Batching device for new building material

A building material and a new type of technology, which is applied in the direction of sales of raw material supply devices, ingredient storage, clay preparation devices, etc., can solve problems such as blockage, ingredient leakage, consumption costs, bumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

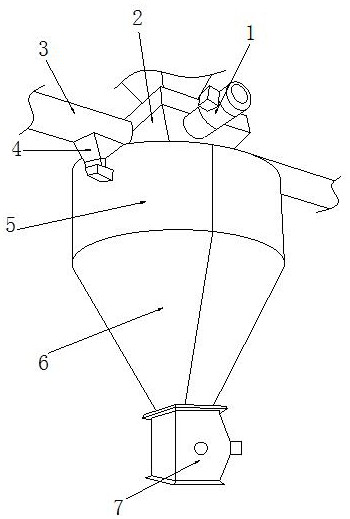

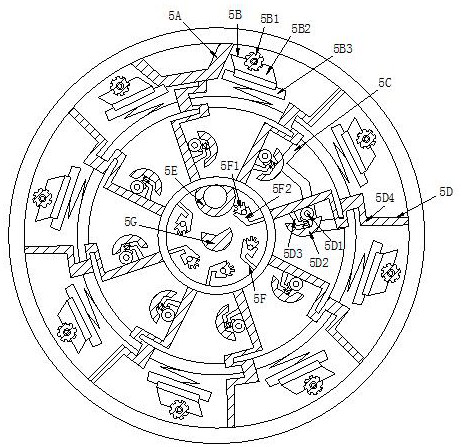

[0032] see Figure 1-Figure 6, the present invention provides a batching device for new building materials, its structure includes: a shaft motor 1, a three-way feeding tank 2, a feeding pipeline 3, a buckle seat 4, a three-frame sliding cylinder tank 5, and a mixing tank 6. The output valve seat 7, the three-frame sliding cylinder groove 5 is nested on the top of the ingredient mixing tank 6 and communicates with each other, and the shaft motor 1 is inserted in the front side of the three-way feeding tank 2, so The feed pipeline 3 horizontally runs through the inside of the three-way feed tank 2 and is on the same horizontal plane. The three-way feed tank 2 is nested on the top of the three-frame sliding barrel tank 5 and communicates with each other. The ingredients are stirred The groove 6 is inserted on the top of the output valve seat 7 and communicates with each other. The feed pipe 3 is fastened together with the three-frame sliding cylinder groove 5 through the buckle ...

Embodiment 2

[0039] see Figure 1-Figure 6 , the present invention provides the dispensing device that is used for new building material, and other respects are identical with embodiment 1, and difference is:

[0040] see figure 2 , the brushing swing frame 5F is composed of a mud brushing fan plate 5F1 and a folding plate frame rod 5F2, the mud brushing fan plate 5F1 and the folding plate frame rod 5F2 are buckled together, and the mud brushing fan plate 5F1 and the folding plate The frame bar 5F2 is on the same vertical plane, and the brushing mud fan plate 5F1 forms a large inertial swing in the same direction at the folding plate end of the folding plate frame bar 5F2, so that the brushing mud is evenly pressed and covered with fine sand and gravel powder to form a mixing operation Effect.

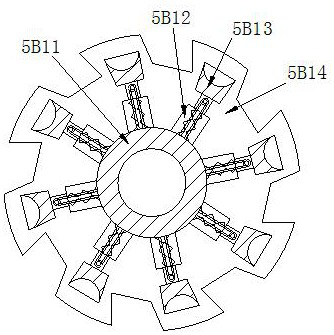

[0041] see Image 6 The brush mud fan plate 5F1 is composed of a finned groove plate 5F11, a buckle bent rod 5F12, a column cap pole 5F13, and a gap wheel body 5F14. The rods 5F13 are fastened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com