Automatic dust-removal paint spraying device for inner wall of pipeline

A painting equipment and automatic technology, applied in the direction of metal processing equipment, grinding/polishing equipment, spraying device, etc., can solve the problems of short pigging distance, small application range, time-consuming and labor-intensive, etc., achieve intensive volume, improve the scope of application, Efficient and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

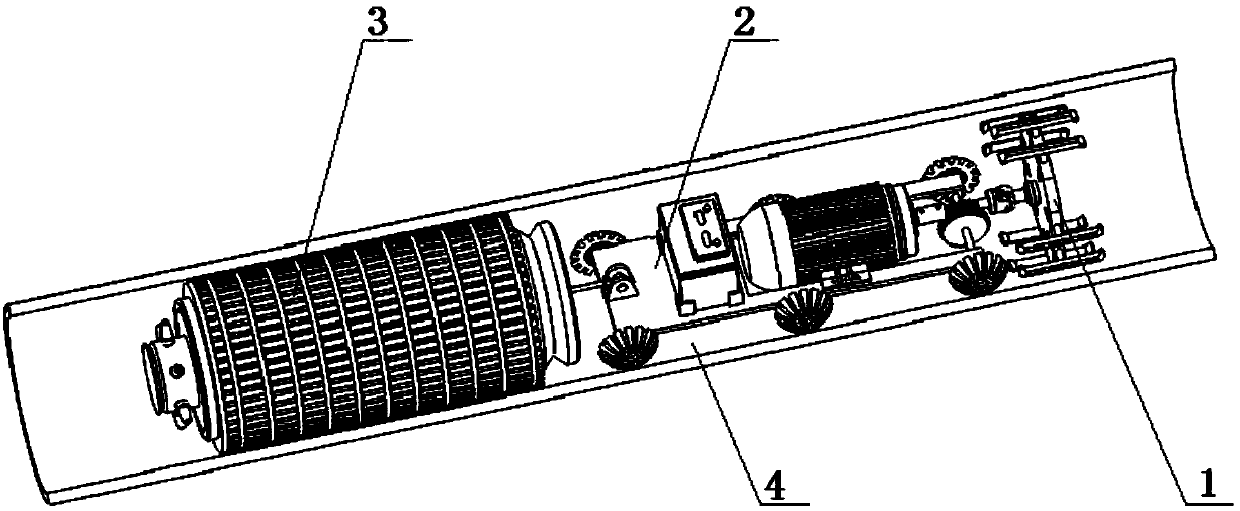

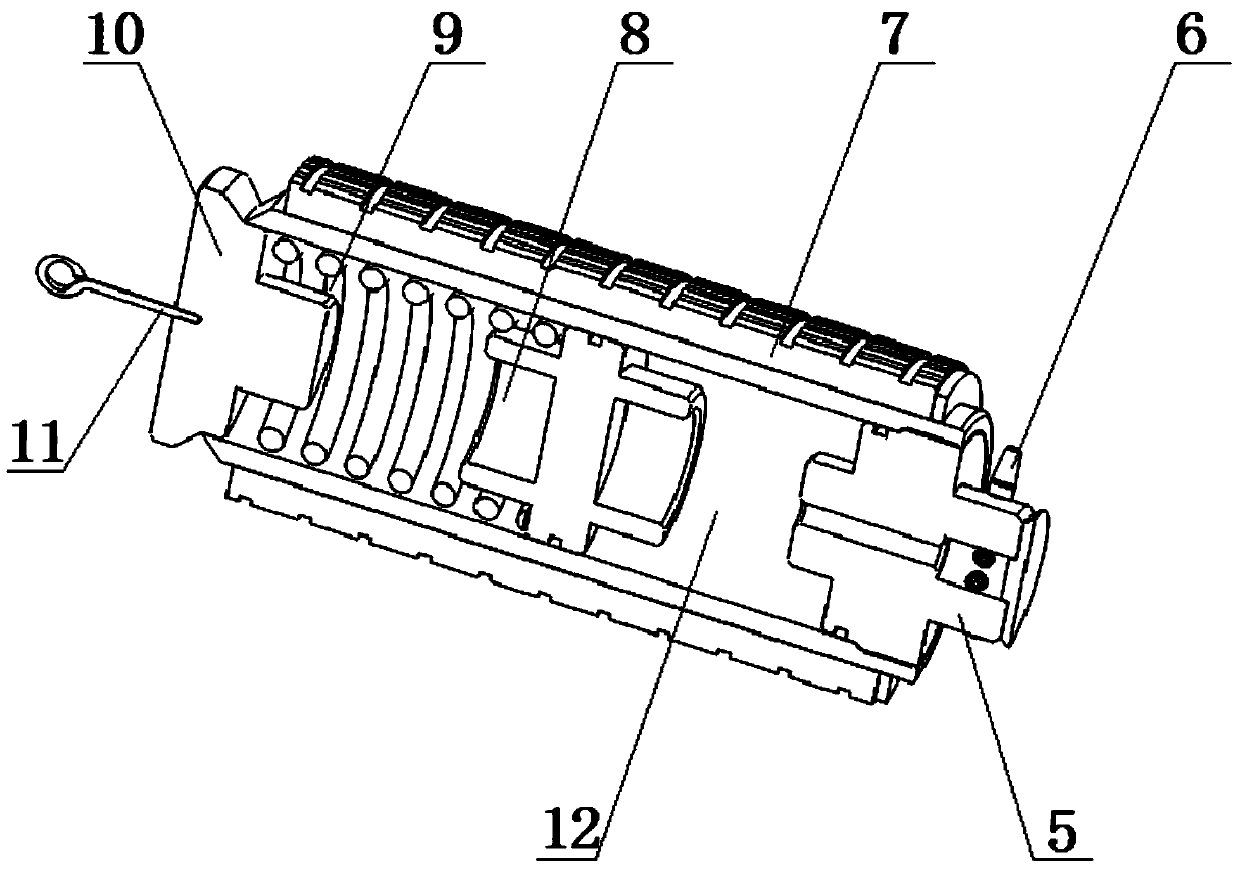

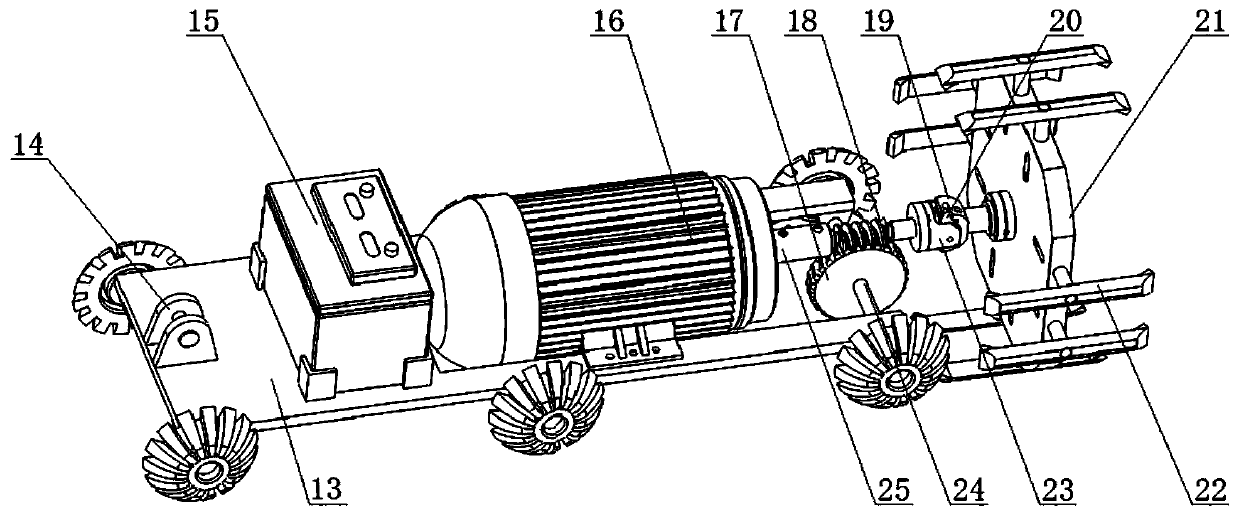

[0018] refer to Figure 1 to Figure 4 Examples of the present invention will be described.

[0019] The automatic rust removal and painting equipment for the inner wall of the pipeline mainly includes three parts: the rust removal device 1, the power device 2, and the paint spraying device 3. The rust removal device 1 and the power device 2 are connected and fixed by a universal coupling. The rotary front end 19 of the universal coupling is connected with the fixed panel 21 by bolts, the rotary rear end 23 of the universal coupling is connected with the worm 18 by bolts, and the rotary front end 19 of the universal coupling is connected with the rotary rear end 23 through the rotary middle end 20, which can Compensate the radial vibration, improve the smoothness of the inner wall of the pipeline after derusting, and provide convenience for the spraying of paint in the follow-up work;

[0020] The tension spring 28 of the derusting device 1 is installed in the draw-in groove o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com