A deep-sea on-site corrosion electrochemical testing device and testing method thereof

A test device and electrochemical technology, applied in the field of marine engineering, can solve problems such as difficulty, difficulty in accurately measuring and controlling seawater quality conditions, etc., and achieve the effects of small size, strong anti-interference ability, and good insulation and sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

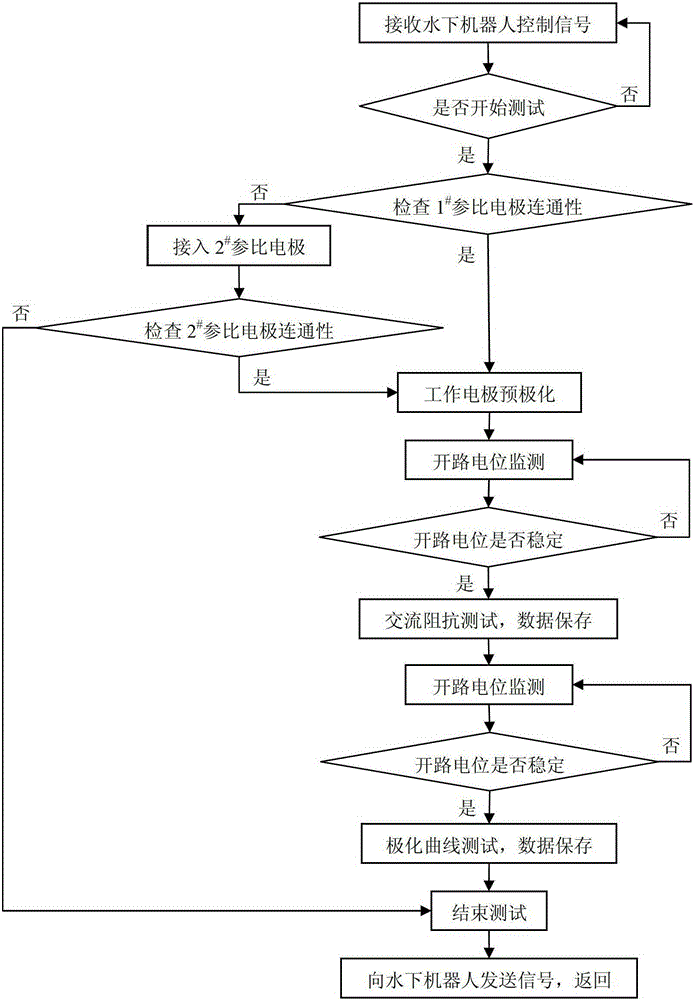

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

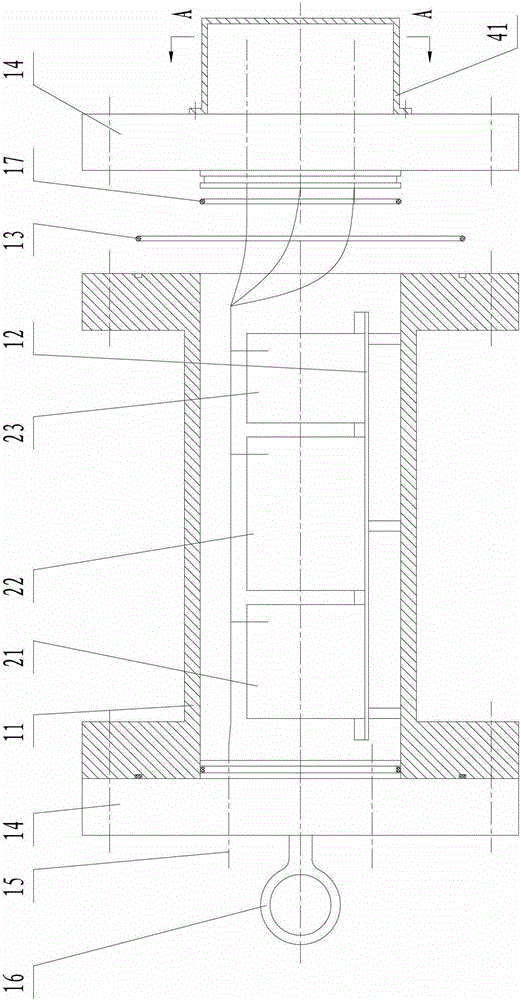

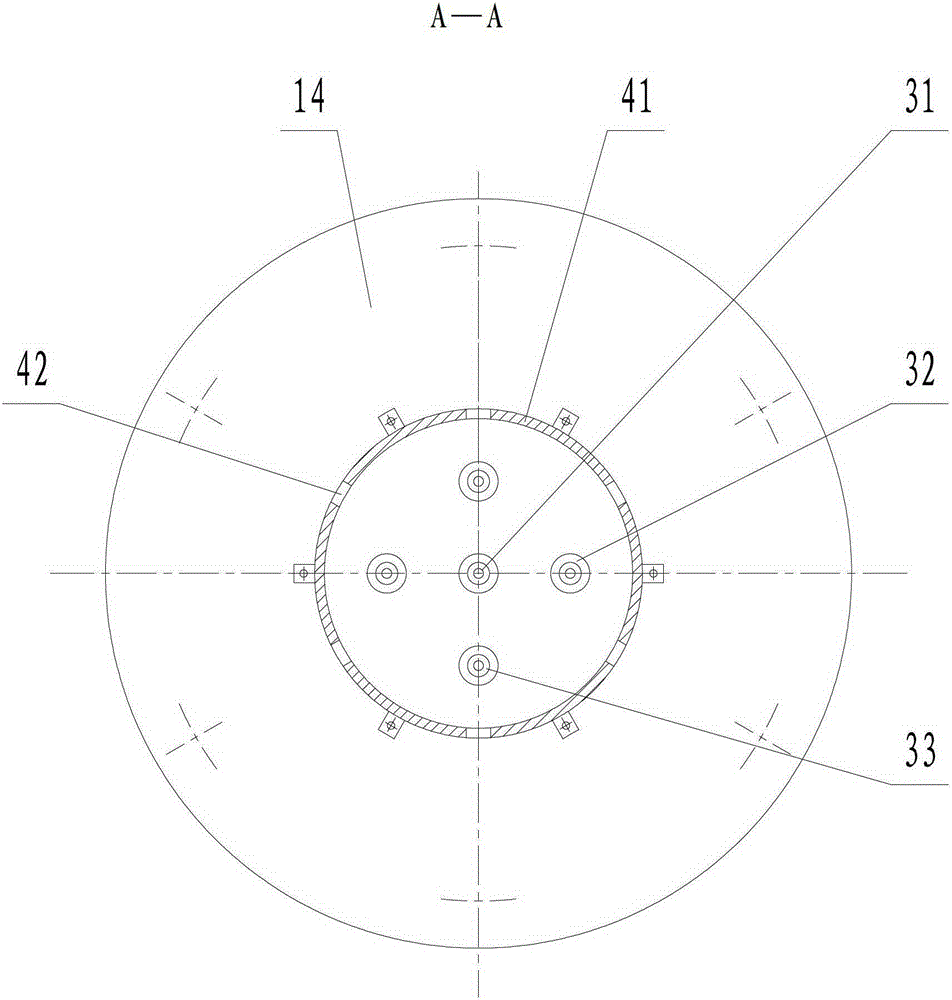

[0028] Such as figure 1 , figure 2 As shown, the test device of the present invention includes a pressure-resistant watertight electronic cabin, a corrosion electrochemical test system, a connector type electrode system and a porous shield 41, wherein the corrosion electrochemical test system is located in the pressure-resistant watertight electronic cabin, and the connector The type electrode system is integrated on the outside of one end of the pressure-resistant watertight electronic cabin, and the corrosion electrochemical test system is connected with the plug-in type electrode system through wires. The porous shield 41 is installed on one end of the pressure-resistant watertight electronic cabin, and the plug-in The type electrode system is housed inside.

[0029] The pressure-resistant watertight electronic cabin includes a cylinder body 11, an umbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com