Self-operated pressure regulator

A pressure-regulating, self-operated technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of narrow application range, easy aging of the diaphragm, easy rupture of the diaphragm, etc., to achieve convenient operation and use Effects of long life and broadened application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

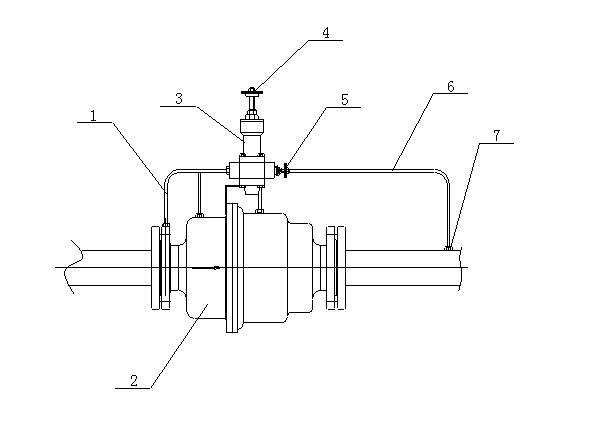

[0012] In the accompanying drawings, the self-operated pressure regulating valve is composed of a pressure taking pipe 1 before the valve, a control valve 2, a pilot 3, a regulating valve 4, a throttle valve 5, a pressure taking pipe 6 after the valve and a pressure taking point 7 after the valve. Among them, one end of the pre-valve pressure pipe 1 is connected to the control valve 2, the other end of the pre-valve pressure pipe 1 is connected to the front end of the pilot 3, the regulating valve 4 is connected to the upper end of the pilot 3, and the rear end of the pilot 3 The throttle valve 5 is connected to one end of the pressure-taking pipe 6 after the valve, and the other end of the pressure-taking pipe 6 after the valve is connected to the pressure-taking point 7 after the valve.

[0013] The control valve (2) is provided with a pressure chamber inside the valve, and the pressure chamber inside the valve is in the form of a piston.

[0014] Working principle of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com