Mechanism for improving the precision of medicine dispensing

A sub-packaging and precision technology, applied in packaging, transportation and packaging, packaging item types, etc., can solve the problems of large and small non-standard loading, affecting product quality, powder cannot be sub-packaged, etc., to achieve hygroscopicity Strong, increase the quality, increase the effect of fluid density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

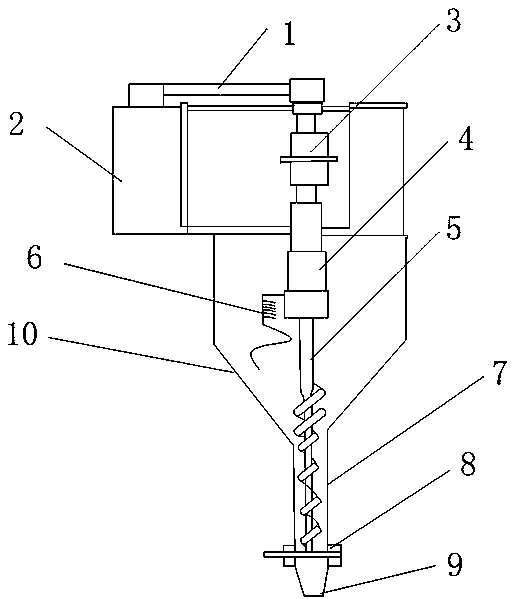

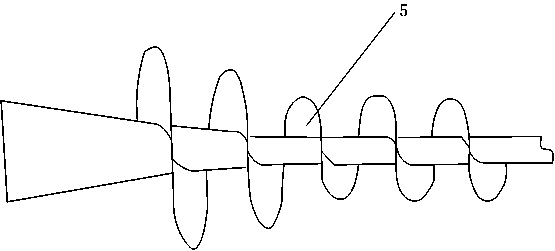

[0026] The mechanism used to improve the accuracy of medicament dispensing, including belt drive 1, motor 2, electromagnetic clutch 3, support 4, connecting rod, feeding screw 5, stirring rod 6, hopper 10, feed inlet located above the hopper 10, A pipe connected to the hopper 10 and located below the hopper 10, a valve 8 located below the pipe, and a feeding nozzle 9, the valve 8 connecting the pipe and the feeding nozzle 9 together;

[0027] The belt transmission device 1 is connected to the motor 2, the electromagnetic clutch 3 is located below the belt transmission device 1, a support 4 is connected below the electromagnetic clutch 3, a stirring rod 6 is connected below the support 4, and the support 4 and the stirring rod 6 are arranged in the hopper 10. Inside, the electromagnetic clutch 3 and the support 4 are both sleeved on the outside of the connecting rod, the connecting rod is connected to the belt transmission device 1, and the feeding screw 5 is connected below the co...

Embodiment 2

[0030] Further, the stirring rod 6 includes a vertical part at the upper part and an S-shaped part at the lower part, and the vertical part is also provided with an arc-shaped strip. The vertical part of the stirring rod 6 is provided with an arc-shaped strip, which can accelerate the strength and speed of the loose powder, so that the powder is not easy to unite.

[0031] There are a plurality of the arc-shaped bars, and a plurality of the arc-shaped bars are arranged inwardly from top to bottom along the vertical part or a plurality of the arc-shaped bars are arranged from top to bottom along the vertical part Facing the inside-facing the outside alternately. In order to enhance the loosening effect of the powder that is loose and easy to unite, multiple arc strips can be used, and the parallel arrangement can also achieve the purpose. The arrangement from the bottom of the upper road to the inner side and the outer side can make the loose area Enlarge, play a better effect.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com