Reverse thrusting device with capacity of adjusting area of spray pipe

A thrust reverser and area adjustment technology, which is applied to jet propulsion devices, machines/engines, etc., can solve problems such as limiting engine adjustment capabilities, and achieve the effect of adjusting requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

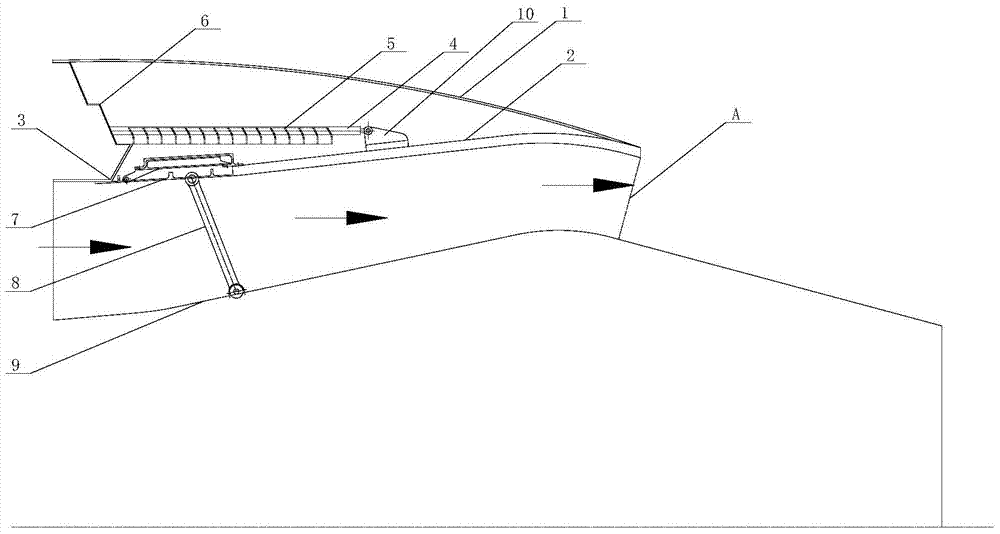

[0018] The invention provides a thrust reverser with nozzle area adjustment capability, characterized in that: the thrust reverser with nozzle area adjustment capability includes a moving part and a fixed part, and the movement mechanism is used to close the thrust reverser The state realizes the adjustment of the area of the culvert nozzle and the opening and closing of the thrust reverser;

[0019] The thrust reverser is mainly composed of a reverse thrust fairing 1, an outer wall of the outer culvert nozzle 2, a diffuser front wall 3, an actuator 4, a cascade 5, a reverse exhaust fairing 6, a choke valve 7, and a pull rod 8. The inner wall surface 9 of the outer culvert nozzle and the support seat 10, wherein the diffuser front wall 3, the inner wall surface 9 of the outer culvert nozzle, the cascade 5, and the reverse exhaust fairing 6 are fixed parts; the components of the fixed part pass through Bolt connection or rivet connection, the reverse thrust fairing 1, the out...

Embodiment 2

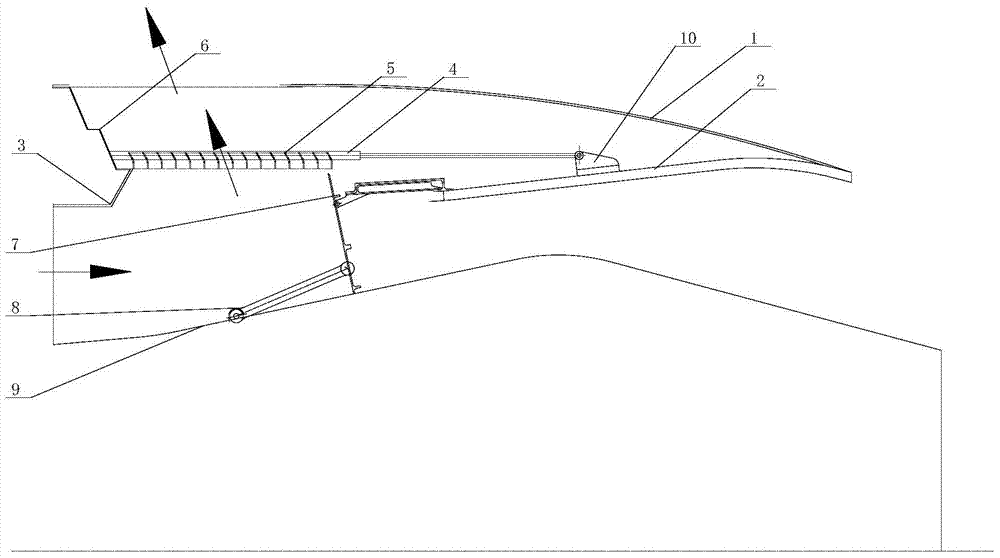

[0025] The invention provides a thrust reverser with nozzle area adjustment capability, characterized in that: the thrust reverser with nozzle area adjustment capability includes a moving part and a fixed part, and the movement mechanism is used to close the thrust reverser The state realizes the adjustment of the area of the culvert nozzle and the opening and closing of the thrust reverser;

[0026] The thrust reverser is mainly composed of a reverse thrust fairing 1, an outer wall of the outer culvert nozzle 2, a diffuser front wall 3, an actuator 4, a cascade 5, a reverse exhaust fairing 6, a choke valve 7, and a pull rod 8. The inner wall surface 9 of the outer culvert nozzle and the support seat 10, wherein the diffuser front wall 3, the inner wall surface 9 of the outer culvert nozzle, the cascade 5, and the reverse exhaust fairing 6 are fixed parts; the components of the fixed part pass through Bolt connection or rivet connection, the reverse thrust fairing 1, the out...

Embodiment 3

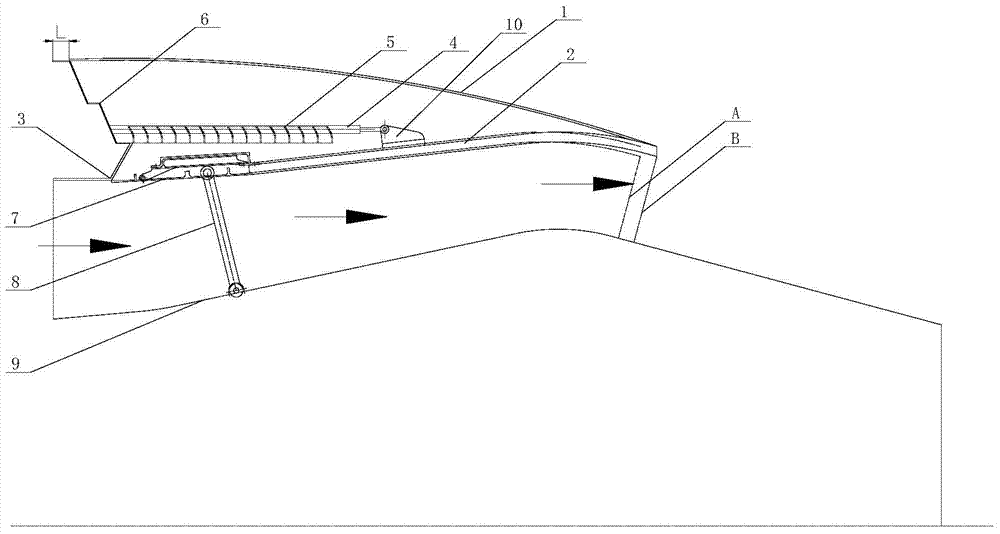

[0032] The invention provides a thrust reverser with nozzle area adjustment capability, characterized in that: the thrust reverser with nozzle area adjustment capability includes a moving part and a fixed part, and the movement mechanism is used to close the thrust reverser The state realizes the adjustment of the area of the culvert nozzle and the opening and closing of the thrust reverser;

[0033] The thrust reverser is mainly composed of a reverse thrust fairing 1, an outer wall of the outer culvert nozzle 2, a diffuser front wall 3, an actuator 4, a cascade 5, a reverse exhaust fairing 6, a choke valve 7, and a pull rod 8. The inner wall surface 9 of the outer culvert nozzle and the support seat 10, wherein the diffuser front wall 3, the inner wall surface 9 of the outer culvert nozzle, the cascade 5, and the reverse exhaust fairing 6 are fixed parts; the components of the fixed part pass through Bolt connection or rivet connection, the reverse thrust fairing 1, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com