pumps, especially pneumatic pumps

A pump chamber and spring chamber technology, applied to pumps, can solve the problems of cost, spring loading into the pump, assembly technology cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

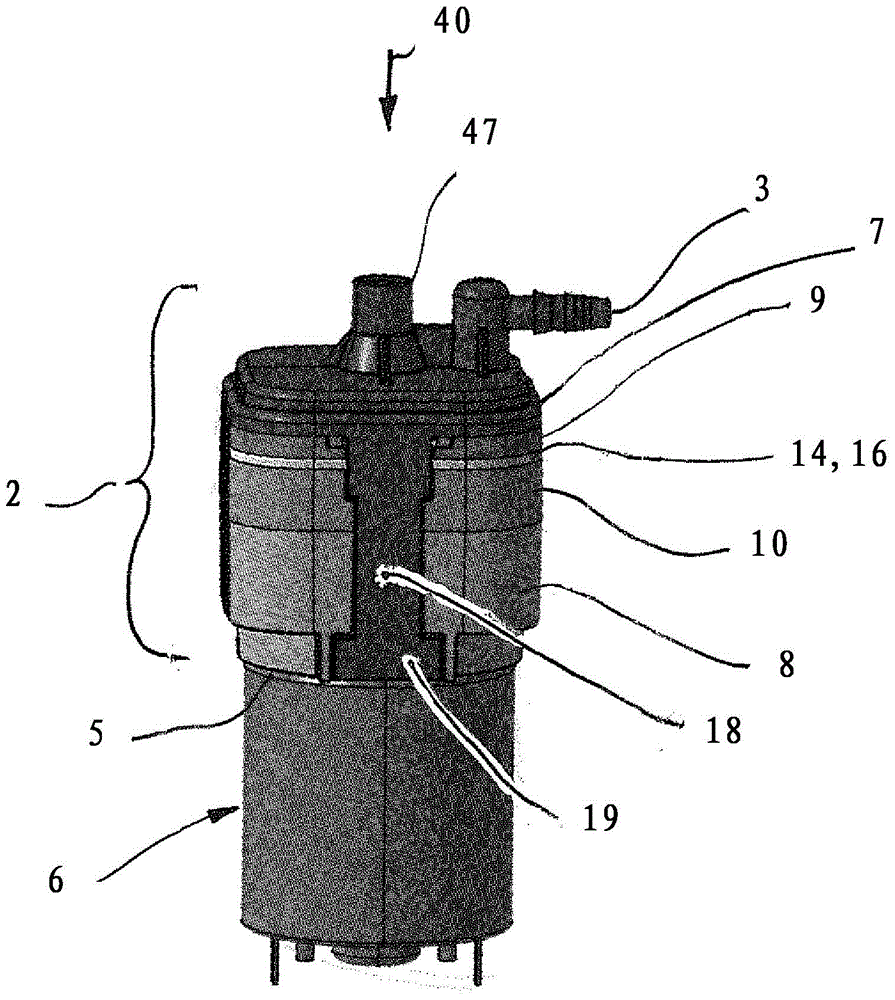

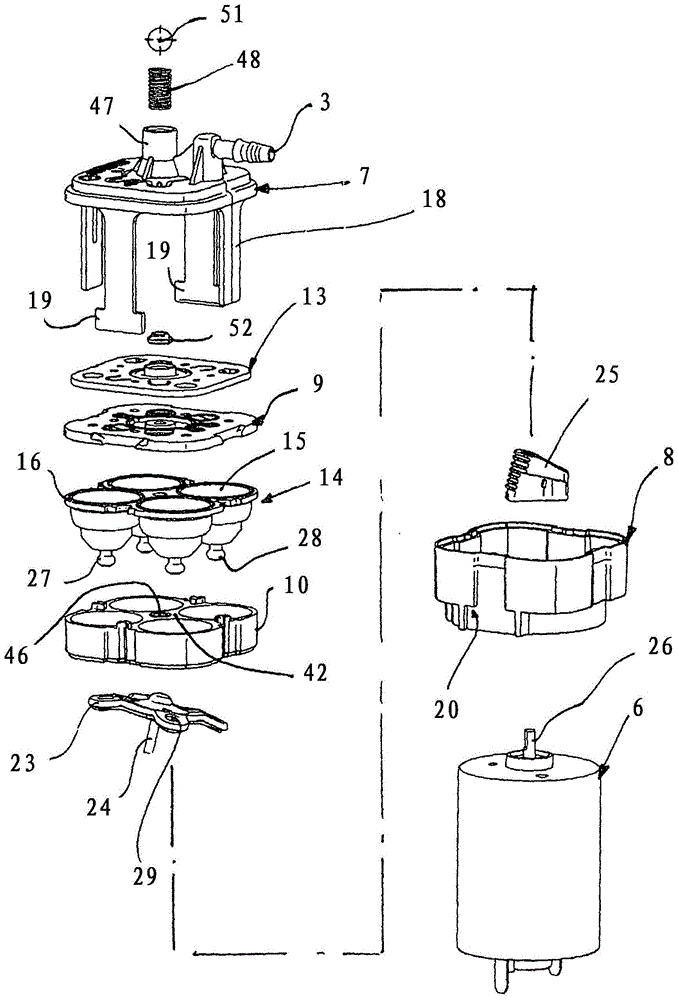

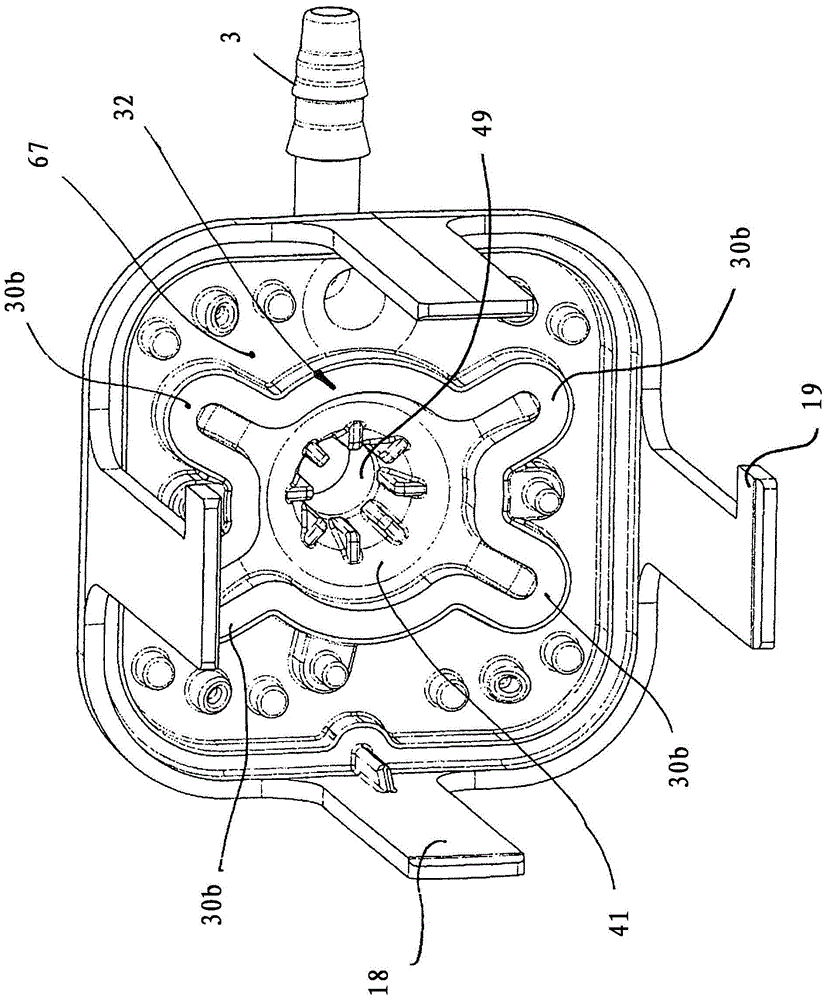

[0023] The invention is explained by way of example for a pneumatic pump, wherein the described embodiment also applies to pumps for liquids. The pump 1 shown in the figure is intended to be installed in a vehicle seat and to fill a seat airbag in order to modify the contour of the vehicle seat, for example in a seating area or a reclining area. The pump 1 comprises a housing 2, in particular made of plastic, onto which a discharge connection 3 is integrally formed. The side of the housing 2 which bears the outlet connection 3 is referred to below as the upper side 4 . A motor 6 , in particular an electric motor, is flanged to the underside 5 of the housing 2 . The housing 2 comprises an upper part 7 and a lower part 8 , wherein the upper part 7 supports the connection socket 3 and forms the upper side 4 . Two plate-shaped supports, an upper support 9 and a lower support 10 , are sandwiched between the upper part 7 and the lower part 8 . A plate-shaped valve membrane 13 mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com