Foldable container

A folding and container technology, applied in the direction of containers, rigid containers, packaging, etc., can solve the problems of high manufacturing and maintenance costs, affecting the working phase rate, and different heights of side panels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

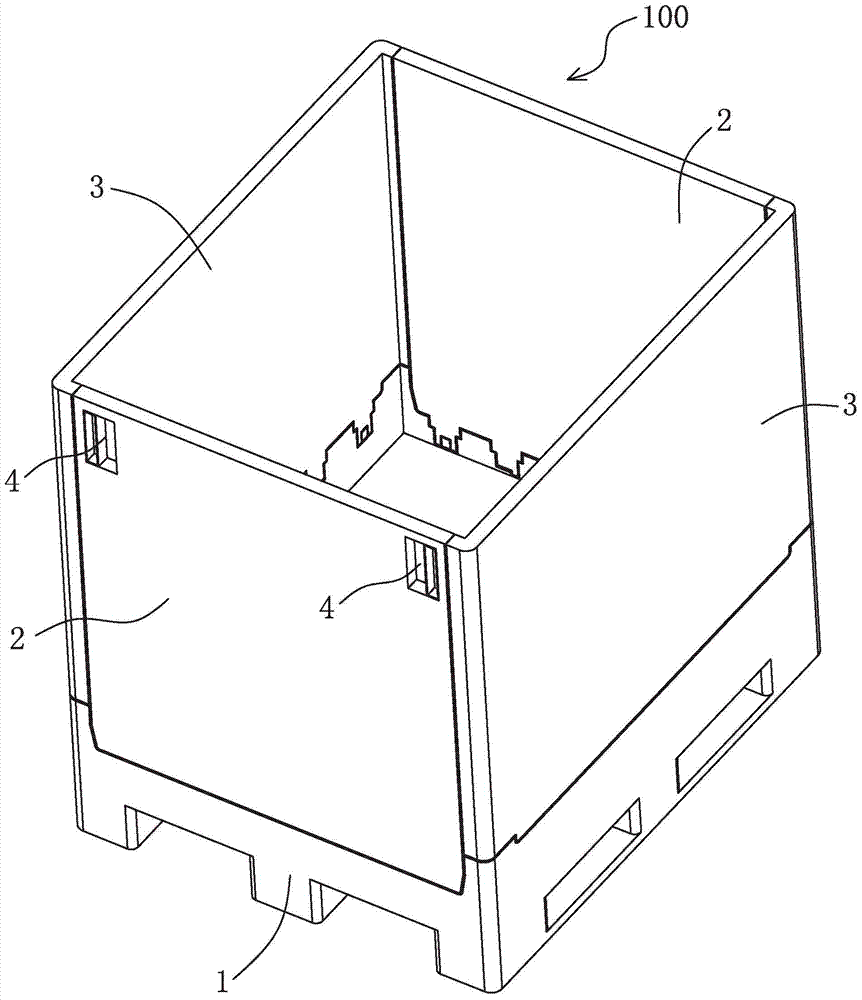

[0033] figure 1 A structural perspective view of a general collapsible container is shown. Such as figure 1 As shown, the collapsible container 100 includes a base 1, two pairs of side panels 2, 3 and a locking buckle 4 for keeping the side panels 2, 3 in an upright state. 3, and then fold the side panels 2 and 3 toward the inside of the container, which can greatly reduce the height of the box and save transportation costs.

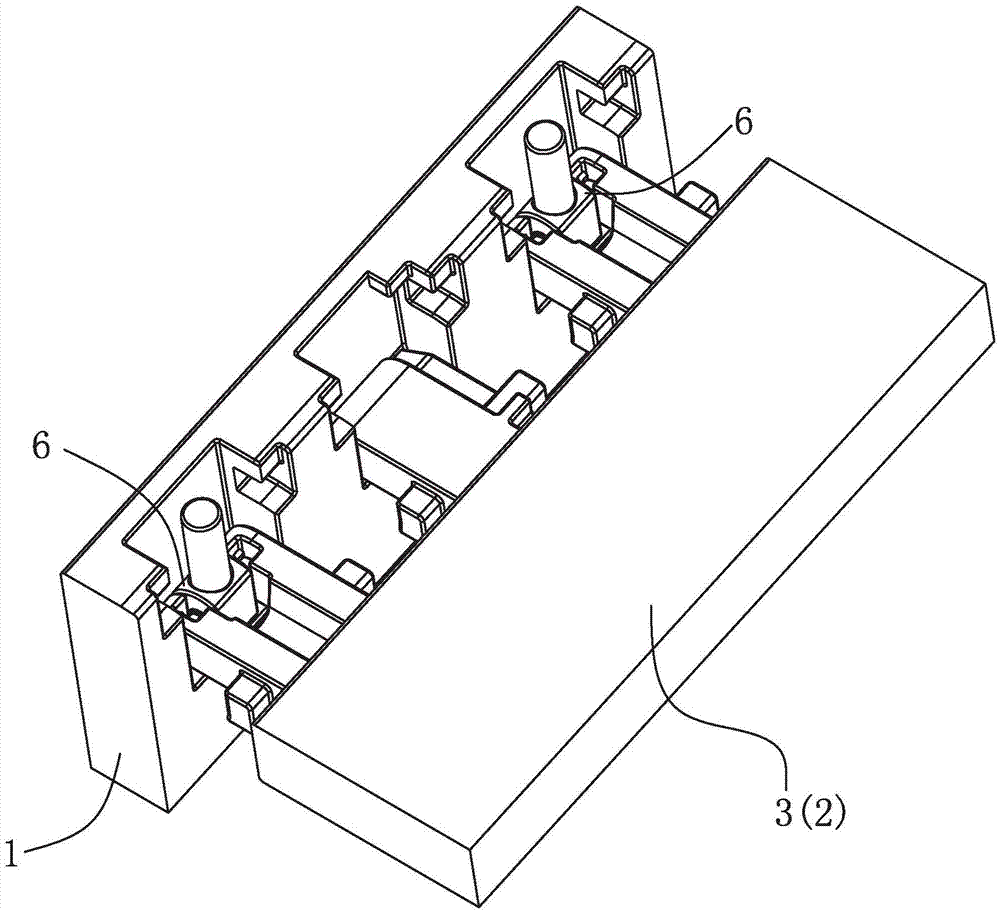

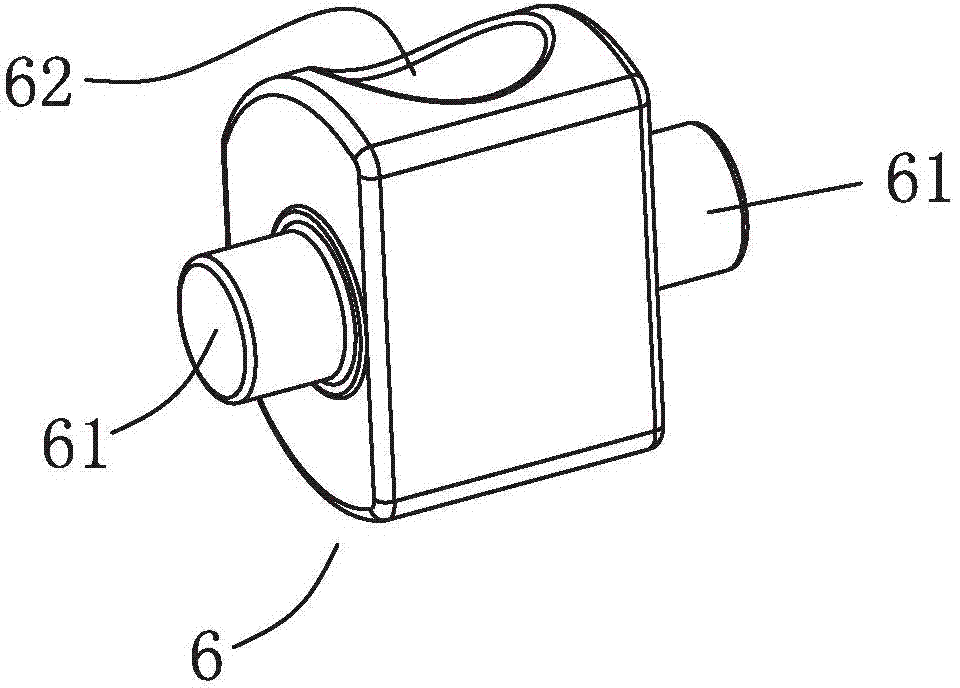

[0034] Figure 2-7 A schematic diagram of the connection structure showing the connection between the side plate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com