Patents

Literature

61results about How to "Realize detection work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

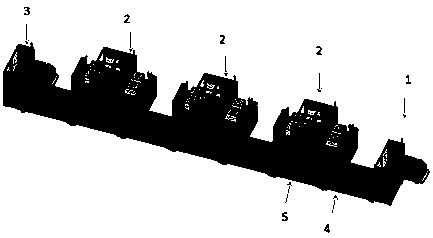

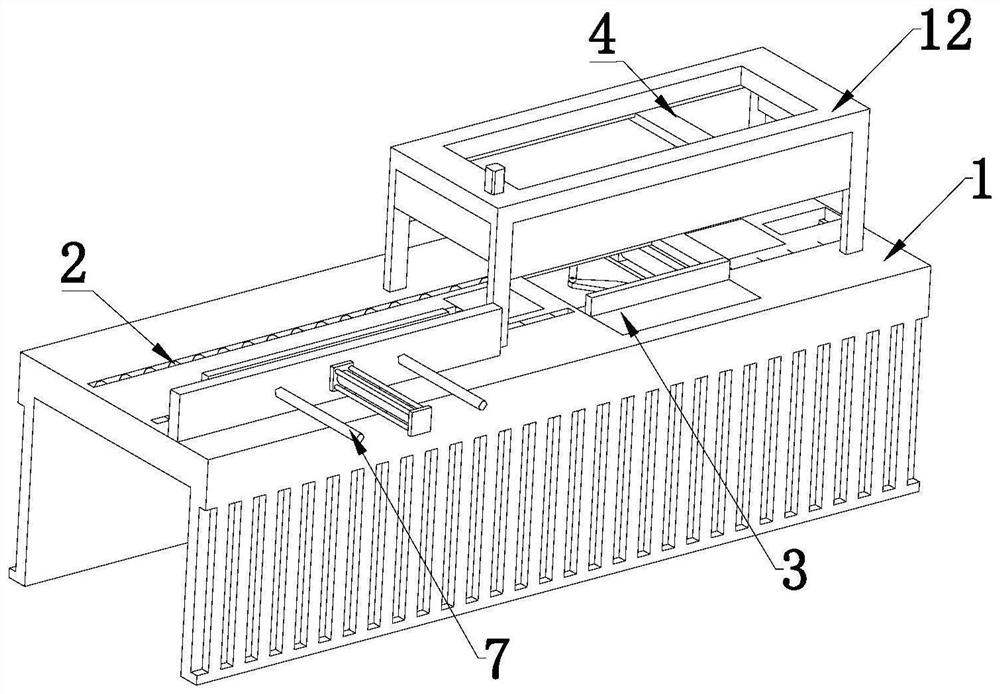

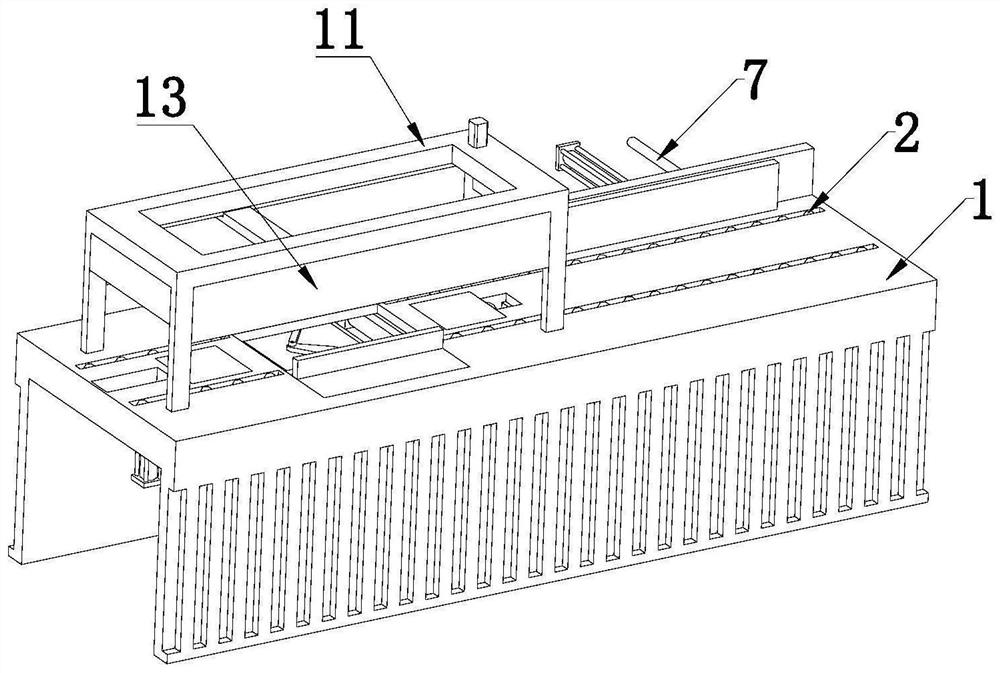

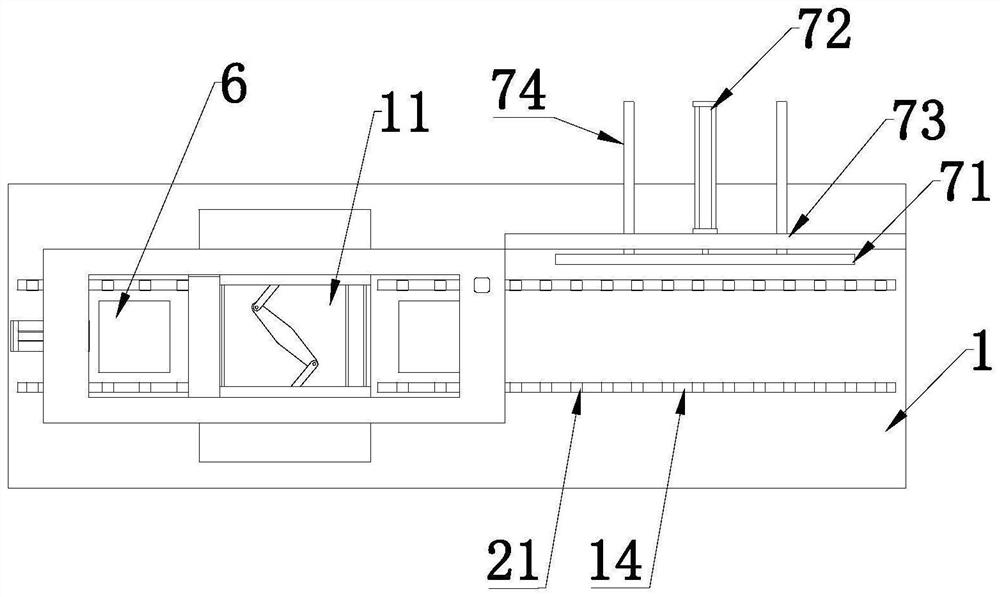

Process equipment for composting and rapid aerobic fermentation of sludge, and automatic control scheme for composting and rapid aerobic fermentation process

ActiveCN106396769AImproving the initial process conditions of aerobic fermentationImprove breathabilityBio-organic fraction processingEnergy inputAutomatic controlProcess equipment

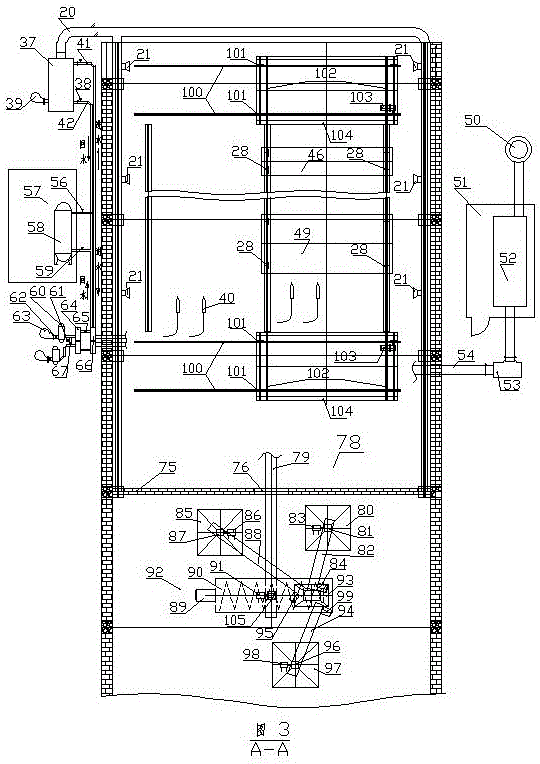

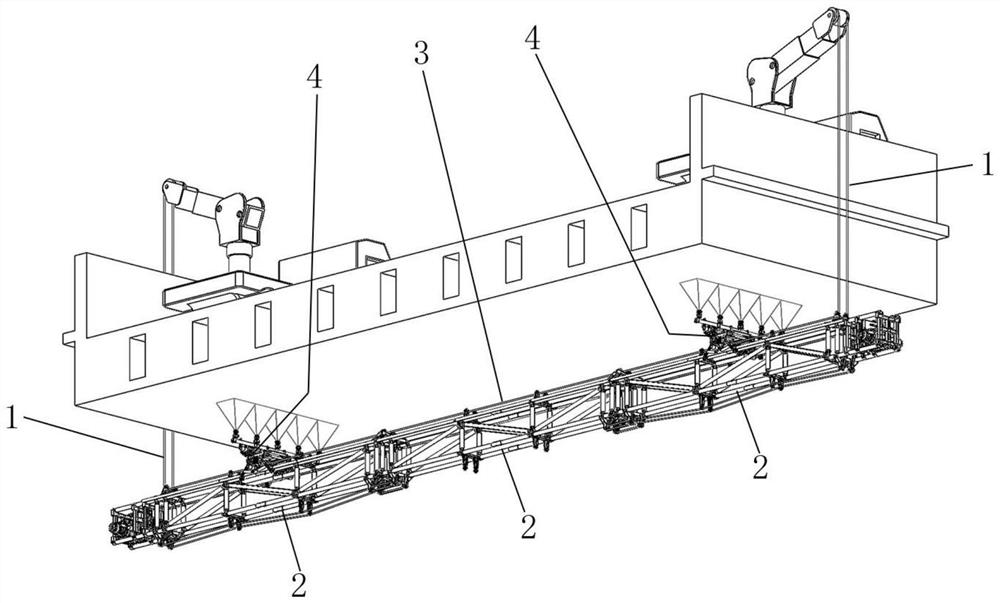

The invention provides process equipment for composting and rapid aerobic fermentation of sludge and an automatic control scheme for a composting and rapid aerobic fermentation process, belonging to the technical field of composting and aerobic fermentation of sludge. The process equipment and automatic control scheme provide optimal initial process conditions for microbial propagation in composting and aerobic fermentation of sludge, enable composting and aerobic fermentation of sludge to rapidly enter a high-temperature fermentation period, accelerate the processes of fermentation and decomposition, shorten a fermentation period, reduce cost and exert beneficial effect on reduction, harmless treatment and stabilization of sludge. The process equipment comprises a solar photovoltaic power generation system, fermentation tanks with in-ground insulation and heating functions, a gas collecting cover having aeration and heating functions, used for collecting water vapor and stink produced in the process of fermentation and capable of moving up and down, a biological deodorizing system, an air supply and heating system for a workshop in winter, a travelling crane-like manipulator-operated material distribution machine, a composting heap turner, a data acquisition trolley, displace trolleys, a boiler system and an automatic control system for batching of raw and accessory materials and for process flow.

Owner:阮航 +2

Soft robot based on SMA and SSMA driving

ActiveCN104175314AControl scalingEasy to controlProgramme-controlled manipulatorFlexible MechanismsRobotic systems

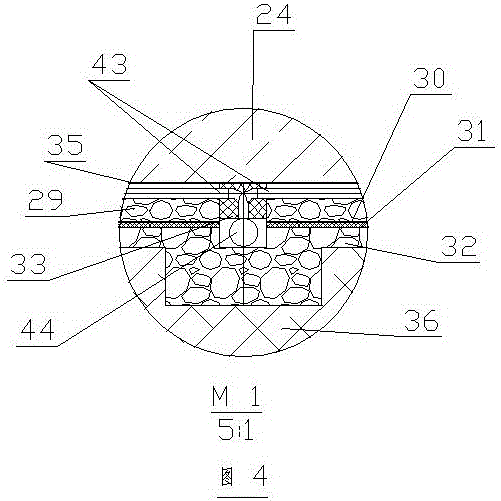

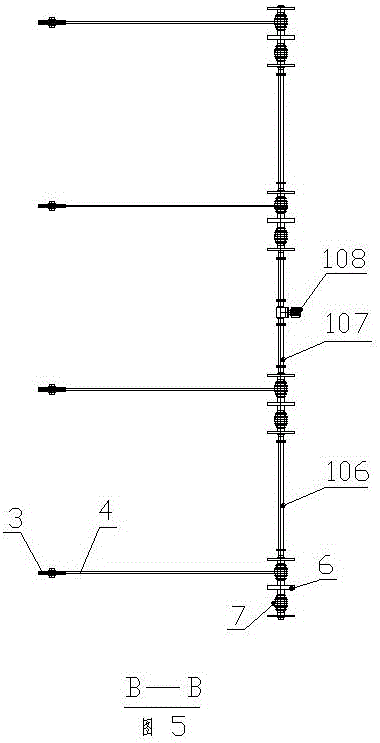

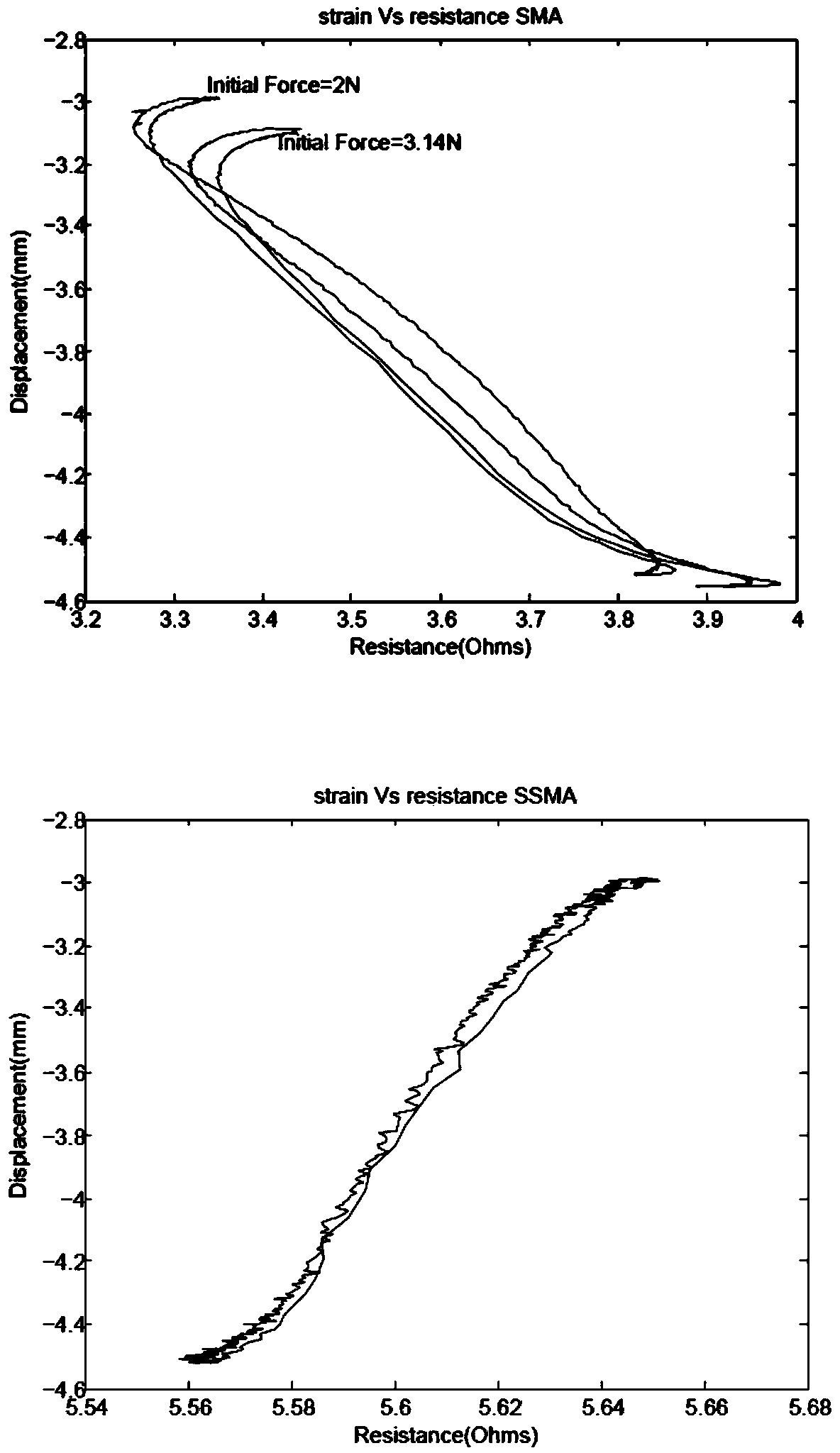

The embodiment of the invention provides a soft robot system which is applicable to detection operation of complex environments and unknown fields, based on SMA, self-feedback and SSMA driving, combines external feedback, and matches soft joints and rigid joints. The modules namely an SSMAs driver element module, a flexible mechanism module and foot SMA driver modules are provided, wherein electric current flowing through SSMAs is adopted to control the telescopic length of the SSMAs so as to control the integral contraction of the robot; the parallel structure of SMA and SSMA realizes SMA self-feedback and the external feedback of the SSMA, so that the accurate control on the soft robot is realized; an external 3D shell is used for connecting the front rigid part with the rear rigid part of the robot, so that the soft robot system has better flexibility; a square spring supports a flexible silica gel shell to provide restoring force and other power; two groups of SMA driver modules in front of and at back of each foot structure are controlled respectively, so that the feet motion is realized, and the motion of the robot is realized along with other units.

Owner:北京神工科技有限公司

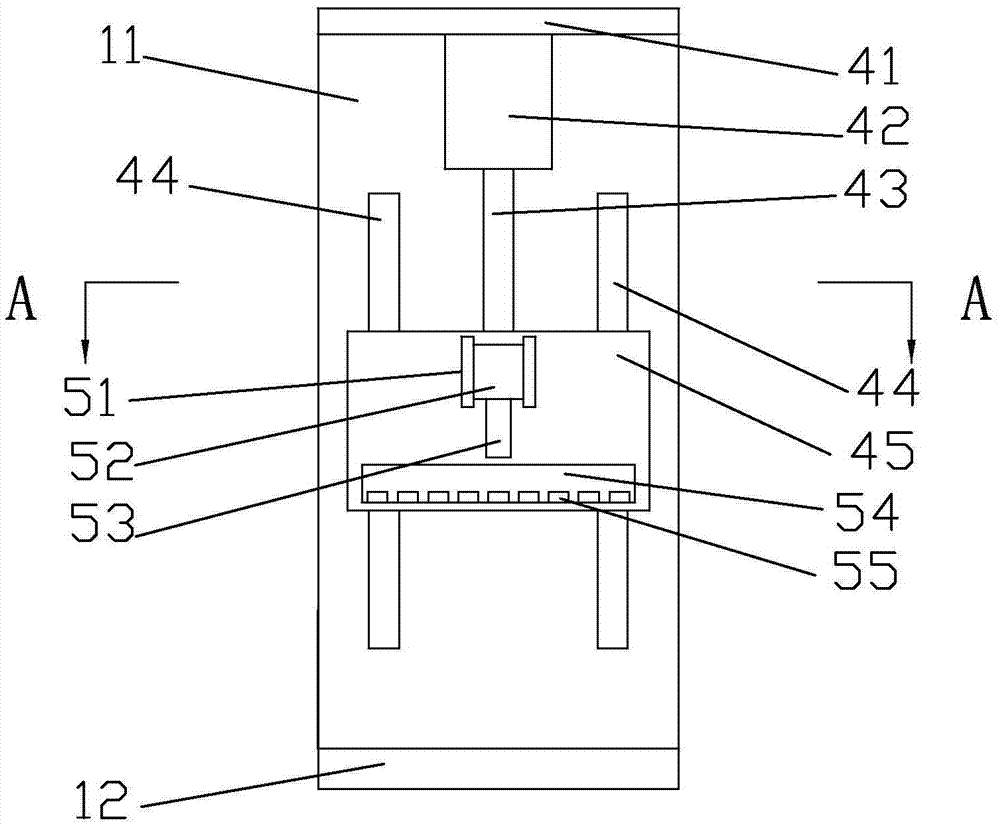

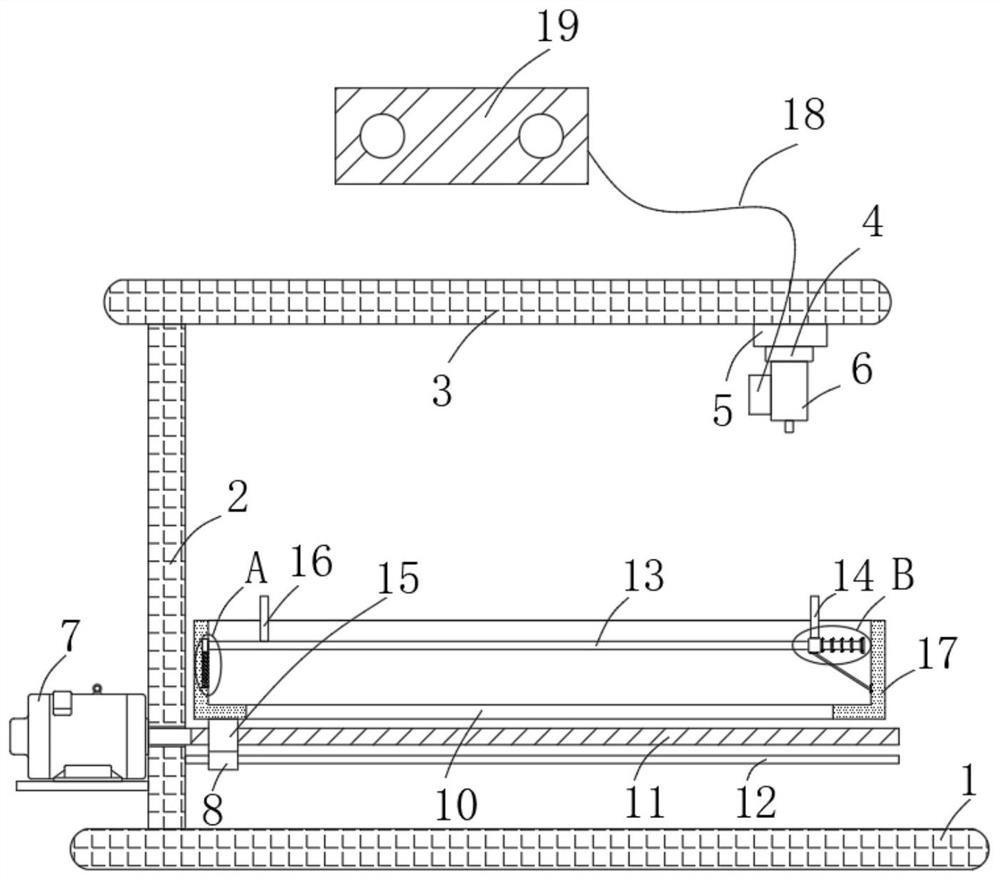

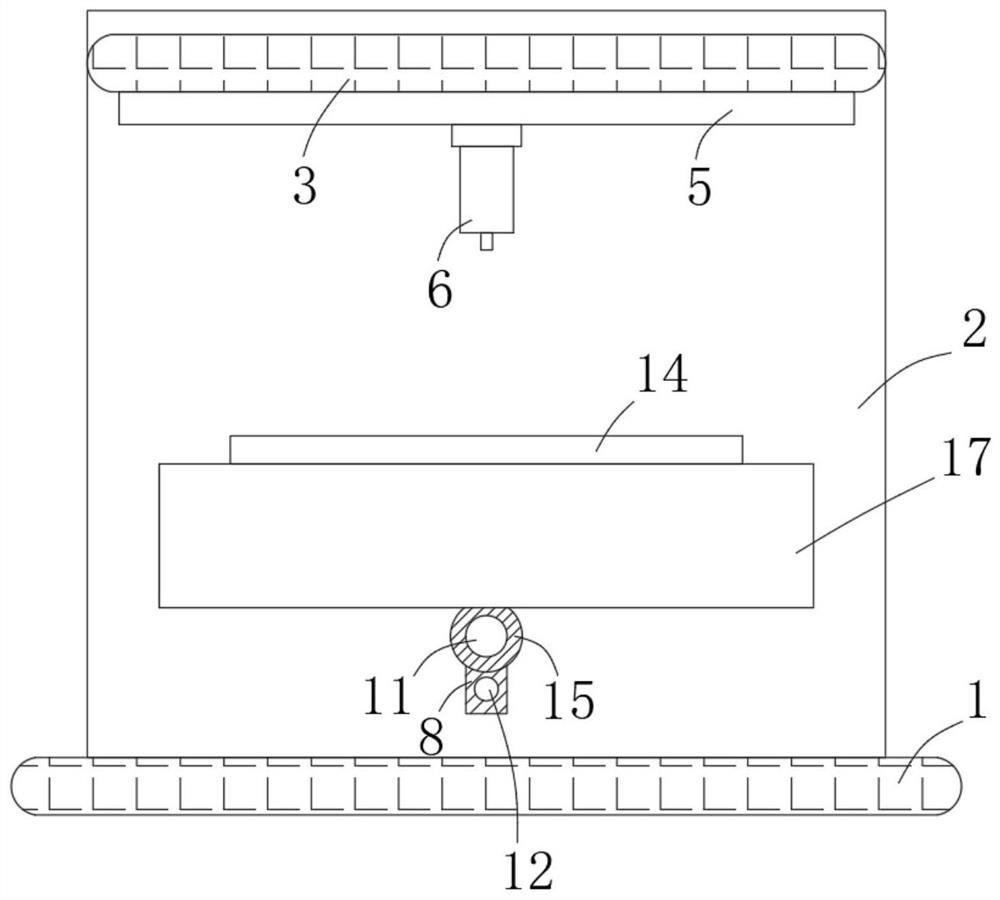

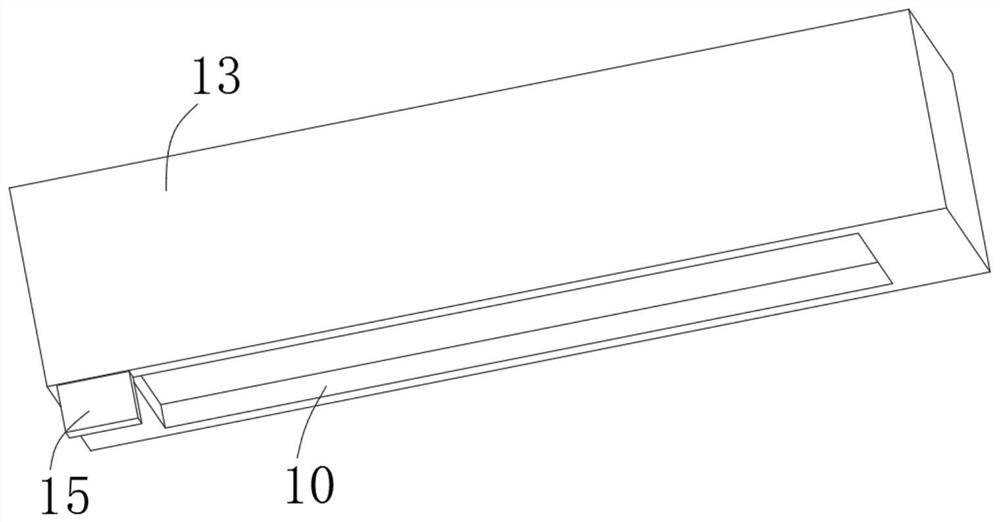

Blanking detection equipment applied to metal workpieces

ActiveCN105438780ASolve the problem of blanking inspectionReduce laborConveyorsOptically investigating flaws/contaminationEngineeringConveyor belt

The invention discloses blanking detection equipment applied to metal workpieces. The blanking detection equipment comprises a rack and a blanking platform, wherein the blanking platform is located on the rack; a conveyor belt is arranged in the blanking platform; a detection device is arranged on the inner side of the blanking platform; the detection device comprises a detection bottom plate, a detection vertical frame, a shooting component and a lifting detection mechanism; the detection bottom plate is arranged on the blanking platform; the detection vertical frame is arranged on the detection bottom plate; the detection vertical frame is provided with the lifting detection mechanism; the lifting detection mechanism is connected with the shooting component; a material baffling device is arranged on the outer side of the blanking platform; the material baffling device comprises a material baffling mechanism, a material baffling transmission mechanism and a material baffling positioning mechanism; the material baffling mechanism is arranged on the outer side of the blanking platform; the material baffling transmission mechanism is connected with the material baffling mechanism; the material baffling mechanism is located below the material baffling mechanism; and the material baffling positioning mechanism is arranged on the lower end of the blanking platform. The blanking detection equipment is simple in structure, high in pertinency and high in automation degree, and is scientific and convenient; and the blanking detection problem after the metal workpieces are machined is well solved.

Owner:南京大目信息科技有限公司

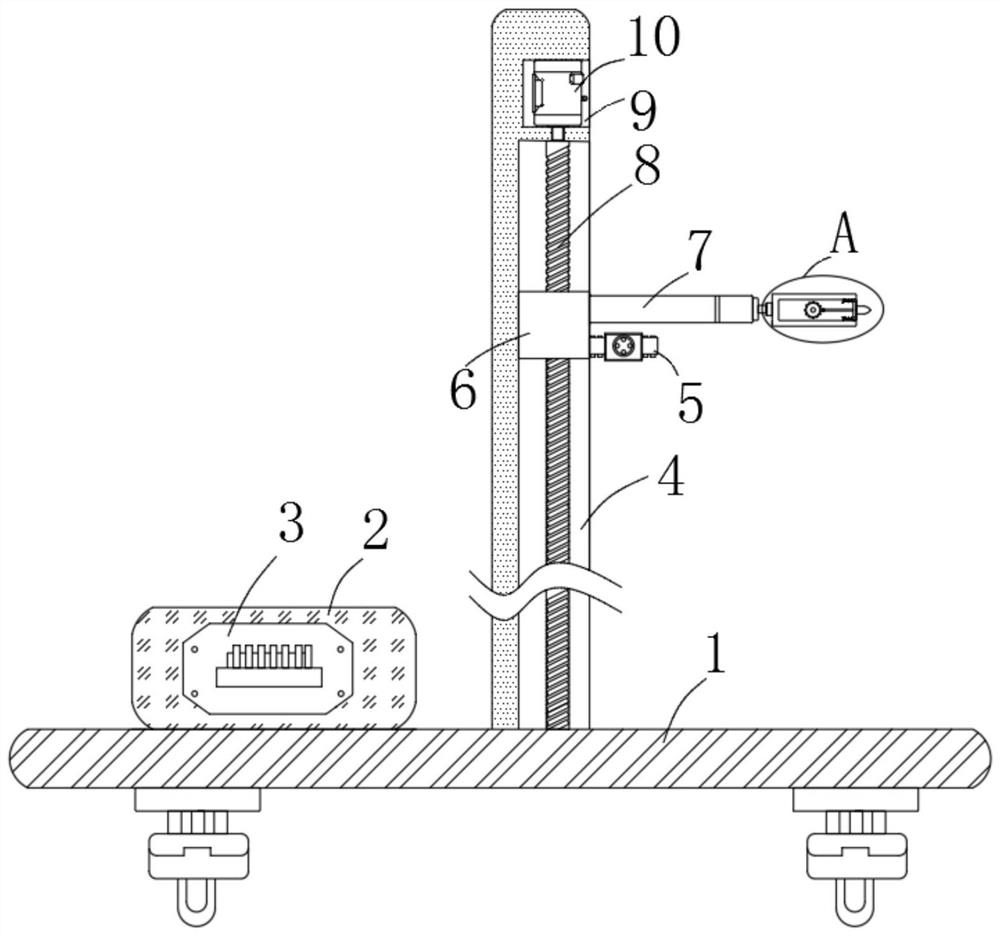

Wall detection device based on architectural design

InactiveCN111830132ARealize lifting workComprehensive testing workAnalysing solids using sonic/ultrasonic/infrasonic wavesElectric machineDisplay device

The invention discloses a wall detection device based on building design and relates to the technical field of wall detection. The wall detection device comprises a base, wherein an upper end of the base is fixedly connected with a display, a side wall of the display is fixedly connected with a sensor, the upper end of the base is fixedly connected with a mounting rod, a mounting groove is formedin an inner side wall of the mounting rod, a lifting mechanism is mounted in the mounting groove, a mounting groove is formed in a side wall of the mounting rod, a first servo motor is mounted in themounting groove, and a tail end of an output shaft of the first servo motor is fixedly connected with an upper end of a threaded rod. The wall detection device is advantaged in that through cooperative use of a driving motor, a threaded rod and a threaded sleeve, lifting work of a telescopic rod and an electric push rod is achieved, then lifting work of the knocking mechanism is achieved, in the lifting process of the knocking mechanism, the comprehensive detection work of the wall surface is achieved, the tedious and complex operation process of manpower is replaced, and work efficiency is improved.

Owner:HUANGSHAN UNIV

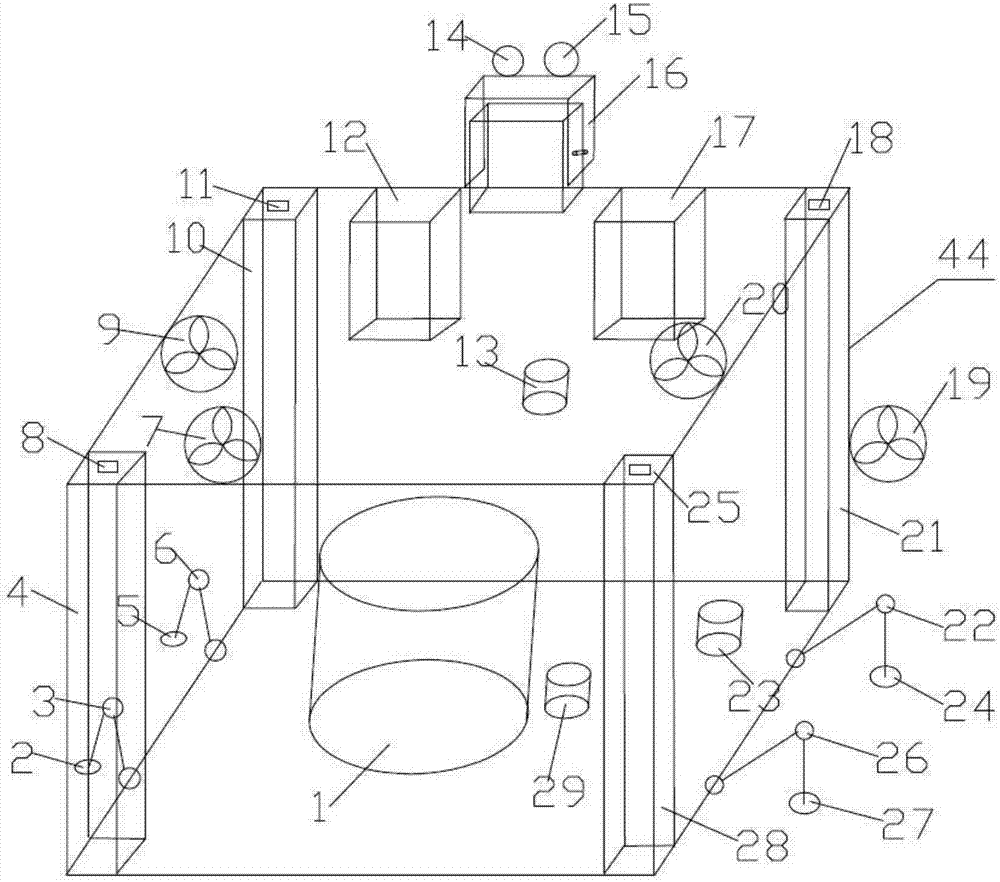

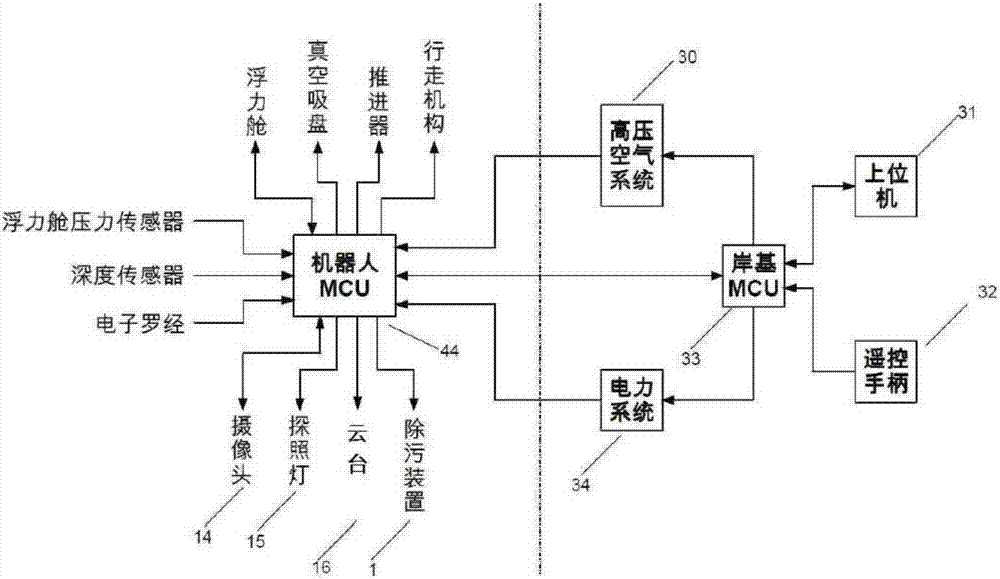

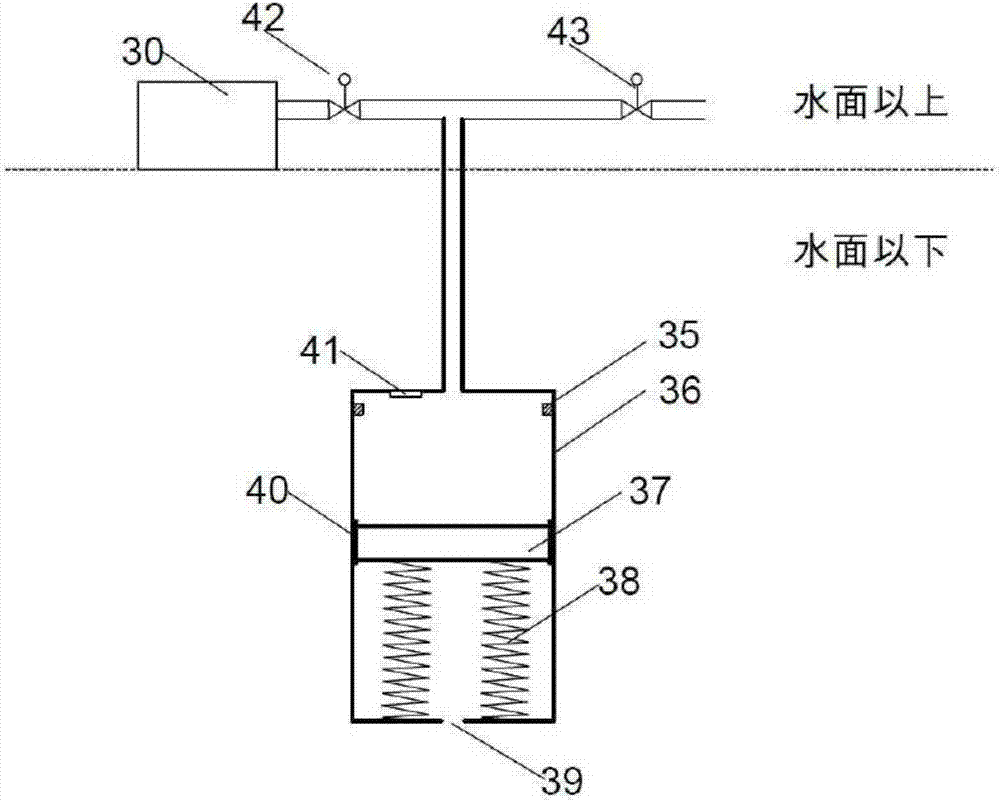

Underwater structure surface cleaning detection system based on buoyancy tank

ActiveCN107010183AImprove adsorption capacityLarge loading capacityVessel cleaningMeasurement devicesSupporting systemSurface cleaning

The invention relates to an underwater structure surface cleaning detection system based on a buoyancy tank. The underwater structure surface cleaning detection system is composed of a shore-based support system and an underwater operating system, the shore-based support system and the underwater operating system are connected through cables and air cables, the shore-based support system is used for providing power, high-pressure air and ensures communication for the underwater operating system, and the underwater shore-based support system controls the underwater operating system to clean and detect underwater structure surface in an underwater marine environment. The buoyancy tank is utilized to adjust the size and operating attitude of the buoyancy of the underwater operating system, the load capacity of the underwater operating system is increased, and the energy consumption of the system is reduced. According to the underwater structure surface cleaning detection system based on the buoyancy tank, each walking foot adopts a cam vacuum adsorption type walking foot and can achieve adsorption of various underwater structure surface, by arranging propellers in different directions, when the surface appearance of the marine structure is complicated, the underwater operating system is more convenient to adsorb the structure surface, so that cleaning and detecting operation are achieved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

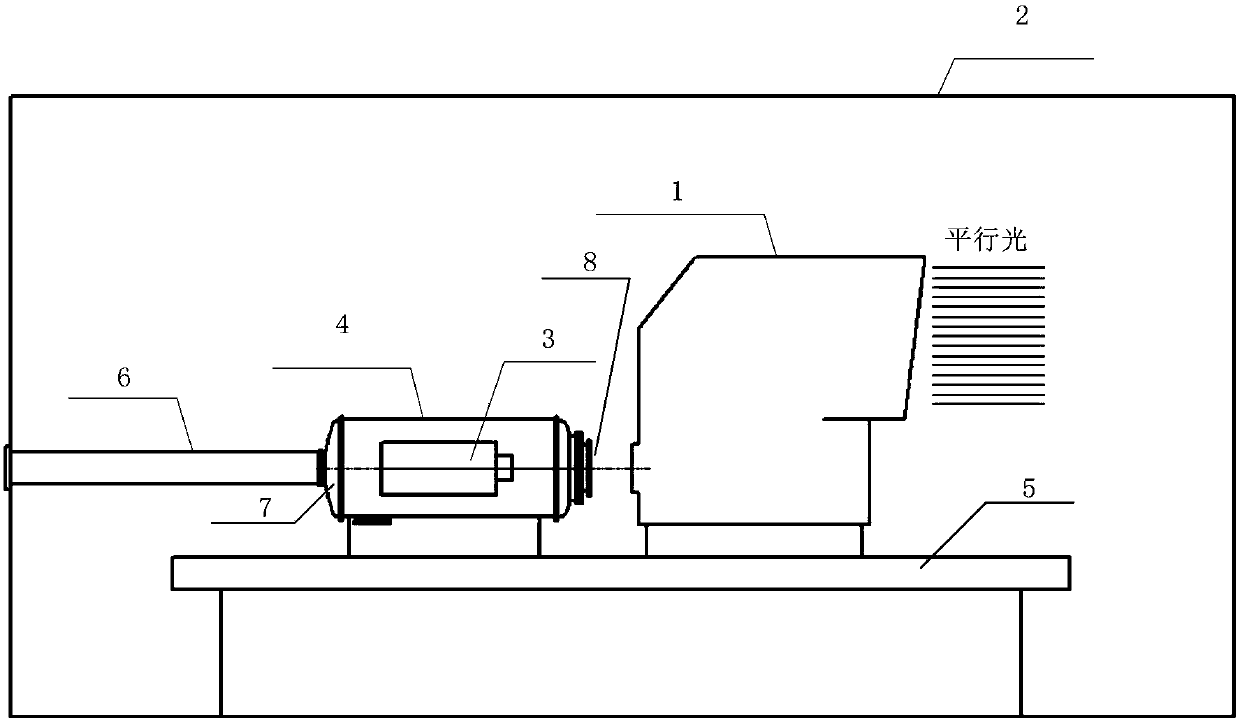

Vacuum optical detection system

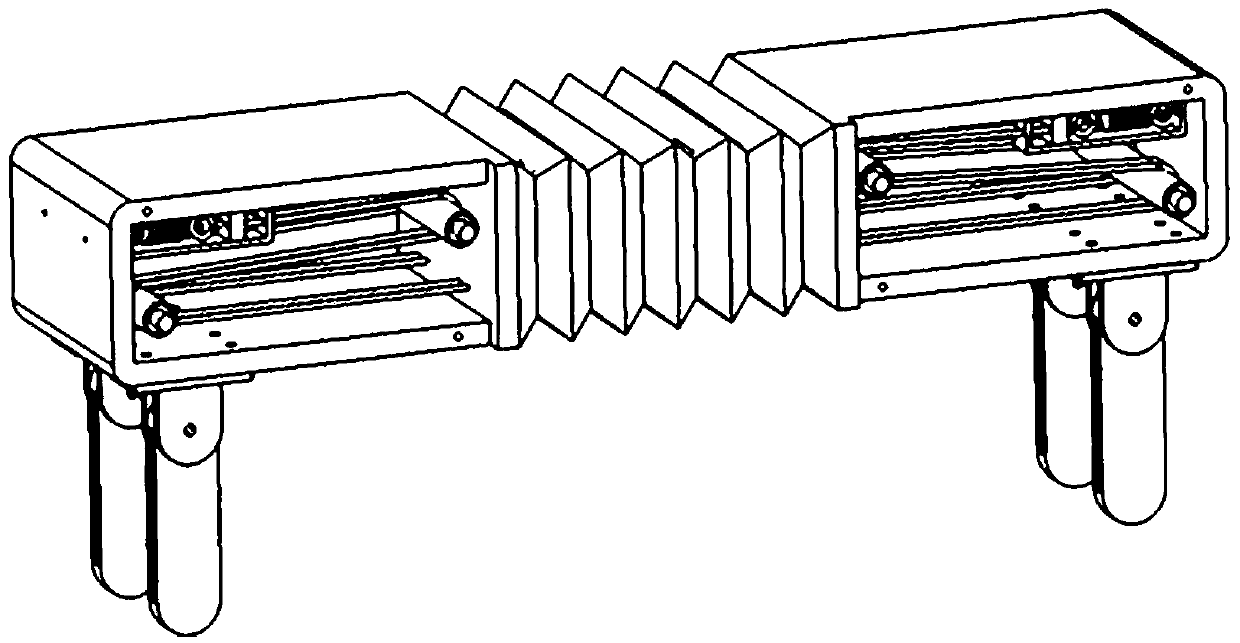

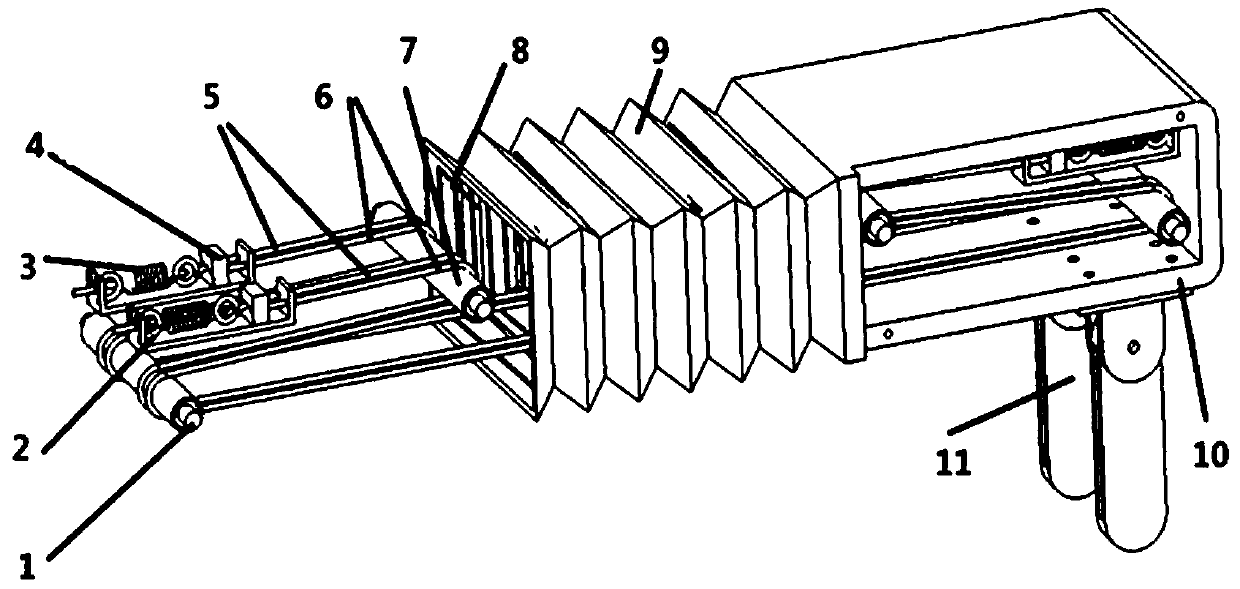

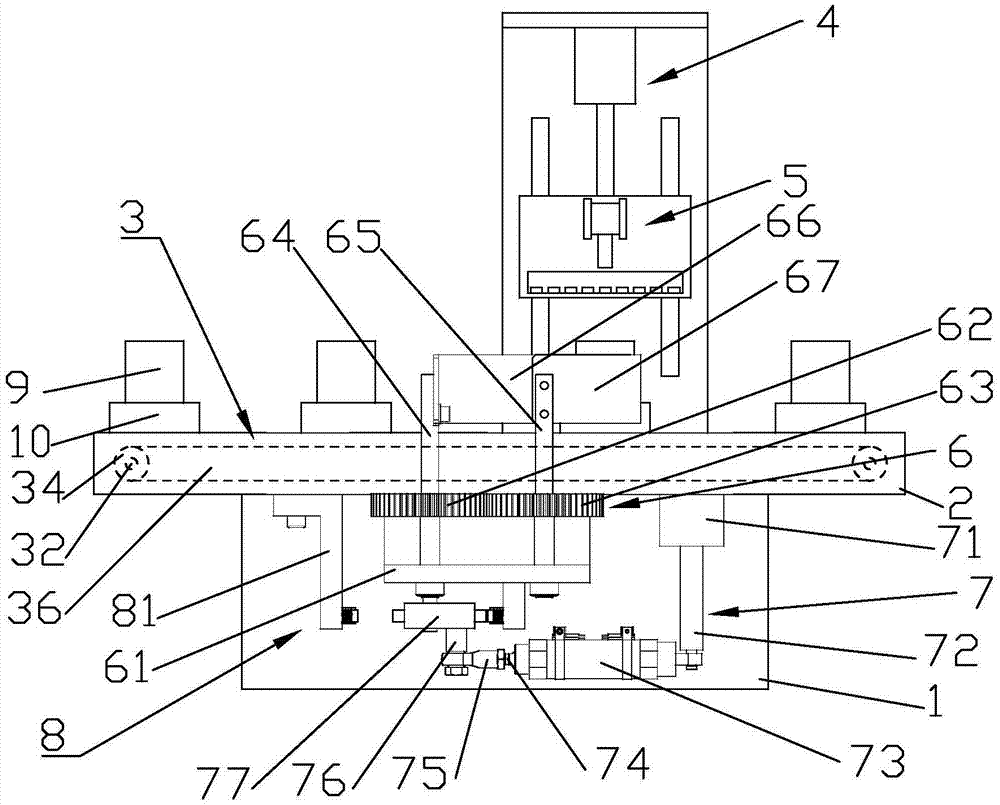

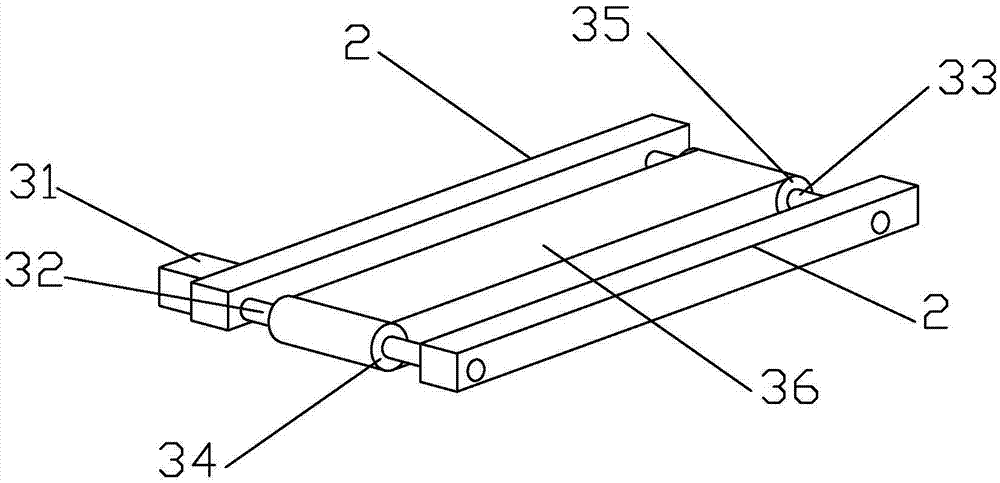

InactiveCN107782537ASolve engineering needsMeet application constraintsOptical apparatus testingAtmospheric airEngineering

The invention provides a vacuum optical detection system. The vacuum optical detection system comprises a space optical remote senor, a low air pressure simulation device, an interferometer, a vacuumcontainer used for containing the interferometer and an accurate adjustment device used for adjusting the space optical remote senor and the vacuum container, wherein the accurate adjustment device and the vacuum container are contained in the low air pressure simulation device; the low air pressure simulation device is a sealed container with an opening; the vacuum container is in flexible sealedcommunication with the opening through a corrugated pipe; the outside air is communicated with the vacuum container through the opening; the low air pressure simulation device is used for providing environment with low air pressure for the space optical remote senor; the accurate adjustment device is used for adjusting the positions of the space optical remote senor and the vacuum container, so that a focal plane of the space optical remote senor is aligned to a focal plane of the interferometer according to the preset position relation, and then the optical detection of the space optical remote senor under the vacuum environment is achieved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

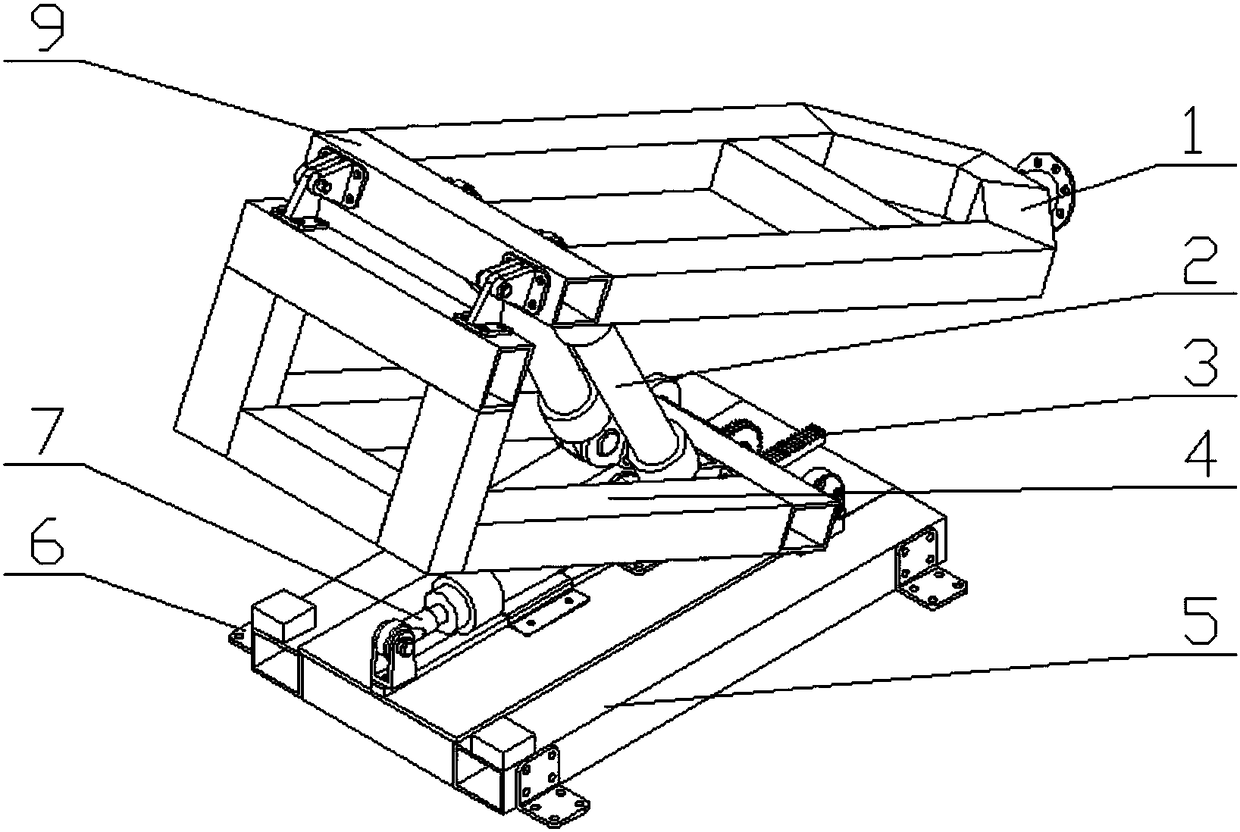

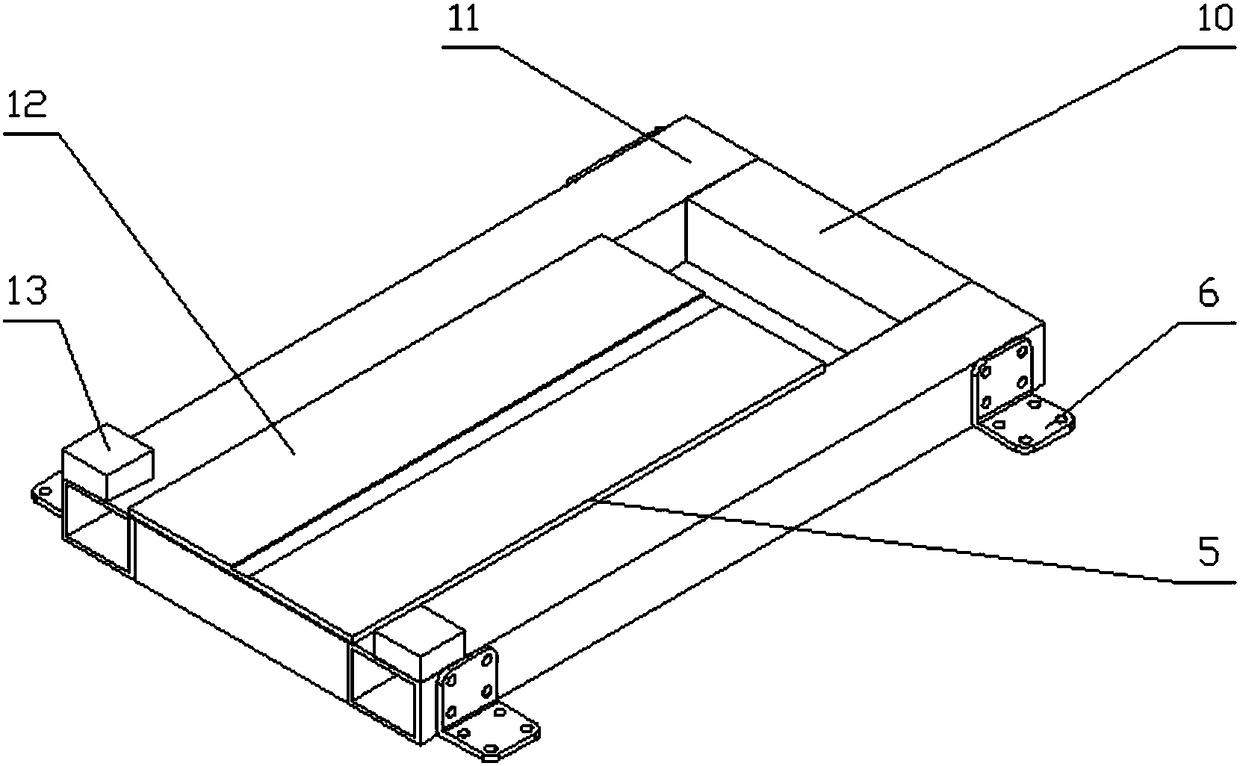

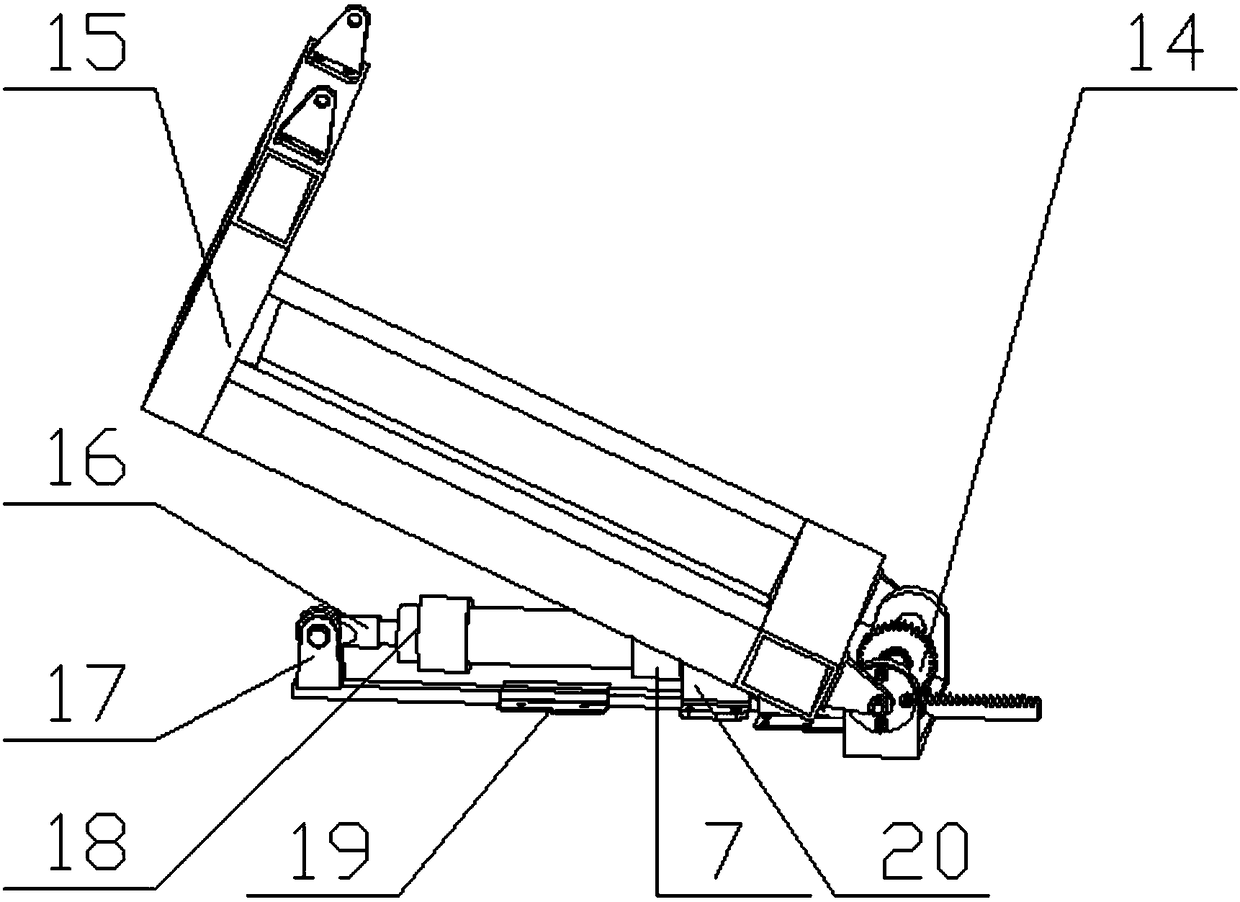

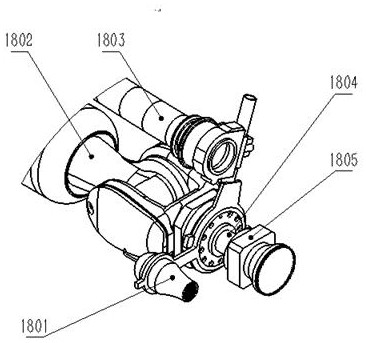

Unmanned ship detecting sonar automatic withdrawing and placing device

The invention relates to an unmanned ship detecting sonar automatic withdrawing and placing device. The device comprises a mounting base module, an overturning module provided with a rack capable of linearly moving and capable of realizing overall overturning by 180 degrees, and a rotating module provided with an oil cylinder capable of extending and capable of realizing 90-degree rotation of a front arm; and one end of the overturning module is connected with the mounting base module, and the other end of the overturning module is connected with the rotating module. The device achieves the technical aims of automatic placement and withdrawal of unmanned ship detecting sonar, and realizes the installation and detecting operations of the sonar on unmanned ships. The withdrawing and placingdevice can improve the adaptability of the detecting sonar and the automatic withdrawing and placing convenience, can improve the detecting efficiency after use, and fills in the blank of the technology at home and abroad.

Owner:TIANJIN NAVIGATION INSTR RES INST

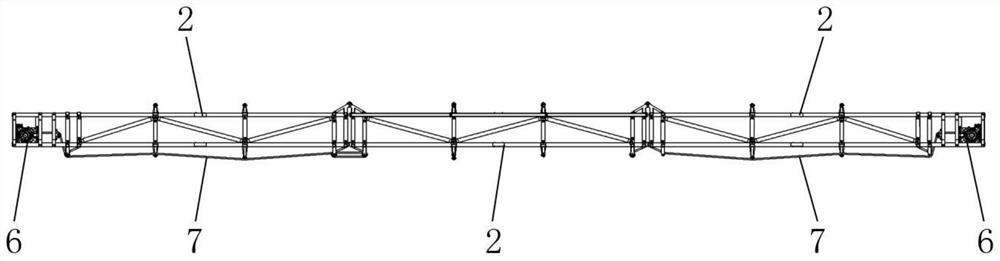

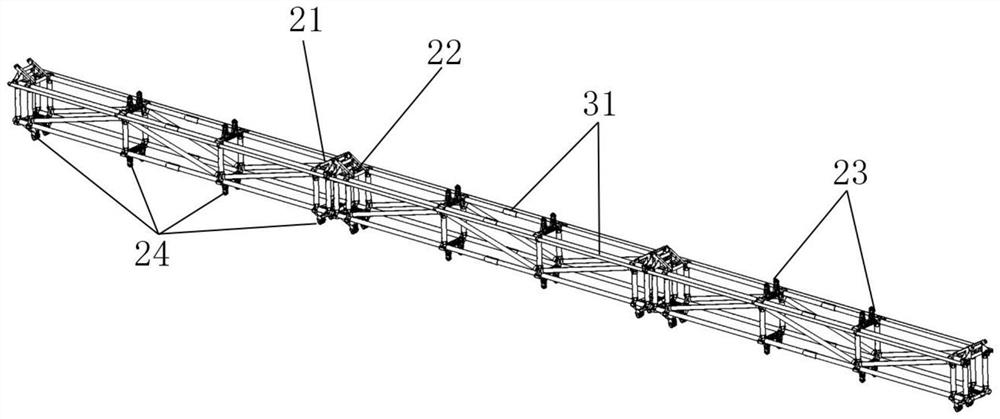

Bridge bottom surface detection operation device

PendingCN113529568AImprove adaptabilityRealize detection workBridge structural detailsTrackwayStructural engineering

The invention discloses a bridge bottom surface detection operation device. The device comprises a bearing rope which has two ends which are separately hung on the outer walls of the two sides in the width direction of a to-be-detected bridge and is distributed at the bottom of the to-be-detected bridge, a plurality of track supports which are slidably hung on the bearing rope and spliced to form an inspection track, and a plurality of inspection vehicles which are movably arranged on the inspection track and are used for detecting the bottom surface of the to-be-detected bridge, wherein each inspection vehicle is provided with a detection module. Therefore, through splicing of the track supports on the bearing rope, the inspection track is formed at the bottom of the to-be-detected bridge and the inspection vehicles carrying detection modules moves along the inspection track to complete detection operation on the bottom face of the to-be-detected bridge. Due to the fact that the hoisting number of the track supports on the bearing rope is uncertain, the actual hoisting number of the track supports can be flexibly adjusted according to the specific width of the current to-be-detected bridge, the adaptability to bridges with different widths is improved, and detection operation on the bottom face of the bridge can be safely and efficiently achieved.

Owner:THE CHINESE UNIV OF HONG KONG SHENZHEN +1

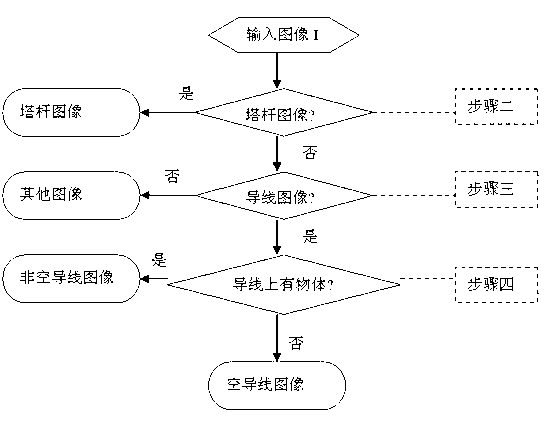

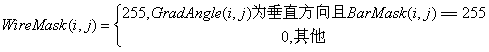

Electric transmission line helicopter routing inspection image classification method

ActiveCN103198326ASimplify laborRealize detection workCharacter and pattern recognitionFault detection and identificationClassification methods

The invention relates to an electric transmission line helicopter routing inspection image classification method. Traditional manual inspection is multiple in potential safety hazards and low in efficiency. According to the method, firstly, LoG transformation is conducted on an input image I to extract bar-type shapes in the image and obtain a BarMask; secondly, an edge is extracted to the image under the BarMask by using an edge detecting method, straight line sections of the edge are detected by using a Hough transformation class method, the fact that whether a pole exists in the image I is judged according to direction, number and length of the straight line sections; then the fact that whether the image under the BarMask is a guide line image is judged; and finally the fact that whether element components or other objects are on a guide line is judged. The electric transmission line helicopter routing inspection image classification method can classify and filter a large number of routing inspection images, and simplifies subsequent fault detect and identification works achieved by manual work or software.

Owner:HANGZHOU JIESHANG SMART GRID TECH CO LTD

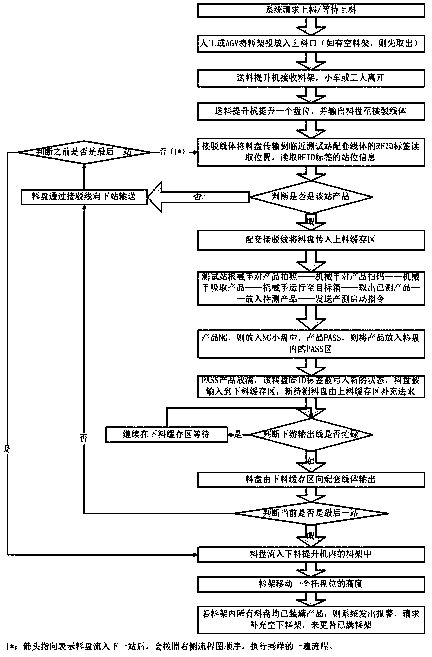

Universal line whole machine device

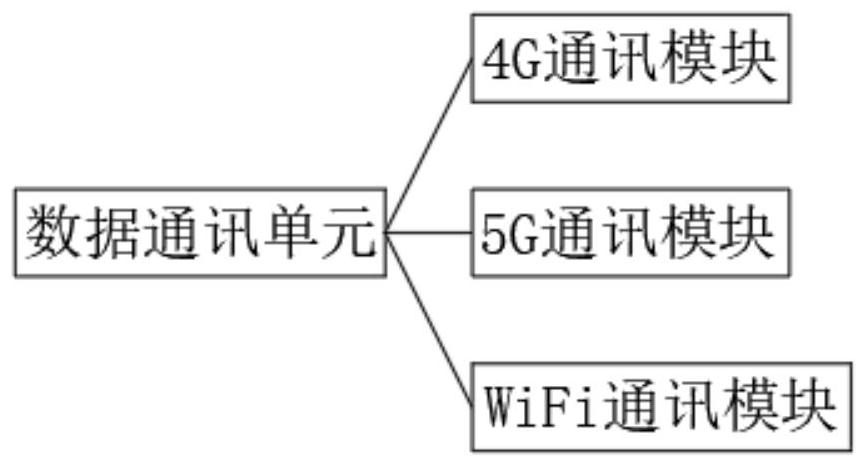

InactiveCN107685985ARealize detection workThe detection process is fastControl devices for conveyorsWireless communicationSimulationAutomation

The invention relates to a universal line whole machine device. The universal line whole machine device is characterized by comprising an automatic feeding machine, an automatic wifi testing unit, anautomatic material receiving machine, a connection line body and matched line bodies; the automatic wifi testing unit comprises a plurality of automatic wifi testing stations; each automatic wifi testing station comprises an automatic wifi testing machine and the corresponding matched line body; the automatic wifi testing machines are connected with the connection line body through the matched line bodies; and the detection work on products can be achieved without special classifying and detecting personnel, the detection speed is high, efficiency is high, and the automation degree is high.

Owner:江苏富联通讯技术股份有限公司

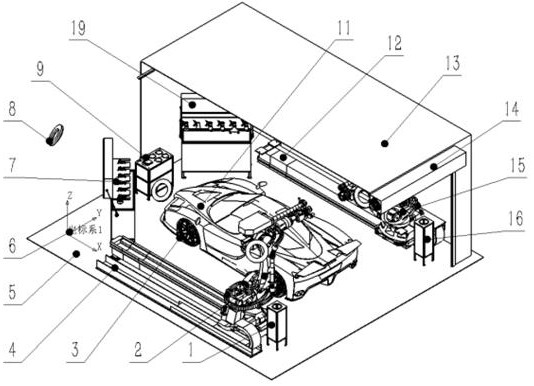

Automobile appearance detection and repair workstation

ActiveCN114536112ARealize detection workEasy to carryPolishing machinesMaterial analysis by optical meansControl engineering3d camera

An automobile appearance detecting and repairing workstation comprises a first polishing solution supplying device, a first robot, a limiting block, a first linear rail, a floor, a space coordinate system, a first tool library, an illuminating lamp, a sand changing library, a second tool library, an automobile, a second linear rail, a workstation body, a roller shutter door, a second robot and a second polishing solution supplying device. According to the invention, the to-be-repaired vehicle is modeled in the self-defined space coordinate system, and the effective working space of the robot is increased and the complexity of the workstation body is reduced through the cooperative layout of the linear rail and the robot; aI graph three-dimensional shooting, imaging and modeling are carried out through a 3D camera, and then self-developed AI self-recognition engine software is compared with appearance data of the vehicle type in a database, so that detection and defect recognition of the appearance of the vehicle body are realized; a repairing program is automatically generated through online programming software, the robot is controlled on line to execute repairing programs such as shaping, grinding and polishing of automobile defect parts, and the whole process is simple, accurate and efficient.

Owner:南通新蓝机器人科技有限公司

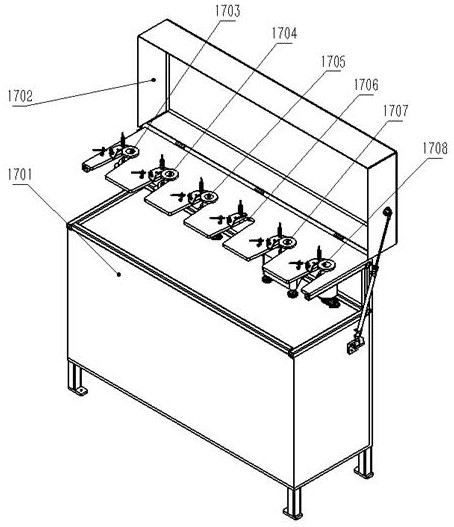

Guide rail profile detection device

PendingCN114345736ARealize detection workAchieve comprehensive detectionSortingStructural engineeringMechanical engineering

The invention discloses a guide rail profile detection device, which belongs to the technical field of profile detection, and comprises a detection table, a detection conveying mechanism, a detection fixing mechanism, a profile detection mechanism, a detection turnover mechanism, a detection lifting mechanism and a defective product moving mechanism, the detection fixing mechanism is located in a mounting groove in the detection table, the detection fixing mechanism is in sliding fit with the detection table, the detection conveying mechanism is rotationally connected to the detection table, a detection frame is arranged on the detection table, the profile detection mechanism is located on the detection frame, and the detection turnover mechanisms are symmetrically arranged at the two ends of the mounting groove. The detection lifting mechanism is connected to the detection table in a sliding mode, the detection lifting mechanism is located beside the detection turnover mechanism, and the defective product moving mechanism is located at the discharging end of the detection table. According to the invention, detection operation can be carried out on different surfaces of the profile, so that detection operation on a plurality of surfaces of the profile is realized.

Owner:惠州市普盈金属科技有限公司

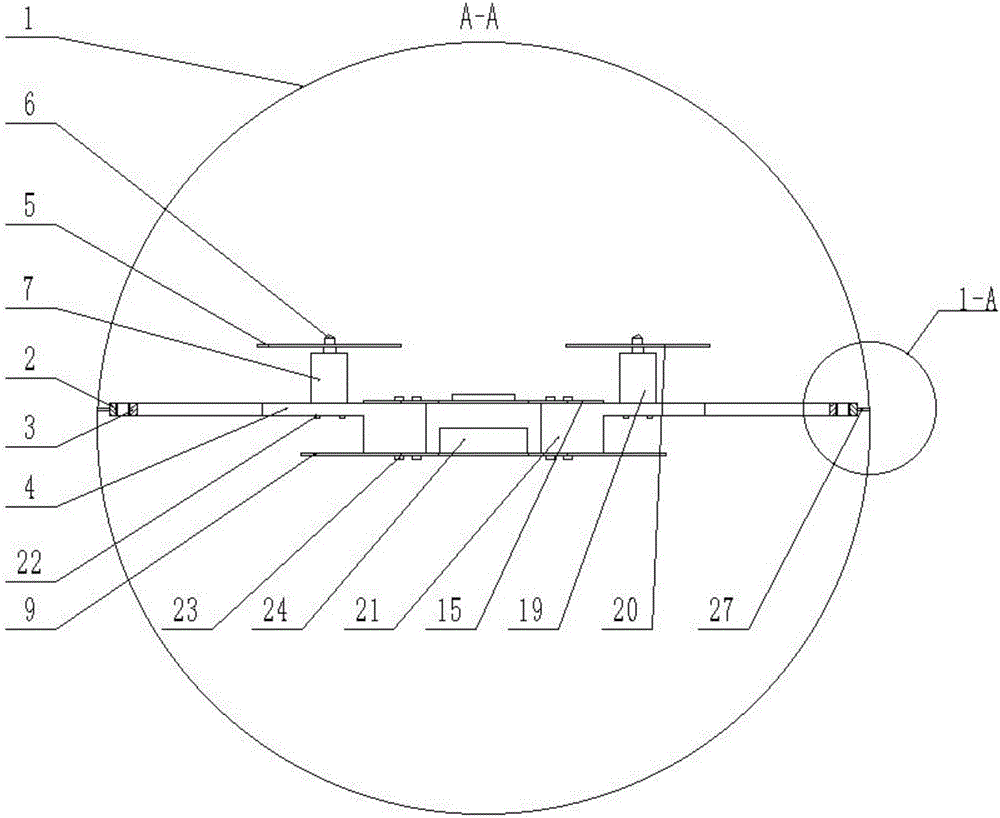

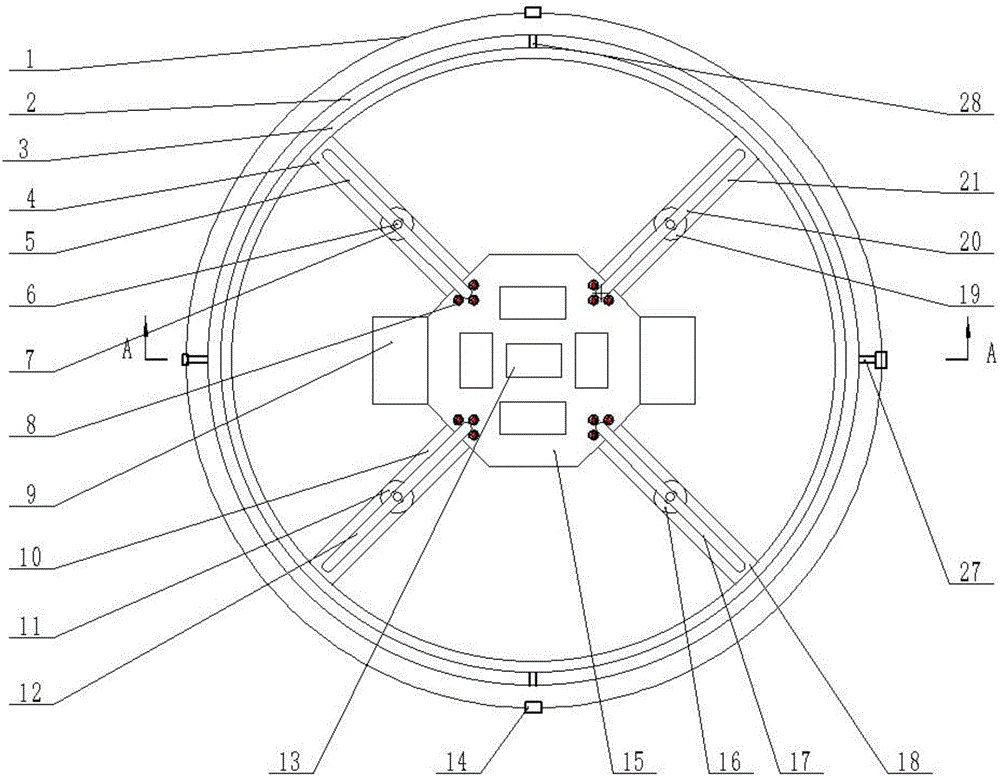

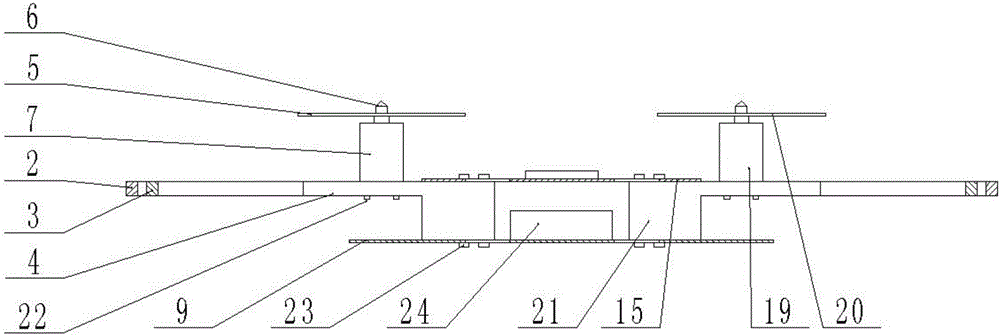

Self-obstacle-avoiding and fixed-point-tracking spherical aircraft

InactiveCN106005406ARealize aerial inspectionRealize detection workPosition/course control in three dimensionsAircraftsBrushless motorsFiber

The invention discloses a self-obstacle-avoiding and fixed-point-tracking spherical aircraft which mainly comprises a spherical framework shell, a gyroscopic stabilizing system outer ring, a gyroscopic stabilizing system inner ring, a motor supporting frame A, a paddle A, paddle tacking knobs, a brushless motor A, a socket cap screw A, a pan-tilt seat, a motor supporting frame B, a brushless motor B, a paddle B, a control system single chip microcomputer, an infrared sensor, a platform, a brushless motor C, a paddle C, a motor supporting frame C, a brushless motor D, a paddle D, a motor supporting frame D, a socket cap screw B, a socket cap screw C, a battery, tee couplings, carbon fiber tubes, a pin A and a pin B. The self-obstacle-avoiding and fixed-point-tracking spherical aircraft runs flexibly without a dead point, is light in weight, small in size and simple in mechanical structure, has better flexibility and adaptability, can be controlled remotely, has an automatic obstacle avoiding function, is provided with an expansion interface in a reservation manner, and can expand a miniature camera and a WIFI (wireless fidelity) module later.

Owner:YANSHAN UNIV

Mobile FOD optical detection system

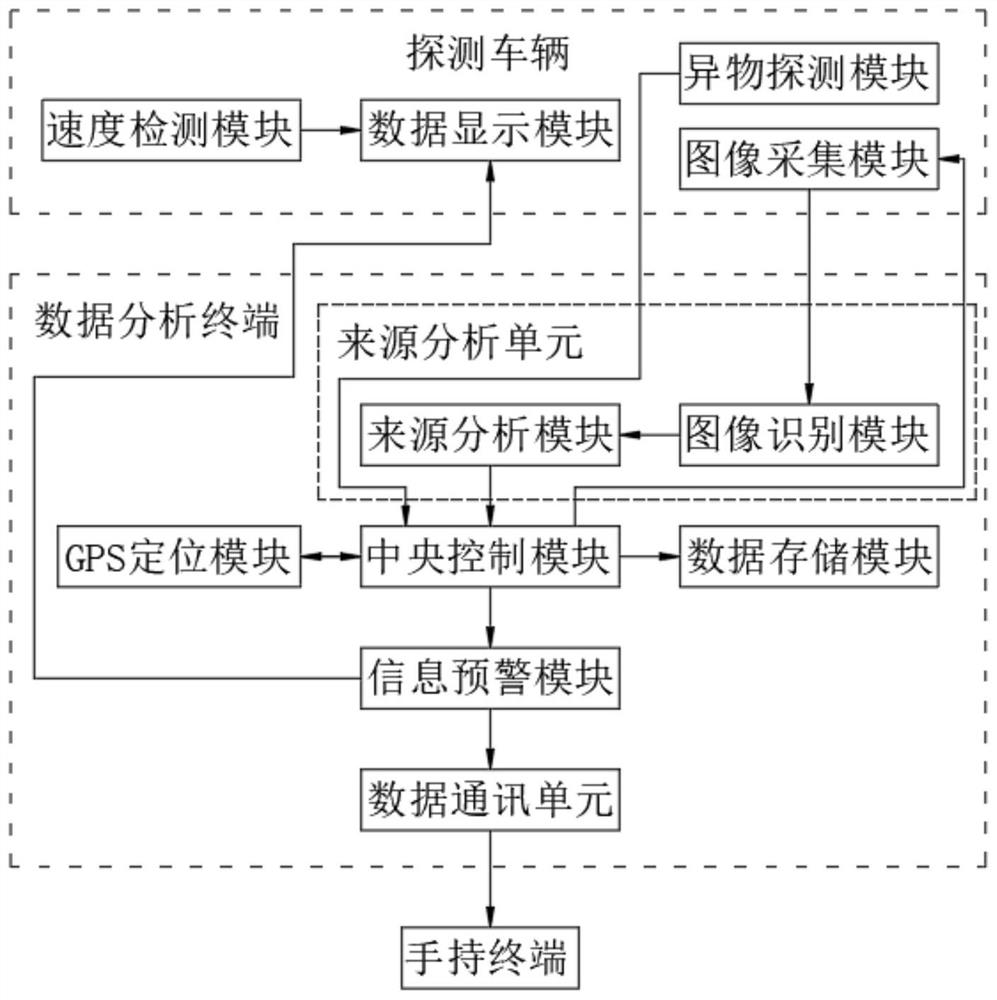

PendingCN114879275ARealize detection workAvoiding FOD SituationsOptical detectionCharacter and pattern recognitionData displayLED display

A mobile FOD optical detection system disclosed by the present invention comprises a detection vehicle, a data analysis terminal and a hand-held terminal, the detection vehicle is provided with a speed detection module, a data display module, an image acquisition module and a foreign matter detection module, and the data display module is an LED display screen. The foreign matter detection module and the image acquisition module are both installed on a vehicle head or a vehicle tail of the detection vehicle, the foreign matter detection module is a mobile FOD optical detector, and the image acquisition module is a high-definition camera. According to the airport pavement FOD detection system, all-weather airport pavement FOD detection work can be achieved, multiple FOD on the airport pavement can be detected at the same time, meanwhile, the data analysis terminal is arranged to be matched with the handheld terminal, early warning information and FOD source information can be provided for surrounding workers after the FOD is detected, and therefore the situation that the FOD appears again is avoided, and the detection efficiency is improved. And practical application and operation are facilitated.

Owner:成都航天凯特机电科技有限公司

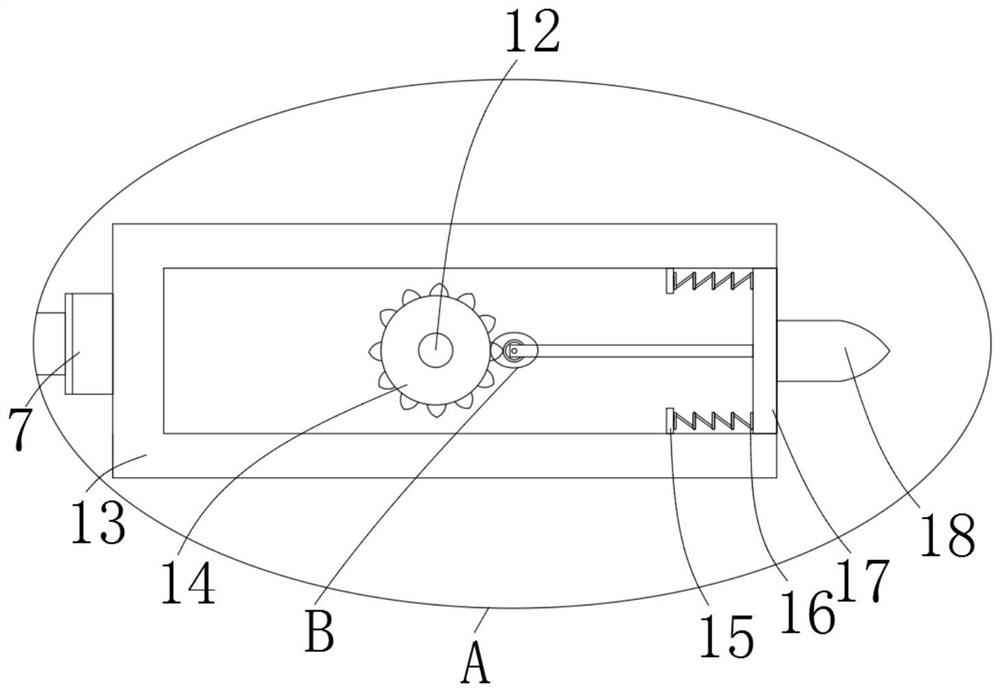

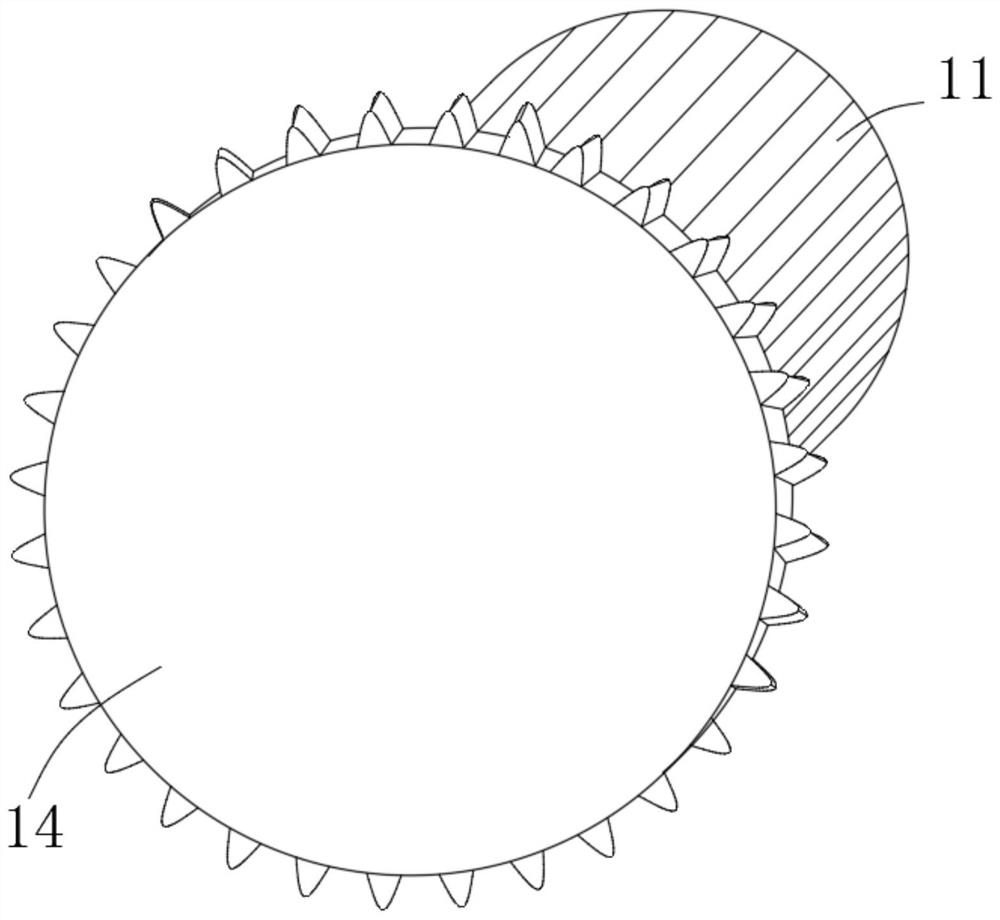

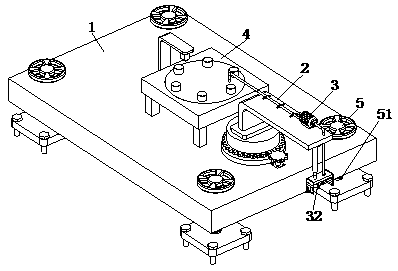

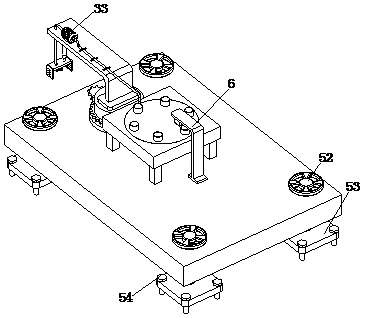

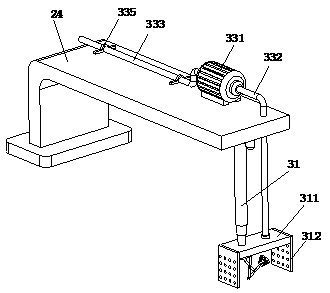

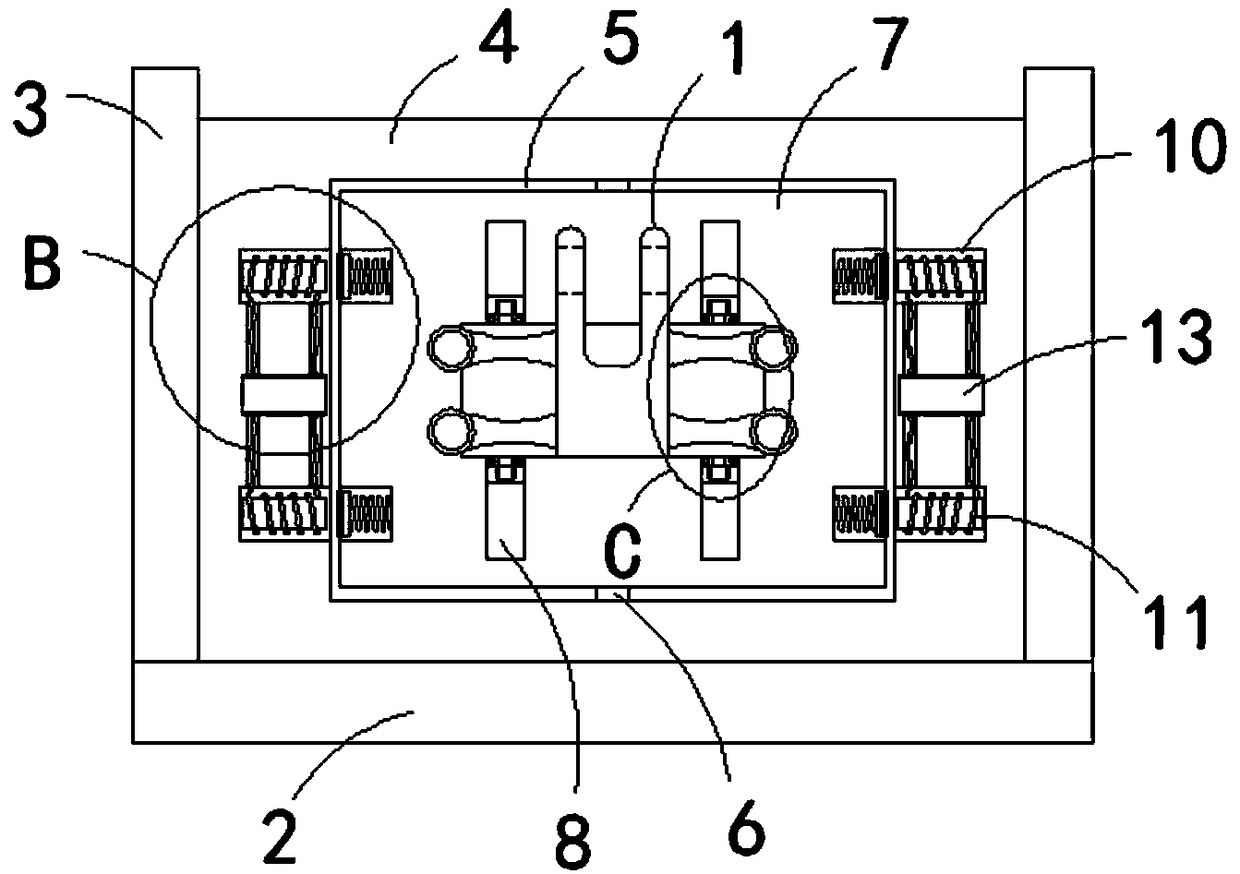

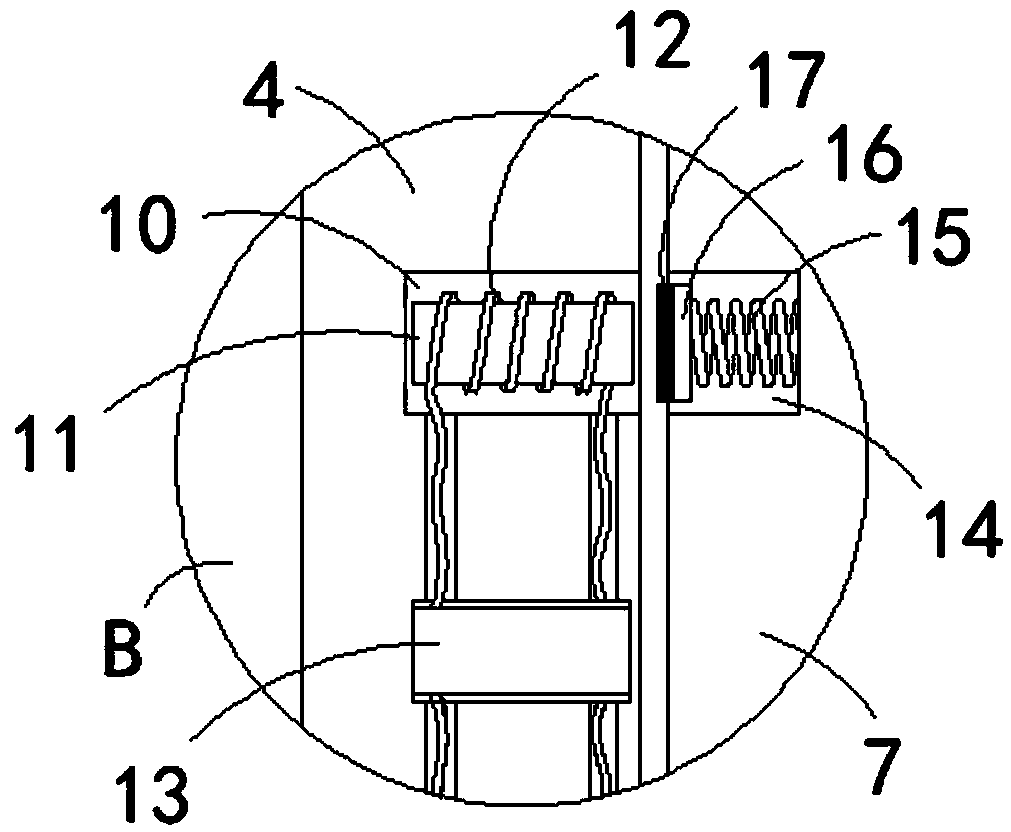

Multidirectional detection equipment for bearing

InactiveCN111609820ARealize detection workAchieve fixationUsing optical meansConveyor partsElectrical and Electronics engineeringGear wheel

The invention discloses multidirectional detection equipment for a bearing. The invention belongs to the technical field of bearing detection. The equipment comprises a feeding device, a mounting frame, a detection auxiliary device and a multi-directional detection device; the feeding device comprises a feeding frame, a feeding assembly and a feeding moving assembly; the feeding assembly is arranged on the feeding frame; the feeding moving assembly is arranged beside the feeding frame; the detection auxiliary device is arranged on the mounting frame; the top flatness detection assembly is vertically arranged at the top of the mounting frame; the outer diameter detection assembly is arranged on the mounting frame; and the radian flatness detection assembly is arranged on the mounting frame.A movable gear rotates to drive two movable toothed plates to move oppositely and oppositely, the two movable toothed plates move to drive two movable blocks to move, the two movable blocks move to achieve fixing and detection assistance on bearings of different sizes, and detection operation on the bearings of different sizes can be achieved.

Owner:马程

Oil exploitation sample oil layer sampling device

InactiveCN110274795AAvoid cloggingAffect the detection effectWithdrawing sample devicesPetroleumImpurity

The invention discloses an exploitation sample oil layer sampling device, belonging to the technical field of oil sampling. The exploitation sample oil layer sampling device comprises a bearing plate, a rotating component, a sampling component, a storage component and four fixed components arranged on the bearing plate in a matrix manner, wherein the rotating component is arranged at the top portion of the bearing plate; the sampling component comprises an electric telescopic rod, an anti-blocking component and an extracting component, the tail end of the electric telescopic rod is arranged on the rotating component, the flexible end of the electric telescopic rod is fixedly connected with a mounting plate, the anti-blocking component is arranged on the mounting plate, the extracting component is arranged on the rotating component, the storage component is arranged at the top portion of the bearing plate, and the top portion of the bearing plate is provided with a detection device. When the anti-blocking component rotates to block the water inlet end of the extracting component while sampling is performed, impurities in petroleum enter the extracting component to block the extracting component when the anti-blocking component is placed in the extracting component to sample petroleum, and the phenomenon that the petroleum detection operation is influenced by impurities contained in the petroleum when the petroleum is detected can be avoided.

Owner:赵健

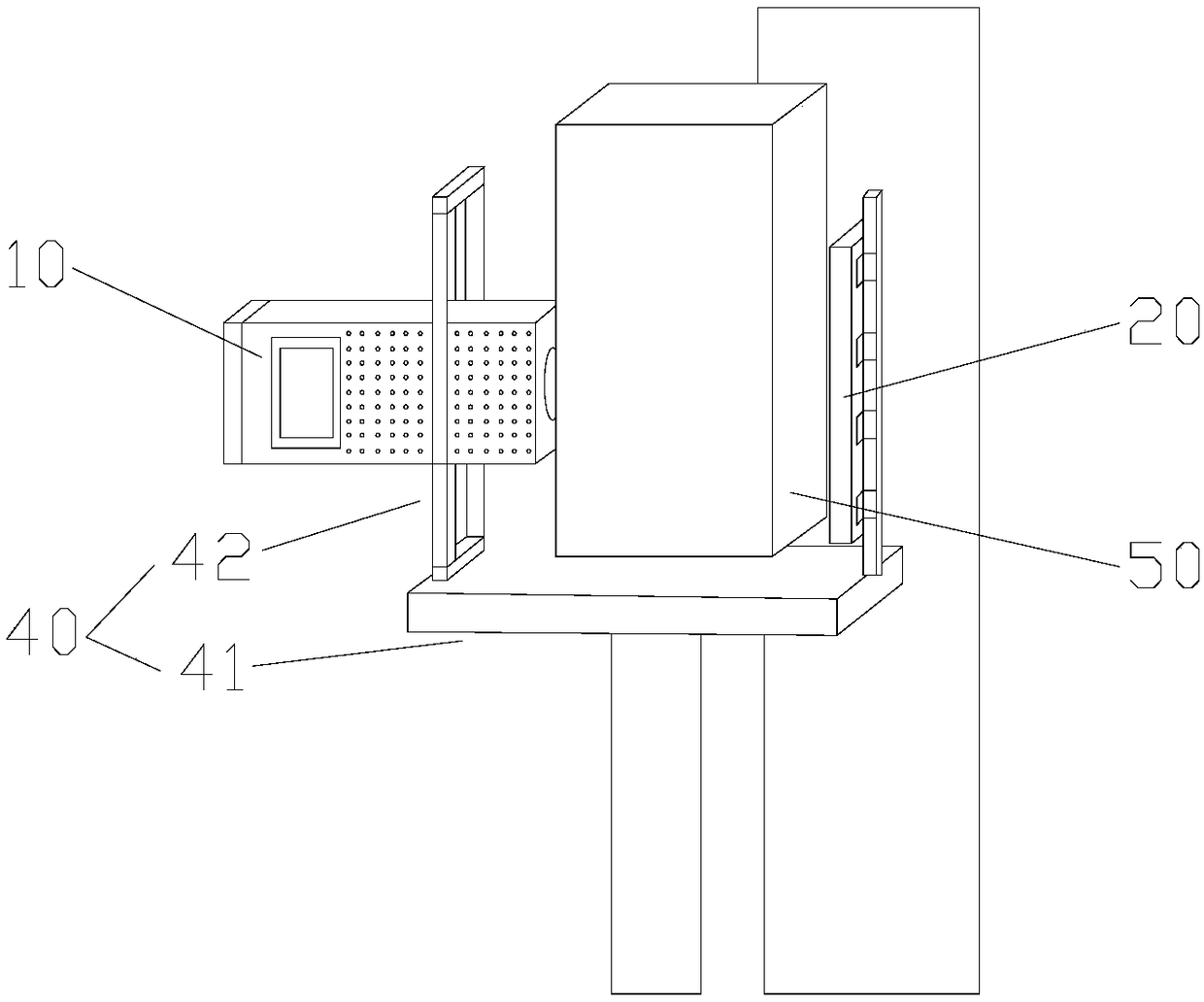

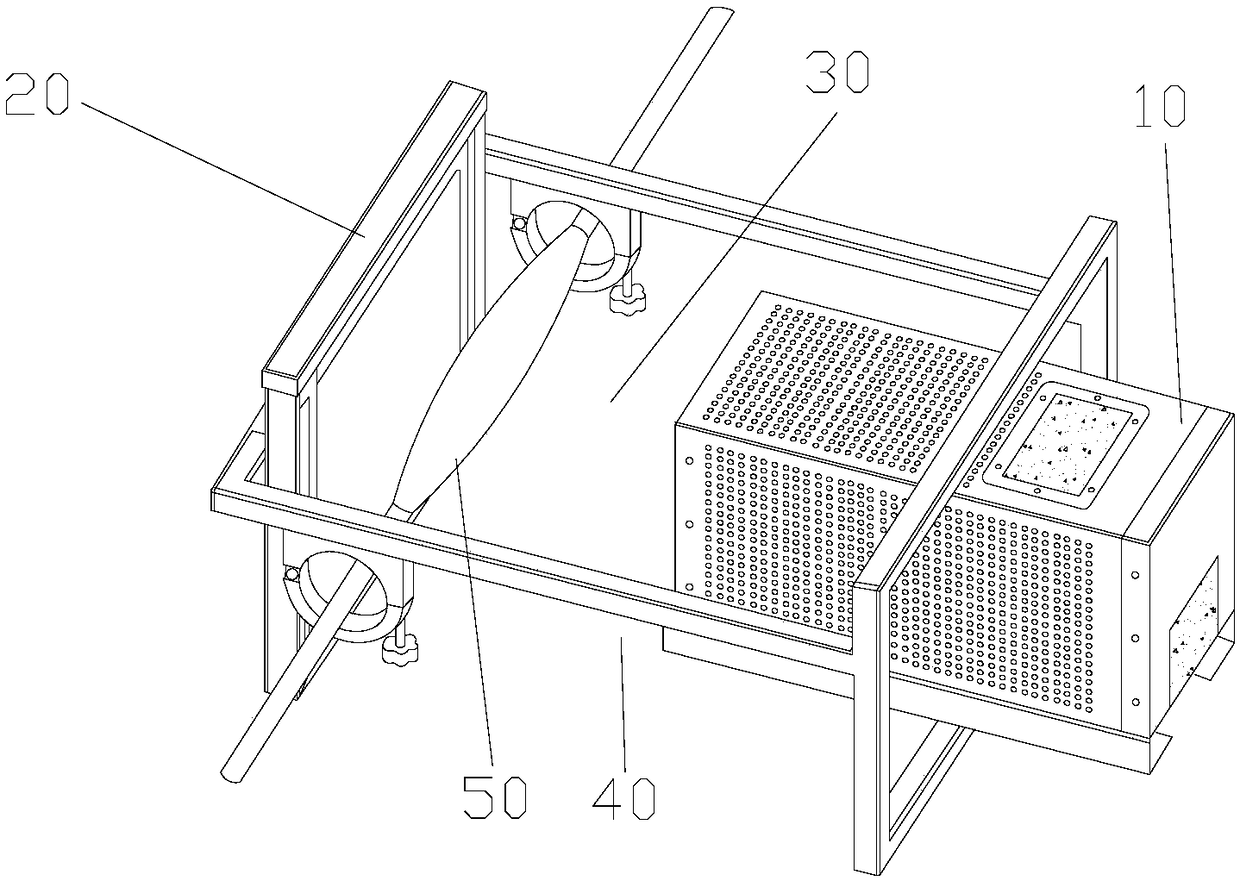

Damage detection equipment

InactiveCN108226194AImprove power supply reliabilityImage quality is clearTesting dielectric strengthMaterial analysis by transmitting radiationPhysicsTesting equipment

The invention provides damage detection equipment, which comprises an X-ray generating device and an imaging device, wherein the X-ray generating device is used for sending out X rays; the imaging device and the X-ray generating device are in opposite arrangement; an accommodating space used for accommodating an electric appliance component to be detected is formed between the X-ray generating device and the imaging device so that the X rays pass through the electric appliance component positioned in the accommodating space and is then imaged on the imaging device. The damage detection equipment solves the problem that the detection equipment in the prior art cannot be used for detecting the inside mechanical damage of the electric appliance component.

Owner:STATE GRID BEIJING ELECTRIC POWER +1

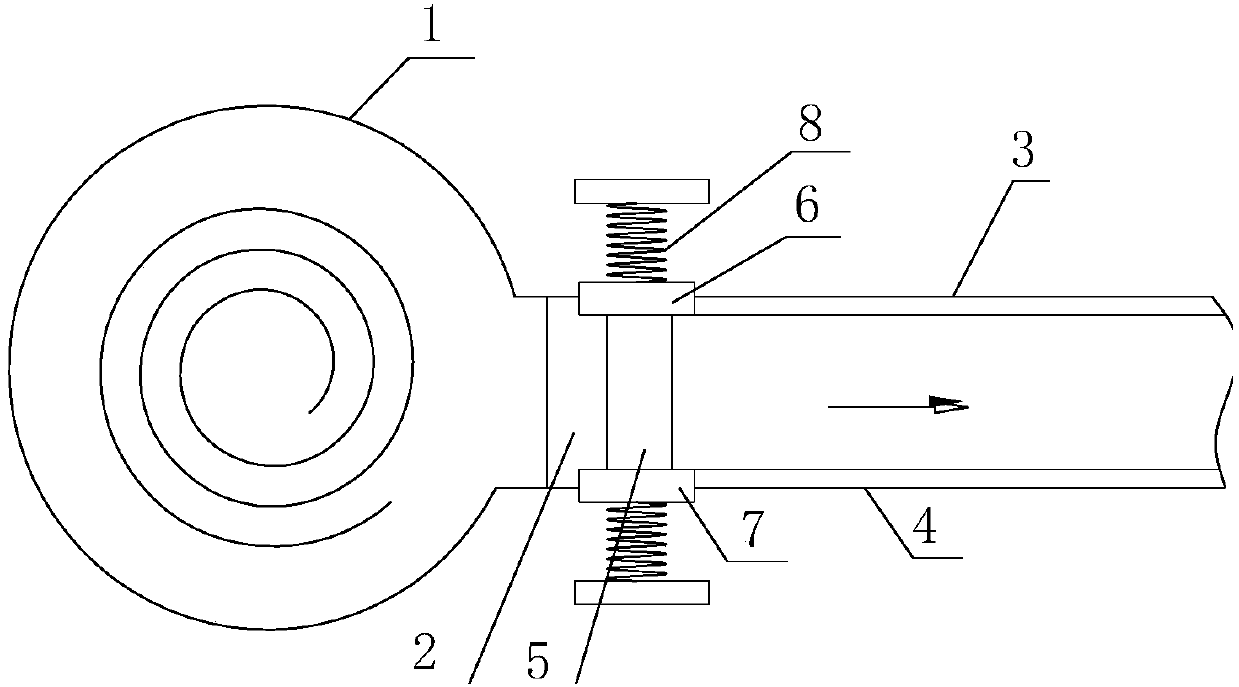

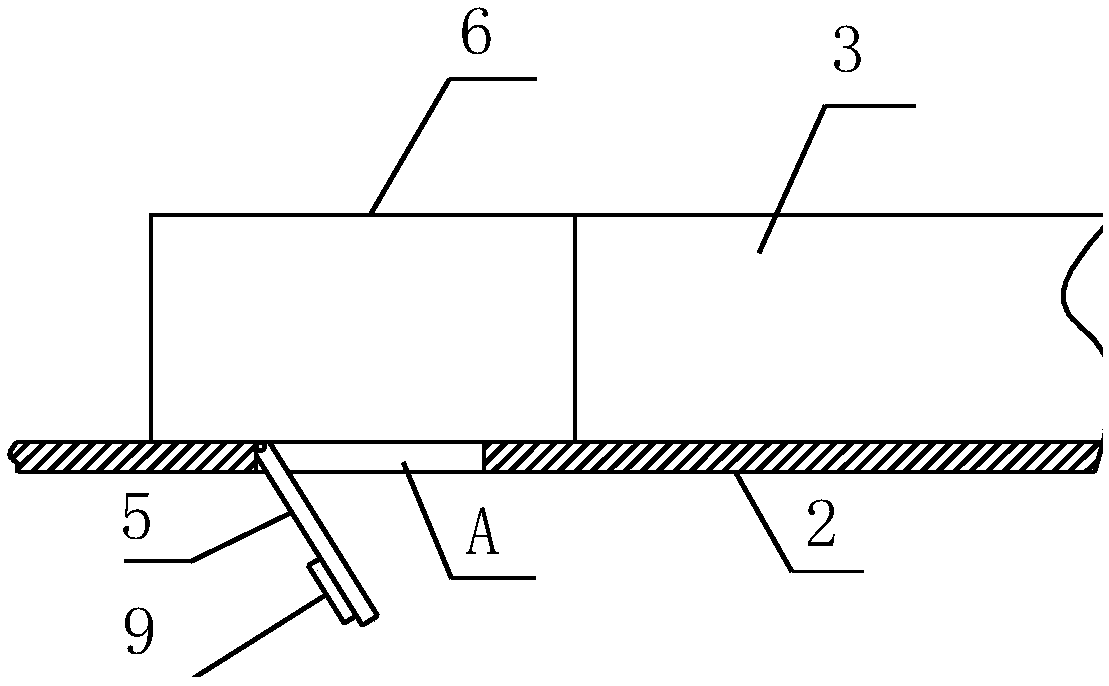

Assembly line resonator automatic detection and screening device

The invention discloses an assembly line resonator automatic detection and screening device which comprises a conveying line and a vibrating disc. The conveying line comprises a base plate, a first side plate and a second side plate, the first side plate and the second side plate are matched with the base plate to form a conveying channel; a notch is formed in the end, close to the vibrating disc,of the base plate, and an overturning plate which can achieve automatic overturning to control opening / closing of the notch is arranged at the notch; a first movable plate is arranged at the end, close to the vibrating disc, of the first side plate and located on one side of the notch, and a second movable plate opposite to the first movable plate is arranged at the end, close to the vibrating disc, of the second side plate; the sides, far away from each other, of the first movable plate and the second movable plate are provided with compression springs, when the compression springs are in the natural state, the sides, getting close to each other, of the first movable plate and the second movable plate and the side wall of the conveying channel are located in one plane, and the notch is in the opening state when the compression values of the compression springs reach the preset values. By means of the assembly line resonator automatic detection and screening device, assembly line detection and screening work of a resonator can be achieved.

Owner:日照瑞达电子科技有限公司

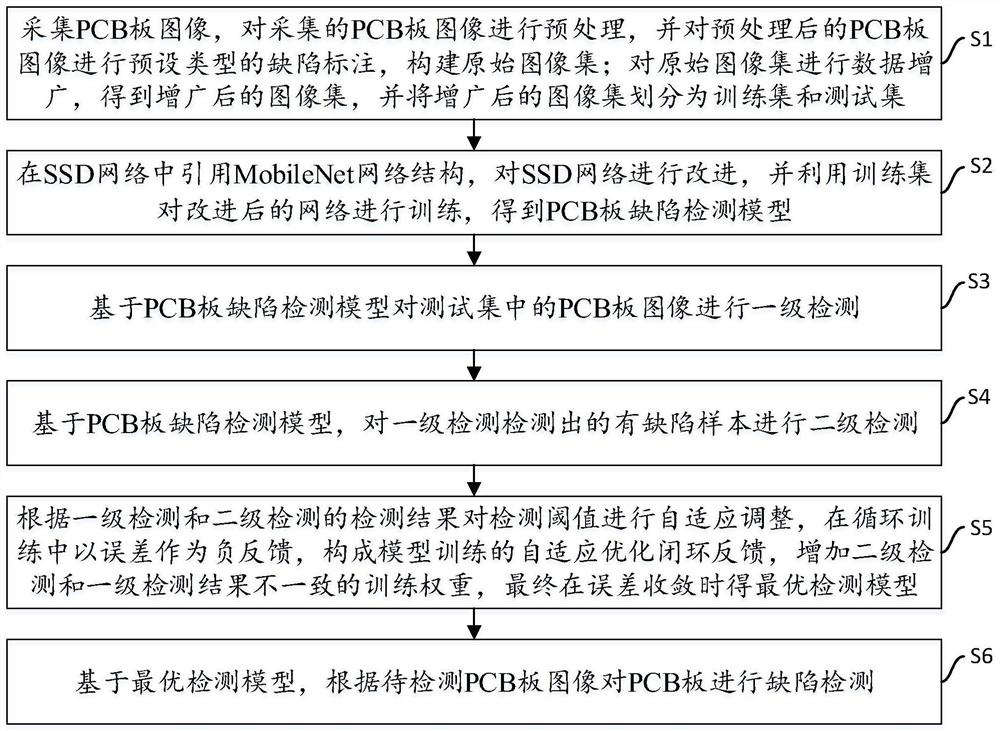

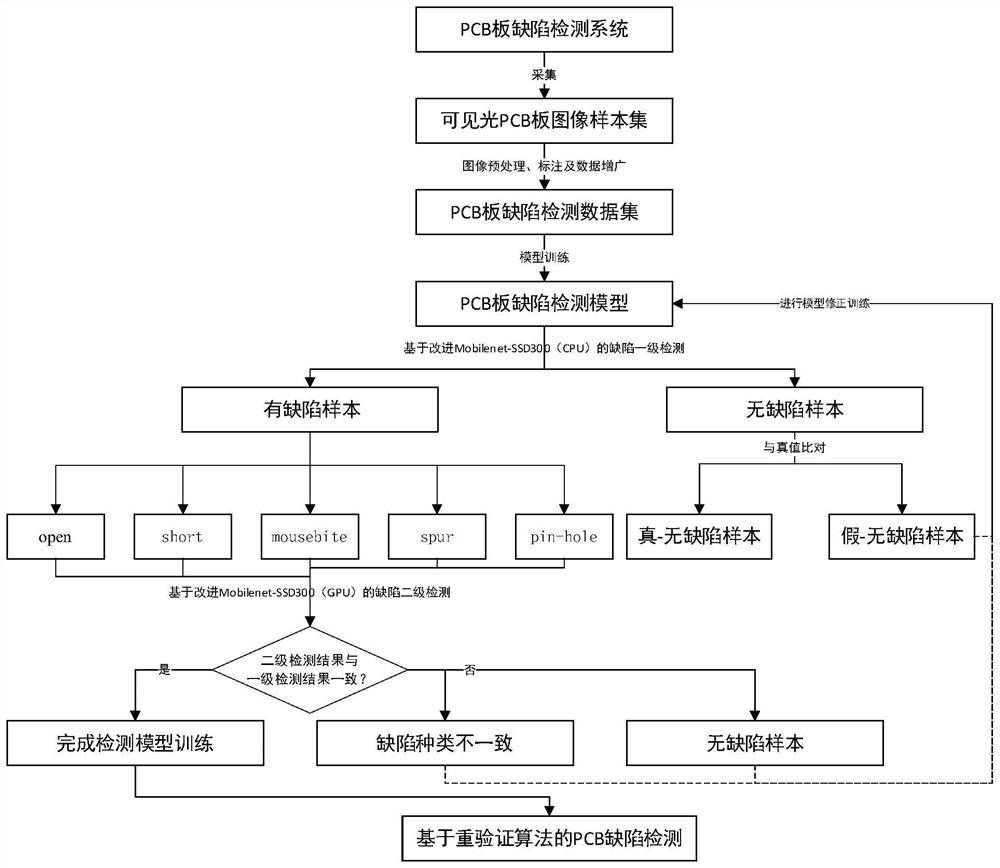

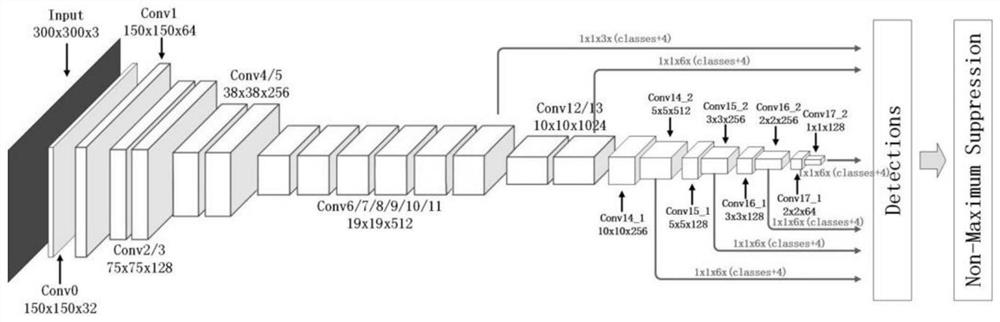

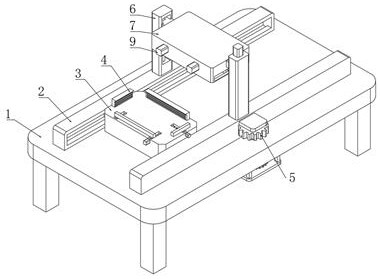

PCB defect detection method based on re-verification detection

PendingCN114387230ARealize detection workEffective expansionImage enhancementImage analysisNegative feedbackAlgorithm

The invention discloses a PCB defect detection method based on re-verification detection, and the method comprises the steps: collecting a PCB image, and constructing a training set and a test set; introducing MobileNet in the SSD, improving the SSD, and training the improved network by using the training set to obtain a PCB defect detection model; performing primary detection on the PCB image in the test set; performing secondary detection on the defective sample detected by the primary detection; the method comprises the following steps: performing adaptive adjustment on a detection threshold according to detection results of primary detection and secondary detection, forming adaptive optimization closed-loop feedback of model training by taking an error as negative feedback in loop training, increasing a training weight of inconsistent secondary detection and primary detection results, and finally obtaining an optimal detection model during error convergence. Defect detection is realized by using the method. According to the invention, defects of the PCB can be accurately detected, and an over-fitting phenomenon is prevented.

Owner:UNIV OF SCI & TECH BEIJING

Automatic detection equipment for electrical control panel

PendingCN114779055AReduce testing costsIncrease contact areaCoupling contact membersWork benchesElectrical controlElectrically conductive

The invention provides an electrical control panel automatic detection device, and relates to the technical field of electrical control panel detection, and the electrical control panel automatic detection device comprises a workbench, the two sides of the upper surface of the workbench are fixedly provided with installation plates, and a placement table is movably installed between the two installation plates; a workpiece positioning mechanism used for fixing a workpiece is arranged on the upper surface of the containing table, and a driving mechanism used for driving the containing table to move is arranged on one side of the workbench. Through the wavy design of the annular metal connecting sheet, the annular metal connecting sheet can be changed according to the shape of the spherical contact on the surface of the circuit board under the connection action of the auxiliary spring, so that the contact area between the annular conductive block and the contact on the circuit board and the contact between the annular metal connecting sheet and the contact on the circuit board can be larger; contact breaking conditions can be effectively reduced, detection work can be better facilitated, and the detection contact can be suitable for detection contacts of different sizes on electrical control panels of different models due to the change of the overall shape of the annular metal connecting piece.

Owner:XIAN JIAOTONG UNIV CITY COLLEGE

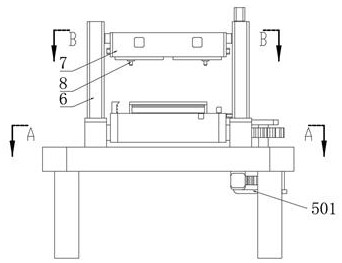

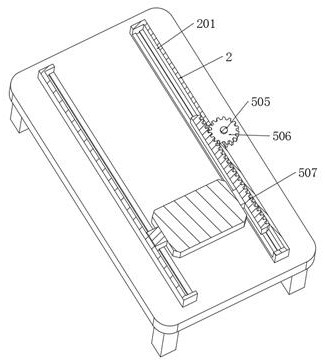

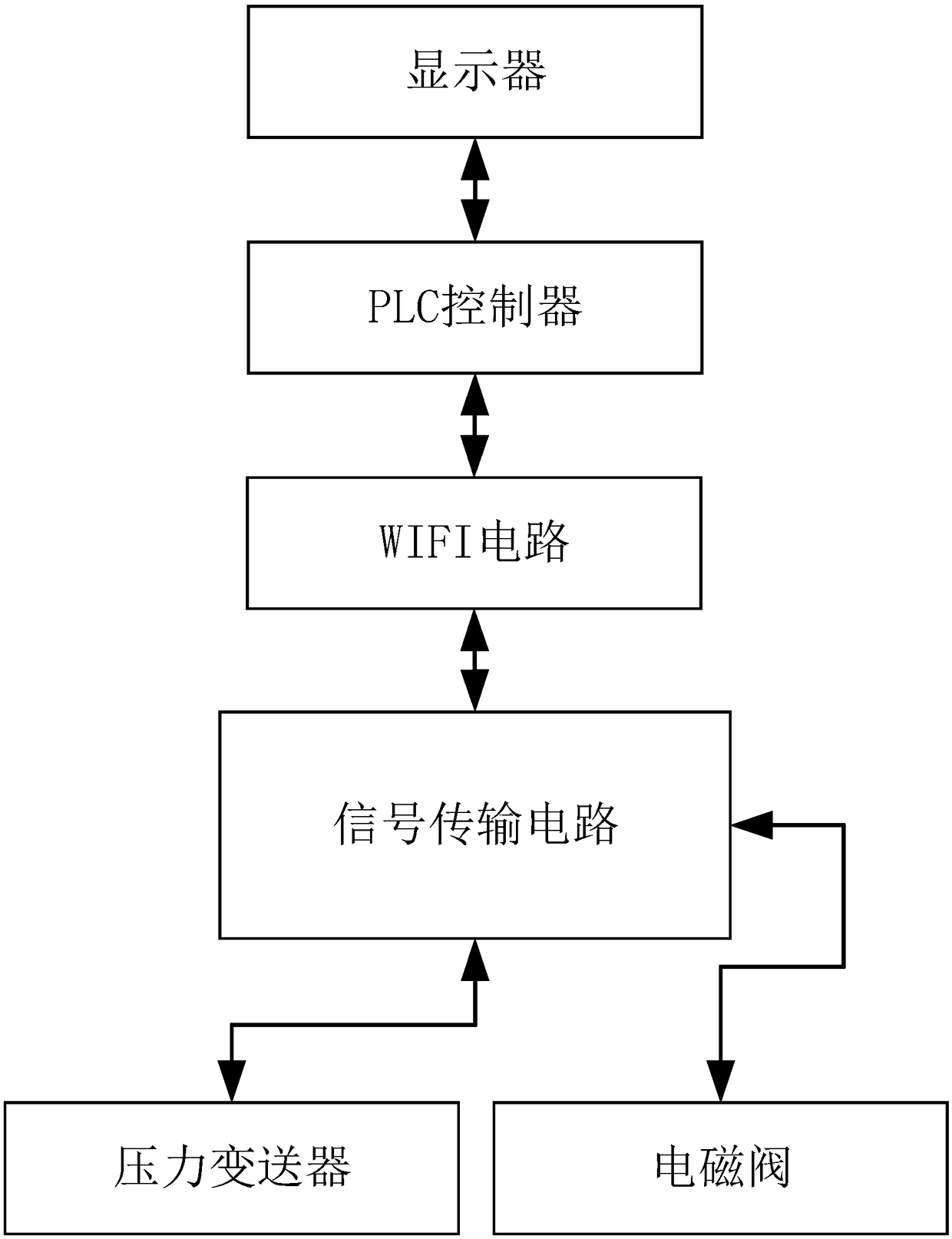

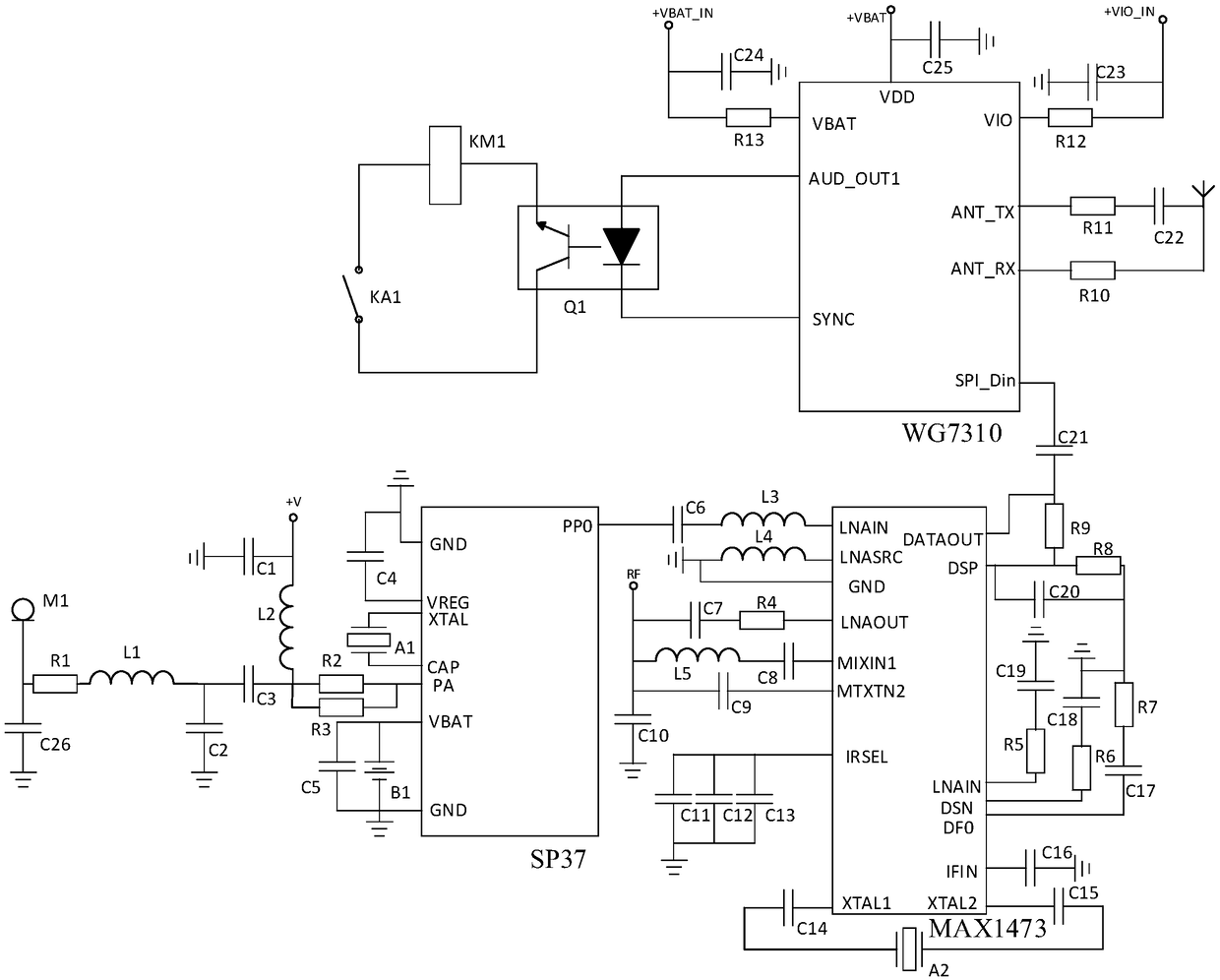

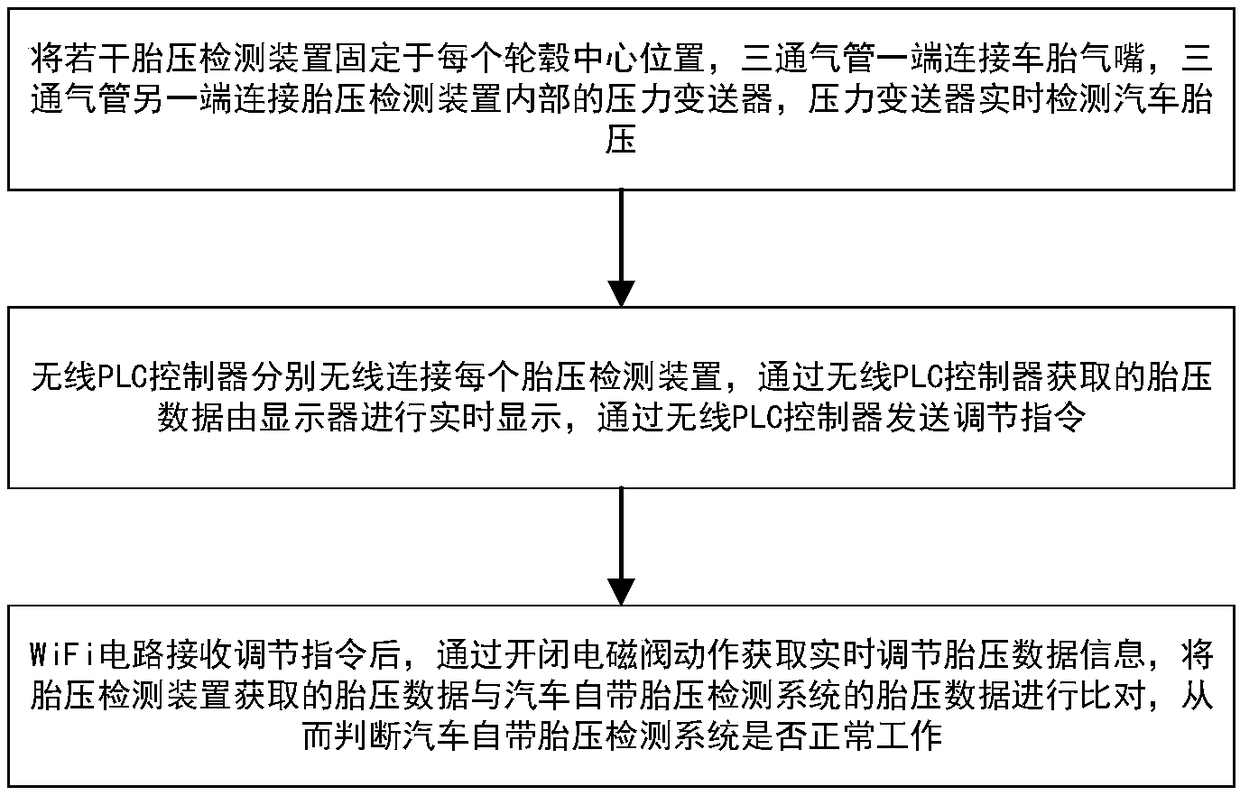

Inspection device and working method of inspection device for automobile tire pressure monitoring system and new energy automobile

The invention provides an inspection device and a working of the inspection device for an automobile tire pressure monitoring system and a new energy automobile. The inspection device comprises a pressure transmitter used for tire pressure inspection, the pressure transmitter is arranged in a tire, a working signal end of the pressure transmitter is connected with a signal receiving end of a signal transmission circuit, and a signal transmitting end of the signal transmission circuit is connected with a WiFi circuit. A wireless signal sending end of the WiFi circuit is connected with a signalreceiving end of a wireless PLC, a display signal end of the wireless PLC is connected with a signal receiving end of a display, and the signal transmitting end of the WiFi circuit is connected with asignal input end of an optical coupling circuit. A working end of the optical coupling circuit is connected with a relay, the relay controls the opening and closing of an electromagnetic valve, the electromagnetic valve is arranged on an air nozzle of the tire, an acquisition signal of the pressure transmitter is obtained through the opening and closing electromagnetic valve, and the WiFi circuitis transmitted to the wireless PLC for data collection.

Owner:CHINA AUTOMOTIVE ENG RES INST

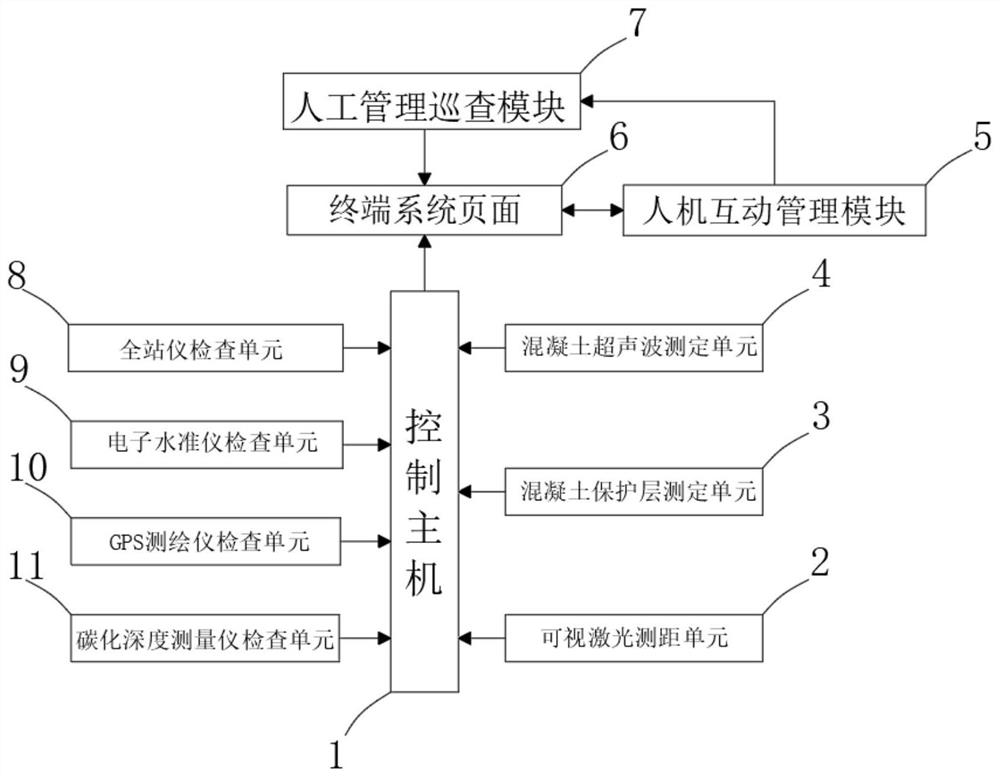

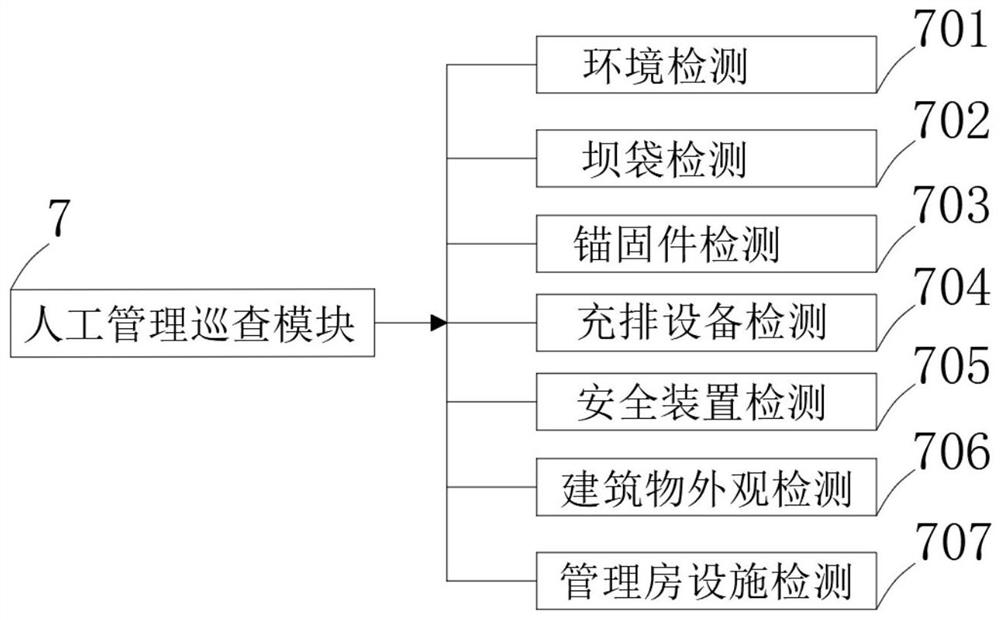

Rubber dam safety detection method and system

PendingCN111811584ARealize detection workRealize sortingBarrages/weirsMeasurement devicesEmbedded systemVisible laser

The invention discloses a rubber dam safety detection method and system and relates to the technical field of rubber dam detection. A control host is included. An input end of the control host is electrically connected with output ends of a visible laser ranging unit, a concrete protective layer measuring unit, a concrete ultrasonic measuring unit, a total station inspection unit, an electronic level inspection unit, a GPS surveying instrument inspection unit and a carbonization depth measuring instrument inspection unit in sequence; the output end of the control host is electrically connectedwith the input end of a terminal system page; the output end of a manual management patrol module is electrically connected with the input end of the terminal system page; through the manual management patrol module, detection work of an external mechanism of a rubber dam is realized, and meanwhile, the manual management patrol module can be connected with the terminal system page so that the information can be transmitted to the terminal system page in time, and the information can be classified and sorted through the terminal system page.

Owner:HYDRAULIC SCI RES INST OF SICHUAN PROVINCE

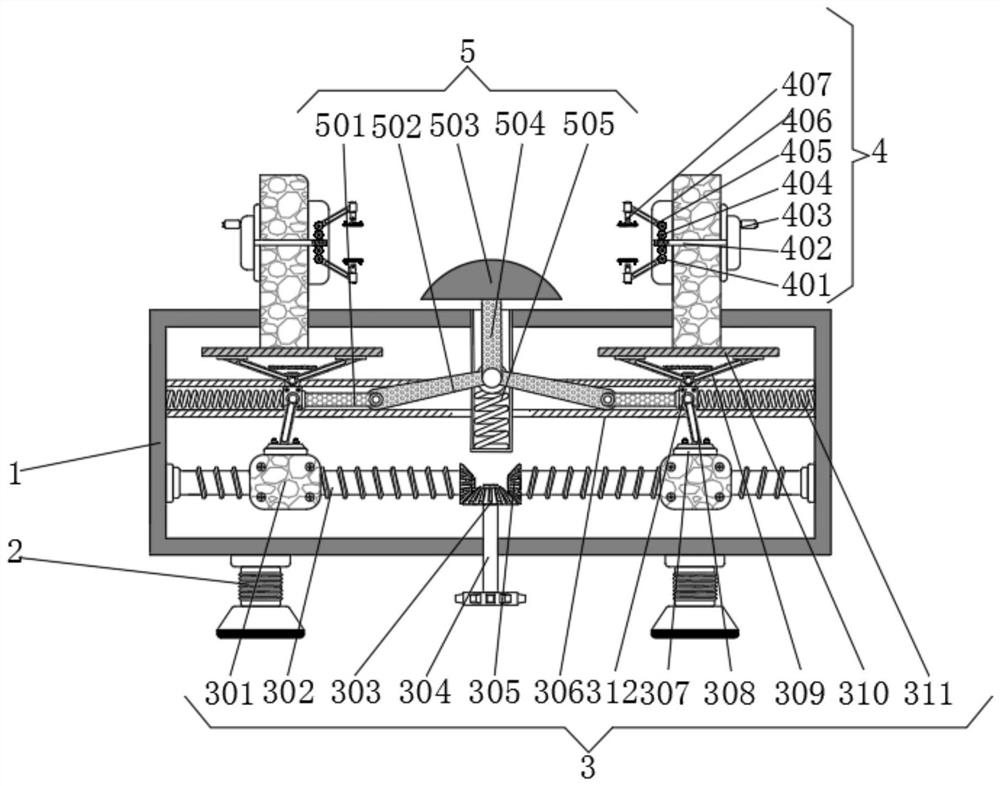

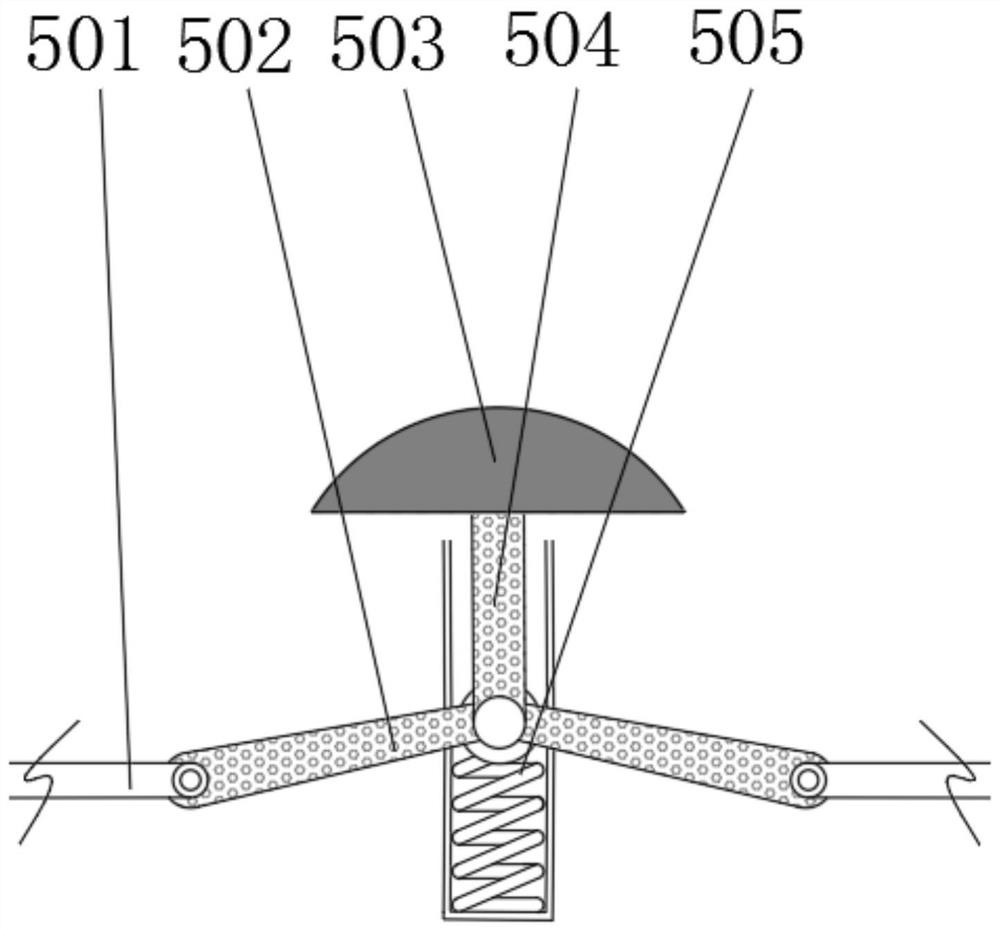

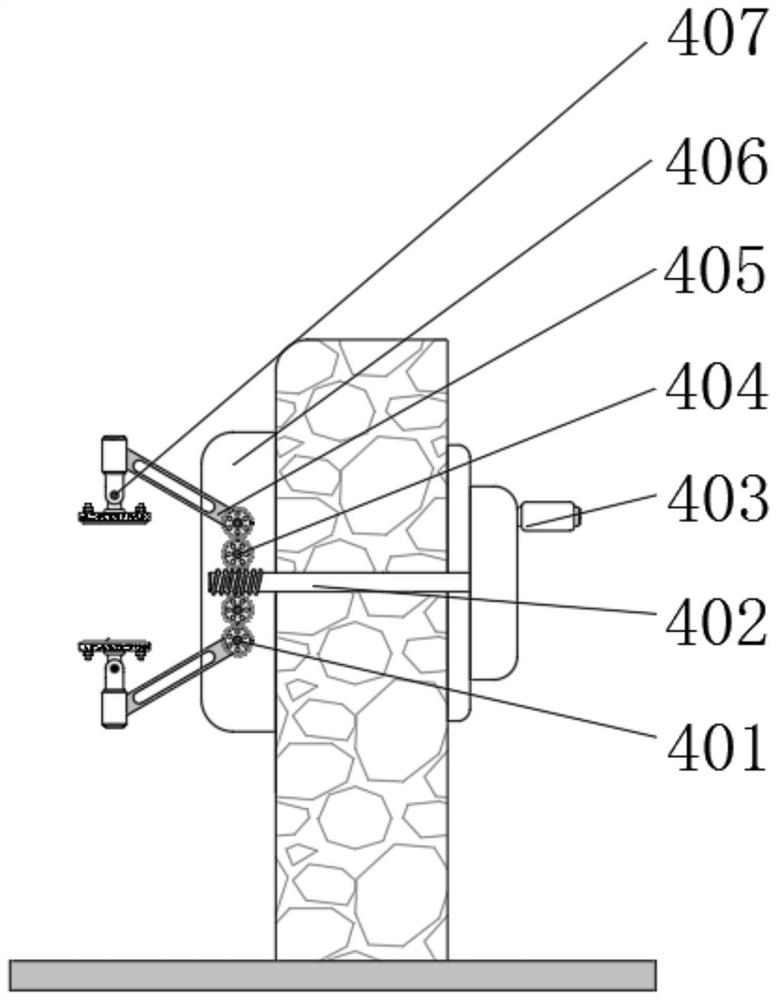

Robot suitable for detecting underwater and overwater parts of bridge pile foundation and control method

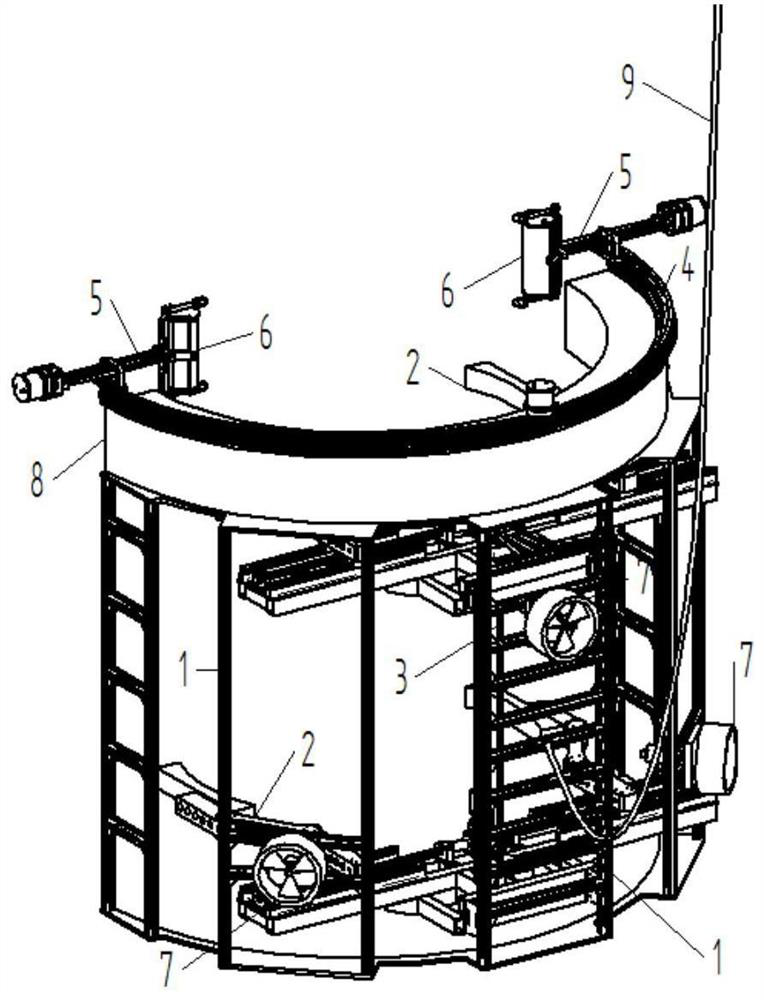

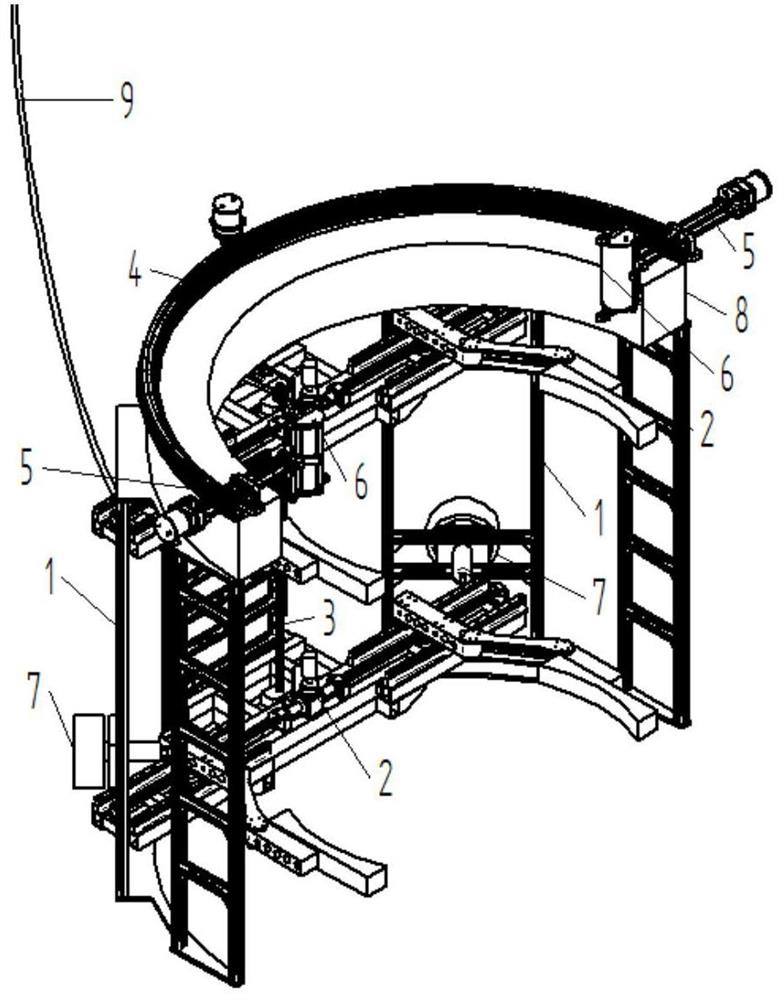

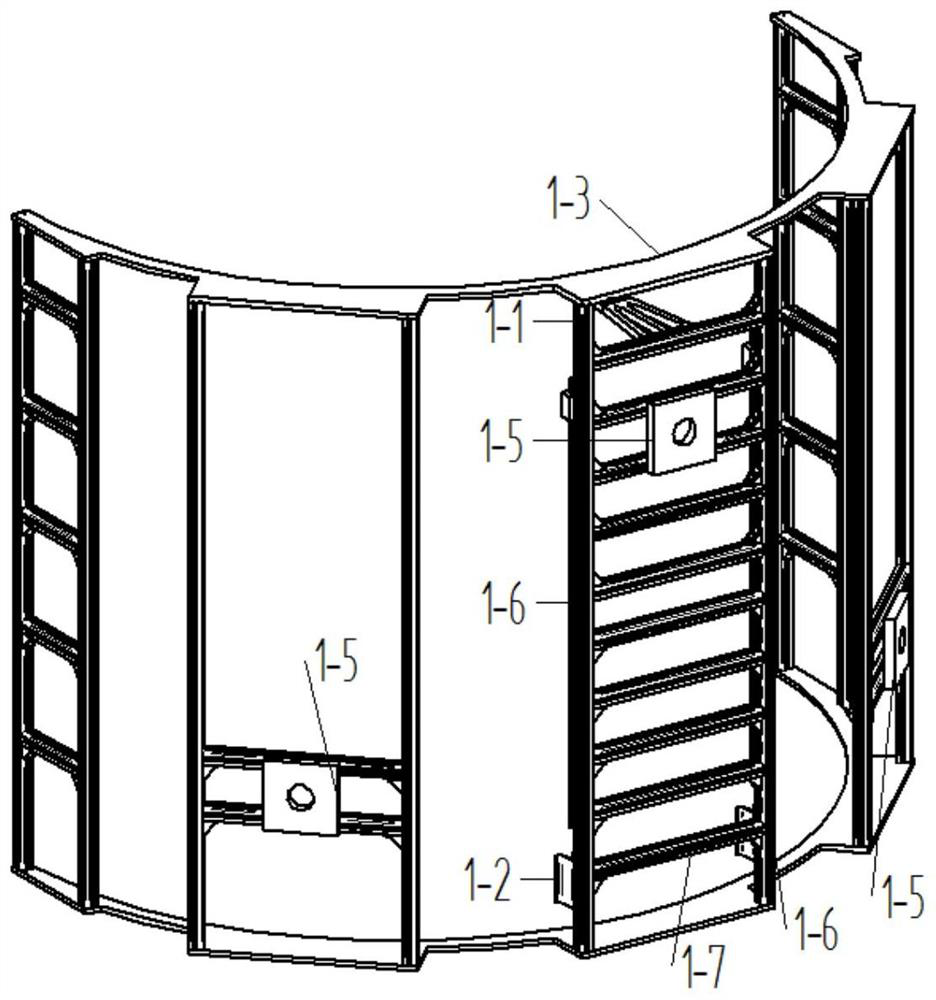

ActiveCN113605468ARealize detection workMeet the detection taskFoundation testingManipulatorUnderwaterStructural engineering

The invention provides a robot suitable for detecting underwater and overwater parts of a bridge pile foundation and a control method. The robot comprises a rack, holding mechanisms, a walking mechanism, a rotating mechanism, an adjusting mechanism, an observation mechanism and the like. An upper layer holding mechanism and a lower layer holding mechanism are arranged, each layer is composed of two parts which are symmetrical left and right, every two parts are connected through a middle power source and a commutator, torque output by the power sources is converted into two holding lead screw mechanisms which are installed on guide rails in the left horizontal direction and the right horizontal direction, and the holding lead screw mechanisms move to drive holding blocks connected to the holding lead screw mechanisms to move left and right. The upper layer holding mechanism and the lower layer holding mechanism are installed on the walking mechanism, two ends of the walking mechanism are fixed on the rack, one end of the walking mechanism is fixedly connected with one layer of holding mechanism, a movable walking nut is connected with the other layer of holding mechanism, the holding mechanism connected with the movable walking nut is driven to move up and down through vertical movement of the movable walking nut on a walking lead screw, and the robot moves up and down along the pile foundation in cooperation with holding and loosening of the holding mechanisms.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

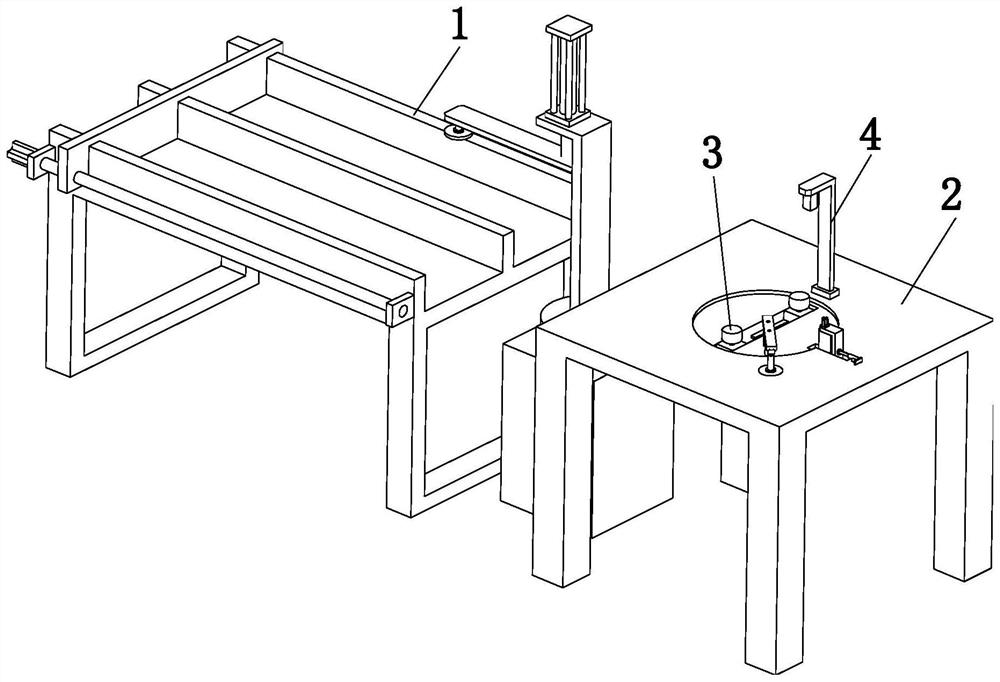

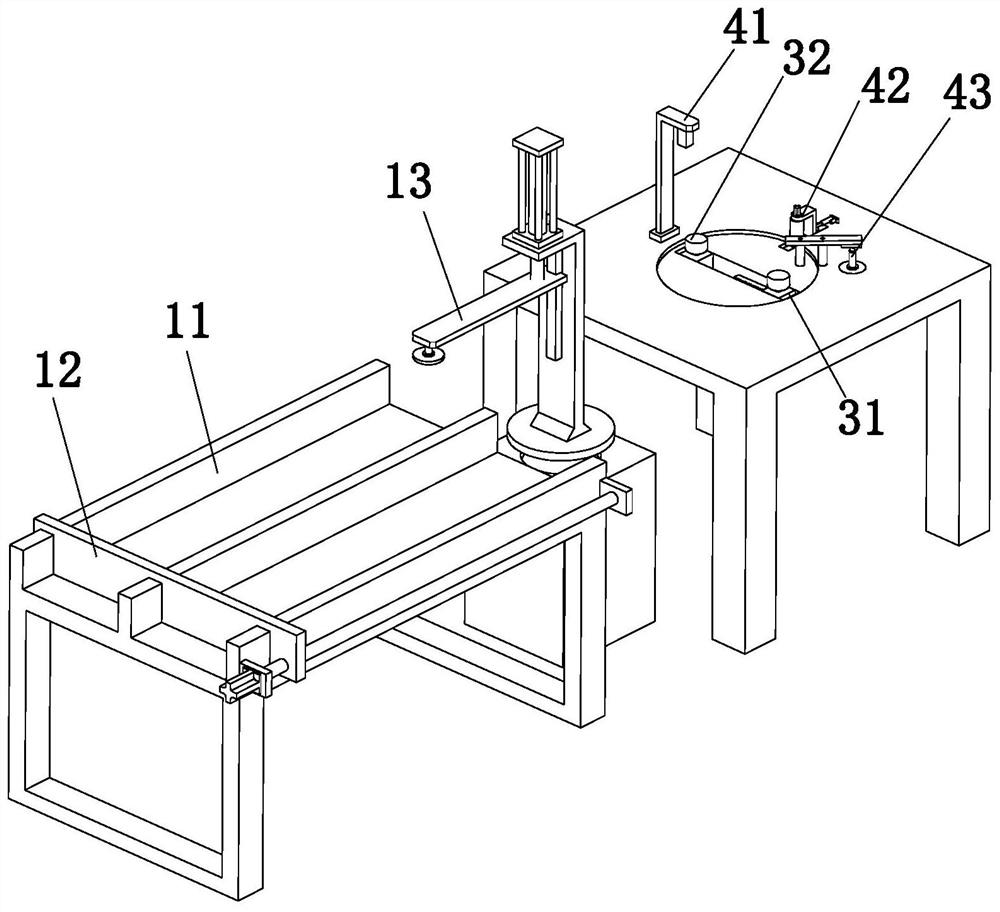

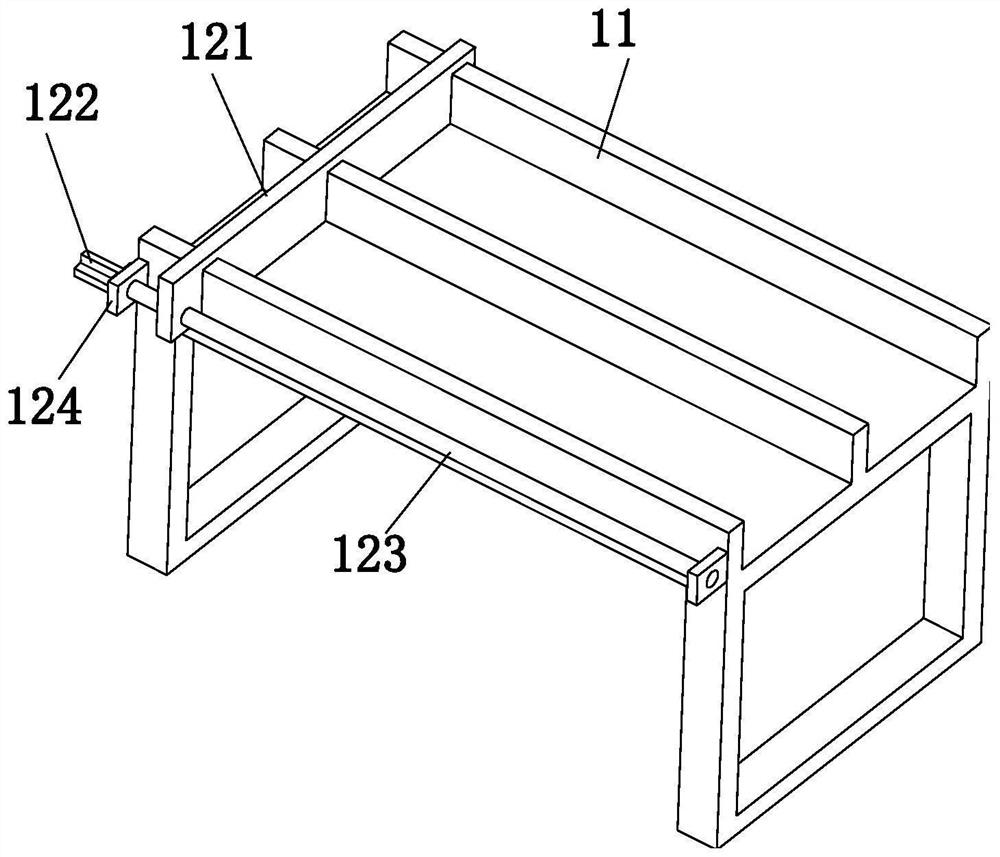

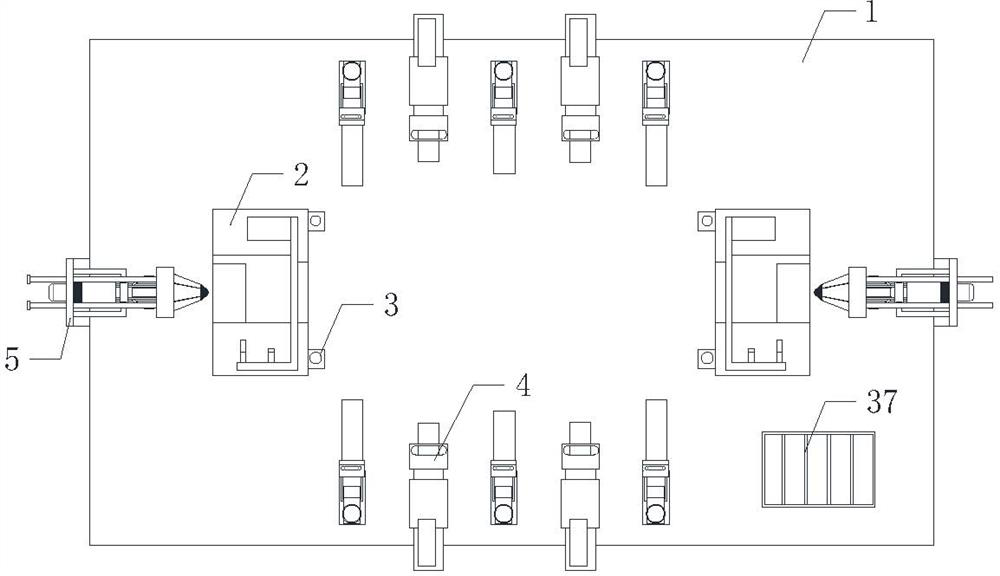

Sample vehicle tubular beam testing fixture

ActiveCN112797866ARapid positioningConsistent positionMechanical measuring arrangementsStructural engineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a sample vehicle tubular beam testing fixture which comprises a base plate, two sets of main positioning pin bases are oppositely arranged on the base plate, each set of main positioning pin base is provided with a positioning groove corresponding to a tubular beam end face flange plate in shape, and each set of main positioning pin base is evenly provided with positioning pin holes in a communicating mode. Two or more groups of detection pin bases are arranged on each group of main positioning pin base; through rapid positioning of the tubular beam, the placement position and direction of the tubular beam can be kept consistent conveniently, the precision of consistency detection of the tubular beam is improved, the detection mode of the tubular beam is effectively simplified, the detection difficulty is reduced, rapid detection of the tubular beam is achieved, meanwhile, the subsequent welding debugging time of the tubular beam is shortened, the welding and detection efficiency is improved, and the detection precision is improved.

Owner:菲格瑞特(苏州)汽车科技有限公司

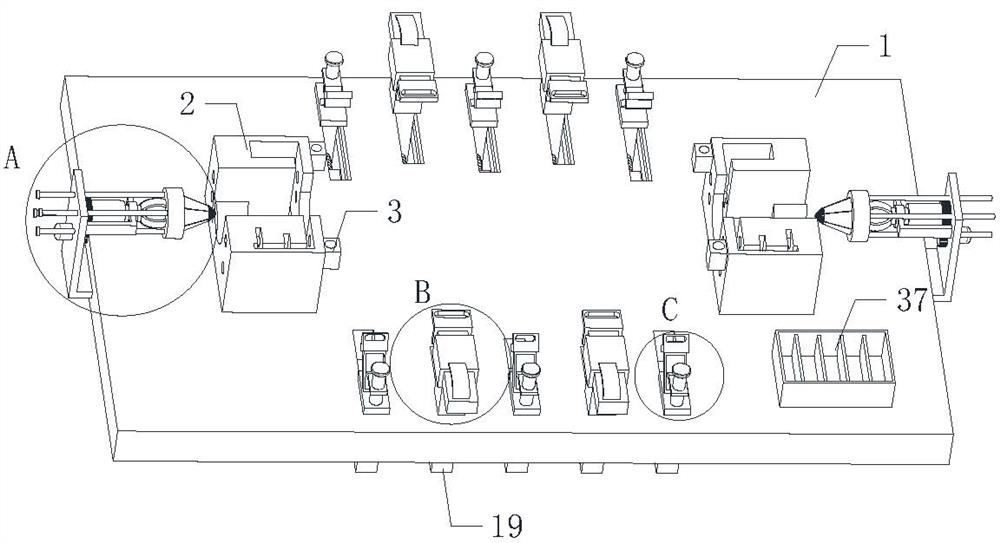

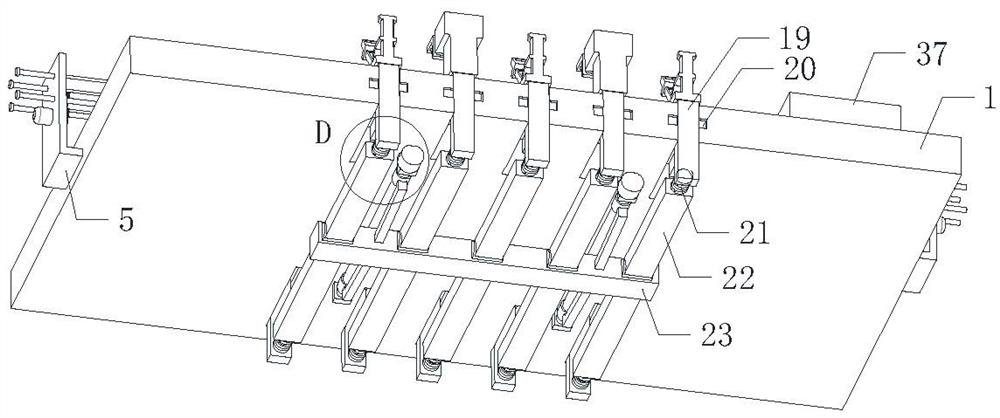

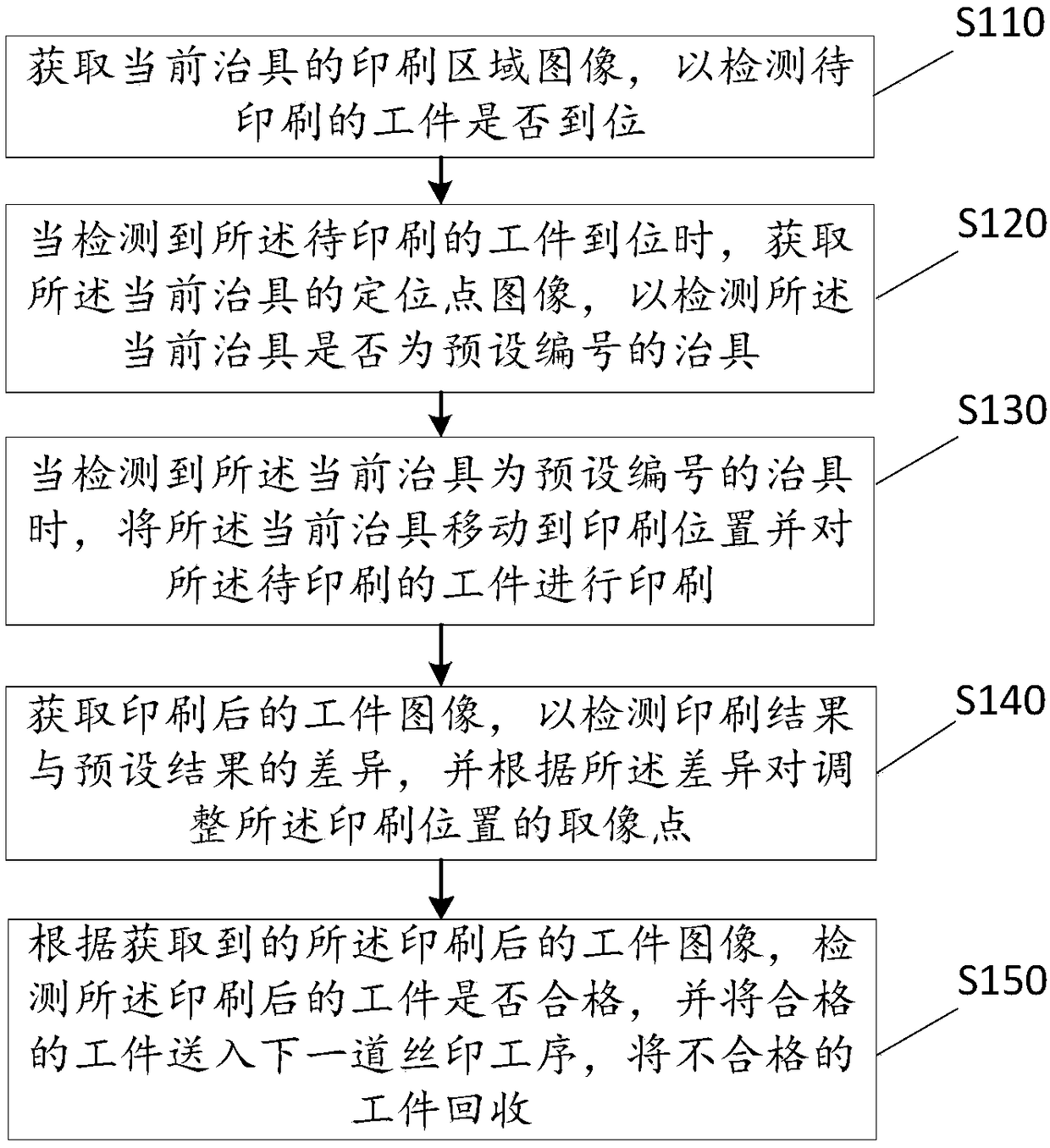

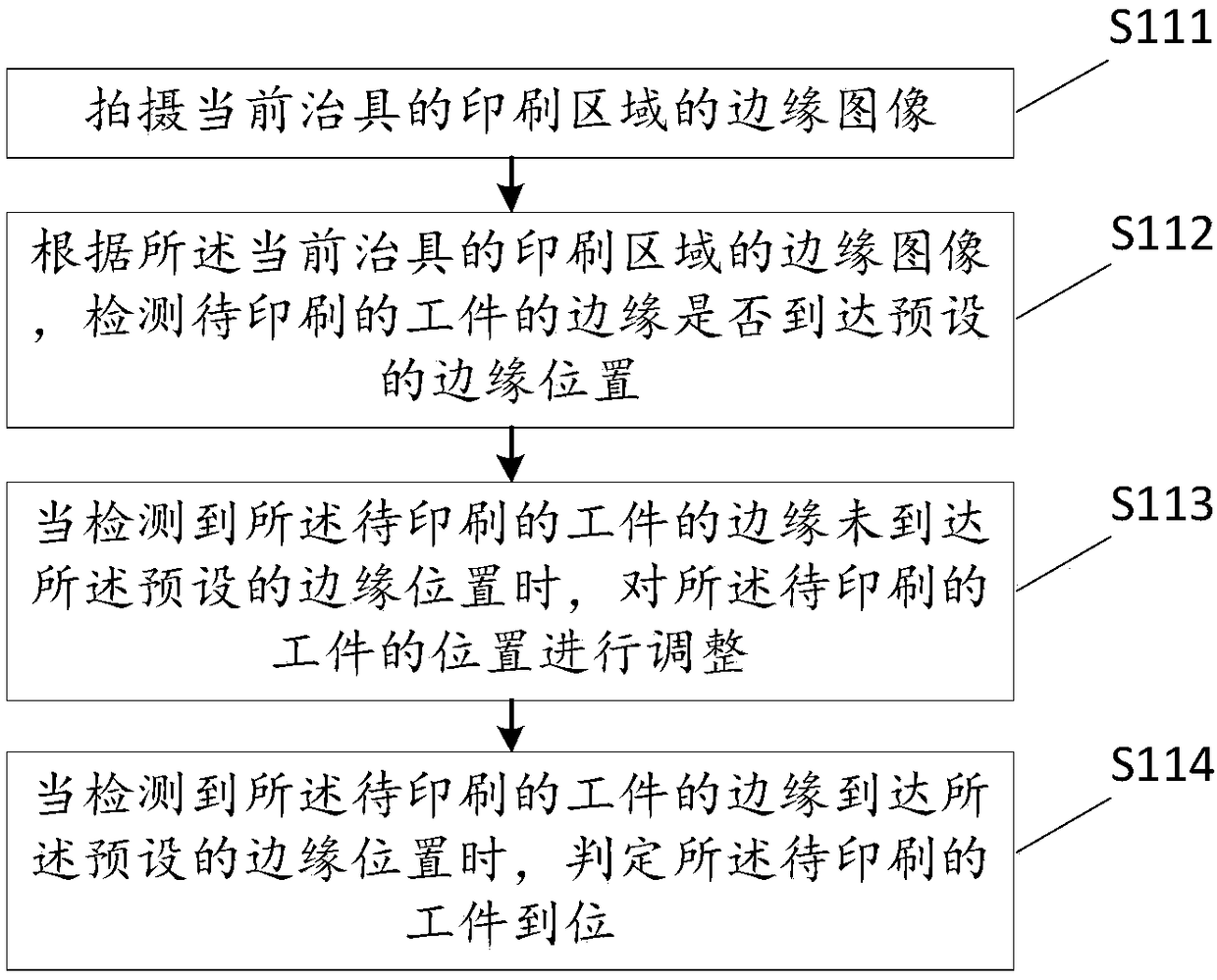

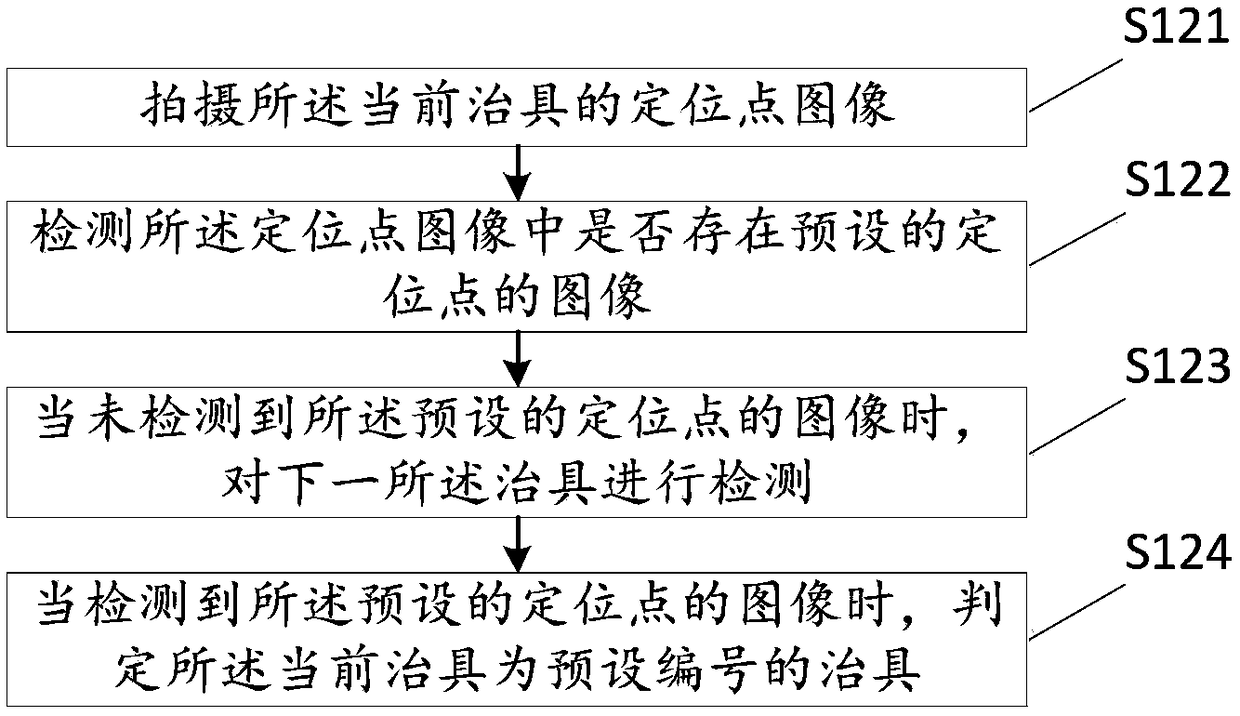

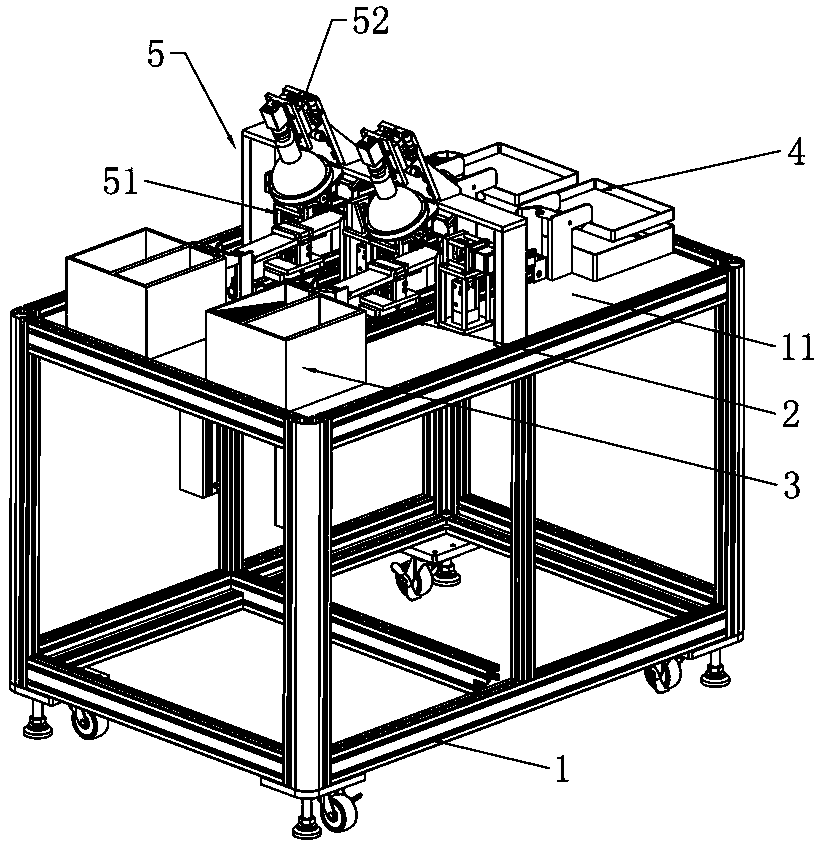

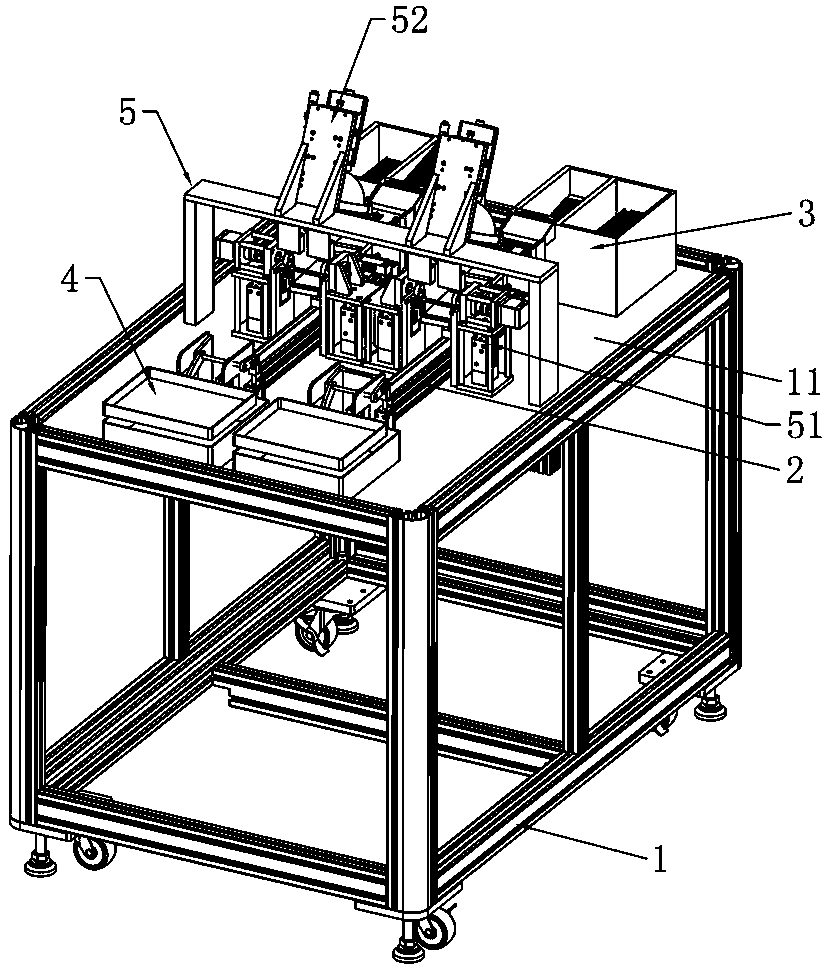

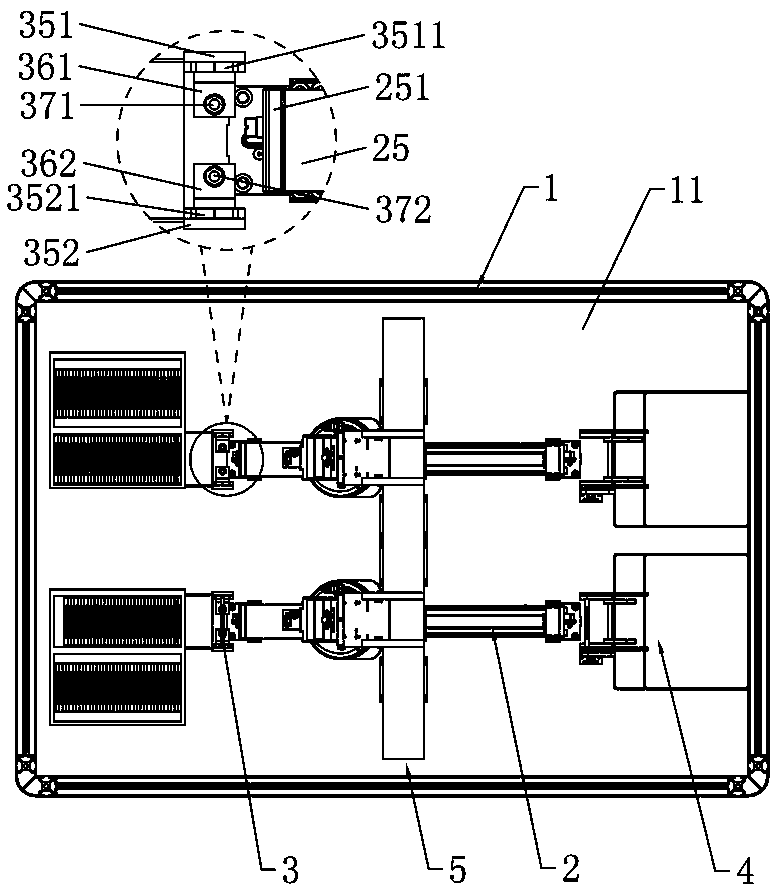

Silk screen detecting method, device and terminal equipment and storage medium

ActiveCN108357193AQuality improvementAvoid wastingScreen printersPrinting press partsScreen printingTerminal equipment

The invention discloses a silk screen detecting method and relates to the field of silk screen printing. The silk screen detecting method comprises the steps that firstly, whether a workpiece is in place or not is detected; when it is detected that the workpiece is in place, whether a current jig is a jig with a preset number or not is detected; when it is detected that the current jig is the jigwith the preset number, the current jig is moved to a printing position, and the workpiece is printed; a workpiece image after printing is acquired so that the difference between a printing result anda preset result can be detected, and according to the difference, an image taking point of the printing position is adjusted; and according to the acquired workpiece image after printing, whether theprinted workpiece is qualified or not is detected, if yes, the workpiece is fed to the next silk screen working procedure, and if no, the workpiece is recovered. The invention further discloses a silk screen printing device and terminal equipment and a storage medium. The workpiece in the silk screen printing process can be effectively detected, the quality of the silk screen printing can be effectively improved, and meanwhile the resource waste in the printing process can be reduced.

Owner:广州泰行智能科技有限公司

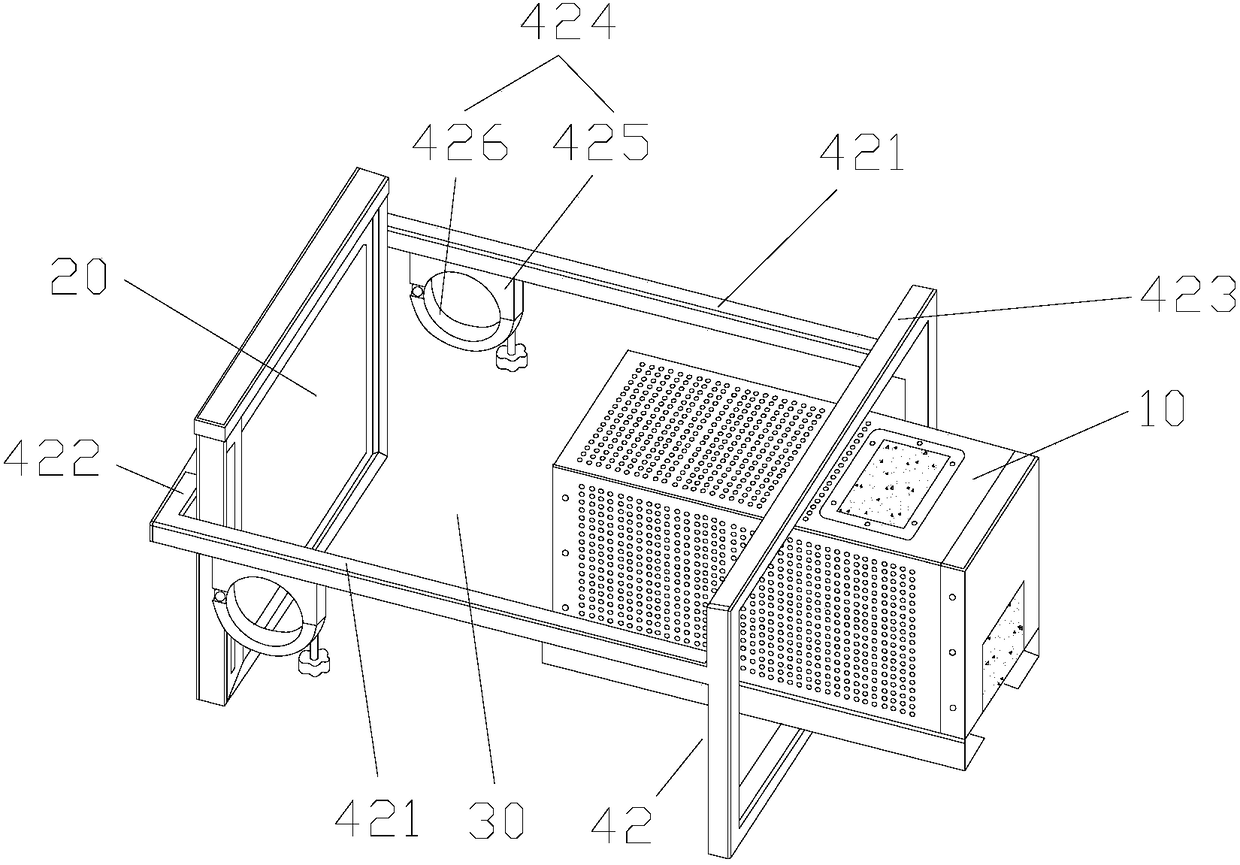

Automatic round rod detection equipment

InactiveCN108421720AAutomatic and efficient inspection workRealize detection workSortingEngineeringPressure sensor

The invention discloses automatic round rod detection equipment. The upper end side of a fixing and supporting plate of a rack of the automatic round rod detection equipment is provided with a material receiving and transferring component, an automatic feeding component and an automatic separating component; a rolling detection component is installed at the upper end side of the material receivingand transferring component; the material receiving and transferring component comprises a transfer driving rodless cylinder, a transfer driving movable seat, a received material lifting driving cylinder, a received material lifting movable seat, a front side material receiving plate and a rear side material receiving plate; the automatic feeding component comprises a discharging frame, a bearingguide block, a movable jacking plate, a jacking cylinder mounting frame, a jacking driving cylinder, a falling guide block, a left side receiving plate, a right side receiving plate, a sensor mountingframe and a pressure sensor; and the rolling detection component comprises a rolling driving mechanism and a CCD detection mechanism. By virtue of the structural design, the automatic round rod detection equipment disclosed by the invention can automatically and efficiently realize detection operation of round rod parts and namely has the advantages of being novel in structural design, high in automation degree, high in work efficiency and capable of effectively lowering the labor cost.

Owner:DONGGUAN UNIV OF TECH

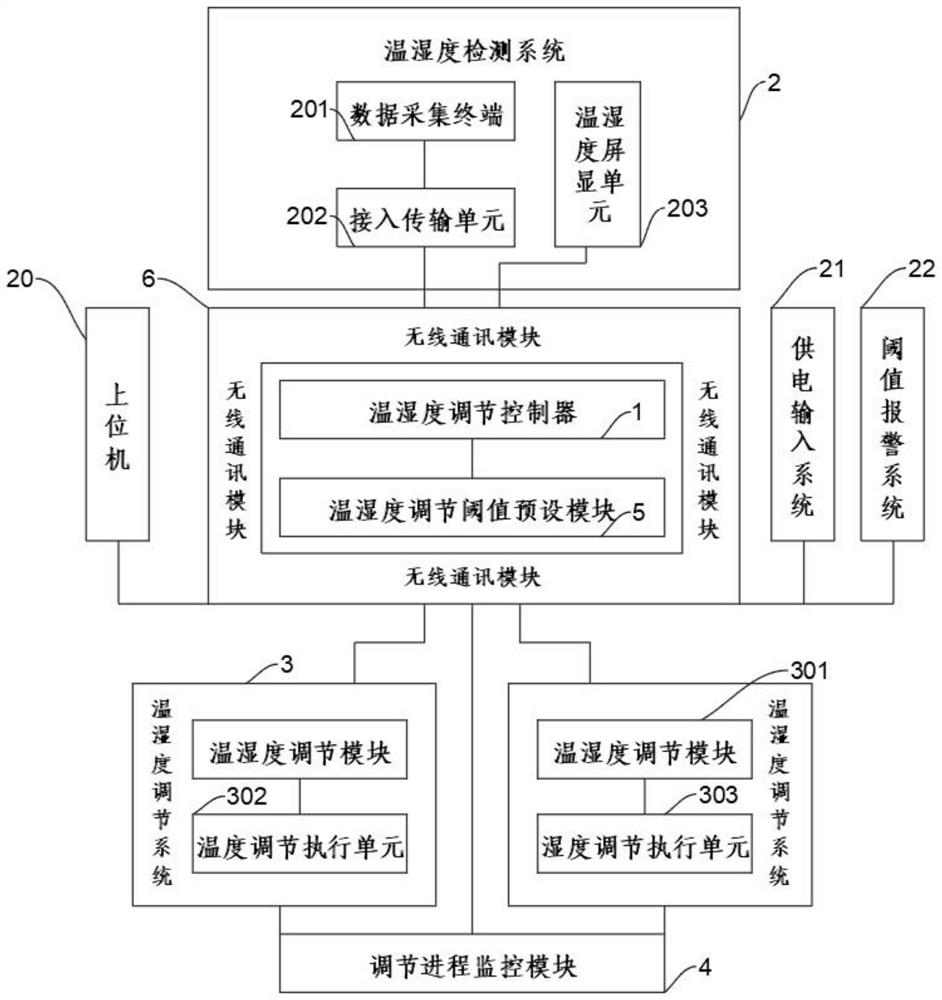

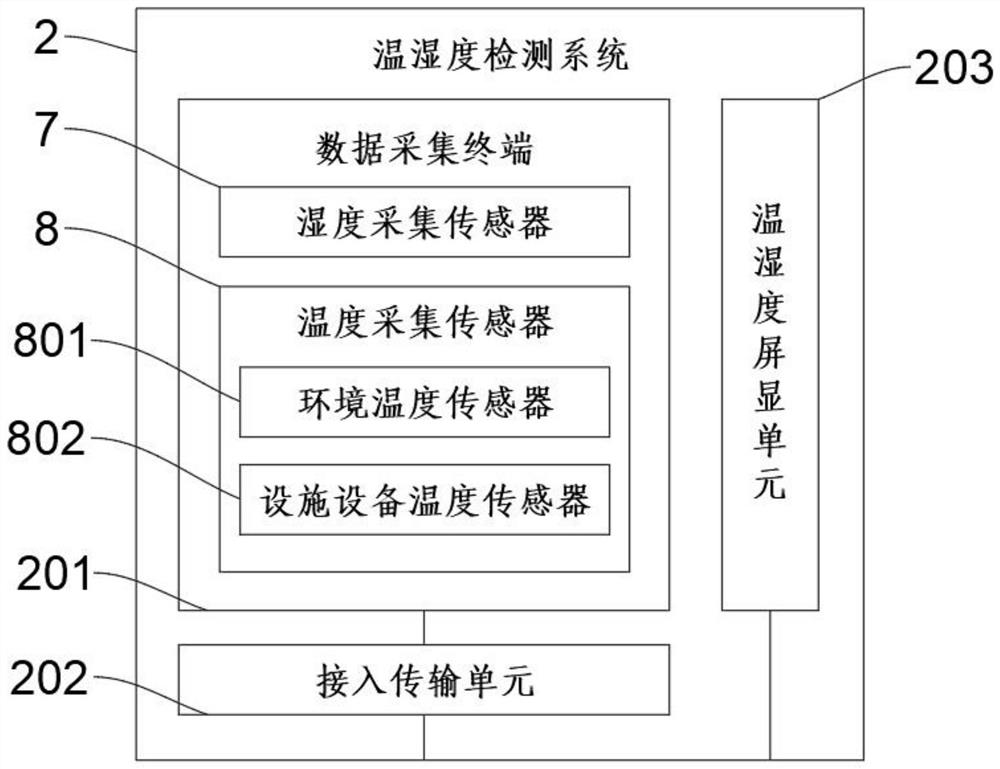

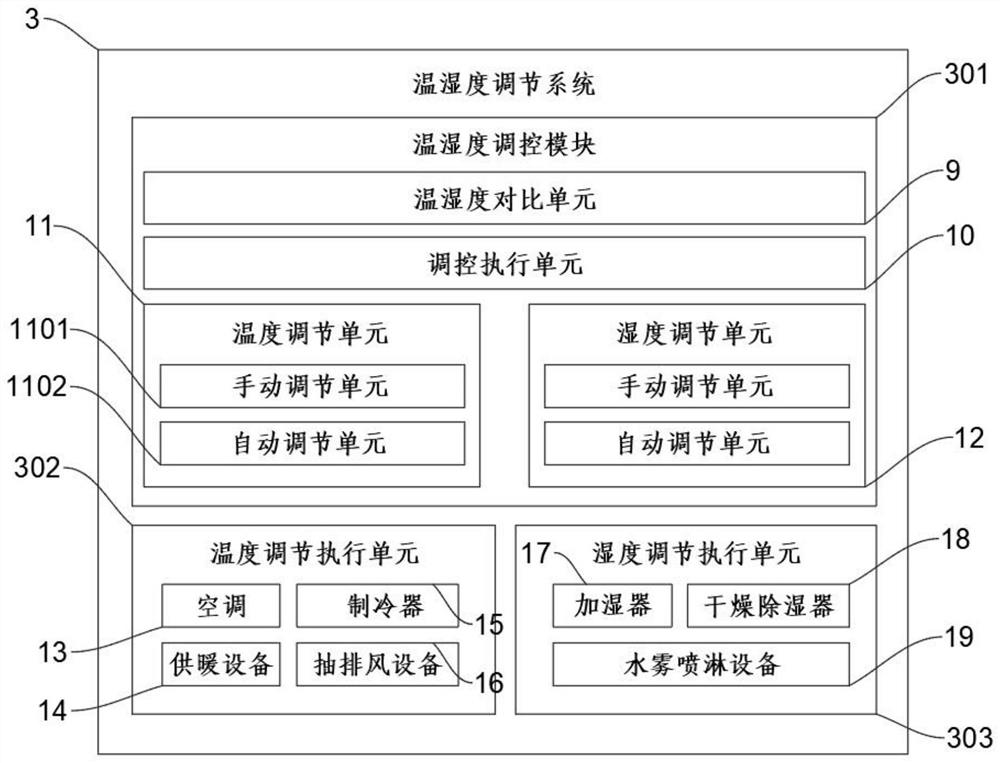

Intelligent building environment temperature and humidity adjustment automatic control system

PendingCN113325908ARealize detection workRealize adjustment workSimultaneous control of multiple variablesAutomatic controlAutomotive engineering

Compared with the prior art, the intelligent building environment temperature and humidity adjustment automatic control system comprises: a temperature and humidity adjustment controller; temperature and humidity detection systems and temperature and humidity adjusting systems which are arranged on all floors of the building and connected with the temperature and humidity adjusting controller; an adjusting process monitoring module which is connected with the temperature and humidity adjusting system; and a wireless communication module which is in communication connection with the temperature and humidity detection systems, the temperature and humidity adjusting systems and the adjusting process monitoring module. The temperature and humidity detection systems comprise data acquisition terminals arranged on all floors of a building and access transmission units connected with the temperature and humidity adjusting controllers and the data acquisition terminal; the temperature and humidity adjusting systems comprise temperature and humidity adjusting modules and temperature regulation execution units and humidity regulation execution units which are connected with the temperature and humidity adjusting modules. According to the technical scheme, compared with the prior art, the indoor temperature and humidity information of the building is accurately detected, and effective temperature and humidity adjustment and control are carried out according to specific requirements.

Owner:衡阳晟达信息技术有限公司

Linkage detection equipment for automobile engine support

ActiveCN109163174AEasy to installEasy to disassembleWork holdersStands/trestlesEngine mountAutomotive engine

The invention belongs to the technical field of machining for automobile engine supports, and particularly relates to linkage detection equipment for an automobile engine support. The linkage detection equipment for the automobile engine support comprises an engine support and a bottom plate, wherein vertical support rods are fixedly connected to the four corners of the top wall of the bottom plate separately, and a support plate is fixedly connected between each two support rods; a rectangular opening is formed in the sidewall of each support plate, and a vertical slide rod is fixedly connected to the center in each rectangular opening; a rotary door slidably sleeves the outer side of each slide rod; two mutually parallel strip-shaped grooves are formed in the inner sidewall of each rotary door; a movable element is slidably connected into each strip-shaped groove, and the engine support is fixedly connected between the two movable elements; and two installation grooves are formed inthe left sidewall and the right sidewall of each rectangular opening separately. The linkage detection equipment for the automobile engine support has the following advantages: shock excitation detection can be carried out on the automobile engine support, so that the machining quality for the automobile engine support is ensured, and the normal running of an automobile engine is guaranteed.

Owner:徐州势甲信息科技有限公司

Terahertz detection method and device for low-speed impact damage of composite material test piece

ActiveCN111999190ARealize non-destructive testing workAchieve clampingMaterial strength using single impulsive forceStructural engineeringSignal processing

The invention discloses a terahertz detection method and device for low-speed impact damage of a composite material test piece. The invention relates to the field of nondestructive testing of composite material test pieces. The device comprises a test platform base and a signal processor; a connecting plate is fixedly mounted at the upper end of the test platform base; a transverse plate is fixedly mounted at the upper end of the connecting plate; an electric sliding rail is fixedly mounted on the side wall of the lower end of the transverse plate; an electric sliding block is connected into the electric sliding rail in a sliding manner; the lower end of the electric sliding block is fixedly connected with a signal transmitter; a signal receiver is fixedly mounted on the side wall of the emitter; the signal receiver is electrically connected with the signal processor through an electric wire; and the signal processor is electrically connected with the signal emitter. Through the cooperative use of the electric sliding rail, the electric sliding block, the signal emitter, the signal receiver and the signal processor, longitudinal movement of the signal emitter is achieved; and meanwhile overall detection of a composite material test piece to be detected is achieved through transverse movement of an installation box.

Owner:CIVIL AVIATION FLIGHT UNIV OF CHINA

Novel metal material plate bending detection device

InactiveCN114414398AStable forceImprove work efficiencyMaterial strength using steady bending forcesElectric machineryBevel gear

The invention relates to the technical field of plate detection, and discloses a novel metal material plate bending detection device which comprises a device body, supporting legs are fixedly connected to the bottom of the device body, a transmission device is fixedly connected to the interior of the device body, and clamping devices are arranged on the left side and the right side of the transmission device. A bending device is arranged in the middle of the transmission device. According to the novel metal material plate bending detection device, an external motor drives an output shaft, the output shaft drives a second bevel gear through a first bevel gear, the second bevel gear drives a threaded rod to rotate, the threaded rod drives a threaded block to move, and the threaded block drives a sliding block to move in a sliding groove through a connecting rod; the sliding block drives the mounting base to move through the pressed rod, the mounting base drives the clamping device to move, meanwhile, the sliding block pushes the bent rod to move through the transverse rod, the bent rod jacks the vertical rod upwards, the vertical rod pushes the bending head to move upwards so as to extrude the plate, and the detection work of the plate is achieved.

Owner:江苏国帆薄板科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com