A mechanism for smooth packaging

A sub-packaging and smooth technology, applied in the directions of packaging, transportation and packaging, packaging items, etc., can solve the problems that powder cannot be sub-packed, affect product quality, and the amount of packaging is suddenly large or small. Quality, improve production efficiency, and facilitate the effect of flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

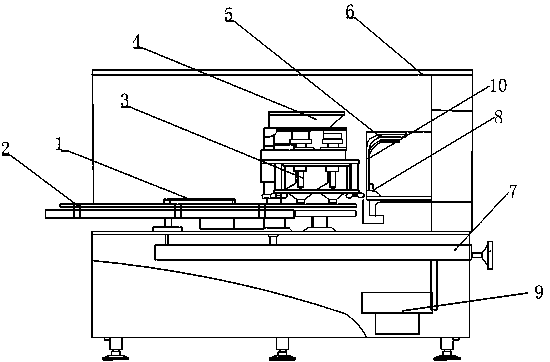

[0032] Such as figure 1 , figure 2 As shown, a smooth dispensing mechanism includes an upper bracket, a lower bracket, a bottle unscrambling turntable 1, an in-out bottle conveying mechanism 2, a dispensing mechanism 3, a feeding device, a stopper unscrambling oscillator 5, and a bottle mounted on the upper bracket. Organic glass cover 6, plugging mechanism, transmission mechanism 7, control panel installed on the upper bracket, lower plug track 10, main motor 9;

[0033] The in-out bottle conveying mechanism 2 is located on the far left, the part of the in-out bottle conveying mechanism 2 is arranged outside the upper bracket, and the rest of the in-out bottle conveying mechanism 2 is arranged in the upper bracket;

[0034] The bottle unscrambling turntable 1, packing mechanism 3, stopper unscrambling oscillator 5, and stopper pressing mechanism 8 are all located in the upper bracket, and the bottle unscrambling turntable 1 is located on the right side of the in-out bottle ...

Embodiment 2

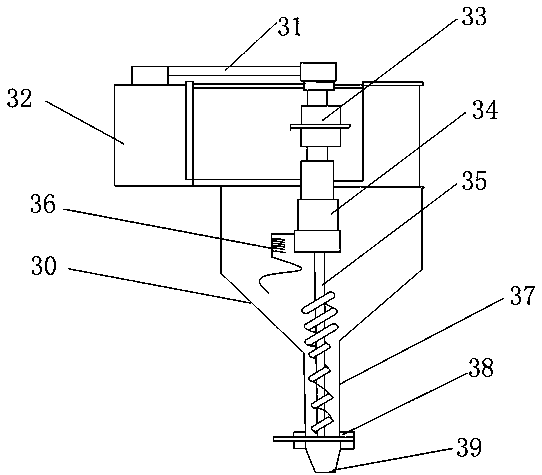

[0040] Such as figure 2 , image 3 As shown further, the stirring rod 36 includes an upper vertical portion and a lower S-shaped portion, and the vertical portion is also provided with an arc-shaped strip. The vertical part of the stirring rod 36 is provided with a curved bar, which can speed up the strength and speed of the loose medicinal powder, so that the medicinal powder is not easy to unite.

[0041] There are a plurality of arc bars, and the plurality of arc bars are arranged facing the inside from top to bottom along the vertical part, or a plurality of arc bars are arranged from top to bottom along the vertical part Facing the inside - facing the outside alternately. In order to enhance the loosening effect of the loose and easy-to-unite powder, multiple arc-shaped strips can be used, and the parallel arrangement up and down can also achieve the purpose. Expand for better results.

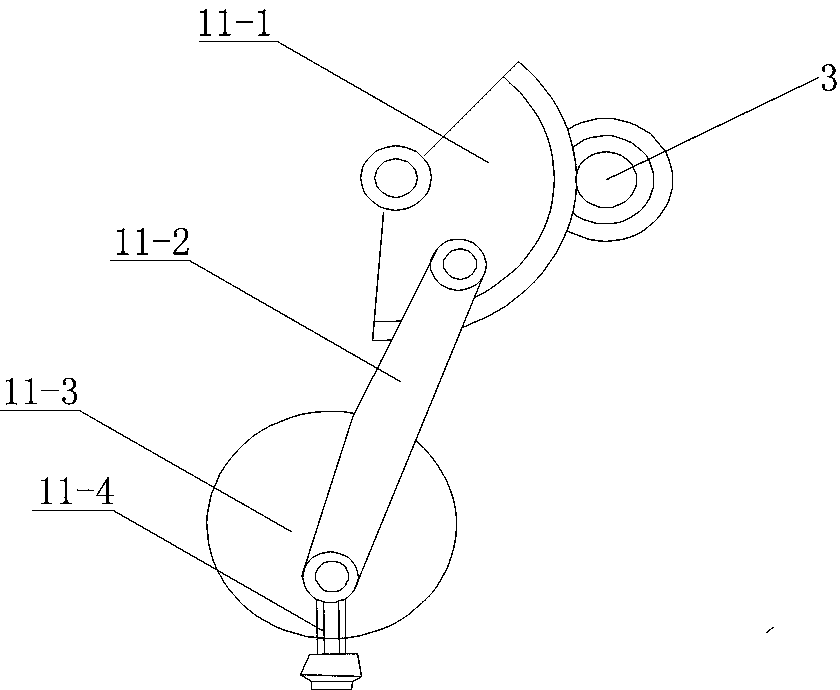

[0042] Further, it also includes a micro-adjustment system 11, the micro-adjustm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com