A two-stage self-sealing thermal recovery packer

A packer and thermal recovery technology, applied in the directions of sealing/packing, production of fluids, and earth-moving drilling, etc., can solve the problems of casing abandonment, casing bending due to heat, and sealing performance degradation, and achieves short setting time, Good sealing and smooth unsealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The implementation of the present invention will be described below in conjunction with the accompanying drawings.

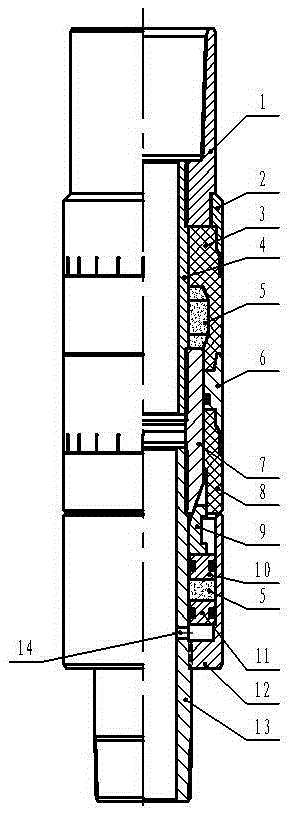

[0009] As shown in the figure, the present invention consists of an upper joint 1, an upper sheath 2, an upper sealing sleeve 3, an upper central tube 4, an expansion solid 5, a lower sheath 6, an inner cone 7, a lower sealing sleeve 8, and a combined slider 9 , upper piston 10, lower piston 11, cylinder block 12 and lower central tube 13, its structure and assembly relationship are as previously described. Wherein, the upper sealing sleeve 3 is a sleeve body, and the middle part is provided with an annulus for filling the expansion solid 5 . The expanded solid 5 is a powdery thermally expanded material. The inner cone 7 is respectively connected with the upper center pipe 4 and the lower center pipe 13 through threads, and its outer lower end is provided with a tapered surface to cooperate with the upper end tapered surface of the combined slider 9 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com