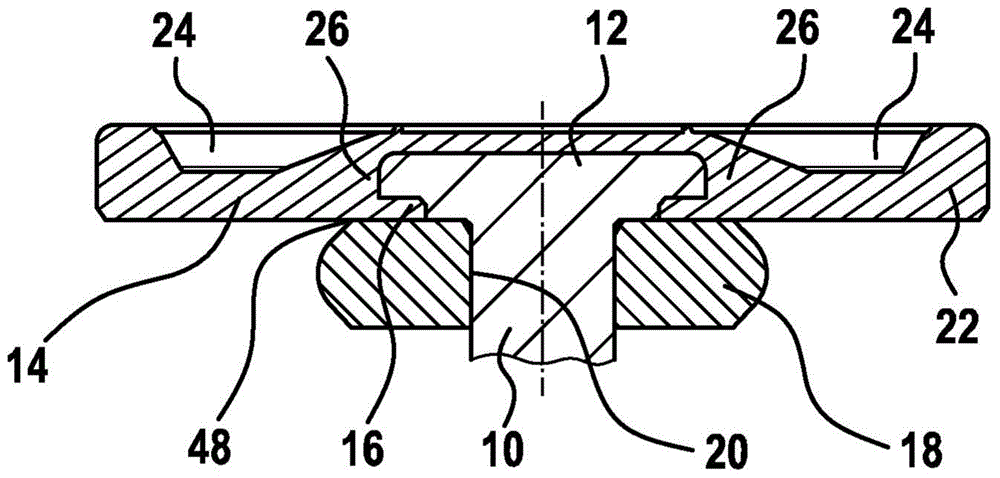

[0027] exist figure 1 shows the working membrane supported by a disc-shaped support element received on the armature.

[0028] figure 1 The working membrane 14 is shown firmly received on the armature head 12 of the armature 10 by means of the undercut 16 . The connection between the working diaphragm 14 and the armature head 12 of the armature 10 can take place, for example, by vulcanization. The armature 10 transmits the reciprocating movement to the working membrane 14 , which is deformed in the elastic region 26 by the reciprocating movement. In order to stabilize the working membrane 14 , a support disc 18 is received on the armature 10 . The connection between the armature 10 and the support disk 18 is realized by means of a press connection, a welding connection, an adhesive connection and / or a screw connection 20 . The edge of the support disc 18 is provided with a rolling radius 48 . Due to the rolling radius 48 on the support disc 18 , the film 14 rests on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com