Novel metal material plate bending detection device

A detection device and new material technology, applied in measuring devices, analyzing materials, testing the strength of materials by applying a stable bending force, etc. The effect of applying force and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

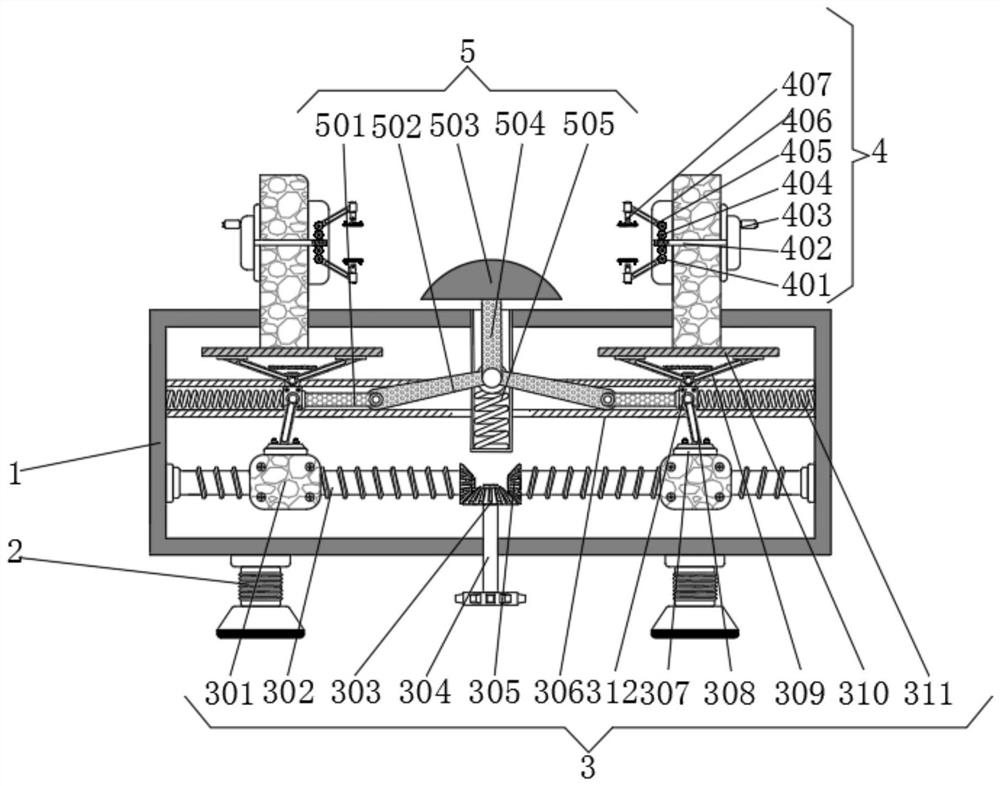

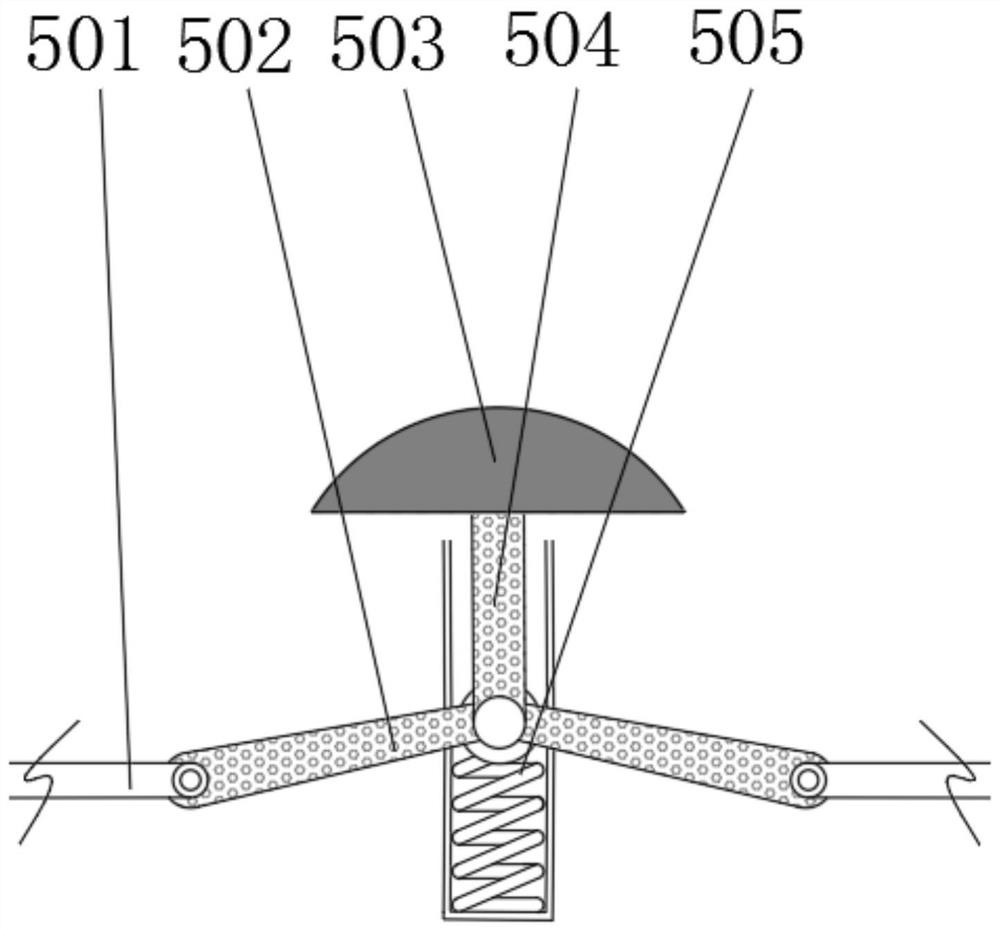

[0021] see figure 1 and 3 , a new metal material plate bending detection device, comprising a device main body 1, the bottom of the device main body 1 is fixedly connected with a support leg 2, the inside of the device main body 1 is fixedly connected with a transmission device 3, and the left and right sides of the transmission device 3 are provided with The middle part of the clamping device 4 and the transmission device 3 is provided with a bending device 5 .

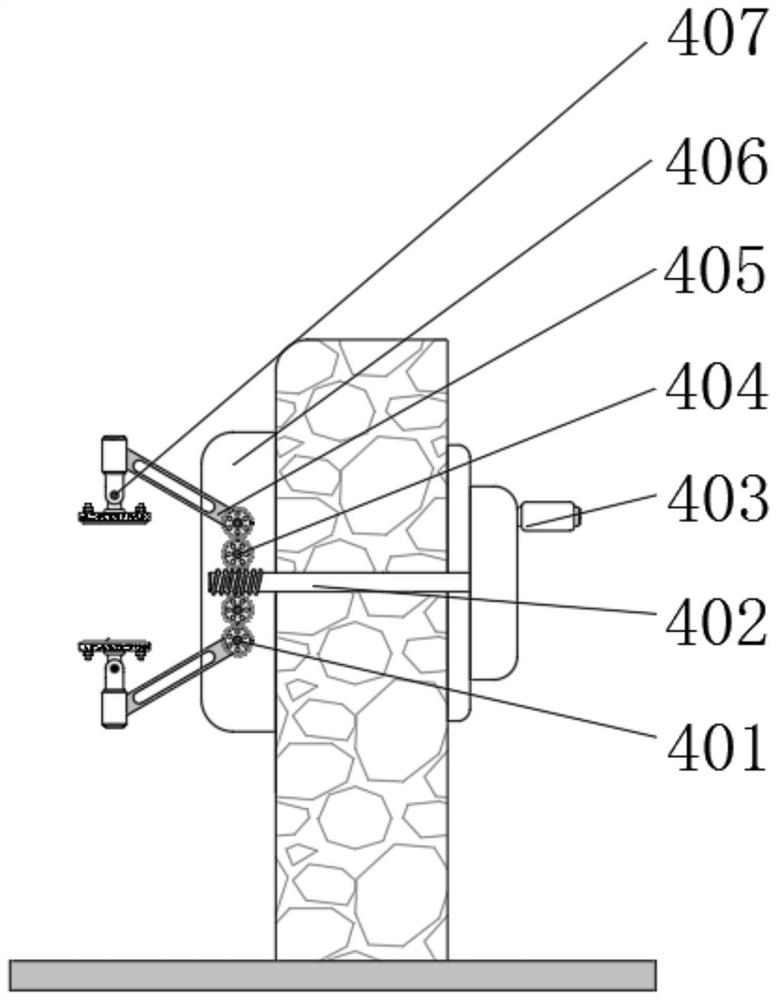

[0022] Further, the clamping device 4 includes a fixed seat 406, a micro threaded rod 402 is rotatably connected to the top of the fixed seat 406, and a handle 403 is fixedly connected to the side of the micro threaded rod 402 away from the bending device 5, and the micro threaded rod 402 is close to the bending One side of the device 5 is meshed with a second gear 404, and the side of the second gear 404 away from the micro threaded rod 402 is meshed with a first gear 401, and the side of the first gear 401 close t...

Embodiment 2

[0025] see Figure 1-3 , a new metal material plate bending detection device, comprising a device main body 1, the bottom of the device main body 1 is fixedly connected with a support leg 2, the inside of the device main body 1 is fixedly connected with a transmission device 3, and the left and right sides of the transmission device 3 are provided with The middle part of the clamping device 4 and the transmission device 3 is provided with a bending device 5 .

[0026] Further, the transmission device 3 includes an output shaft 304, the top of the output shaft 304 is fixedly connected with a first bevel gear 303, the left and right sides of the first bevel gear 303 are meshed with a second bevel gear 305, the second bevel gear The side of the gear 305 away from the output shaft 304 is fixedly connected with a threaded rod 302, the side of the threaded rod 302 away from the output shaft 304 is threaded with a threaded block 301, the top of the threaded block 301 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com