Patents

Literature

31results about How to "Realize lifting work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

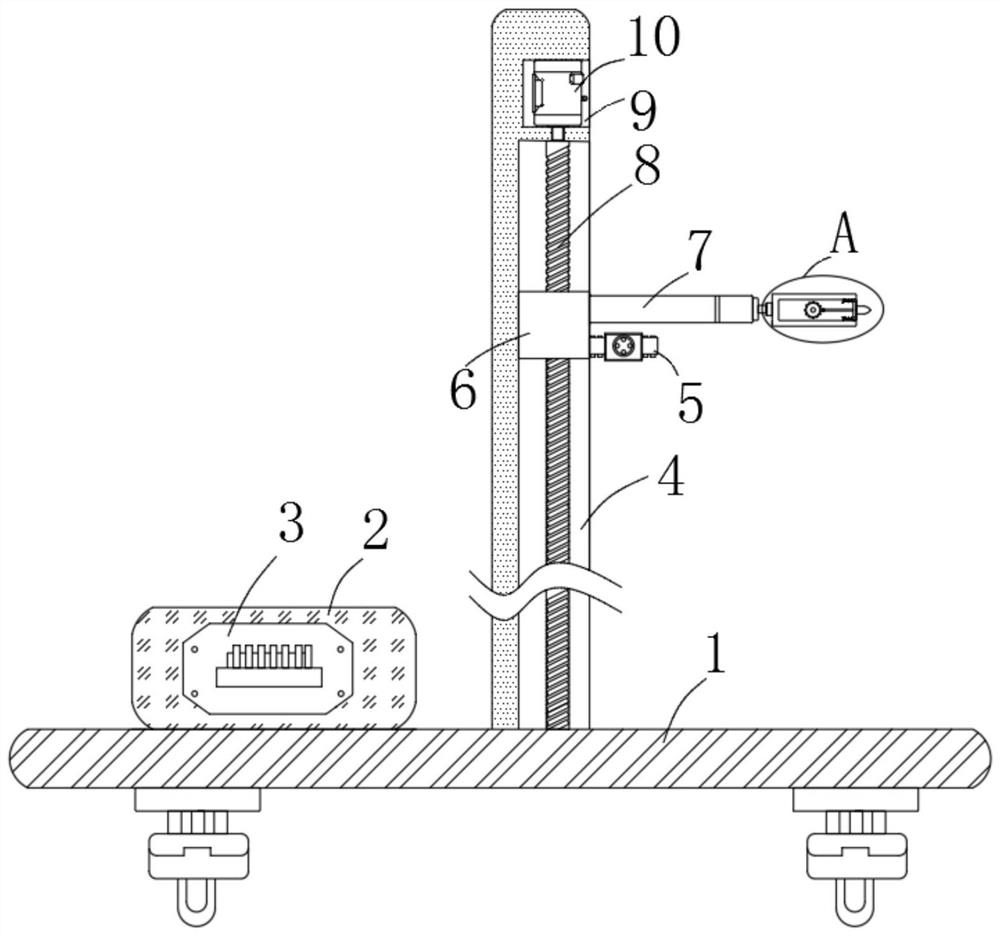

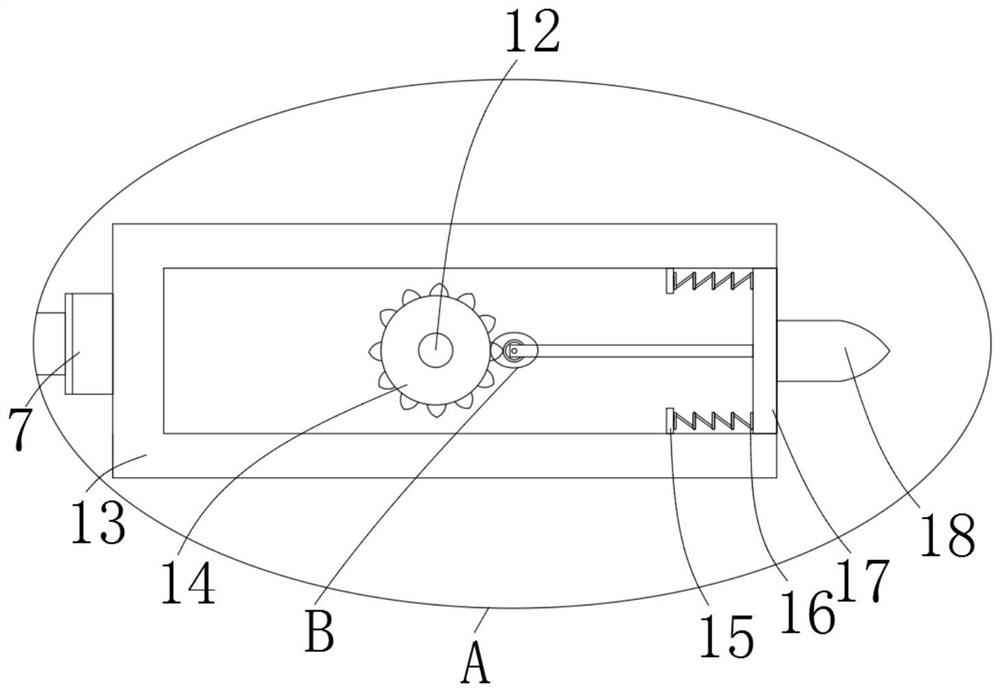

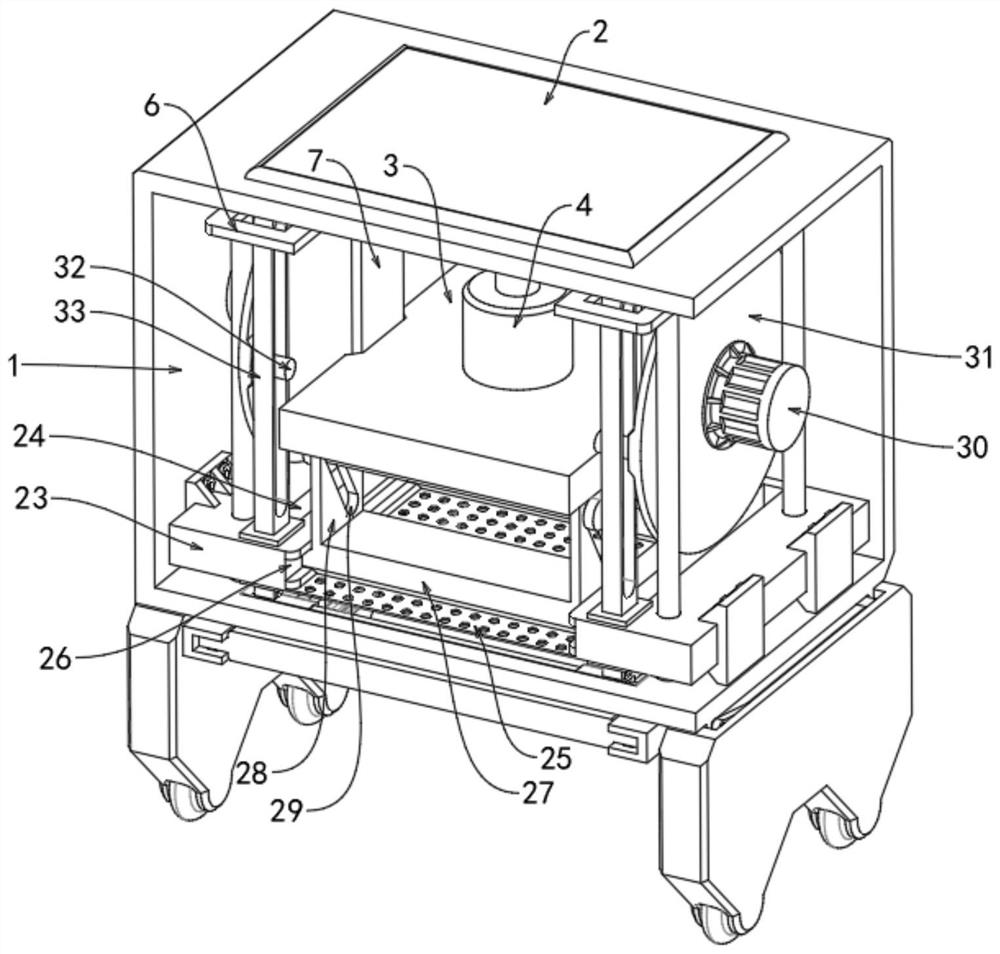

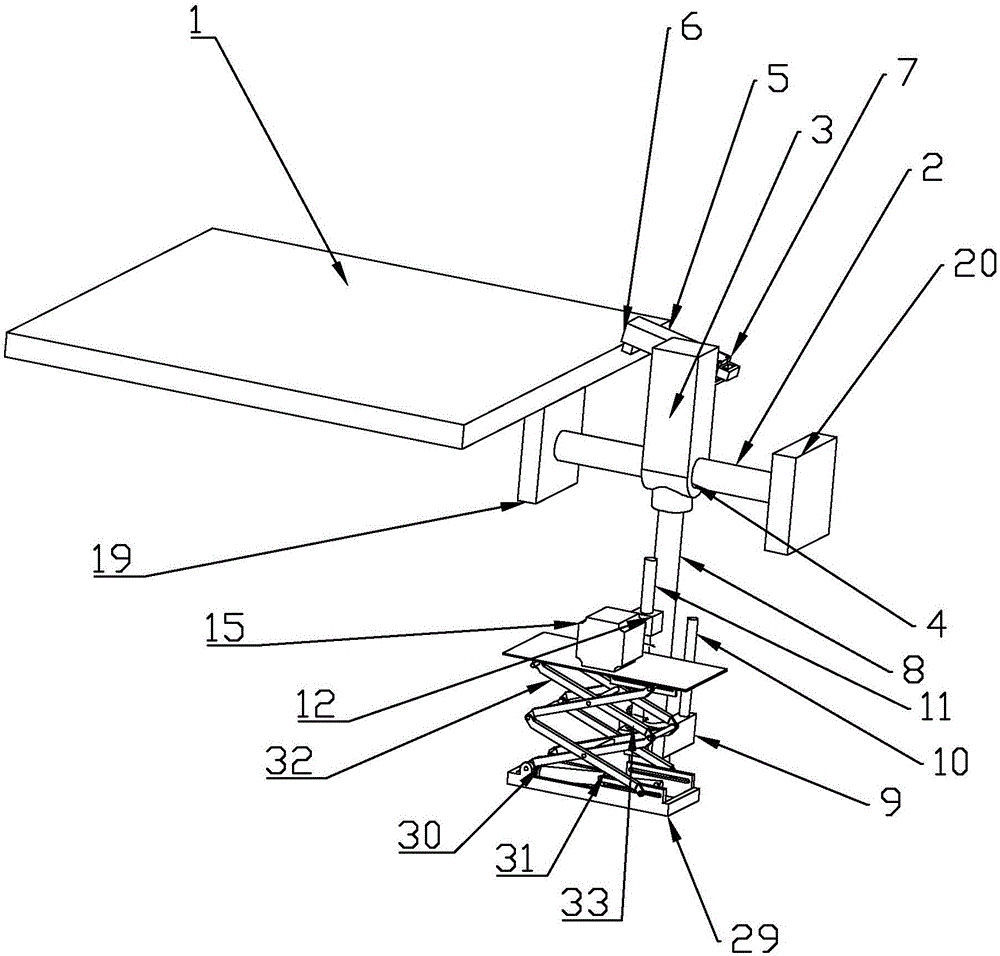

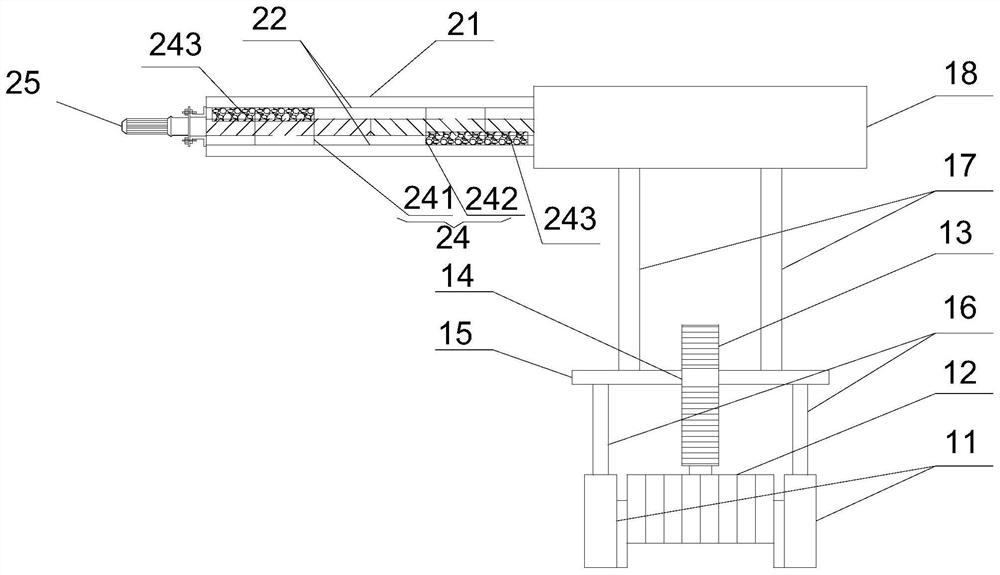

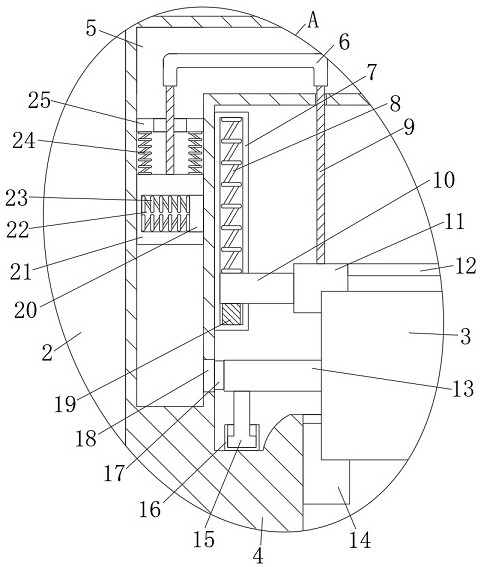

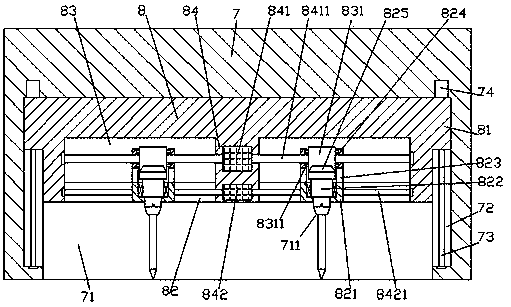

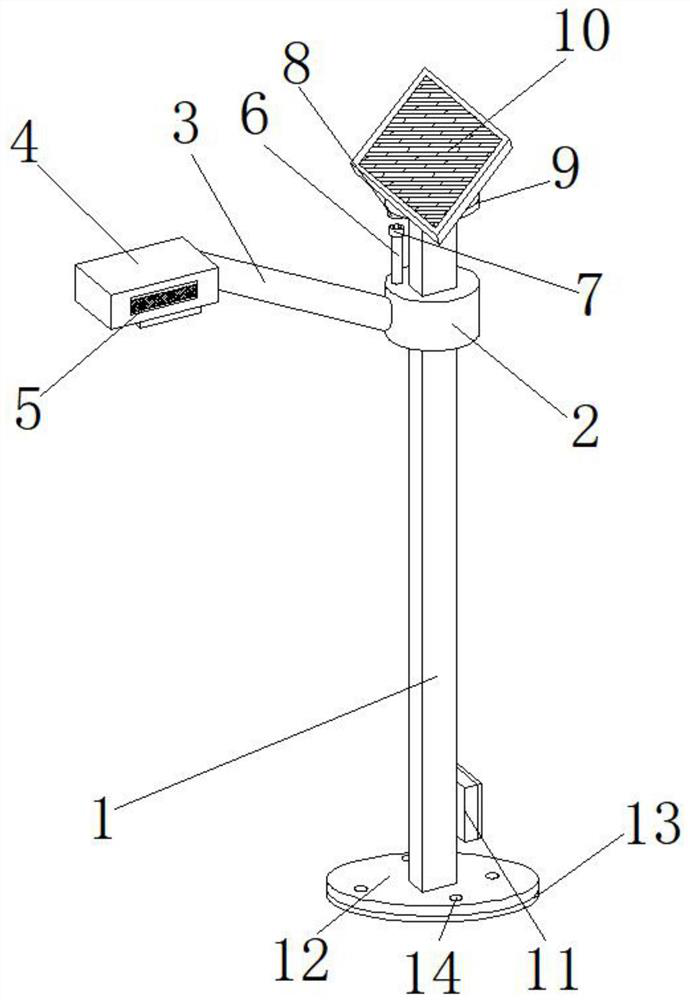

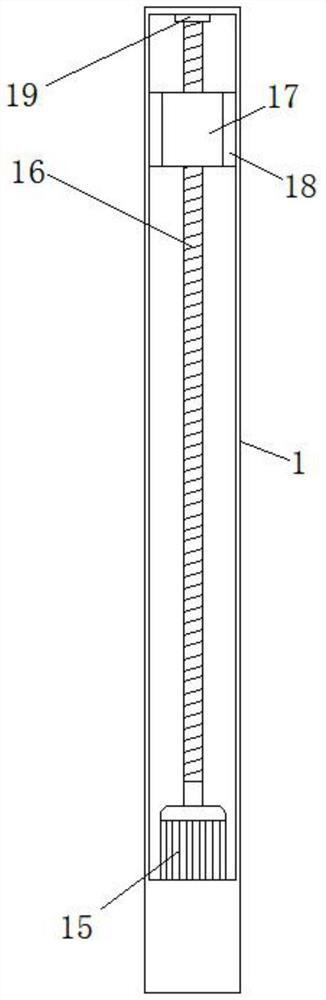

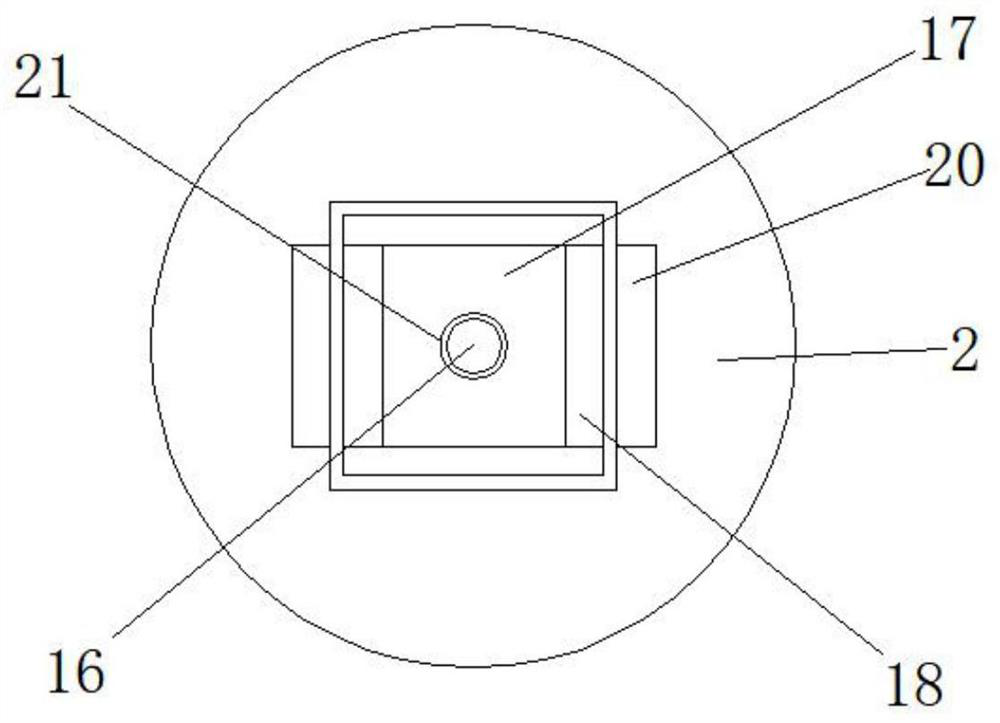

Wall detection device based on architectural design

InactiveCN111830132ARealize lifting workComprehensive testing workAnalysing solids using sonic/ultrasonic/infrasonic wavesElectric machineDisplay device

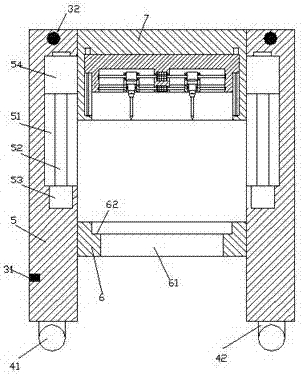

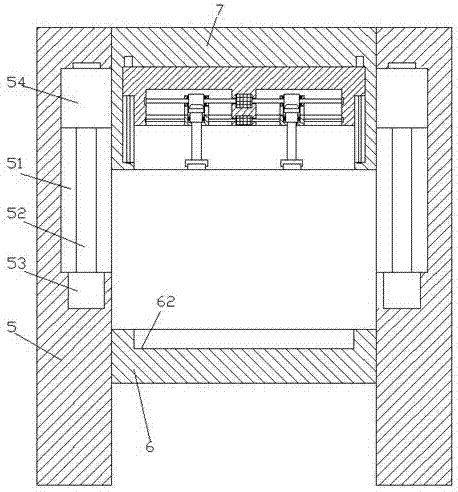

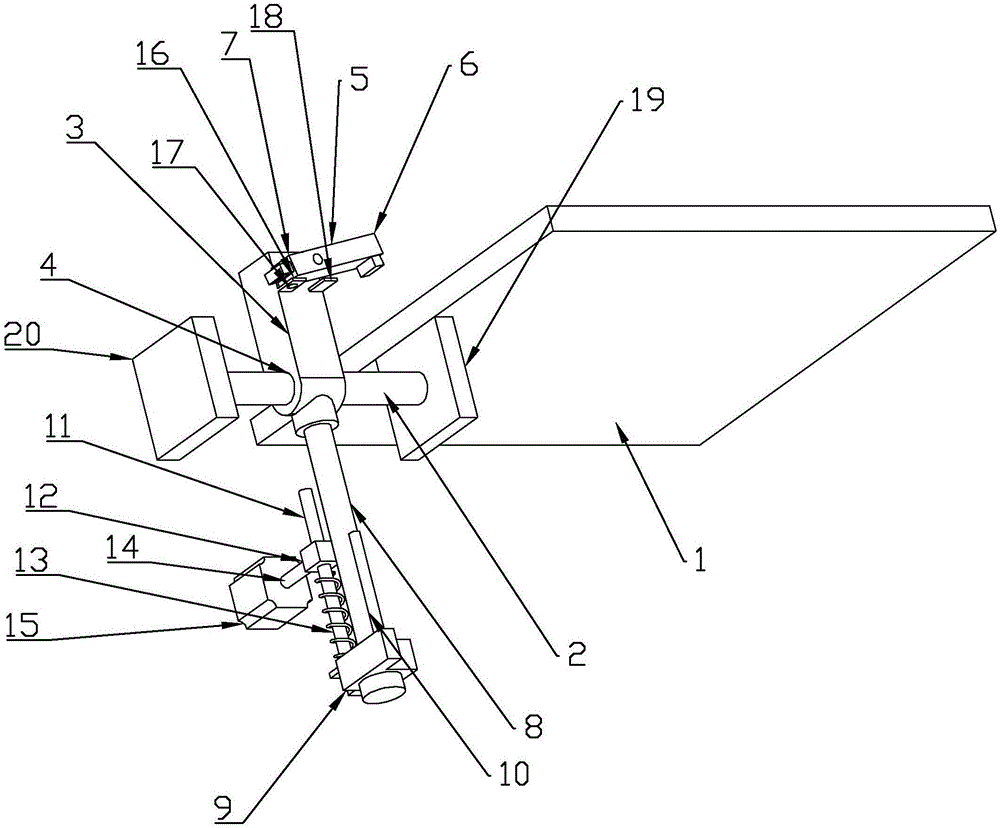

The invention discloses a wall detection device based on building design and relates to the technical field of wall detection. The wall detection device comprises a base, wherein an upper end of the base is fixedly connected with a display, a side wall of the display is fixedly connected with a sensor, the upper end of the base is fixedly connected with a mounting rod, a mounting groove is formedin an inner side wall of the mounting rod, a lifting mechanism is mounted in the mounting groove, a mounting groove is formed in a side wall of the mounting rod, a first servo motor is mounted in themounting groove, and a tail end of an output shaft of the first servo motor is fixedly connected with an upper end of a threaded rod. The wall detection device is advantaged in that through cooperative use of a driving motor, a threaded rod and a threaded sleeve, lifting work of a telescopic rod and an electric push rod is achieved, then lifting work of the knocking mechanism is achieved, in the lifting process of the knocking mechanism, the comprehensive detection work of the wall surface is achieved, the tedious and complex operation process of manpower is replaced, and work efficiency is improved.

Owner:HUANGSHAN UNIV

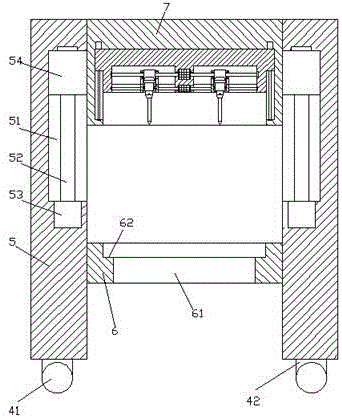

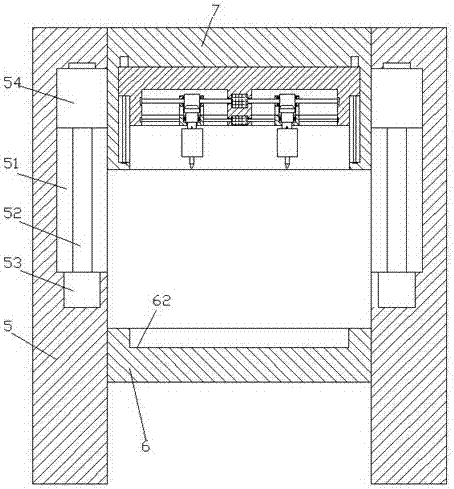

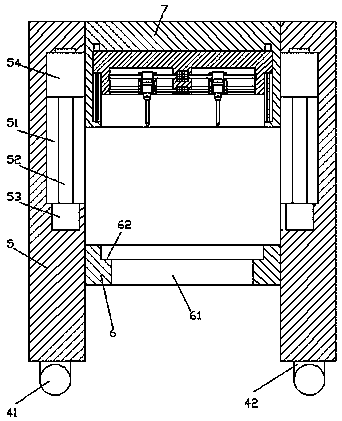

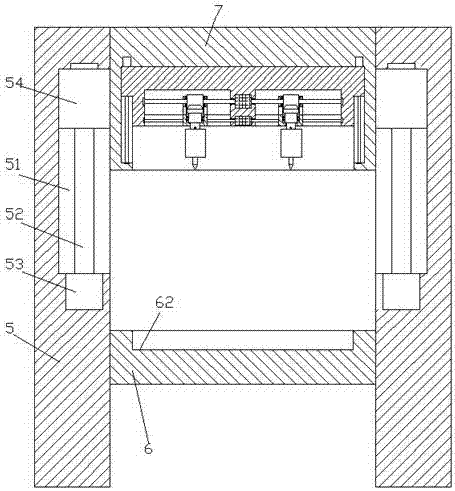

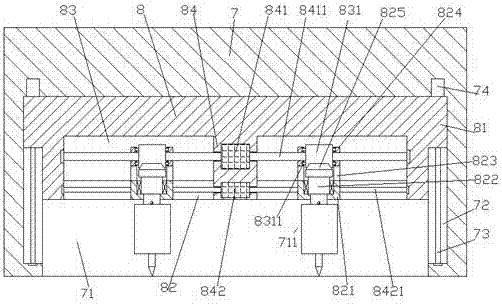

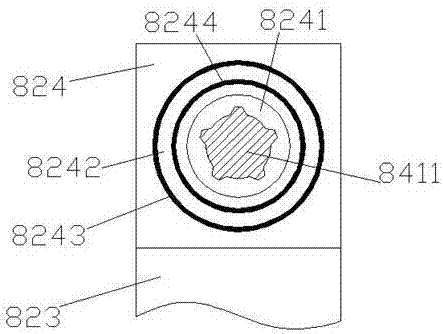

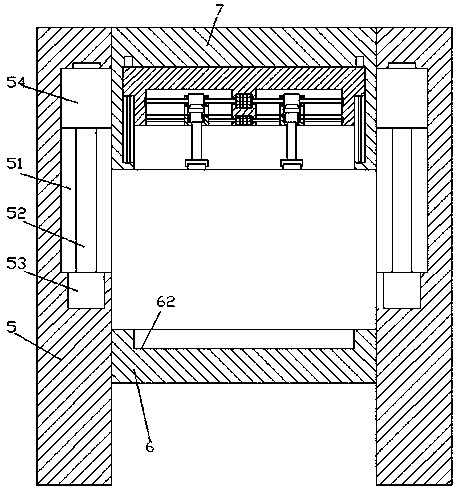

Multifunctional paint spraying equipment

ActiveCN106944283AImprove work efficiencyRealize lifting workSpraying apparatusEngineeringEquipment use

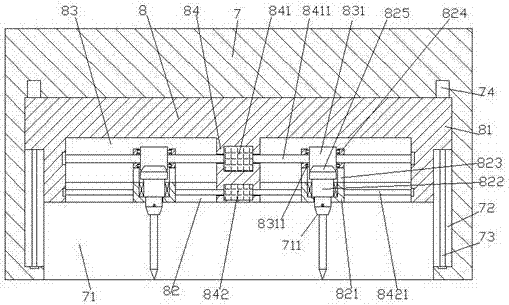

The invention discloses multifunctional paint spraying equipment. The multifunctional paint spraying equipment comprises a bracket and a foundation support, wherein the left side and the right side of the bracket are arranged correspondingly, and the foundation support is fixed between the inner sides of the left side and the right side of the bracket; a paint spraying device is arranged between the inner sides of the left side and the right side of the bracket above the foundation support; the end face of the bottom of the paint spraying device is internally provided with a first sliding and running slot, and the first sliding and running slot is internally connected with paint spraying sliding and running block in a translation fit manner; the end face of the bottom of the paint spraying sliding and running block is internally provided with a second sliding and running slot, the top of the second sliding and running slot is provided with a transmission cavity in a communicating manner, and the second sliding and running slot is internally provided with a partition plate extending upwards; and the top expansion portion of the partition plate enters the transmission cavity in a jacking manner, the tail side of the partition plate is fixedly connected with the top end in the transmission cavity, the partition plate divides the second sliding and running slot into a left guide slot body and a right guide slot body and divides the transmission cavity into a left transmission cavity body and a right transmission cavity body, and the position, between the left guide slot body and the right guide slot body, of the partition plate is internally provided with a first power device. The multifunctional paint spraying equipment is simple in structure and reasonable in design, work efficiency is improved, and equipment use safety is improved.

Owner:JIANGSU SULI MACHINERY SHARES CO LTD

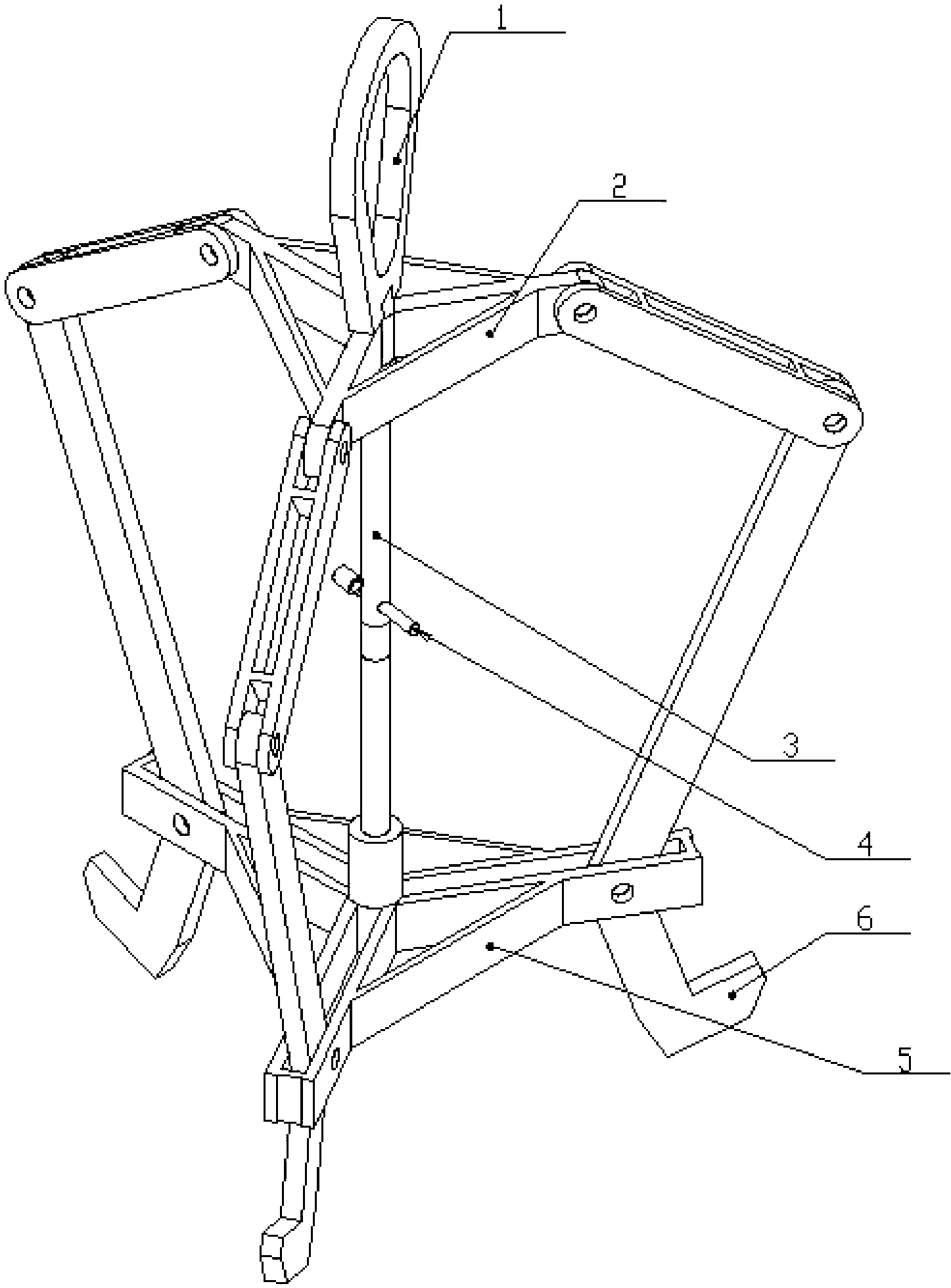

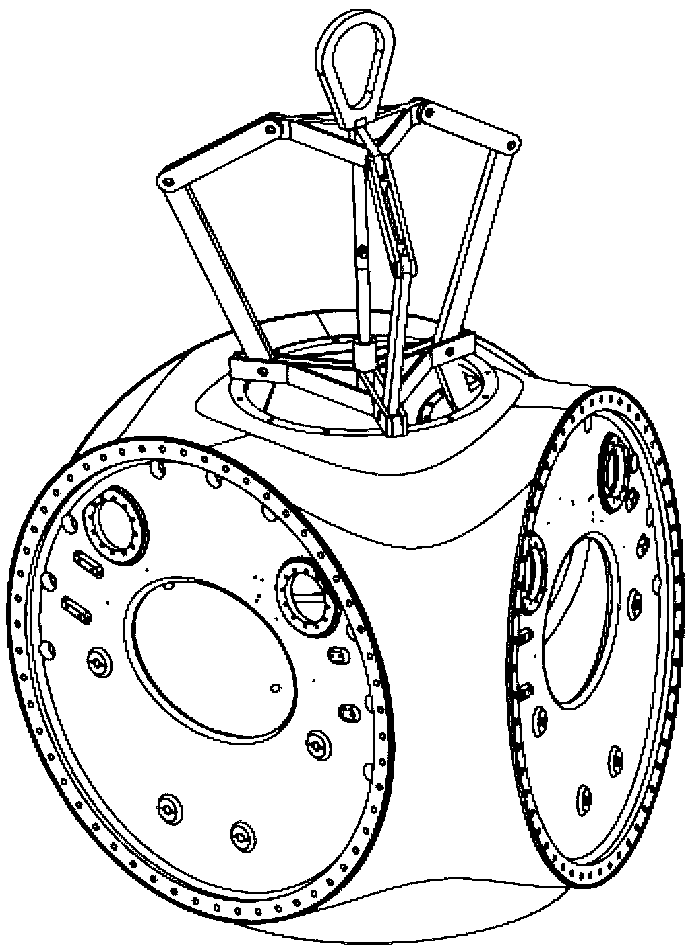

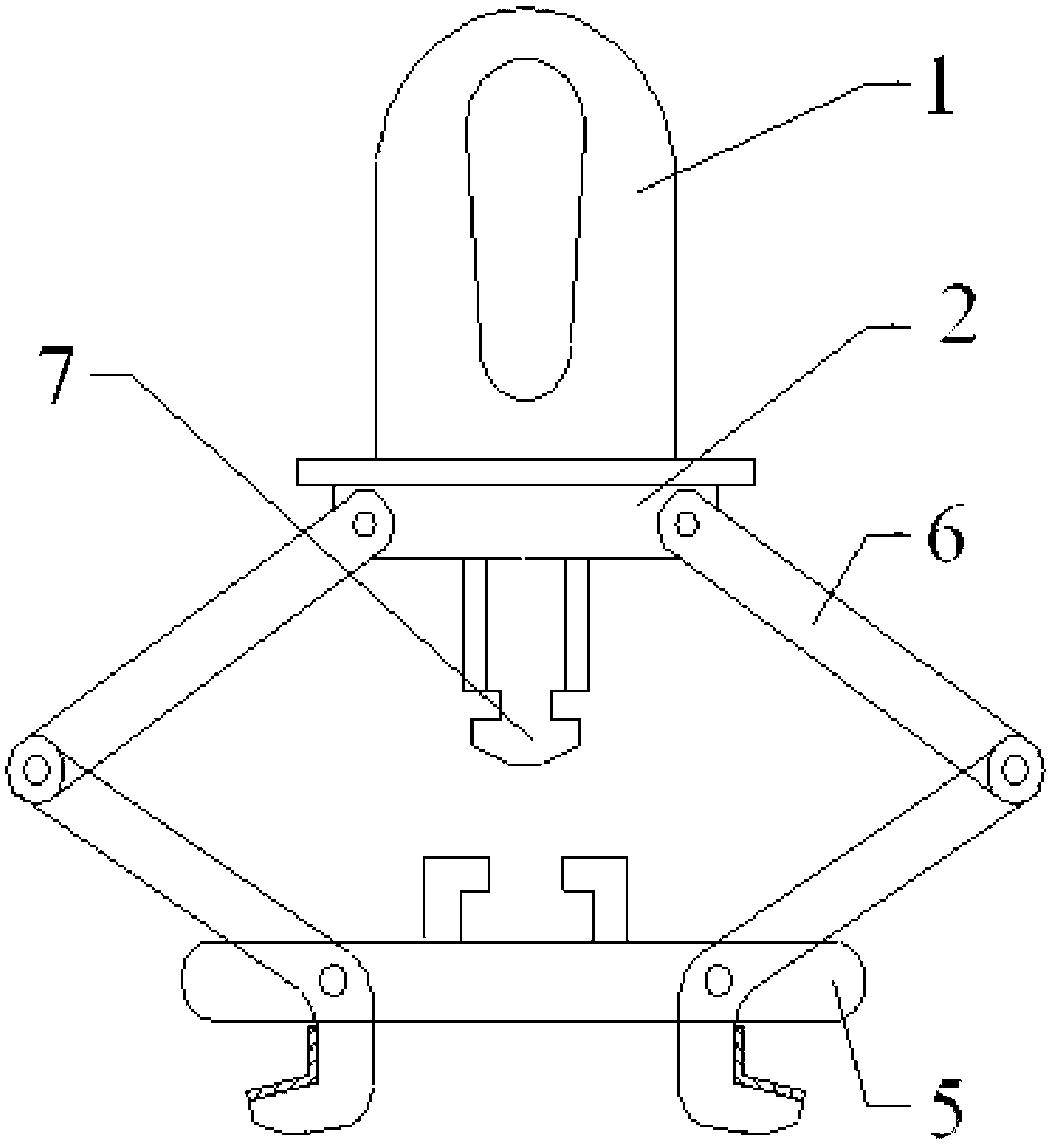

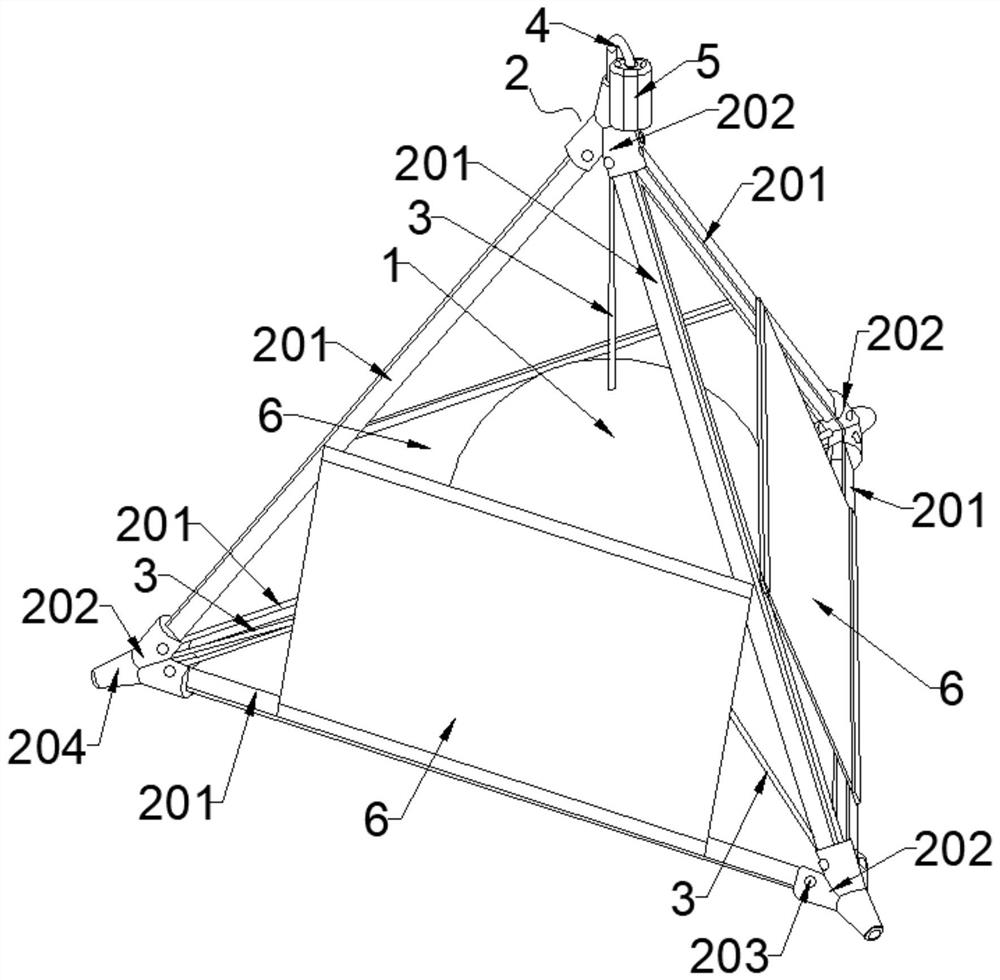

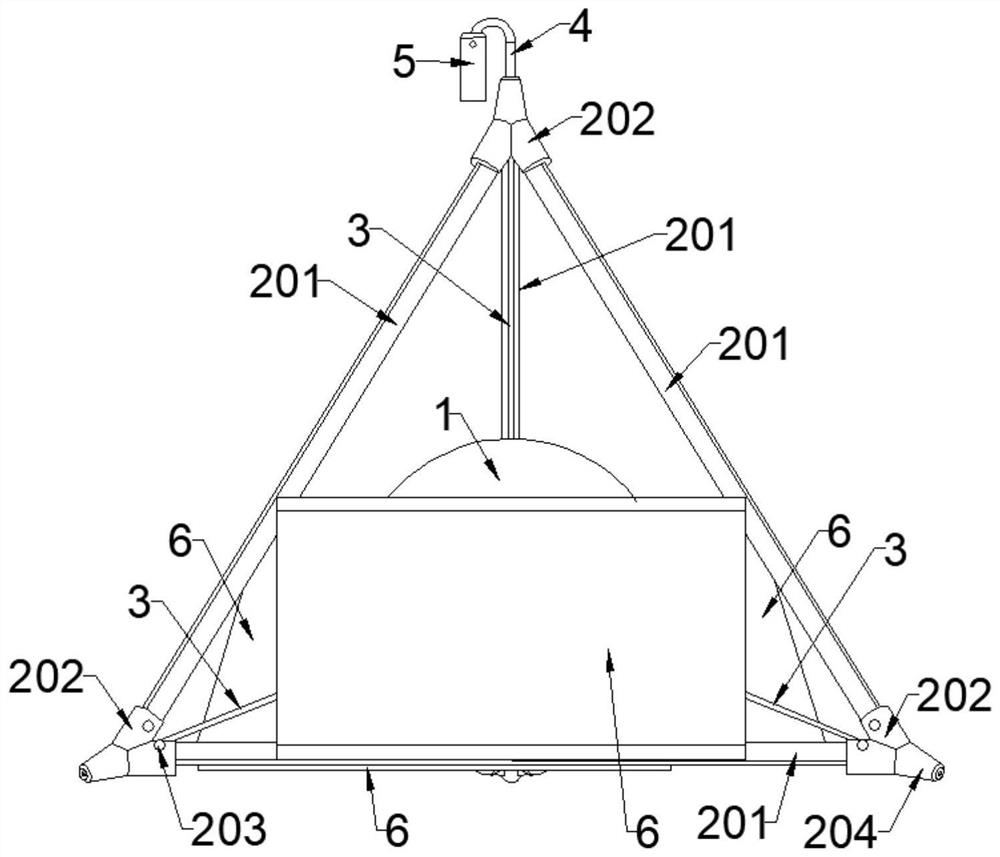

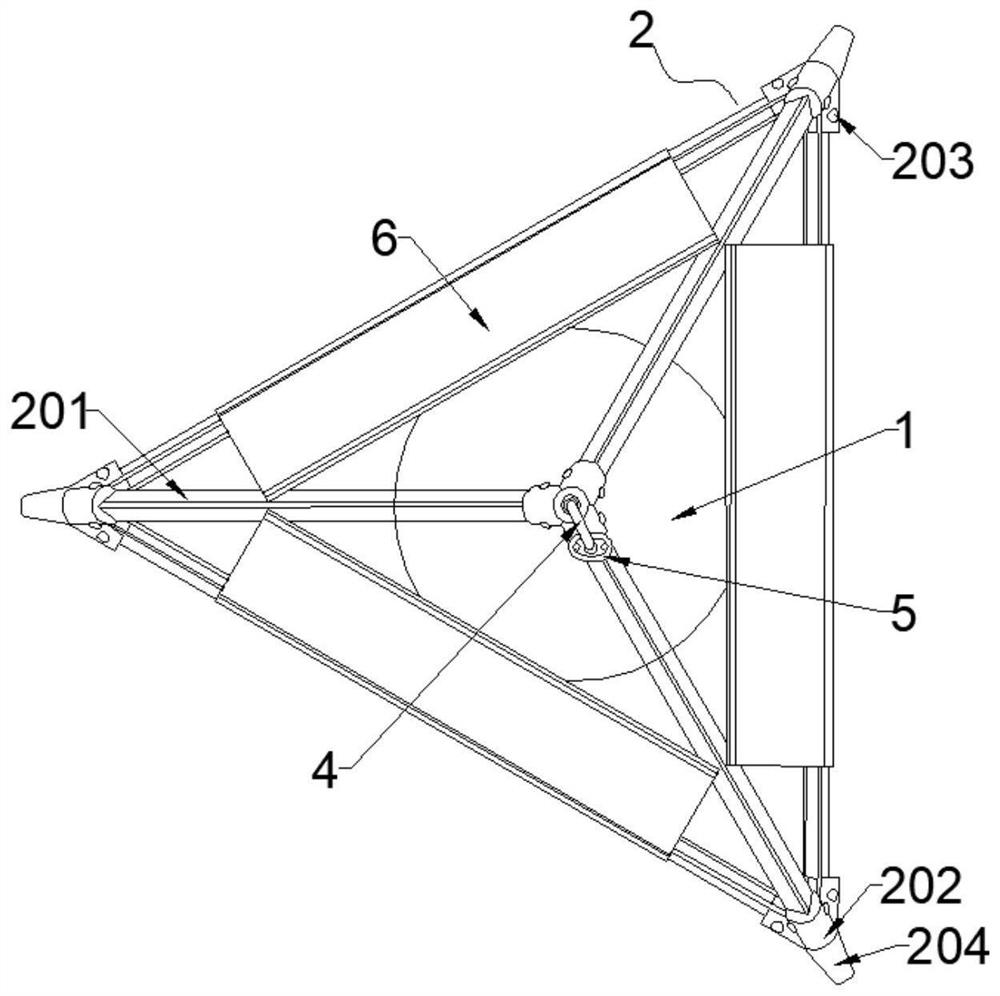

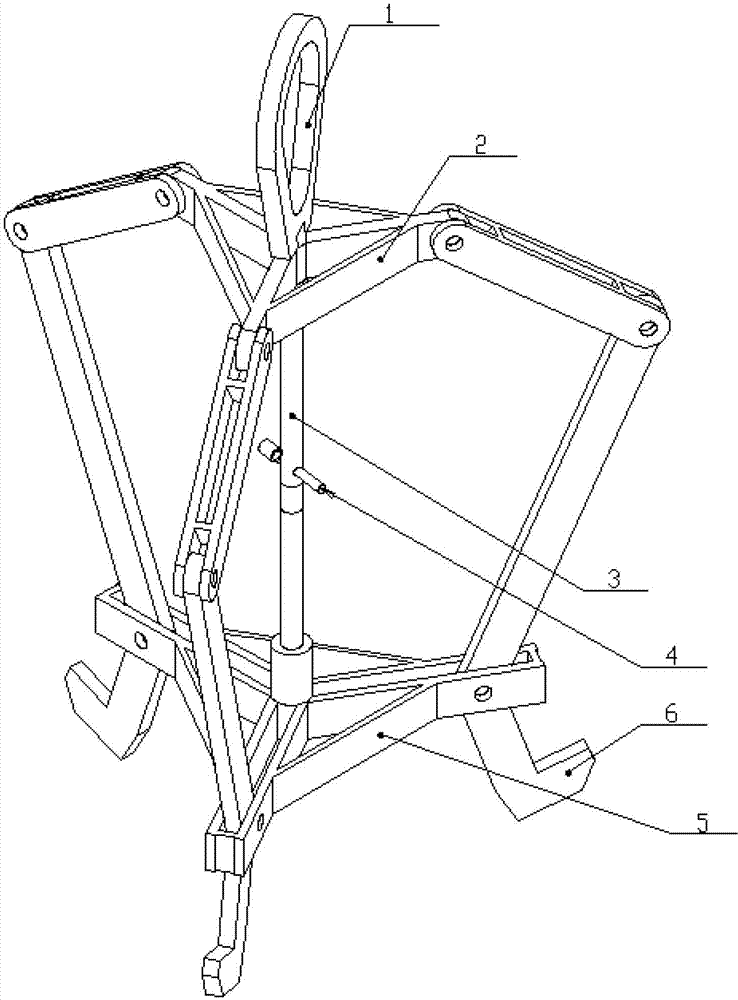

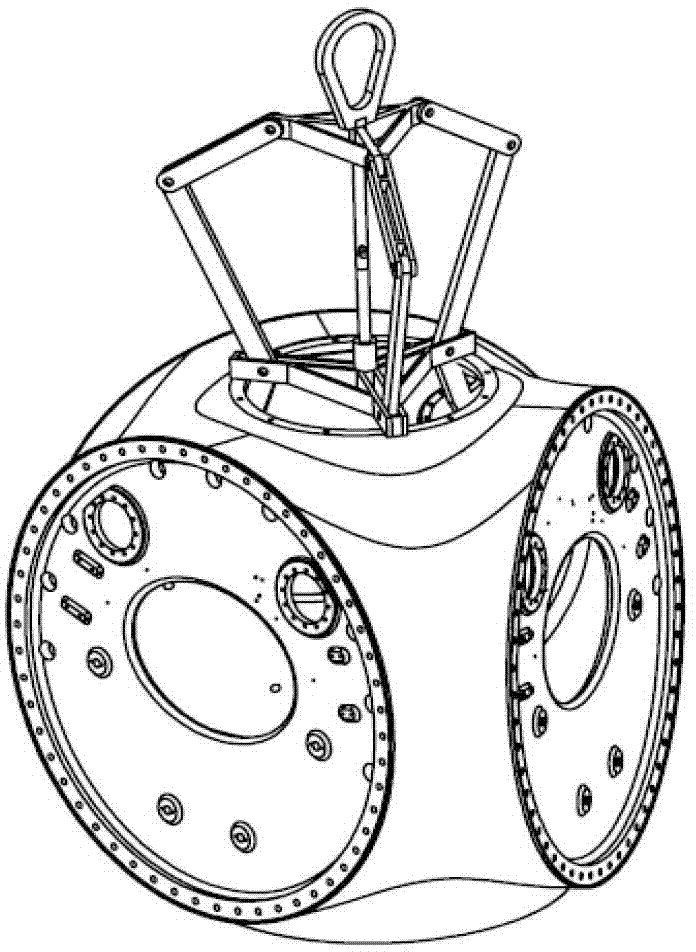

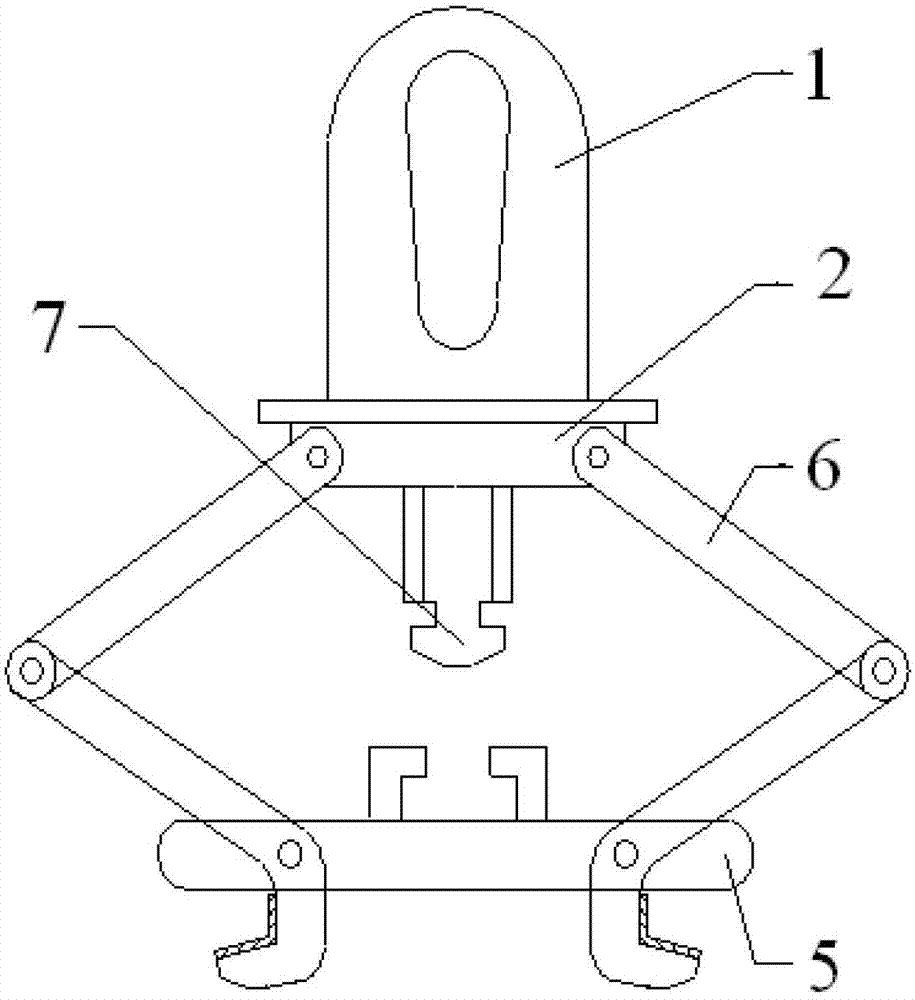

Fan hub hanger with rotational locking mechanism and using method thereof

ActiveCN103010932AAvoid safety hazardsLow costLoad-engaging elementsEngineeringElectrical and Electronics engineering

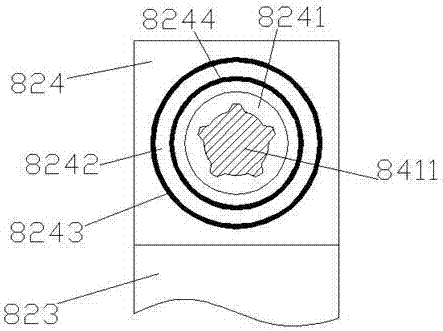

The invention discloses a fan hub hanger with a rotational locking mechanism and a using method thereof. The fan hub hanger with the rotational locking mechanism comprises a ring, an upper connection module, an intermediate connection module, a lower connection module, a claw module and a rotational locking mechanism, wherein the ring is fixed right above the upper connection module which is connected with the intermediate connection module; the intermediate connection module is connected with the claw module which is fixed on the lower connection module; the rotational locking mechanism is mounted right below the upper connection module; and a slot matched with the rotational locking mechanism is formed on the upper surface of the lower connection module. The invention further discloses a using method for the fan hub hanger with the rotational locking mechanism. The fan hub hanger has the advantage that a worker does not need to ascend to transport a hub.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

Bridge construction facility

InactiveCN107178036AImprove work efficiencyRealize lifting workBridge erection/assemblyBoring/drilling componentsIdler-wheelBuilding construction

The invention discloses a bridge construction facility, which comprises upstands arranged oppositely on the left and right sides and abutments fixed between the inner sides of the uprights on the left and right sides. Rollers are rotatable, and drilling elements are arranged between the inner sides of the left and right sides of the stand above the abutment. The bottom end surface of the drilling element is provided with a first sliding cavity, and the first sliding cavity is movably connected with a drilling slide. There is a second sliding chamber in the bottom end surface of the drilling slider, and a transmission chamber is provided on the top of the second sliding chamber. There is an upwardly extending spacer between the second sliding chambers, and the top of the spacer is elongated. The section jacks into the transmission cavity and the tail part is fixedly connected with the top of the transmission cavity; the invention has simple structure, reasonable design, improves work efficiency and improves the safety of equipment use.

Owner:冯斌斌

Facility for bridge construction

InactiveCN107022957ARealize lifting workImprove the safety of useBridge erection/assemblyArchitectural engineeringLong segment

The invention discloses a facility for bridge construction, which comprises vertical frames opposite to each other on the left and right sides and an abutment fixed between the inner sides of the vertical frames on the left and right sides. The bottom is rotatably provided with rollers, and a drilling element is arranged between the inner sides of the left and right sides above the abutment, and a first sliding cavity is provided in the bottom end surface of the drilling element, and the first sliding cavity is movable and connected with a drilling hole. Slider, the bottom end surface of the drilling slider is provided with a second sliding cavity, and the top of the second sliding cavity is provided with a transmission cavity arranged in communication. Between the second sliding cavity, there is an upwardly extending spacer, and the top of the spacer is extended. The long section is jacked into the transmission cavity and the tail is fixedly connected to the top of the transmission cavity; the invention has simple structure, reasonable design, improves work efficiency, and improves the safety of equipment use.

Owner:冯斌斌

Material polishing equipment

ActiveCN107030580ARealize lifting workImprove the safety of useGrinding carriagesPolishing machinesEngineeringEquipment use

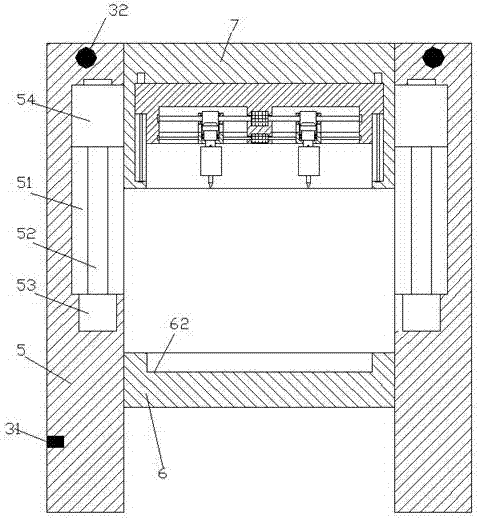

The invention discloses material polishing equipment. The material polishing equipment comprises frames correspondingly arranged on the left and right sides and a chassis fixed between inner sides of the frames on the left and right sides; a polishing component is arranged above the chassis and between the inner sides of the frames on the left and right sides, a first sliding connection groove is formed in the end face of the bottom of the polishing component, a polishing sliding connection block is connected into the first sliding connection groove in a smooth fit manner, a second sliding connection groove is formed in the end face of the bottom of the polishing sliding connection block, and a through transferring connection cavity is formed in the top of the second sliding connection groove; a dividing plate extending upwards is arranged between parts of the second sliding connection groove, an extending part on the top of the dividing plate penetrates into the transferring connection cavity, and the tail end of the extending part is fixedly connected with the top end of the interior of the transferring connection cavity; and the second sliding connection groove is divided by the dividing plate into a left guide connection groove and a right guide connection groove, the transferring connection cavity is divided by the dividing plate into a left transferring connection cavity body and a right transferring connection cavity, and a first electric rotating machine is arranged in the position, between the left guide connection groove and the right guide connection groove, of the dividing plate. The material polishing equipment is simple in structure and reasonable in design, the working efficiency is improved, and the equipment using safety is improved.

Owner:NANTONG TONGYANG MECHANICAL & ELECTRICAL MFR

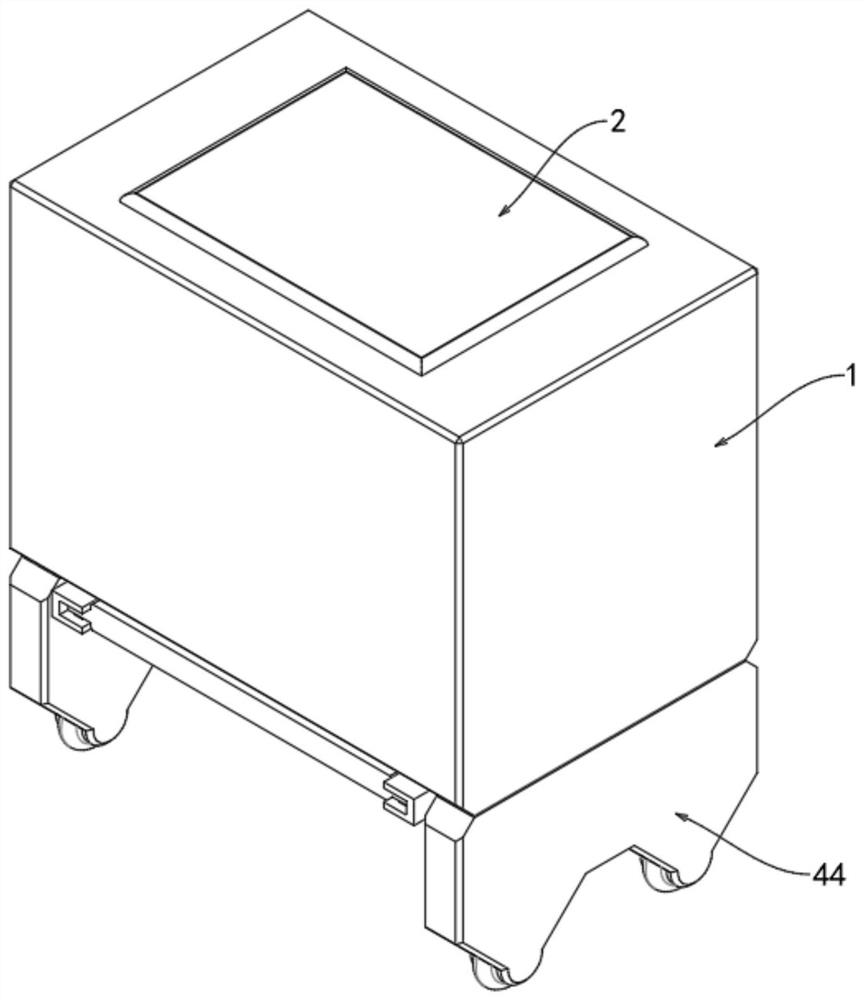

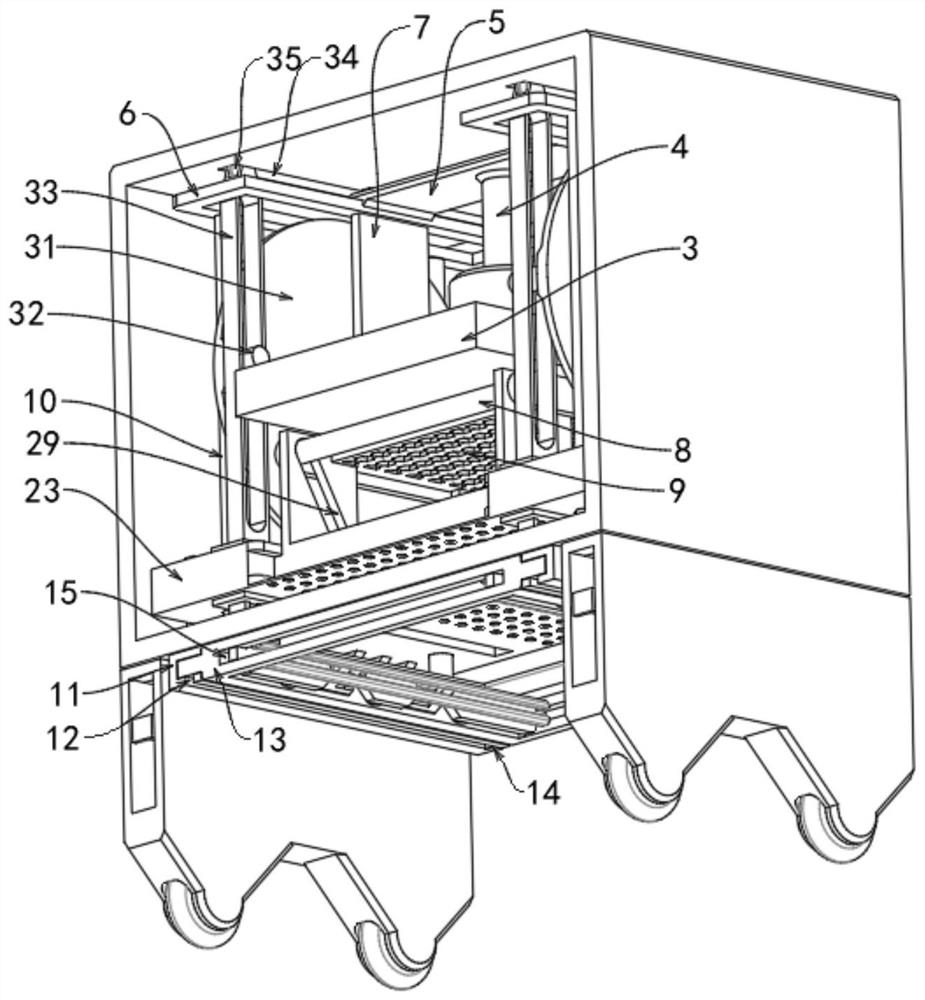

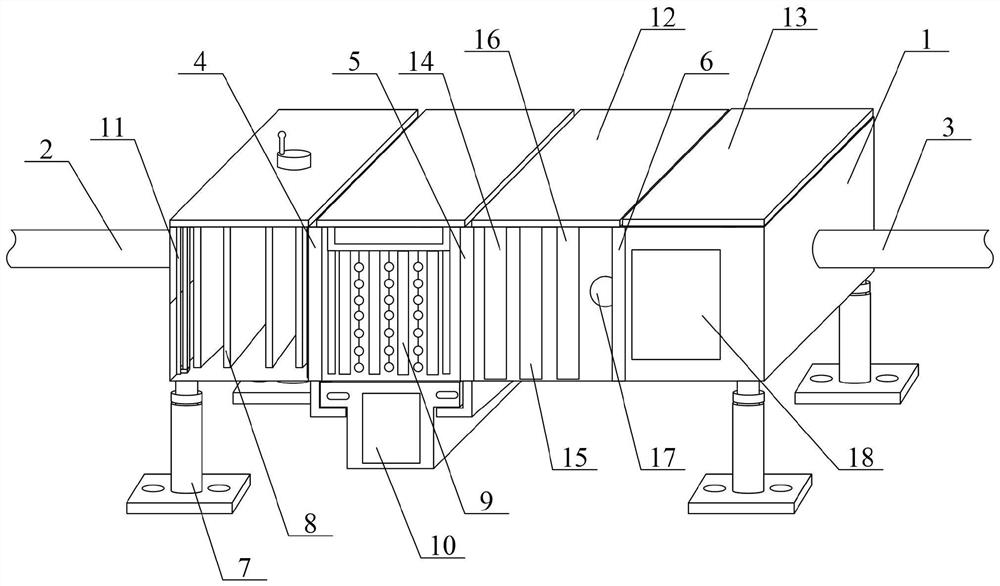

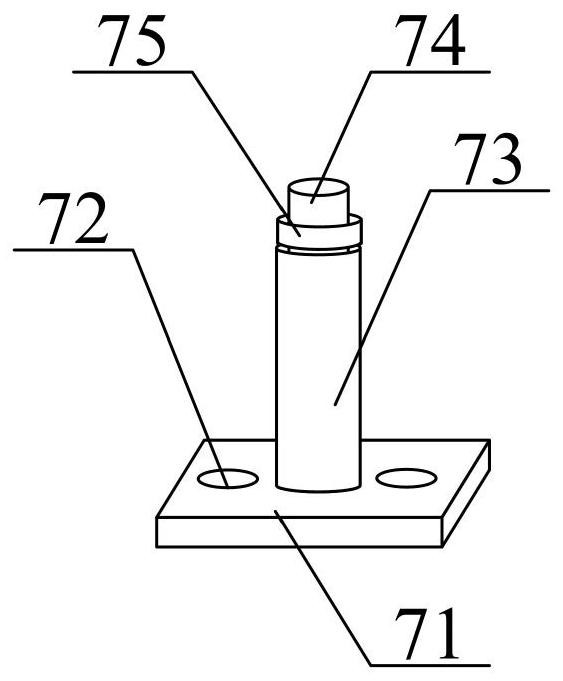

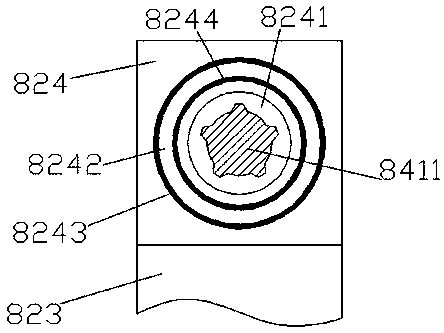

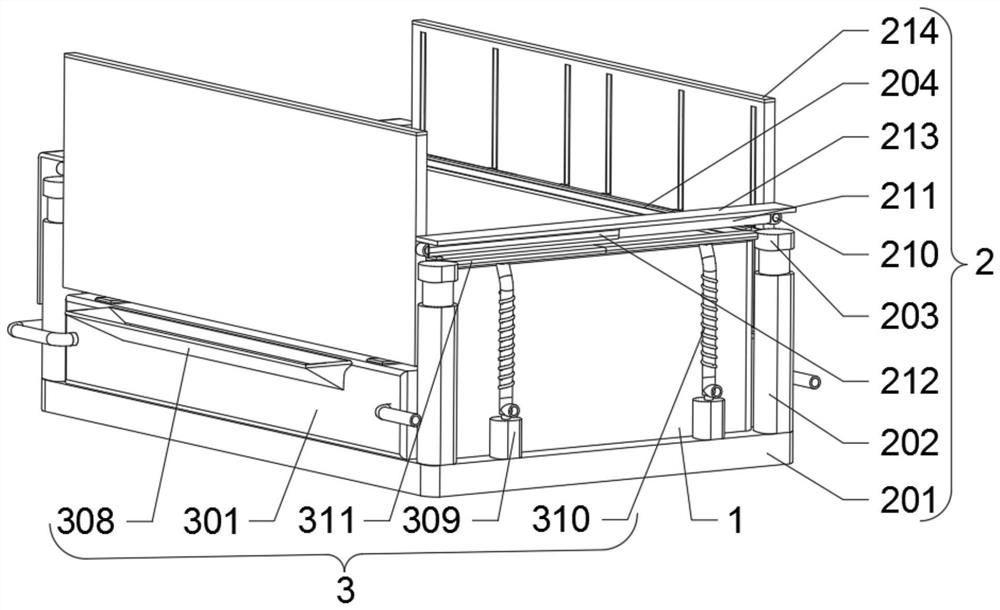

Novel full-automatic medicine ironing therapeutic apparatus

InactiveCN114869578AWell mixedEfficient mixingMedical devicesTherapeutic coolingMedicinal herbsInsulation layer

The invention is suitable for the technical field of medicine ironing treatment, and provides a novel full-automatic medicine ironing therapeutic apparatus which comprises a therapeutic apparatus box, a control panel used for controlling equipment is fixedly installed on the therapeutic apparatus box, a heat insulation layer used for heat preservation is arranged in the therapeutic apparatus box, and a transmission mechanism used for movement is arranged on the heat insulation layer. The transmission mechanism comprises a transmission assembly and a processing assembly, a clamping assembly used for clamping is arranged below the therapeutic apparatus box body, a twisting and flattening mechanism used for twisting and flattening a medicine bag is arranged below the therapeutic apparatus box body, and a stabilizing rod moves up and down in a reciprocating frame through shaking of a movable block; and at the moment, the movable block drives a twisting and flattening roller to vibrate and twist and flatten a medicine bag at the bottom, then medicinal materials in the medicine bag can be fully mixed, meanwhile, sprayed hot water can be effectively mixed with hot water through vibration, and the utilization rate of the medicinal materials is increased.

Owner:PEOPLES HOSPITAL OF HENAN PROV

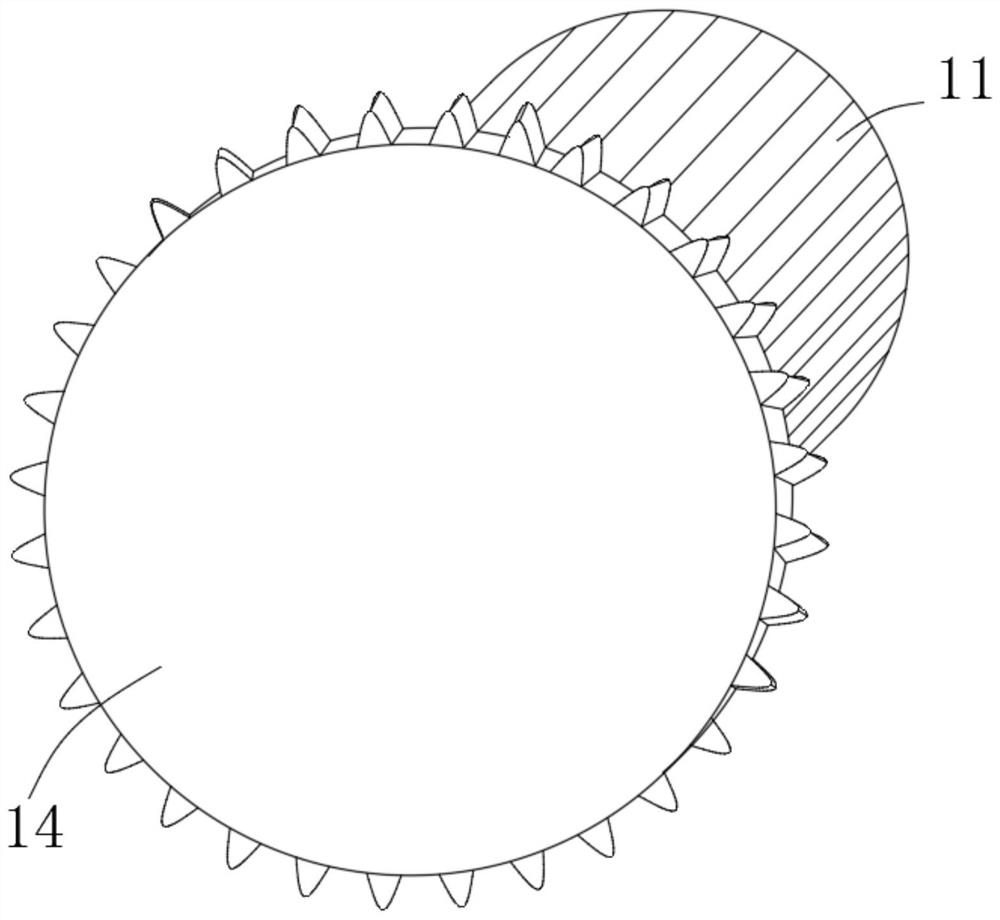

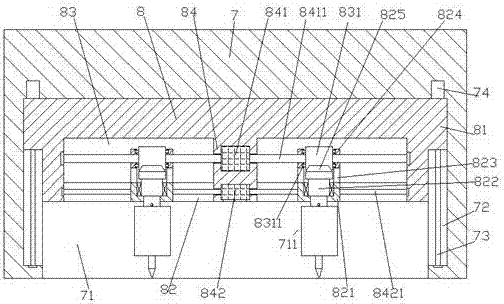

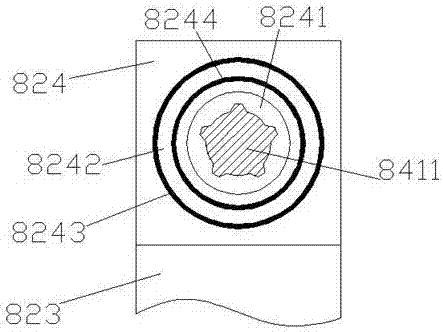

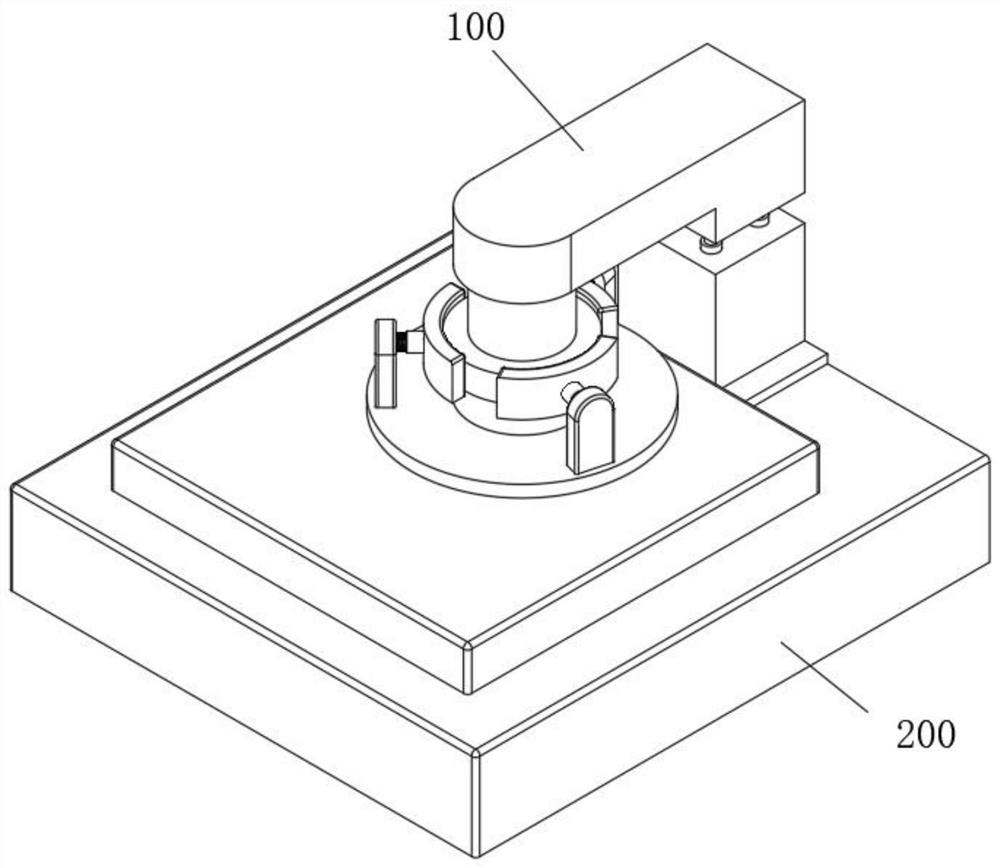

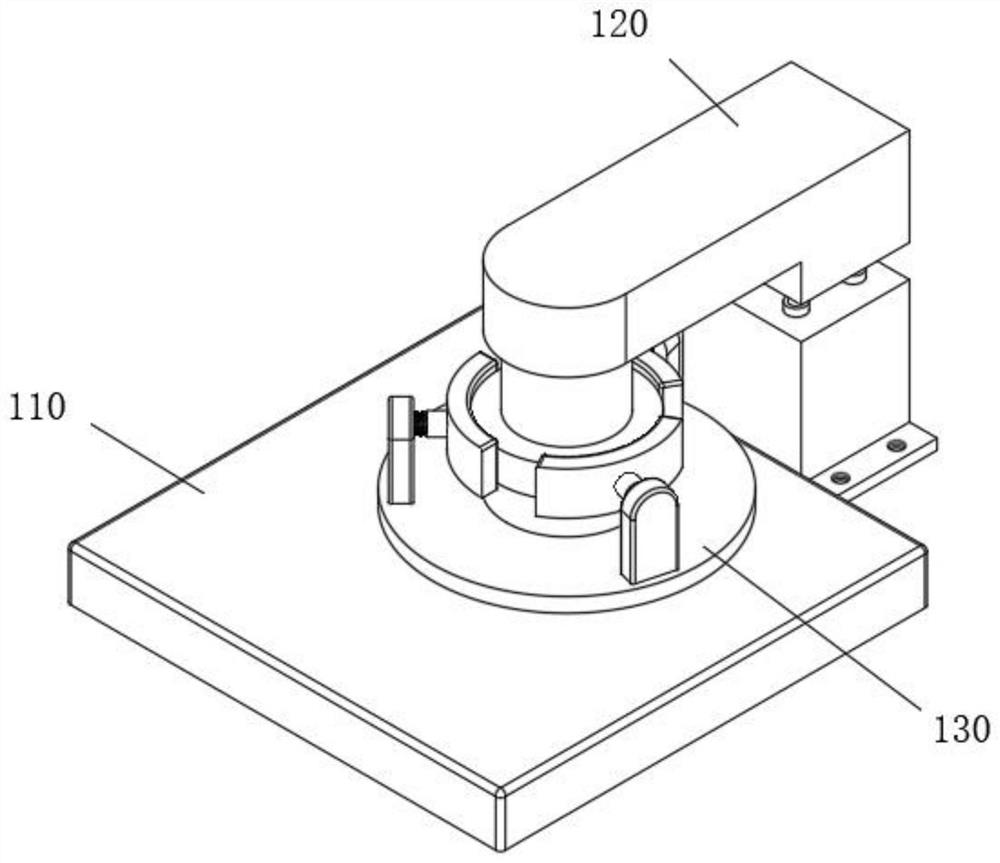

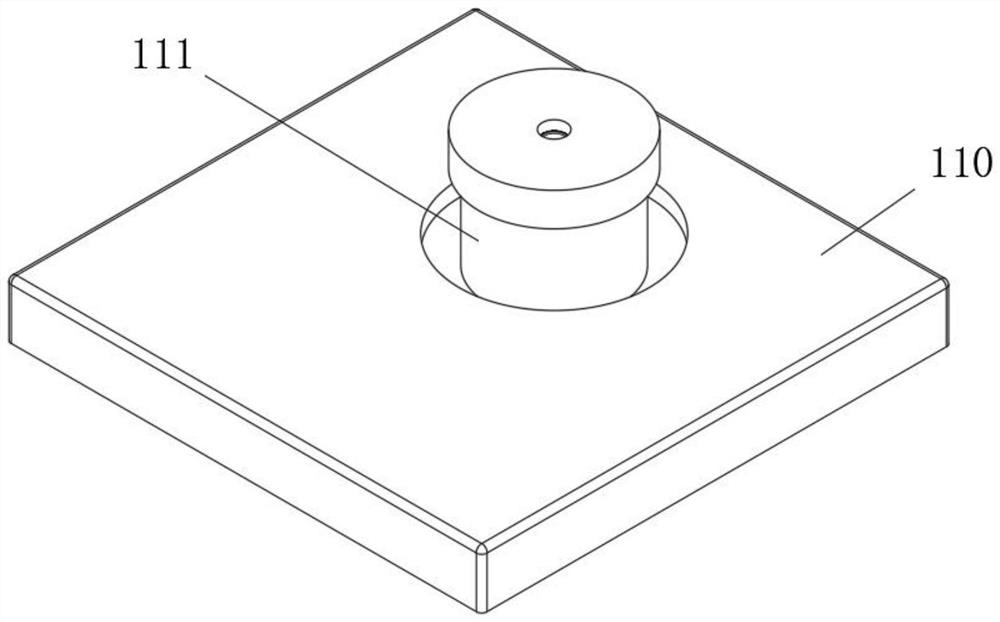

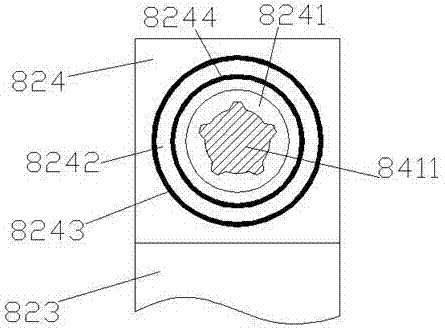

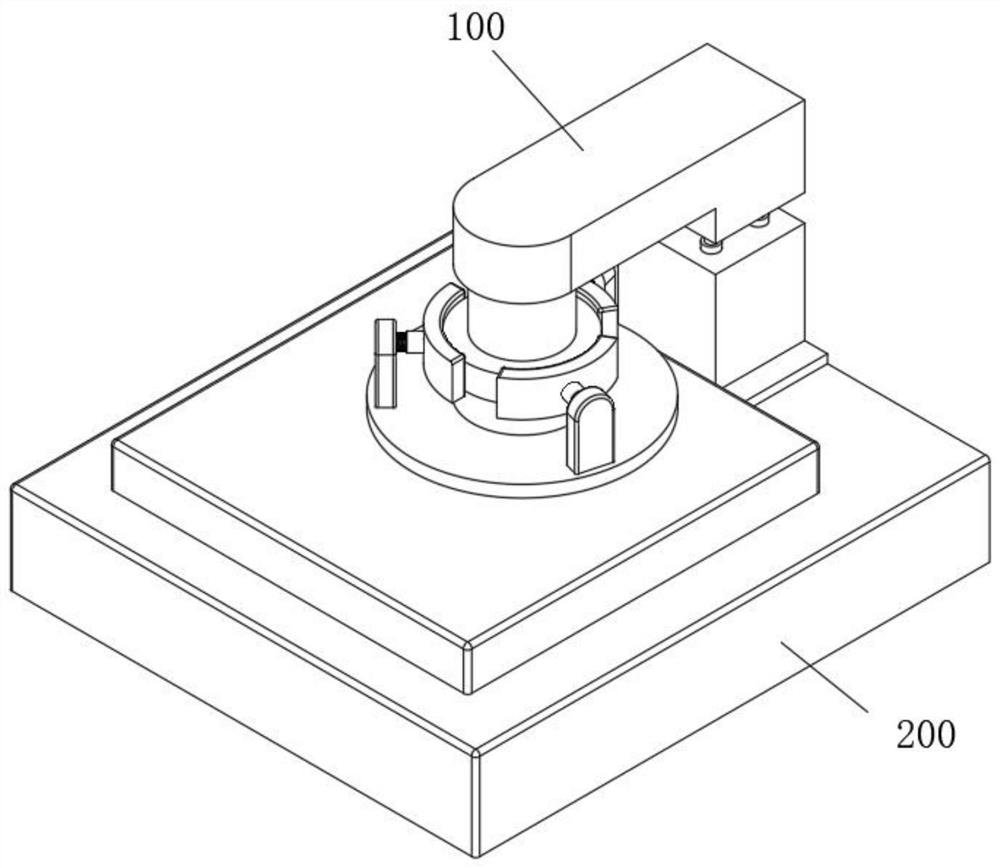

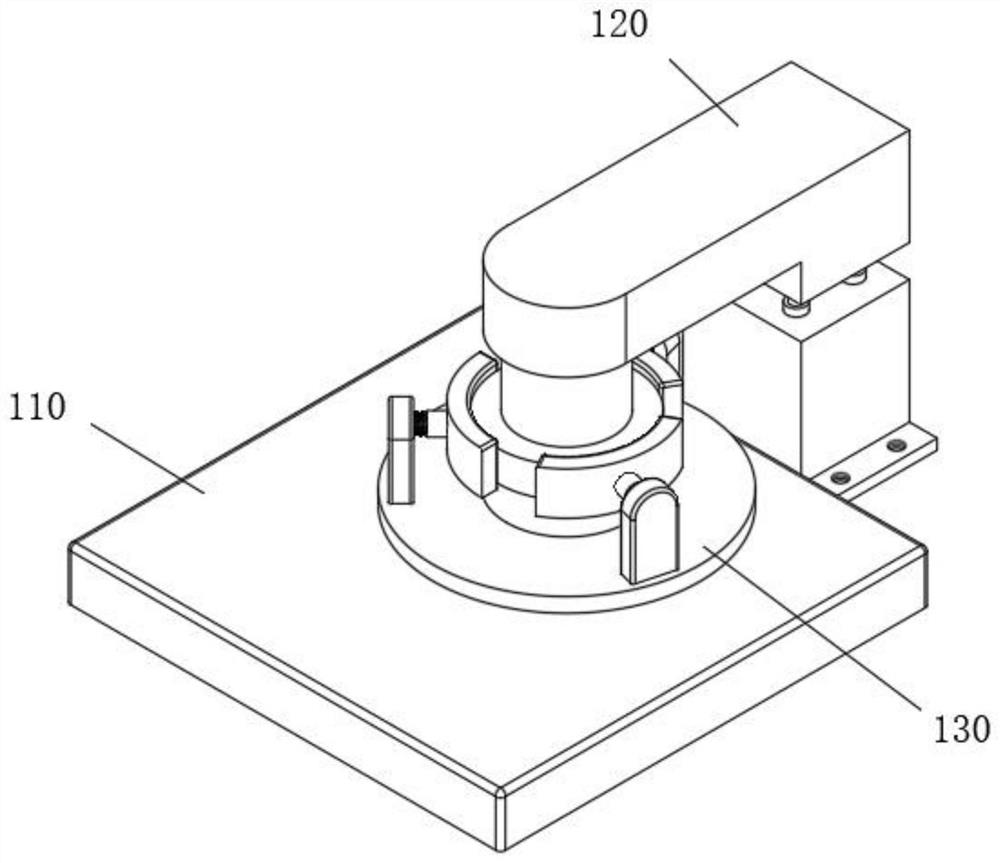

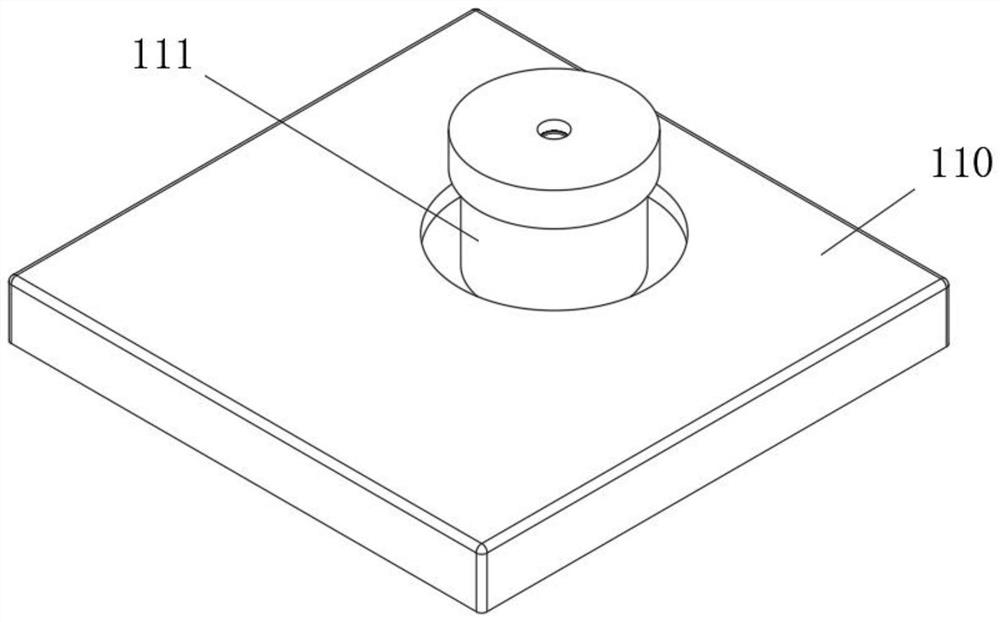

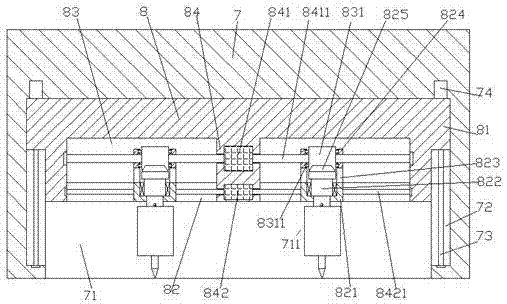

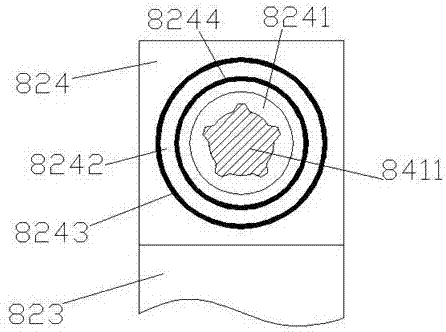

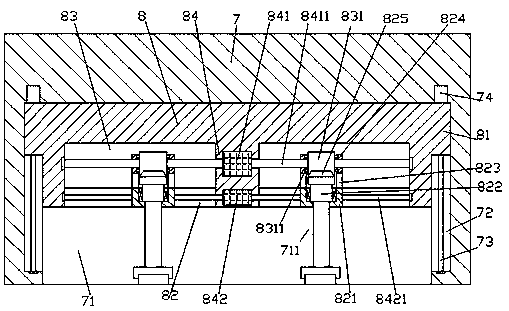

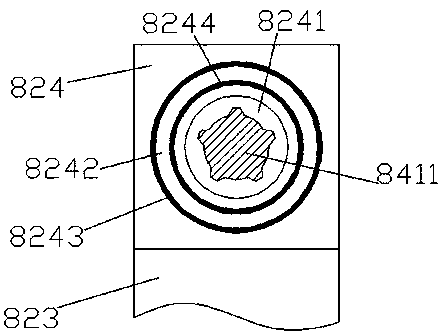

Molding grinding machine for grinding intelligent loudspeaker magnet

ActiveCN112743420AImprove stabilityAvoid affecting the grinding effectGrinding carriagesGrinding drivesCircular discGear wheel

The invention relates to a molding grinding machine, in particular to a molding grinding machine for grinding an intelligent loudspeaker magnet. The molding grinding machine comprises a base and a grinding mechanism installed above the base; in the molding grinding machine for grinding the intelligent loudspeaker magnet, double sides of a magnetic block can be clamped through an operation desk and a clamping device which are arranged, and the placed magnetic block can be stabilized conveniently through inserting cooperation of an inserting column and a magnetic block hole; through inserting cooperation of an inserting rod and an inserting hole, the clamped magnetic block can be conveniently stabilized once more; through multiple stabilizing work, the situation that the magnetic block is easy to shake during grinding and consequently the grinding effect is affected can be avoided; according to the grinding device arranged, a grinding motor works to drive a base gear to rotate, a disc is conveniently driven to rotate, and a grinding piece can be driven to rotate through rotation of the disc; and the magnetic block can be polished through friction between the polishing piece and the surface of the magnetic block.

Owner:湖南美磁科技有限公司

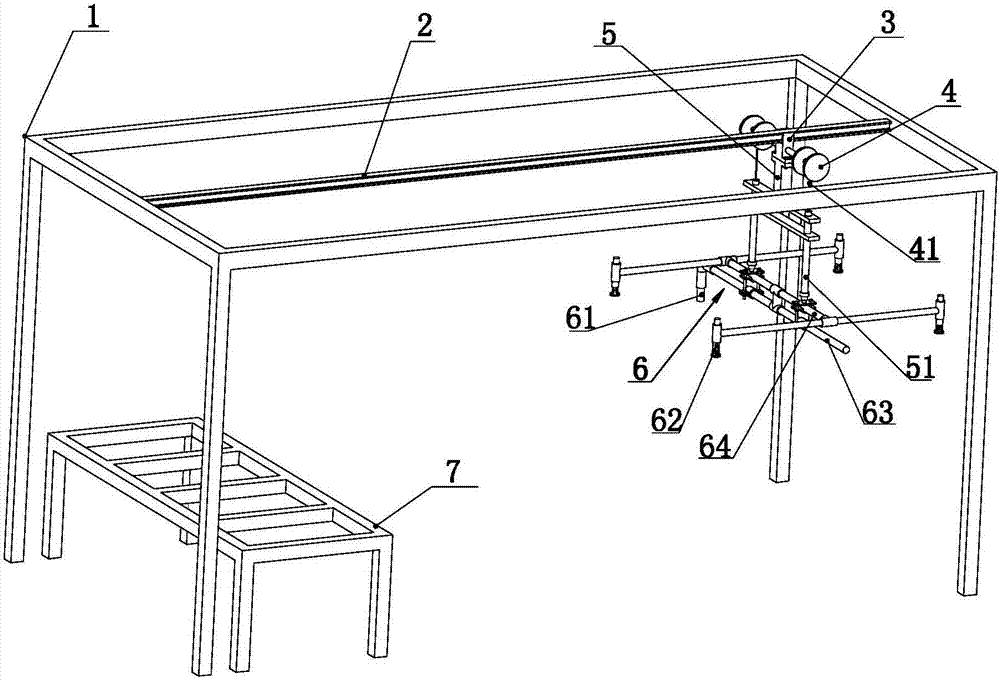

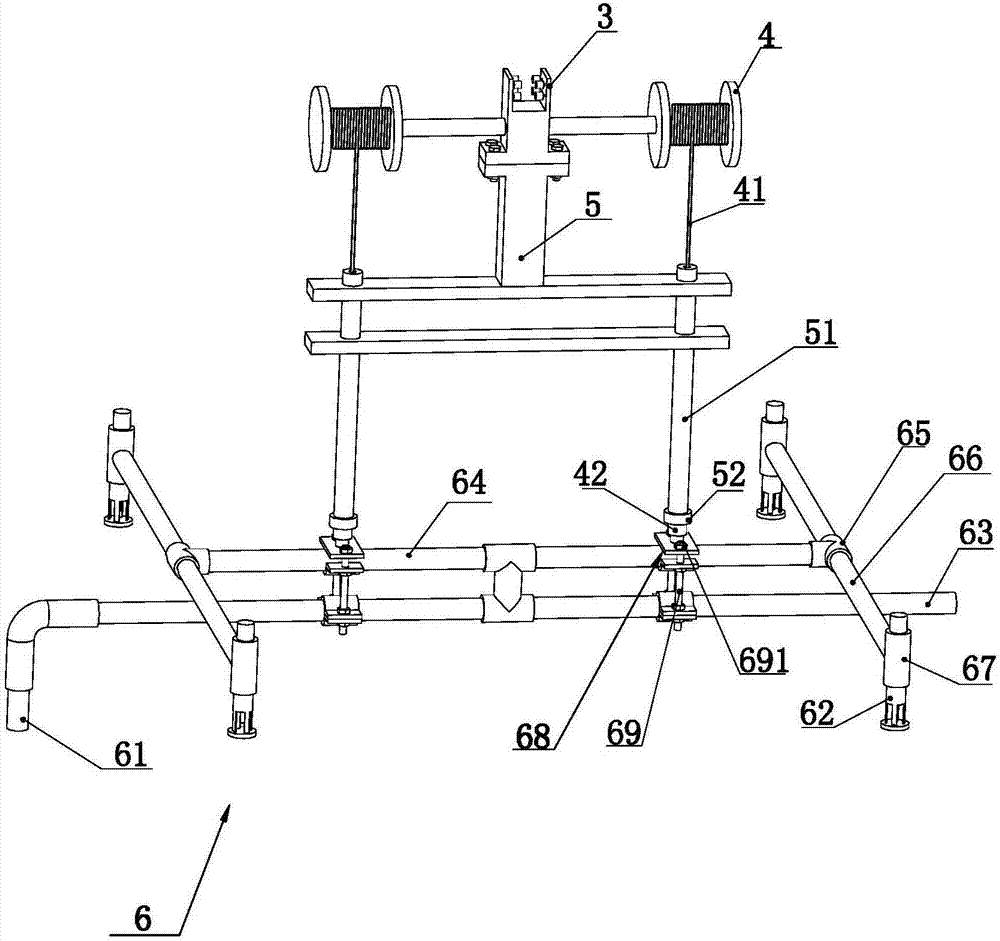

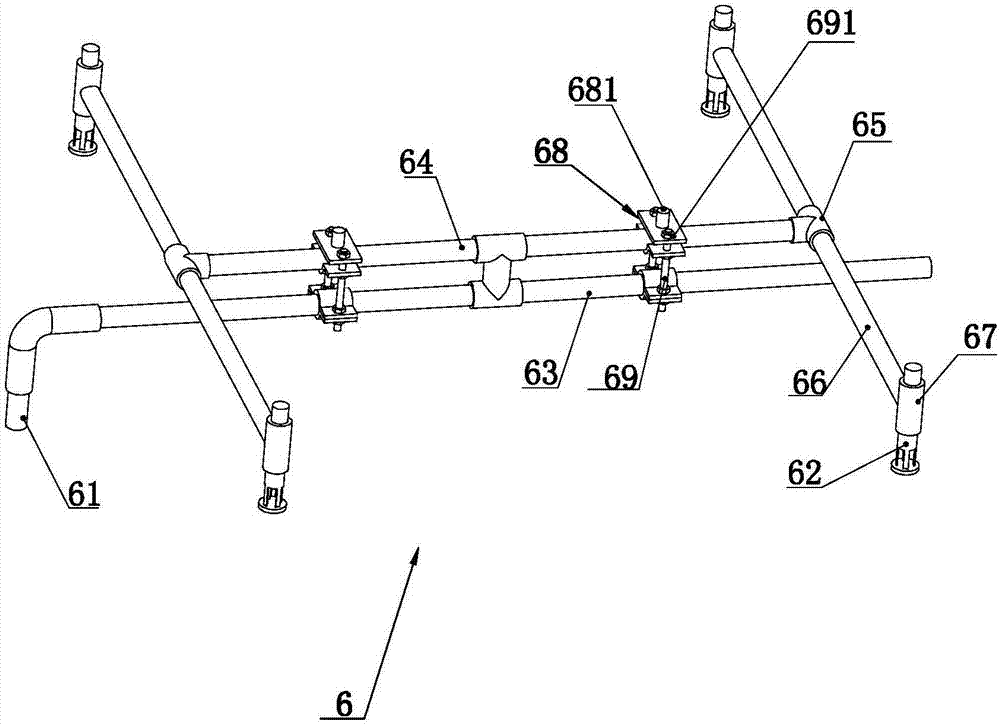

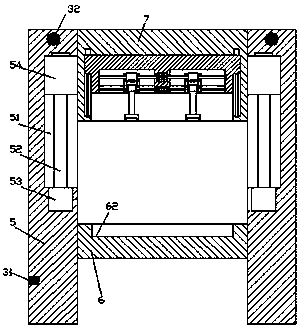

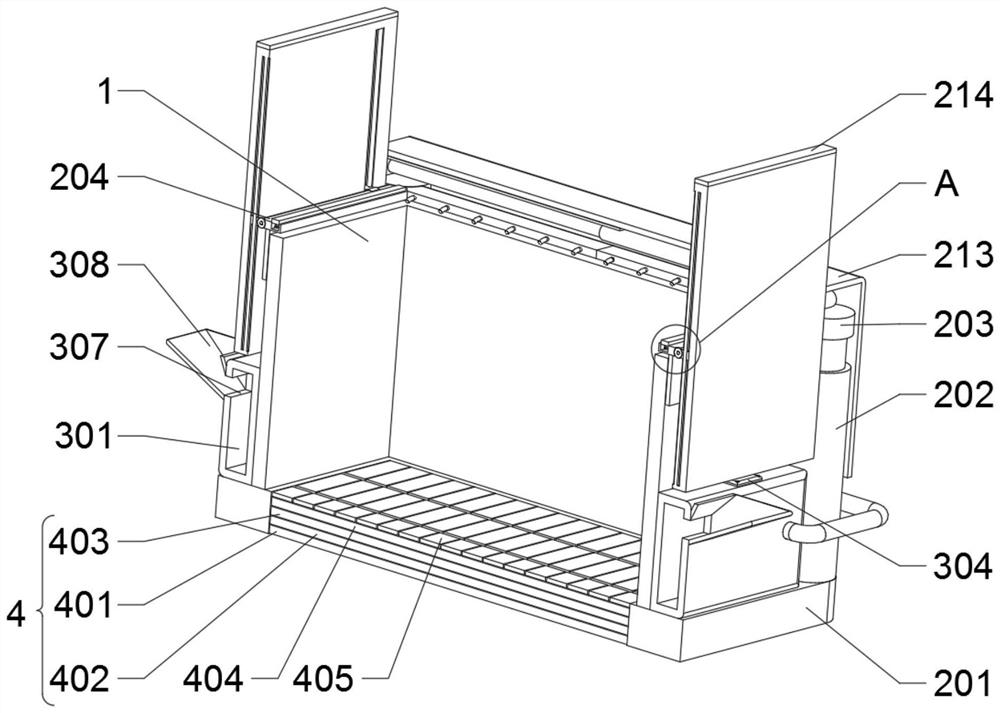

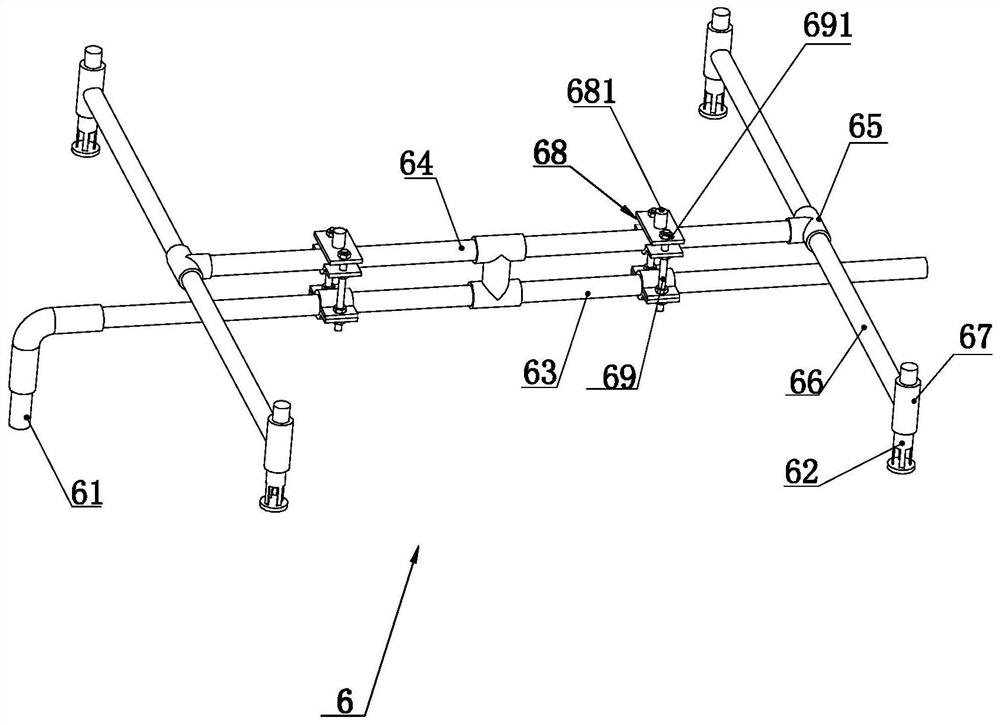

Water distribution device for fire sprinkler head

The invention discloses a water distribution device for a fire sprinkler head which solves the problem that climbing is required repeatedly in the process of detecting a nozzle. The water distribution device for the fire sprinkler head is characterized by comprising a traveling crane, a coil-winding machine, a lifting frame and a sprinkler head frame, wherein the traveling crane comprises a crane body; the coil-winding machine is connected with the crane body and comprises at least one coil winding wheel; each coil winding wheel is respectively wound with steel wire ropes; the lifting frame comprises at least one wire penetrating pipe; each wire penetrating pipe is respectively and vertically arranged; the lower end of each wire penetrating pipe is respectively connected with limiting barrels; each steel wire rope is respectively connected with suspension devices on a part which is positioned below the wire penetrating pipes; each suspension device respectively comprises a limiting block; the sprinkler head frame comprises a water inlet pipe for supplying water and a plurality of sprinkler heads used for experiment. The water distribution device for the fire sprinkler head has the beneficial effect that detection work of the sprinkler heads is successfully carried out while the phenomenon that working personnel is required to climb repeatedly is avoided.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

Safe material polishing equipment

InactiveCN107695857AReasonable designImprove work efficiencyGrinding carriagesPolishing machinesEquipment useEngineering

The invention discloses safe material polishing equipment. The safe material polishing equipment comprises frame bodies correspondingly arranged on the left and right sides, and a chassis fixed between the inner sides of the frame bodies on the left and right sides; polishing parts are arranged between the inner sides of the frame bodies on the left and right sides above the chassis; first slidinggrooves are formed in the bottom end surfaces of the polishing parts; polishing sliding blocks are smoothly matched and connected into the first sliding grooves; second sliding grooves are formed inthe bottom end surfaces of the polishing sliding blocks; transfer cavities, arranged in a communicating manner, are formed in the tops of the second sliding grooves; division plates upwards expandingare arranged between the second sliding grooves; the top expansion parts of the division plates penetrate into the transfer cavities, and the tail ends are fixedly connected with the top ends in the transfer cavities; the division plates divide the second sliding groove into a left guide groove and a second guide groove and divide the transfer cavity into a left transfer cavity and a right transfer cavity; and a first electric rotating machine is arranged in the division plate between the left guide groove and the right guide groove. The safe material polishing equipment is simple in structureand reasonable in design, improves the working efficiency, and improves the equipment use safety.

Owner:南宁盛世凌云电子科技有限公司

Central air conditioner fresh air purification device

ActiveCN112212425AEasy to clean upEasy to change jobsMechanical apparatusLighting and heating apparatusFresh airEngineering

The invention provides a central air conditioner fresh air purification device. The device comprises a purification box, an air inlet pipe, a fresh air outlet pipe, a first hollowed-out plate, a second hollowed-out plate, a partition plate, an adjustable locking fixing base structure, a rotatable lifting filter frame cover structure, an impingement drying frame structure, an observable drawing cleaning box structure, a U-shaped sliding rail, a first fixing cover, a second fixing cover, a primary filter, a negative ion generator, an electrostatic dust collector, an fresh air fan and an efficient filter. Through arrangement of a first sealing cover, a rotating rod, a pushing rod, a first filter screen, an L-shaped sliding rod, a threaded fixing pipe and the purification box, the pushing rodcan be grasped to rotate during working, and through threaded connection of the rotating rod and the threaded fixing pipe, the first sealing cover drives the first filter screen to move upwards, the first filter screen can be cleaned and replaced conveniently in the using process, and meanwhile lifting work is achieved.

Owner:嘉兴和禹净化科技有限公司

Unmanned aerial vehicle throwing type displacement monitoring device based on navigation system

PendingCN113804139AReal-time monitoring of displacement changesRealize lifting workSatellite radio beaconingEnergy efficient board measuresElectrical batteryUncrewed vehicle

The invention relates to an unmanned aerial vehicle throwing type displacement monitoring device based on a navigation system, and belongs to the technical field of geographic detection devices. The device comprises: a positioning part composed of a shell, a mounting base, a positioning assembly, a balancing weight and a battery, wherein the shell has a cavity, the cavity wall of the cavity is a spherical inner wall, the bottom surface of the mounting base is a spherical outer wall, the mounting base is mounted in the cavity, the bottom surface of the mounting base is attached to the inner wall of the cavity, the balancing weight is mounted on the mounting base, the positioning assembly and the battery are both mounted on the balancing weight, the positioning assembly is provided with an upward antenna, the battery is electrically connected with the positioning assembly, and the navigation system is in communication connection with the reference part and the positioning assembly; and a regular tetrahedron frame, wherein a connecting rod is arranged in the regular tetrahedron frame, the shell is installed in the regular tetrahedron frame through the connecting rod, a hook is arranged on the regular tetrahedron frame, a block is suspended on the unmanned aerial vehicle, a vertical hole is formed in the top end of the block, the hook is hooked in the vertical hole, each surface of the regular tetrahedron frame is provided with a solar cell panel, and the battery is electrically connected with the solar cell panels.

Owner:国家电网有限公司西南分部

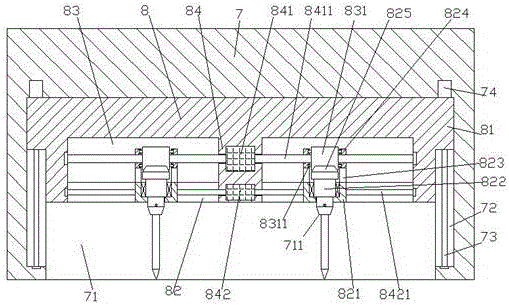

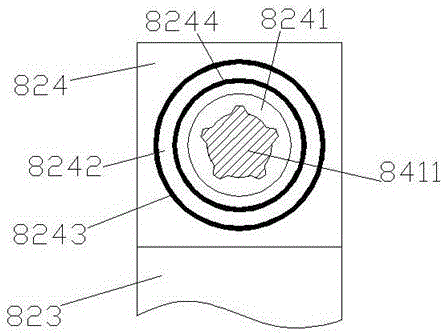

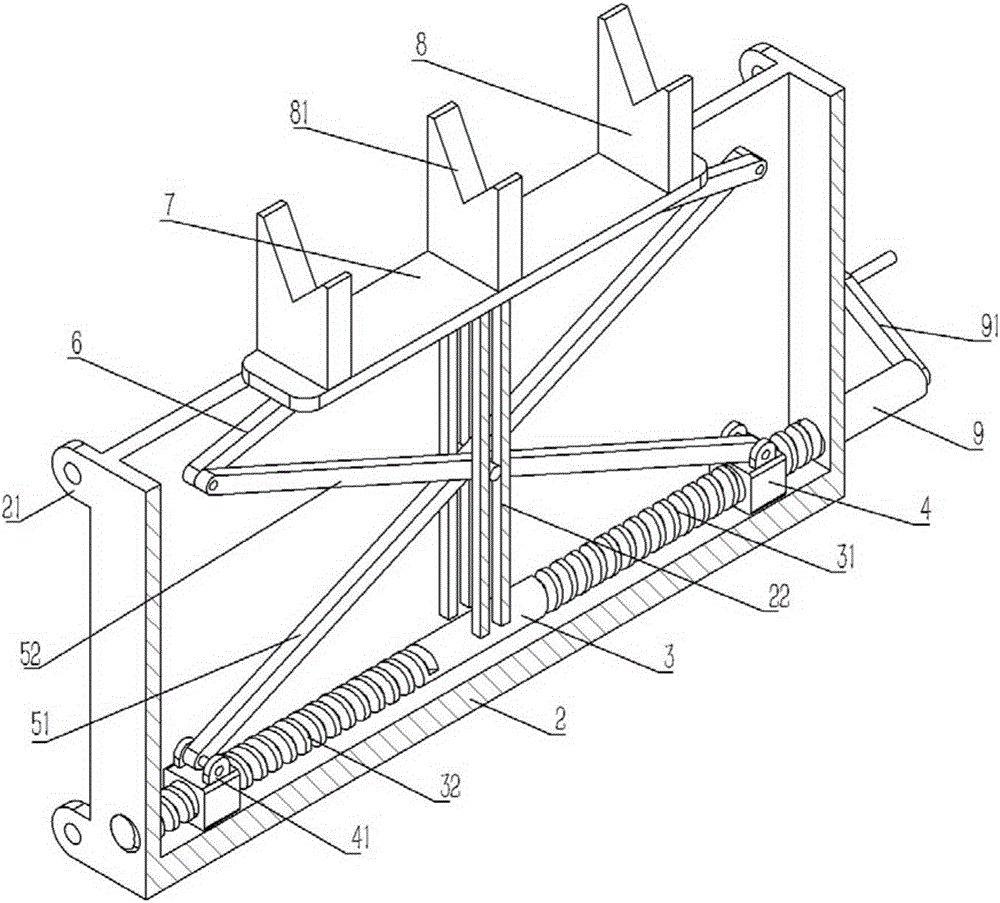

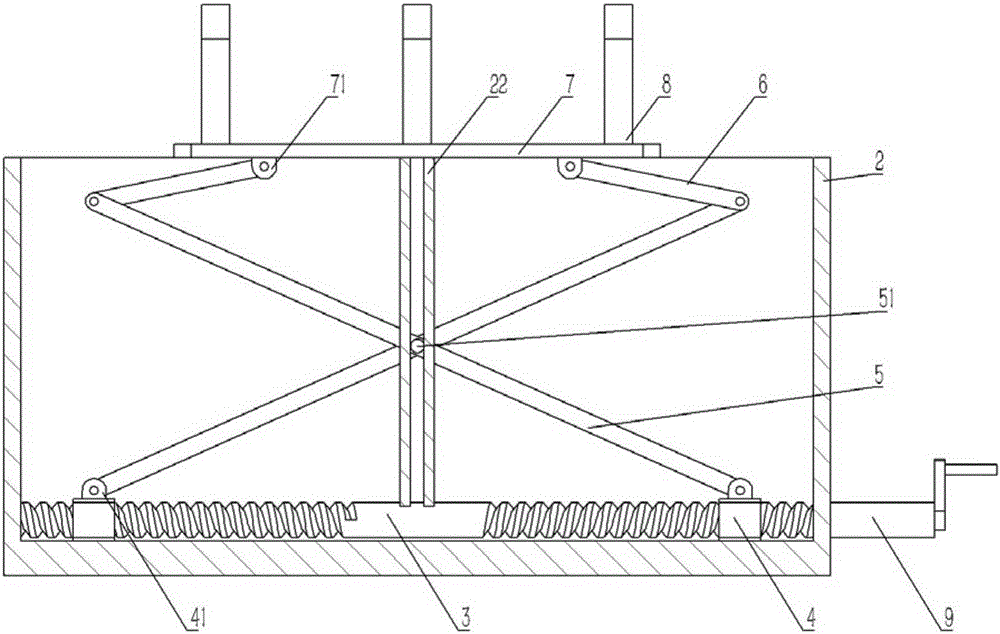

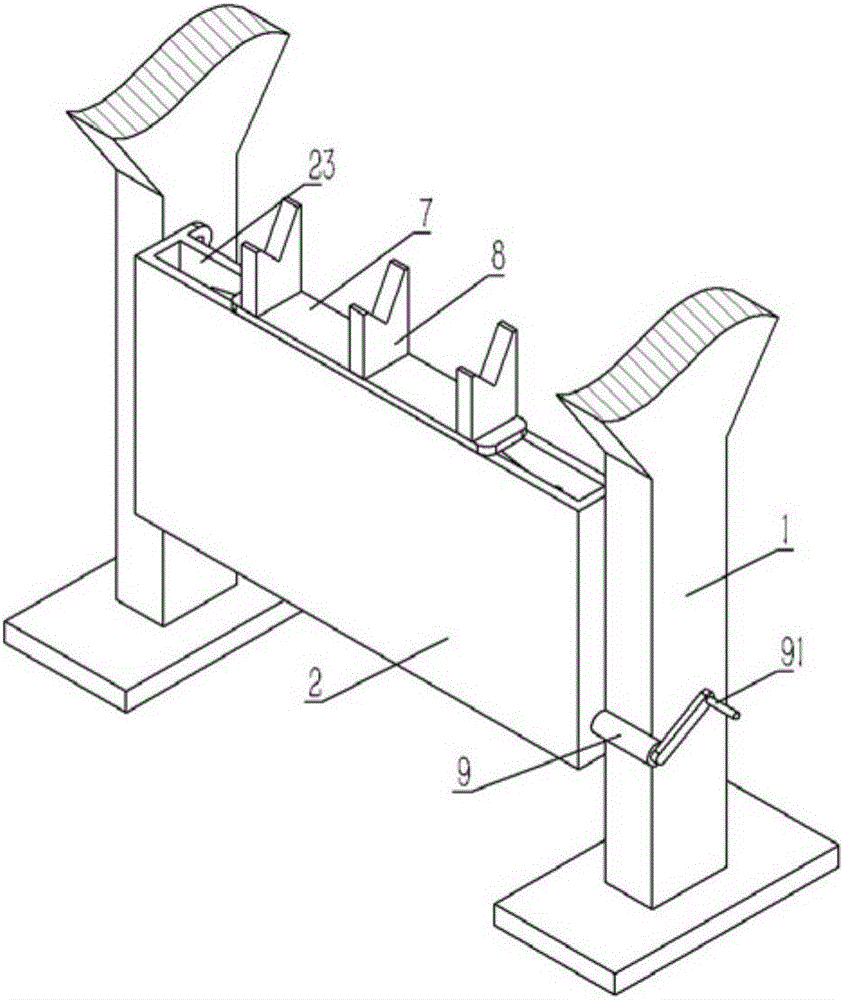

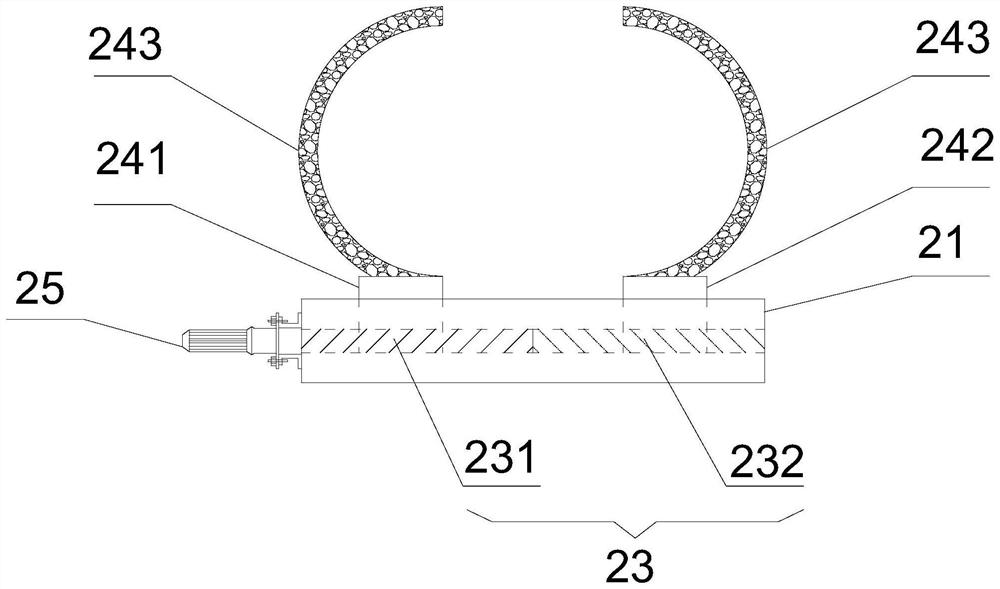

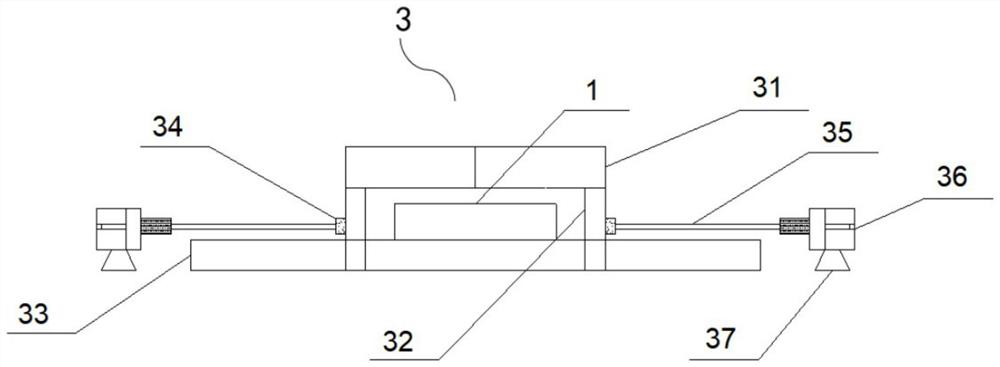

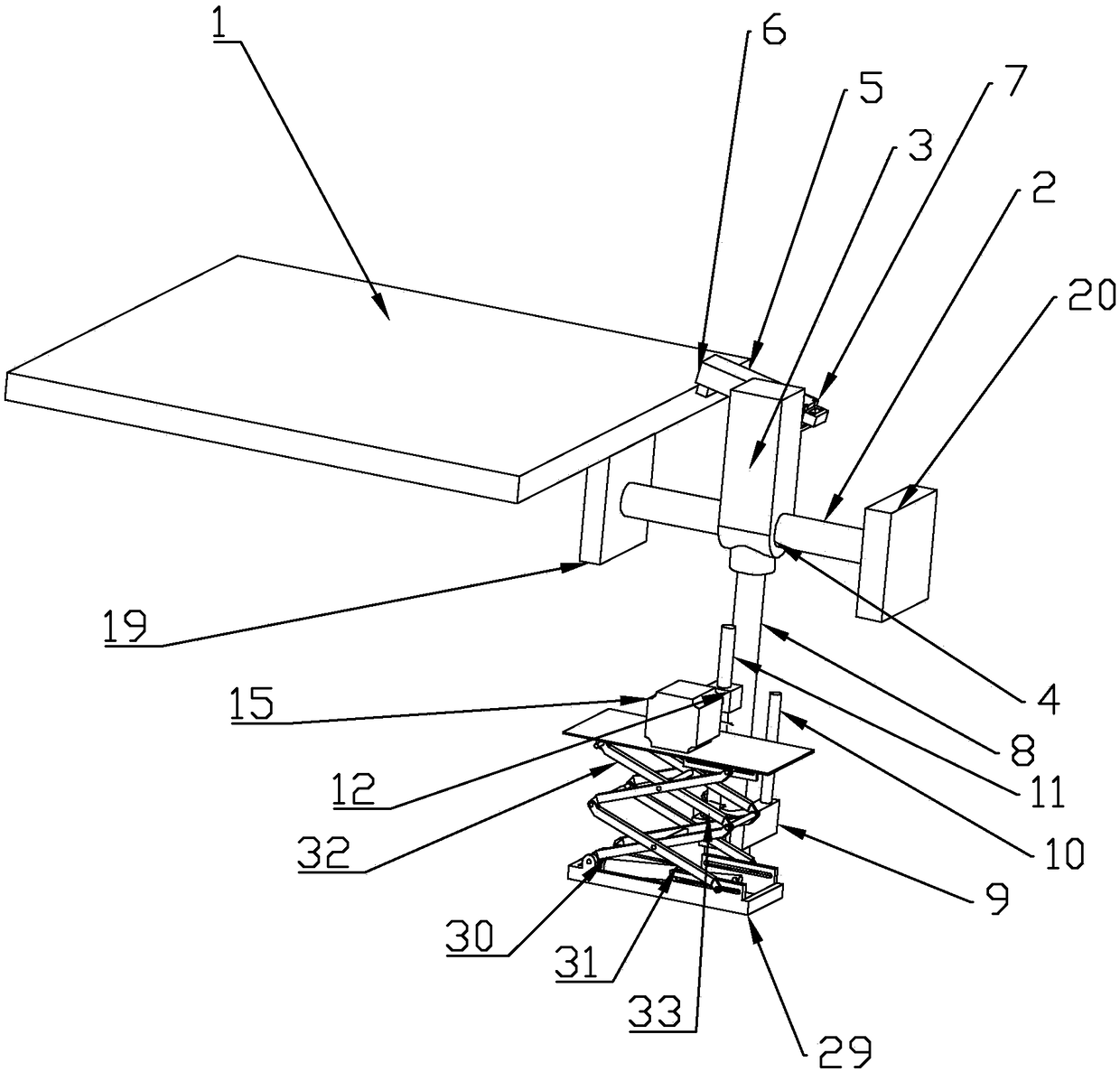

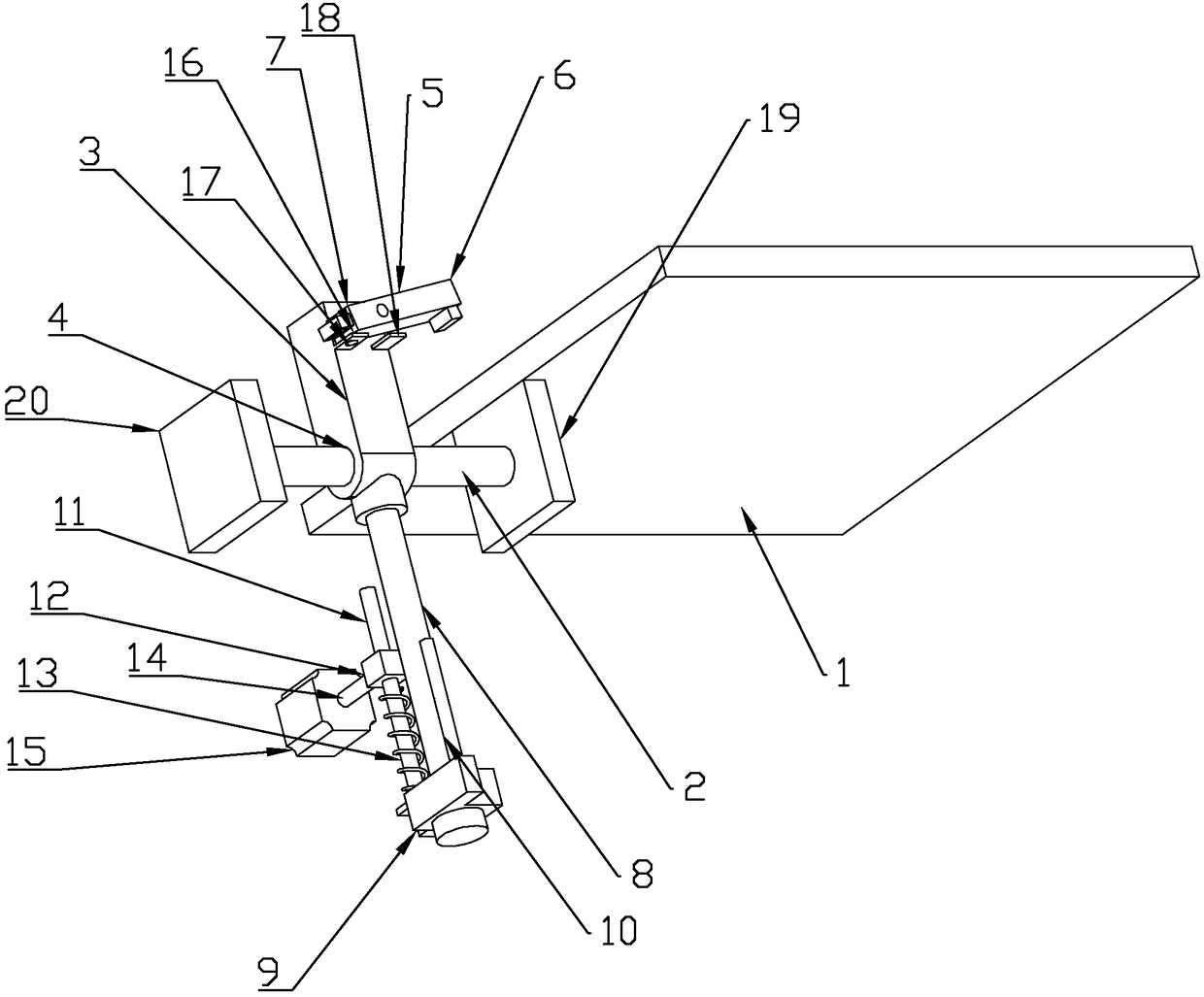

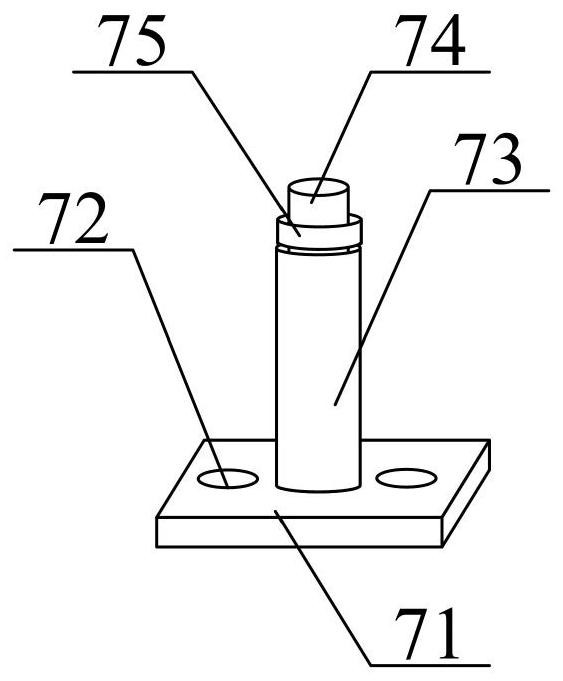

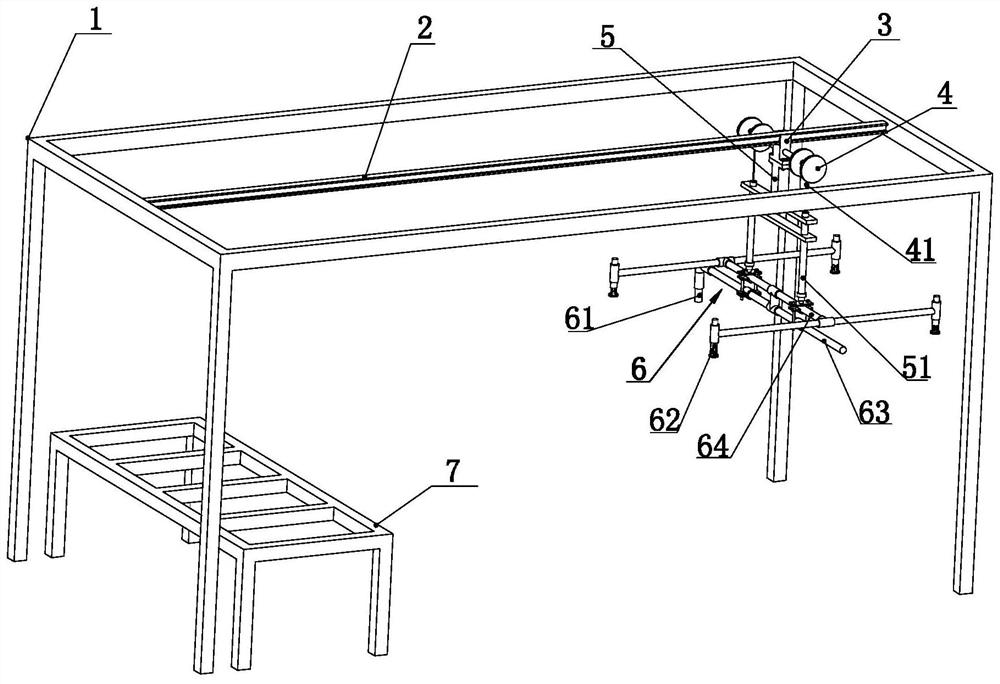

A roll changing bracket for a multi-axis textile winding device

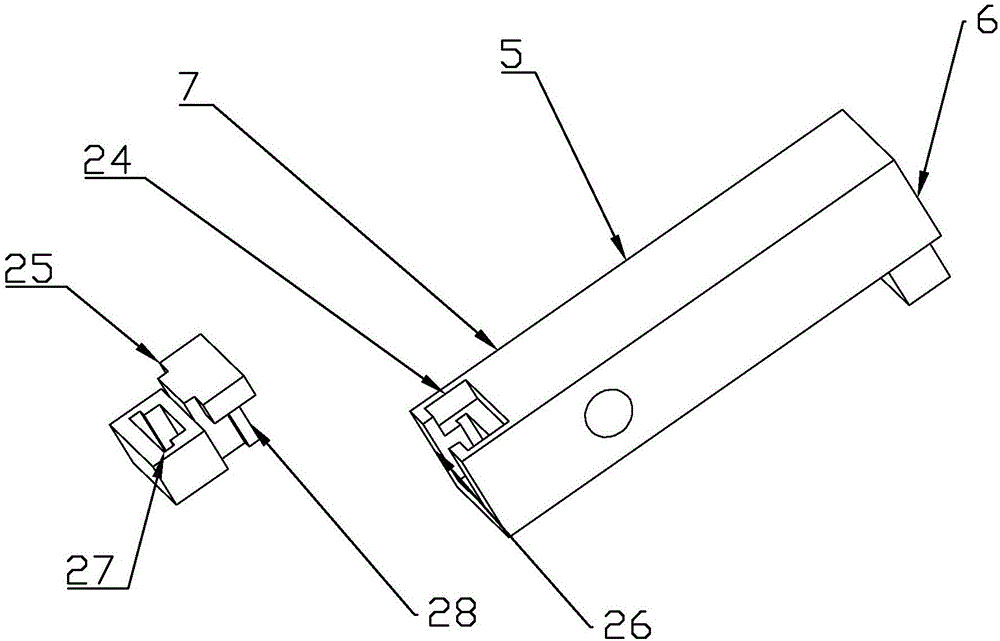

ActiveCN103964242BQuickly implement lifting workRealize lifting workWebs handlingEngineeringScrew joint

The invention discloses a roller changing supporting frame of a multi-shaft spinning winding device. The roller changing supporting frame comprises two supporting columns, a rectangular support is fixed between the supporting columns, a rotary shaft is hinged to the interior of the rectangular support, left-hand threads and right-hand threads are formed at the two ends of the rotary shaft respectively, rectangular sliding blocks are in screw joint with the two ends of the rotary shaft respectively, first hinge supports are formed on the rectangular sliding blocks, long connecting rods are hinged to the first hinge supports of the two ends of the rotary shaft, the middles of the two long connecting rods are hinged together through a pin shaft, short connecting rods are hinged to the other ends of the long connecting rods, the short connecting rods are hinged to second hinge supports, the second hinge supports are fixed to the lower bottom face of a carrier plate, a plurality of vertical supporting plates are fixed to the carrier plate, and V-shaped groove openings are formed in the upper ends of the supporting plates. One end of the rotary shaft is fixedly connected with a connecting shaft, and the other end of the connecting shaft penetrates through the supporting columns and is fixedly provided with a handle. The lifting work of fully winding rollers can be achieved fast and manually, and winding roller replacement is facilitated, and work efficiency is improved.

Owner:南通格瑛纺织品有限公司

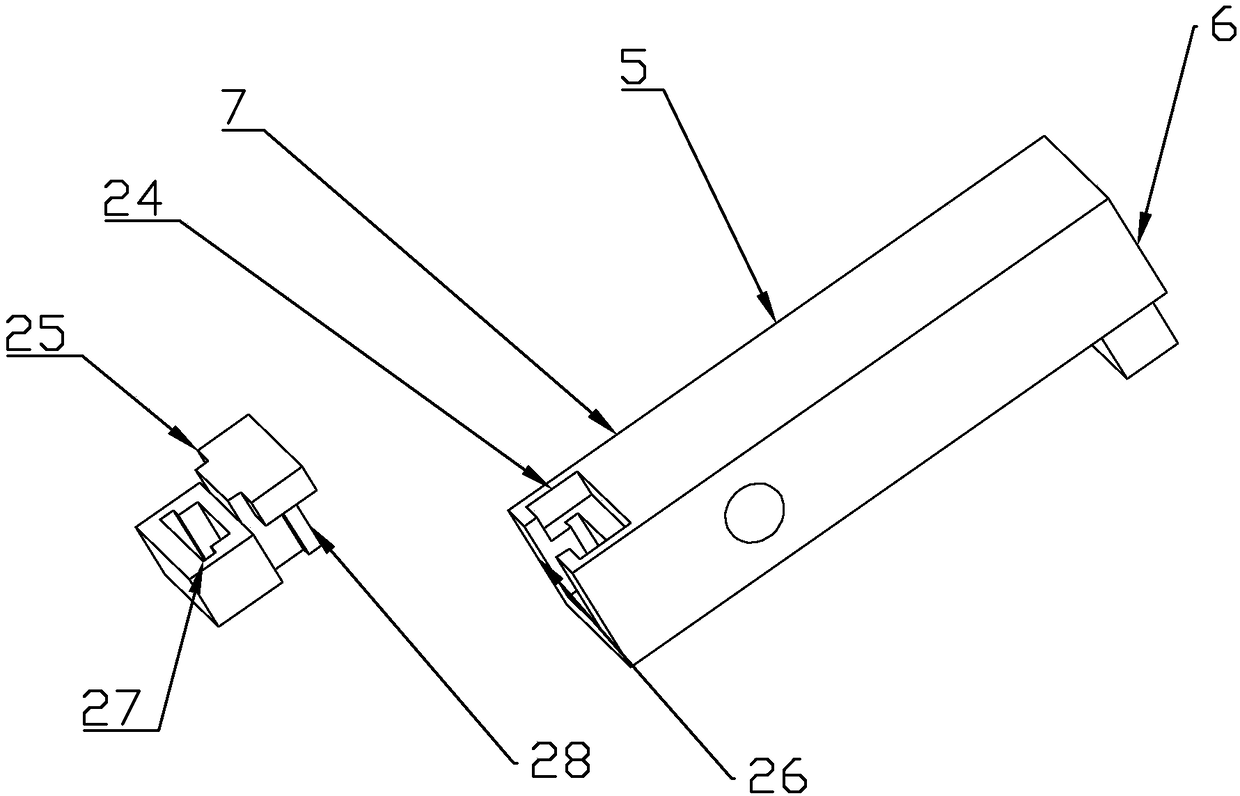

Clamp structure with three-dimensional machining function

ActiveCN106113160AAchieve liftingRealize lifting workMulti-purpose machinesWork benchesEngineeringMechanical engineering

The invention discloses a clamp structure with a three-dimensional machining function. When the distance is shortened, under the action of driving force of a rotary mechanism, the end, close to a second slide block, of a linkage rod moves towards a third slide block. When the distance is increased, under the action of a first spring, the end, close to the second slide block, of the linkage rod moves away from the third slide block. When the first slide block slides to a mounting table to abut against the mounting table, under the limiting action of the mounting table, the first slide block cannot continue to move and then cannot continue to move on a rail strip, and at the same time, the rotary mechanism continues to rotate, so that the second slide block moves on a slide bar so as to be close to the first slide block; an ejector rod arranged on the second slide block moves towards a clamping block at the same time, finally, the ejector rod abuts against the gravity end, the clamping end moves towards the mounting table, and therefore the clamping end clamps a board arranged on the mounting table. In this way, the board is prevented from being damaged by too large clamping force in the clamping process.

Owner:丰县正海金属科技有限责任公司

Novel multifunctional paint spraying equipment

InactiveCN107335565AReasonable designImprove work efficiencySpraying apparatusAgricultural engineeringEquipment use

The invention discloses a new type of multi-functional painting equipment, which comprises correspondingly arranged brackets on the left and right sides and a base fixed between the inner sides of the left and right brackets, and a painting device is arranged between the inner sides of the left and right brackets above the base. The bottom end surface of the paint spraying device is provided with a first slide groove, and a paint spray slide block is connected in translation in the first slide groove, a second slide groove is provided in the bottom end surface of the paint spray slide block, and a There is a transmission chamber connected to each other, and an upwardly expanded partition board is provided between the second slide grooves. The top extension of the partition board is pushed into the transmission chamber and the tail side is fixedly connected to the top of the transmission chamber. The partition board connects the first The second slide groove is divided into a left guide groove and a right guide groove and the transmission chamber is divided into a left transmission chamber and a right transmission chamber, and a first power device is arranged in the partition plate between the left guide groove and the right guide groove; The invention has simple structure and reasonable design, improves work efficiency and improves the safety of equipment use.

Owner:深圳绿淋环保科技有限公司

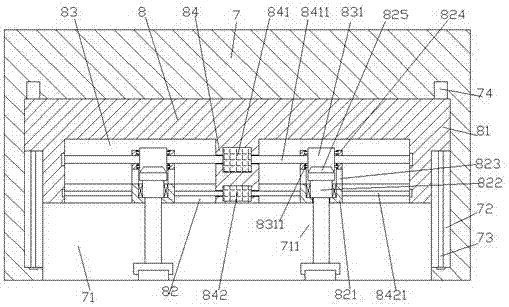

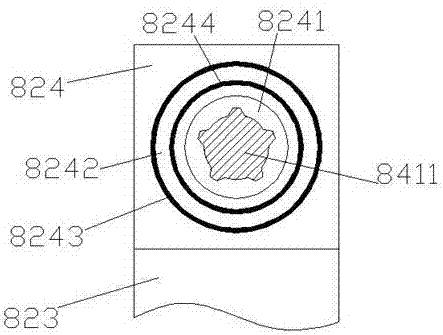

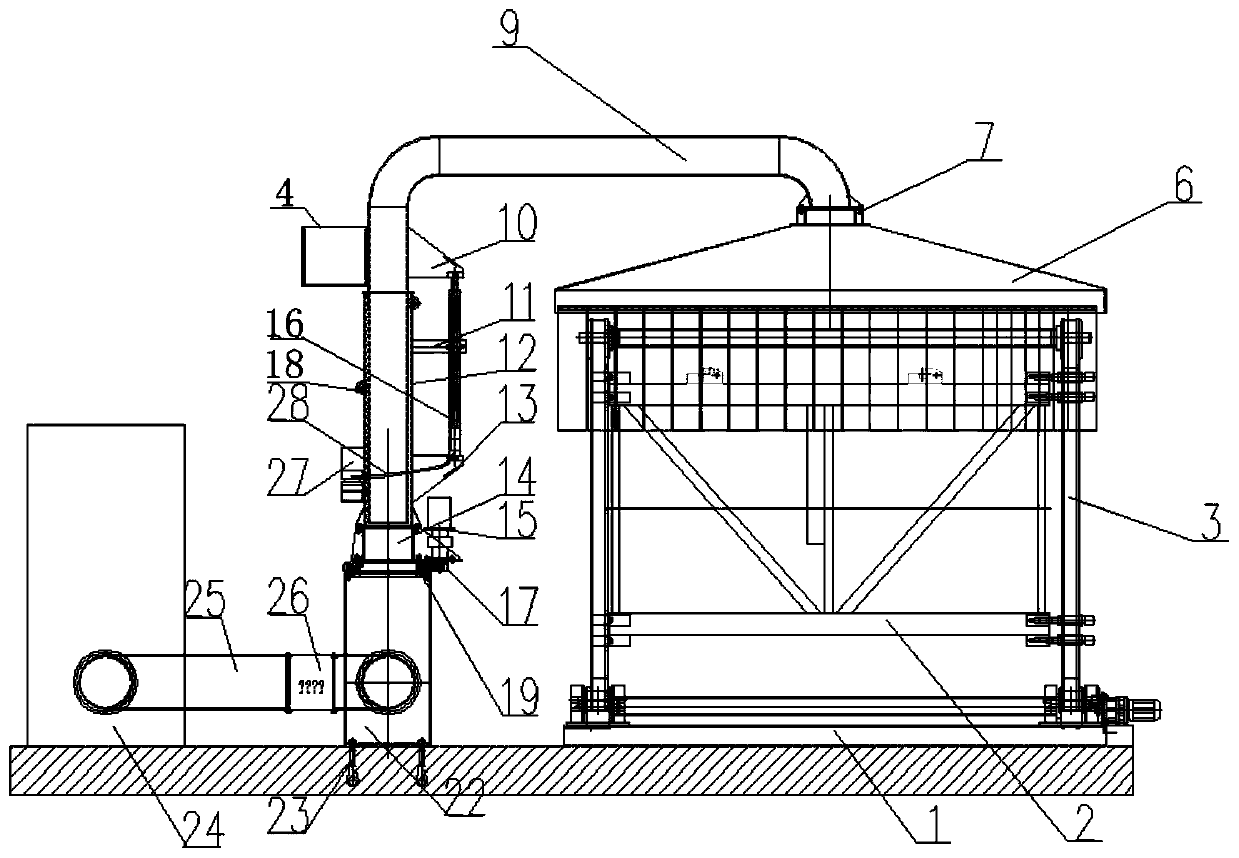

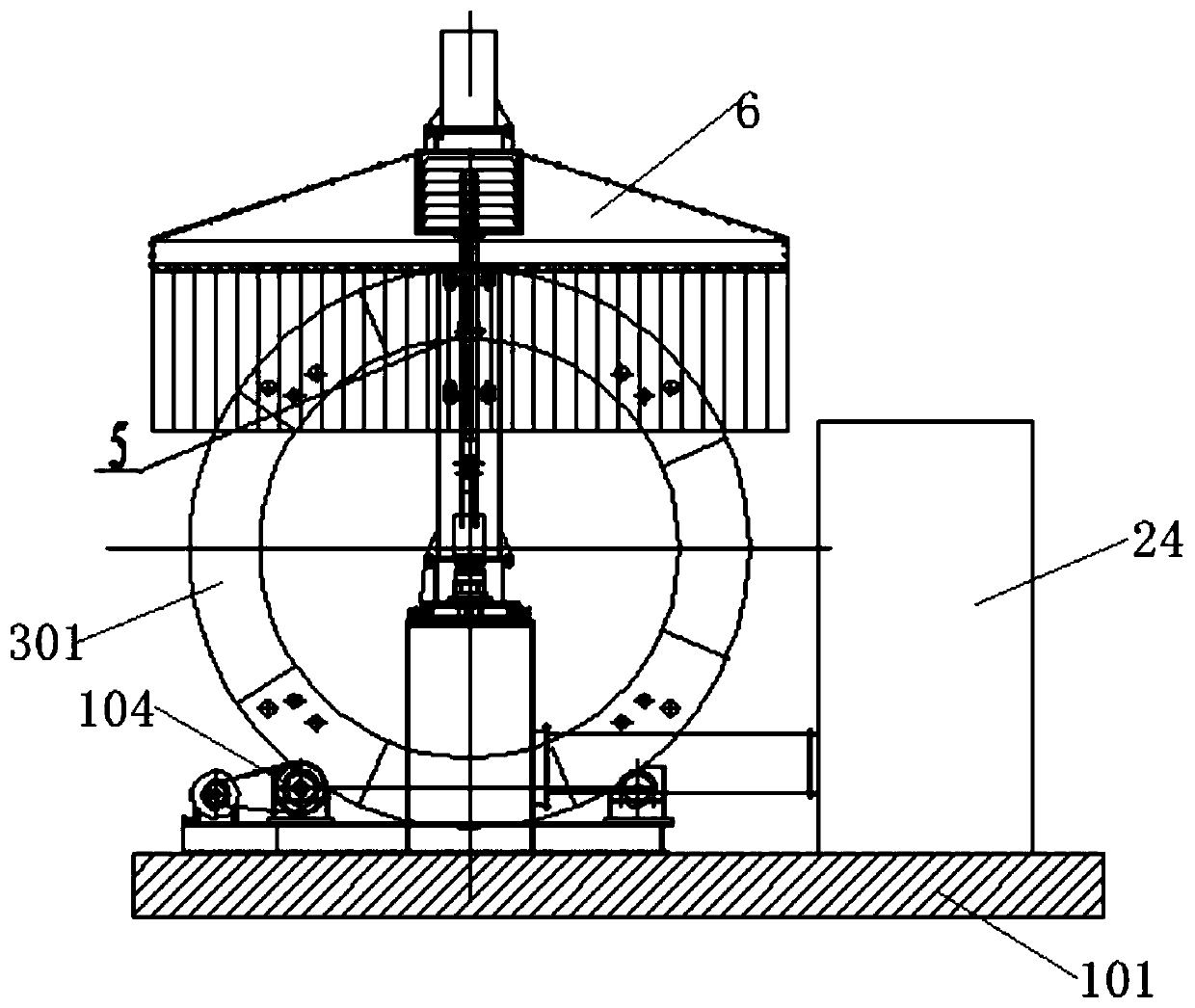

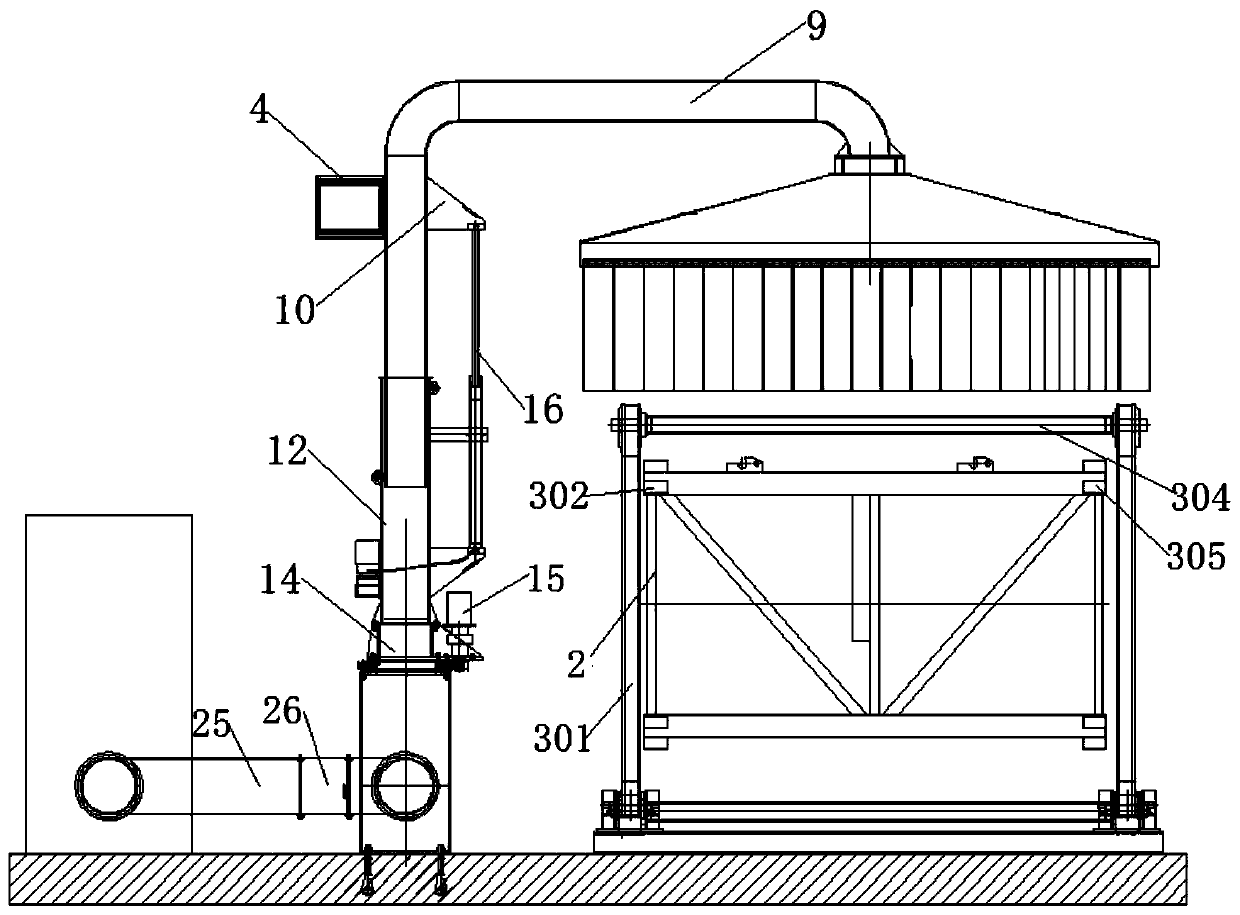

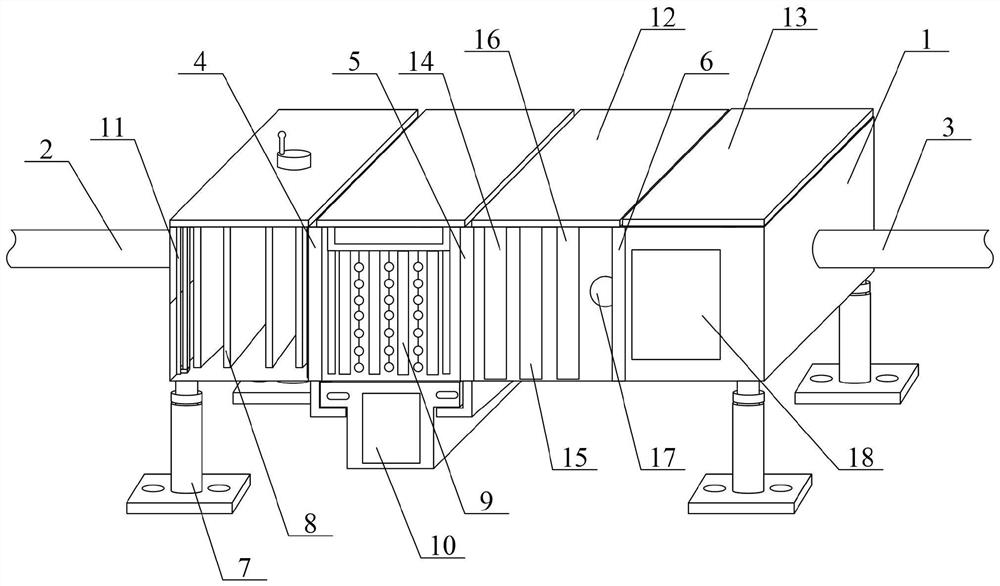

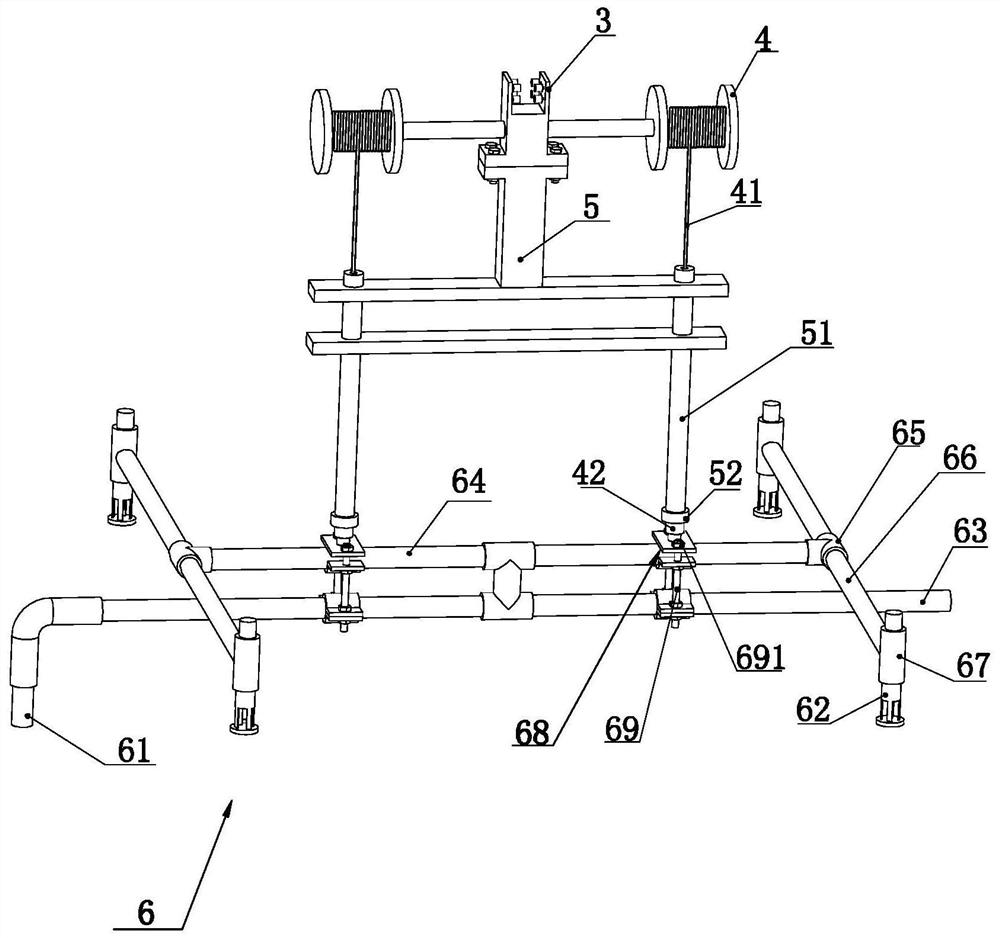

Tower crane standard joint welding device and method

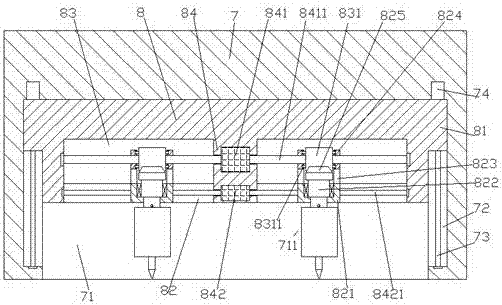

PendingCN110280939AStable supportEasy to take outWelding/cutting auxillary devicesAuxillary welding devicesEngineeringTower crane

The invention discloses a tower crane standard joint welding device and a method. The tower crane standard joint welding device and the method solve the problems that a standard joint welding tool in the prior art is large in floor area, and smog generated due to welding harms the human body health, and have the beneficial effects that dust can be effectively removed and the welding precision and quality are improved. According to the scheme of the tower crane standard joint welding device, the tower crane standard joint welding device comprises a bottom frame, a positioning mold and a smoke collecting hood, wherein the bottom frame supports a rotating mechanism; the positioning mold is used for positioning a main limb of a to-be-welded standard joint, and the rotating mechanism is in contact with the positioning mold so that the positioning mold can be driven to rotate due to rotation of the rotating mechanism; the smoke collecting hood is used for collecting soot generated due to welding from the position above the positioning mold and / or the side portion; the smoke collecting hood communicates with a pipeline; an outer pipeline is inserted into one side of the pipeline to be arranged; a lifting mechanism is arranged between the pipeline and the outer pipeline, and the outer pipeline is connected with a slewing mechanism; and through the slewing mechanism and the lifting mechanism, the pipeline is driven to lift and rotate, so that the standard joint where welding is completed is elevated from the positioning mold.

Owner:SHANDONG DAHAN CONSTR MACHINERY

Fan hub hanger with rotational locking mechanism and using method thereof

ActiveCN103010932BAchieve angleRealize lifting workLoad-engaging elementsLocking mechanismEngineering

The invention discloses a fan hub hanger with a rotational locking mechanism and a using method thereof. The fan hub hanger with the rotational locking mechanism comprises a ring, an upper connection module, an intermediate connection module, a lower connection module, a claw module and a rotational locking mechanism, wherein the ring is fixed right above the upper connection module which is connected with the intermediate connection module; the intermediate connection module is connected with the claw module which is fixed on the lower connection module; the rotational locking mechanism is mounted right below the upper connection module; and a slot matched with the rotational locking mechanism is formed on the upper surface of the lower connection module. The invention further discloses a using method for the fan hub hanger with the rotational locking mechanism. The fan hub hanger has the advantage that a worker does not need to ascend to transport a hub.

Owner:CRRC WIND POWER(SHANDONG) CO LTD

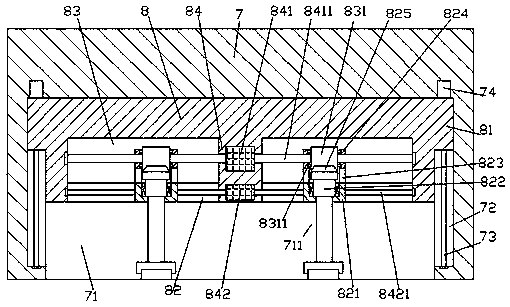

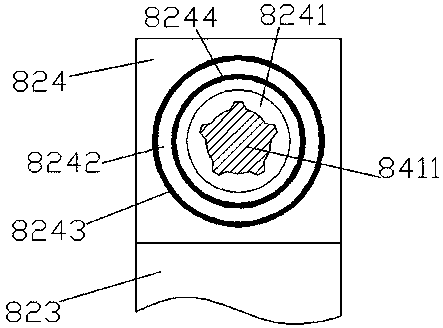

A communication base station charging pile integration device

ActiveCN111318484BRealize lifting workConvenient lifting workCleaning using toolsElectric machineEngineering

The cleaning device of the present invention includes an opening and closing mechanism, a cleaning assembly fixedly connected with the opening and closing mechanism; the cleaning assembly includes a lifting mechanism, and a moving mechanism fixedly connected with the lifting mechanism; the lifting mechanism includes a vertical column fixedly connected with the opening and closing mechanism, The first driving motor fixed between the vertical columns, the threaded column connected with the output shaft of the first driving motor, the nut sleeved on the threaded column and threadedly connected with the threaded column, and the horizontal rails fixedly connected with both ends of the nut Rod, the first telescopic rod positioned between the cross bar and the vertical column; one end of the first telescopic rod is fixedly connected to the cross bar, and the other end of the first telescopic rod is fixedly connected to one end of the vertical post; the lifting mechanism also includes a support rod, and a fixed horizontal block; one end of the support rod is fixedly connected with the horizontal bar, and the other end of the support rod is fixedly connected with the fixed horizontal block. The cleaning work of the communication tower body of the present invention not only has high automation, but also has high efficiency, saves manpower and time.

Owner:江西长林鑫源通信科技有限公司

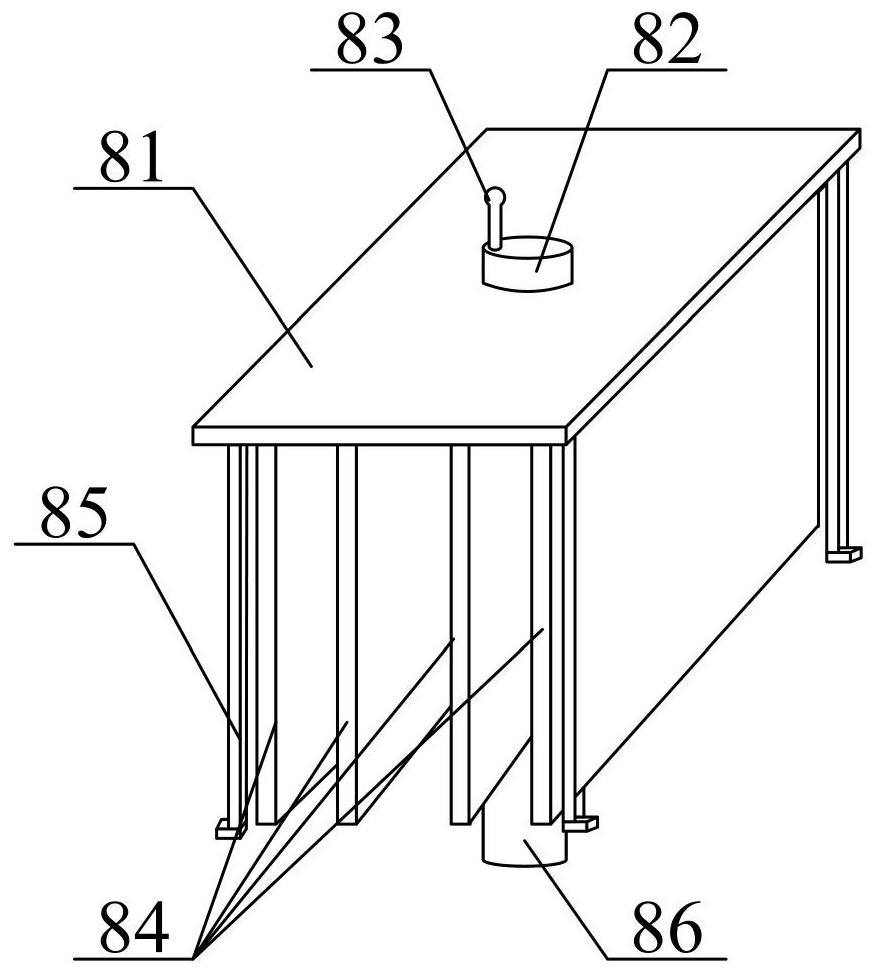

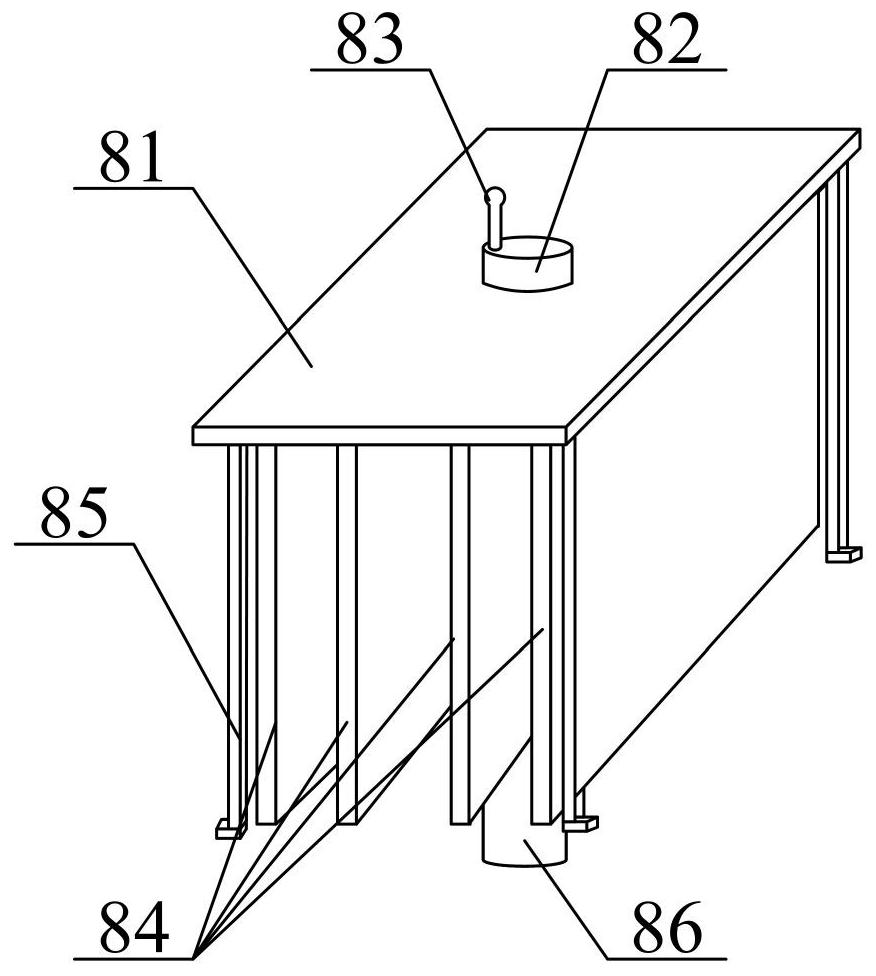

A stainless steel freezer rack for conveniently taking freezer boxes

InactiveCN111568054BRealize lifting workEasy accessVariable dimension cabinetsFittingClassical mechanicsStructural engineering

Owner:THE SECOND AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

A forming grinder for grinding magnets of intelligent audio speakers

ActiveCN112743420BImprove stabilityAvoid affecting the grinding effectGrinding carriagesGrinding drivesCircular discGear wheel

The invention relates to a forming mill, in particular to a forming mill for grinding magnets of intelligent audio speakers. It includes a base and a grinding mechanism installed above the base. This is used in a forming grinder for smart audio speaker magnet grinding. The operating table and clamping device are provided to clamp the magnetic block on both sides. The plug-in fit of the block hole is convenient for stabilizing the placed magnetic block, and the plug-in fit between the insert rod and the socket is convenient for stabilizing the clamped magnetic block again. Multiple stabilizing work can avoid the magnetic block from easily shaking when it is polished , affecting the grinding effect, the set grinding device drives the base gear to rotate through the grinding motor, which is convenient to drive the disc to rotate. Through the rotation of the disc, the grinding piece can be driven to rotate. block for sanding.

Owner:湖南美磁科技有限公司

A multifunctional painting equipment

ActiveCN106944283BImprove work efficiencyRealize lifting workSpraying apparatusEngineeringMechanical engineering

The invention discloses multifunctional paint spraying equipment. The multifunctional paint spraying equipment comprises a bracket and a foundation support, wherein the left side and the right side of the bracket are arranged correspondingly, and the foundation support is fixed between the inner sides of the left side and the right side of the bracket; a paint spraying device is arranged between the inner sides of the left side and the right side of the bracket above the foundation support; the end face of the bottom of the paint spraying device is internally provided with a first sliding and running slot, and the first sliding and running slot is internally connected with paint spraying sliding and running block in a translation fit manner; the end face of the bottom of the paint spraying sliding and running block is internally provided with a second sliding and running slot, the top of the second sliding and running slot is provided with a transmission cavity in a communicating manner, and the second sliding and running slot is internally provided with a partition plate extending upwards; and the top expansion portion of the partition plate enters the transmission cavity in a jacking manner, the tail side of the partition plate is fixedly connected with the top end in the transmission cavity, the partition plate divides the second sliding and running slot into a left guide slot body and a right guide slot body and divides the transmission cavity into a left transmission cavity body and a right transmission cavity body, and the position, between the left guide slot body and the right guide slot body, of the partition plate is internally provided with a first power device. The multifunctional paint spraying equipment is simple in structure and reasonable in design, work efficiency is improved, and equipment use safety is improved.

Owner:JIANGSU SULI MACHINERY SHARES CO LTD

A fixture structure with three-dimensional processing function

ActiveCN106113160BAchieve liftingRealize lifting workMulti-purpose machinesWork benchesEngineeringWood plank

The invention discloses a clamp structure with a three-dimensional machining function. When the distance is shortened, under the action of driving force of a rotary mechanism, the end, close to a second slide block, of a linkage rod moves towards a third slide block. When the distance is increased, under the action of a first spring, the end, close to the second slide block, of the linkage rod moves away from the third slide block. When the first slide block slides to a mounting table to abut against the mounting table, under the limiting action of the mounting table, the first slide block cannot continue to move and then cannot continue to move on a rail strip, and at the same time, the rotary mechanism continues to rotate, so that the second slide block moves on a slide bar so as to be close to the first slide block; an ejector rod arranged on the second slide block moves towards a clamping block at the same time, finally, the ejector rod abuts against the gravity end, the clamping end moves towards the mounting table, and therefore the clamping end clamps a board arranged on the mounting table. In this way, the board is prevented from being damaged by too large clamping force in the clamping process.

Owner:丰县正海金属科技有限责任公司

Bridge construction equipment

InactiveCN108247097ARealize lifting workImprove the safety of useBoring/drilling machinesArchitectural engineeringBuilding construction

The invention discloses bridge construction equipment. The bridge construction equipment comprises vertical frames oppositely arranged on the left side and the right side and a base table fixed between the inner sides of the vertical frames on the left side and the right side. Supporting rods are fixedly arranged at the bottoms of the vertical frames. A rolling wheel is rotationally arranged at the bottom of each supporting rod. A drilling element is arranged at the position, between the inner sides of the vertical frames on the left side and the right side, of the upper portion of the base table. A first sliding cavity is formed in the bottom end face of the drilling element. A drilling sliding block is connected in the first sliding cavity in a clearance fit manner. A second sliding cavity is formed in the bottom end face of the drilling sliding block. A conveying cavity arranged in a communicating manner is formed in the top of the second sliding cavity. A partition body extending upwards is arranged between the portions of the second sliding cavity. The extending segment of the top of the partition body is jacked into the conveying cavity, and the tail of the extending segmentof the top of the partition body is fixedly connected with the inner top end of the conveying cavity. The bridge construction equipment is simple in structure and reasonable in design, the work efficiency is improved, and the use safe of the equipment is improved.

Owner:南宁市博腾安防科技有限公司

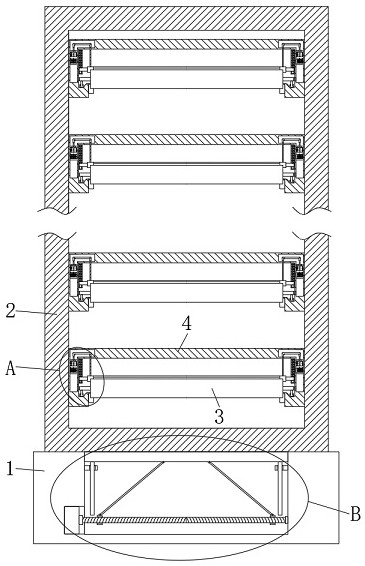

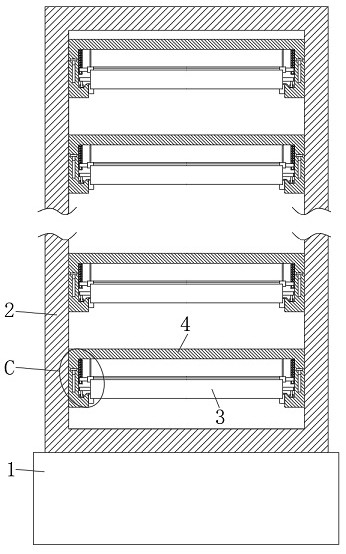

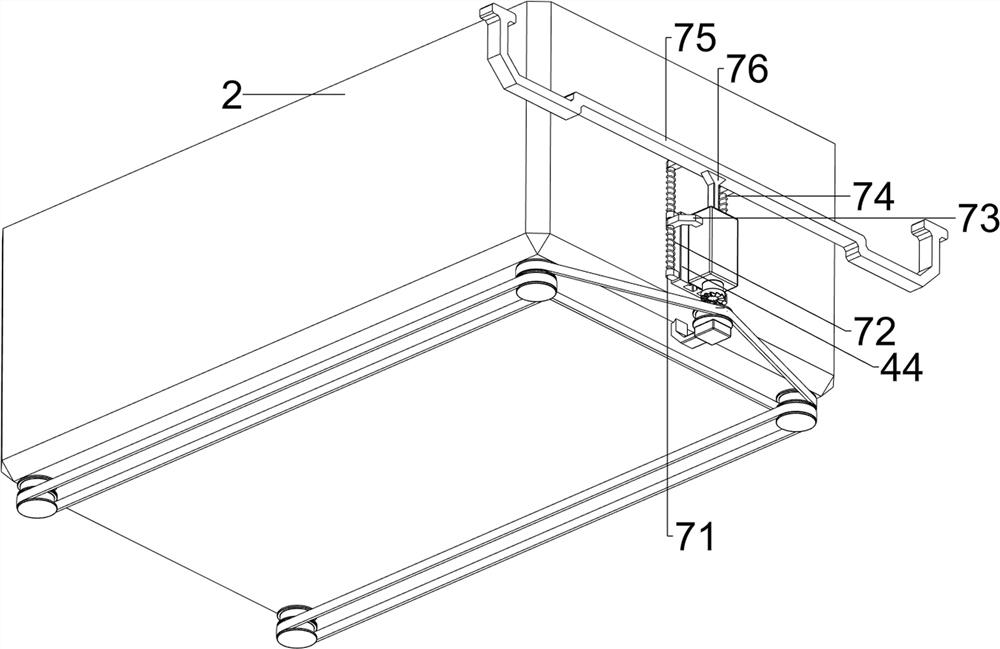

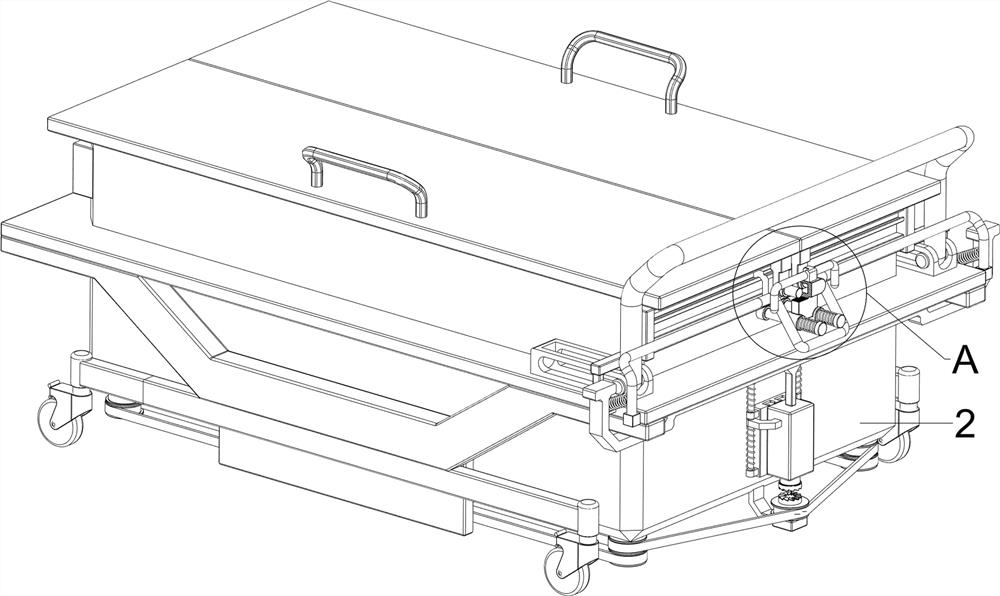

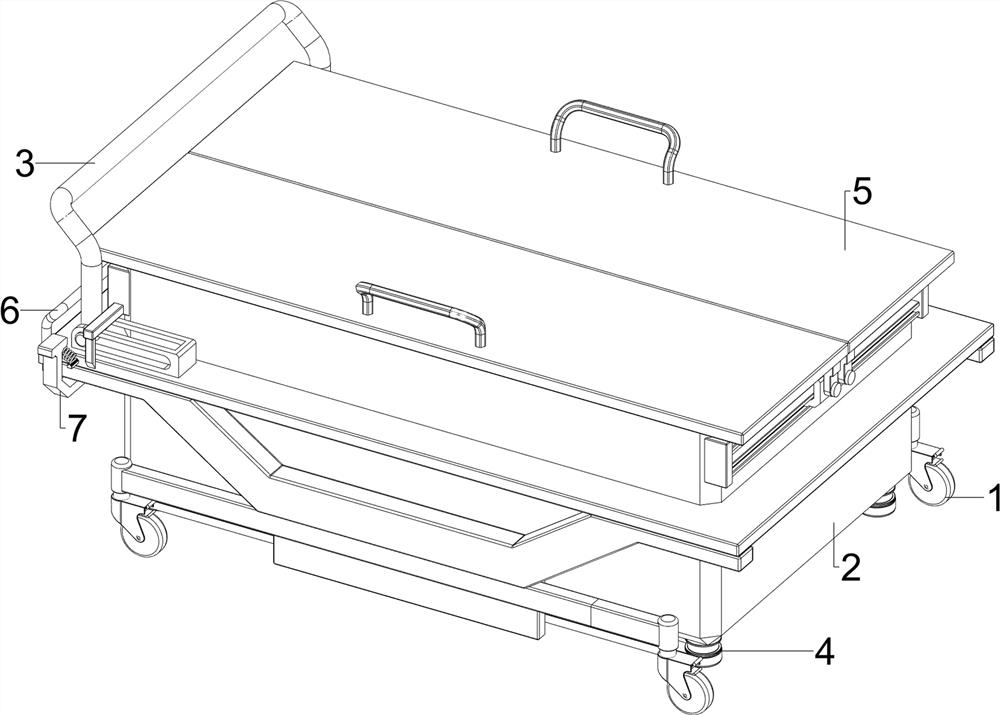

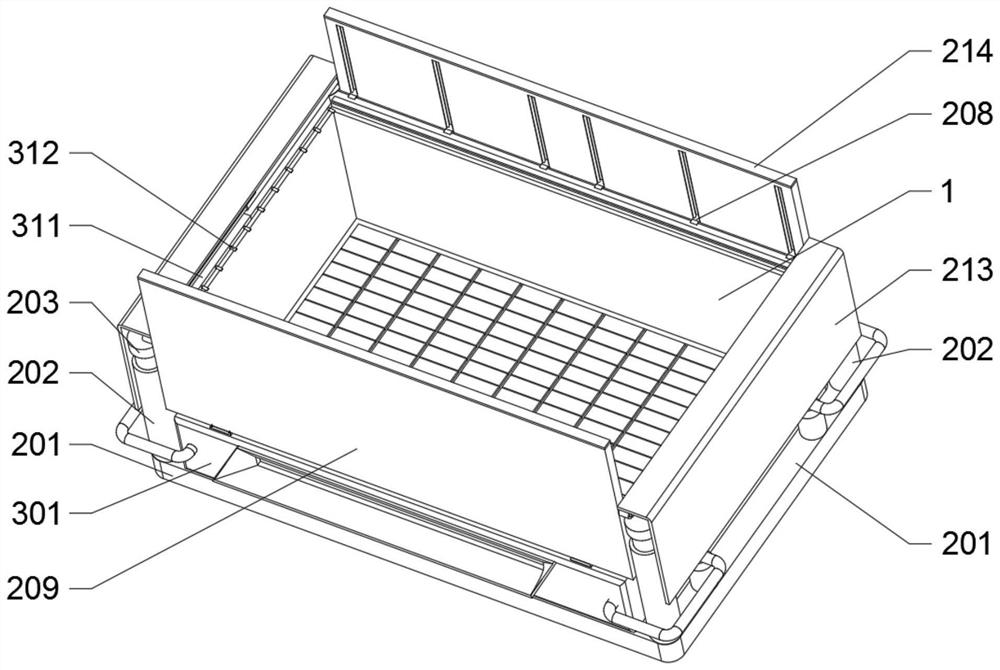

Temporary medicine transfer equipment for endocrinology department

PendingCN114454939AEasy to take outRealize lifting workLifting framesHand carts with multiple axesBiomedical engineeringEndocrinology department

The invention relates to transfer equipment, in particular to temporary medicine transfer equipment for the endocrinology department. The technical problem to be solved is to provide the temporary medicine transfer equipment for the endocrinology department, which is convenient to move and convenient to store and take. According to the technical scheme, the temporary medicine transfer equipment for the endocrinology department comprises rolling wheels, a storage frame, conveying mechanisms and a lifting mechanism, the conveying mechanisms are arranged on the two sides of the storage frame, the rolling wheels are symmetrically and rotationally connected to the bottoms of parts of the conveying mechanisms, and the lifting mechanism is arranged between the storage frame and the conveying mechanisms. Through cooperation of the conveying mechanism and the lifting mechanism, medicine can be placed on the device and then manually pushed, the medicine can be conveyed to a destination, and meanwhile when an undercarriage automatically ascends and descends, people can conveniently take out the medicine.

Owner:魏芳

Central air-conditioning fresh air purification device

ActiveCN112212425BEasy to clean upEasy to change jobsMechanical apparatusLighting and heating apparatusFresh airScrew thread

The invention provides a central air-conditioning fresh air purification device, including a purification box, an air inlet pipe, a fresh air outlet pipe, a first hollow plate, a second hollow plate, a partition plate, an adjustable locking fixing seat structure, and a rotatable lifting filter frame cover structure , impactable drying frame structure, observable pull-out cleaning box structure, U-shaped slide rail, first fixed cover, second fixed cover, primary filter, negative ion generator, electrostatic precipitator, fresh air fan and high-efficiency filter . The arrangement of the first sealing cover, the rotating rod, the pushing rod, the first filter screen, the L-shaped sliding rod, the threaded fixing pipe and the purification box in the present invention is beneficial to grasp the pushing rod to rotate during work, and fix it by the rotating rod and the screw thread The pipe thread connection is arranged so that the first sealing cover drives the first filter net to move upwards, which is convenient for cleaning and replacing the first filter net during use, and realizes lifting work at the same time.

Owner:嘉兴和禹净化科技有限公司

Sludge conversion biological bed and use method thereof

InactiveCN114477680AAvoid damageImprove survival rateBiological sludge treatmentStationary filtering element filtersCold airSludge

The invention provides a sludge conversion biological bed and a use method thereof, and relates to the technical field of sludge treatment.The sludge conversion biological bed comprises a biological bed body, a protection mechanism is fixed to the bottom of the biological bed body, and a watering mechanism is fixed to the top of the protection mechanism. According to the biological bed, when sunshade protection needs to be conducted on the biological bed body, a second electric telescopic rod is started firstly, when the second electric telescopic rod works, a protection plate can be driven to rotate, meanwhile, the protection plate can drive a sliding block to rotate, the protection plate is attached to the top of a connecting plate, and when the protection plate is attached to the connecting plate, the protection plate can apply pressure to a sealing plate; according to the biological bed, the sealing plate moves downwards, meanwhile, the sealing plate enables the compression spring to deform, restoring force generated when the compression spring deforms drives the sealing plate to move upwards, pressure is applied to the protection plate, and therefore sealing work of the biological bed body is achieved, and external cold air is prevented from entering the biological bed to damage organisms in the biological bed.

Owner:绿谷通泰(北京)环保科技有限公司

A fire sprinkler nozzle water distribution test device

ActiveCN106938131BAchieve stabilityAvoid shakingMachine part testingFire rescueFire sprinklerTest rig

The invention relates to a water distribution test device for fire sprinkler heads, which is used to solve the problem that repeated climbing is required in the process of inspecting sprinkler heads. A fire sprinkler water distribution test device is characterized in that it includes a crane, a wire winder, a hanger and a sprinkler frame, the crane includes a vehicle body, the wire winder is connected to the vehicle body, and the wire winder It includes at least one winding wheel, each of which is wound with a wire rope, and the hanger includes at least one threading pipe, and each of the threading pipes is vertically arranged; the lower end of each threading pipe is connected to a limit Each of the steel wire ropes is connected with a lifter on the part below the threading pipe, each of the lifters includes a limit block, and the nozzle frame includes a water inlet pipe for water supply and a number of The nozzles used in the experiment. The beneficial effect is that it can ensure the smooth progress of the sprinkler detection work while avoiding workers from repeatedly ascending heights.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

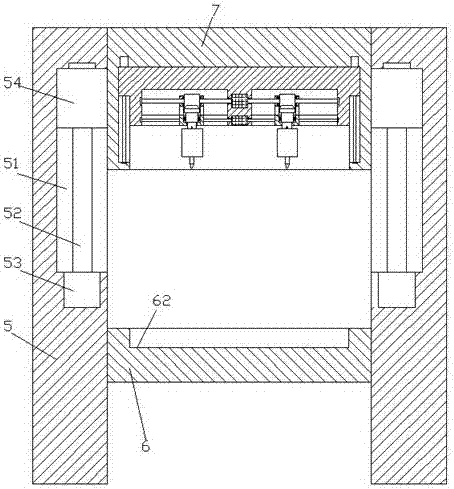

Lamp lifting and fastening device and lamp

PendingCN113432086AQuick liftRealize lifting workMechanical apparatusLighting support devicesElectric machineryEngineering

The invention relates to the technical field of lamps, and discloses a lamp lifting and fastening device and a lamp. The device comprises a lamp post, a movable sleeve and a control box. The lamp post is movably sleeved with a movable sleeve, permanent magnets B are embedded into the two sides of the interior of the movable sleeve, a motor is installed at the bottom of the inner side of the lamp post, a lead screw is installed at the top end of the motor in a transmission mode, a movable block is installed on the inner side of the lamp post in an interactive mode, permanent magnets A are fixedly installed on the two sides of the movable block, and a screw hole is formed in the center of the movable block in a penetrating mode. A permanent magnet A and a permanent magnet B attract each other to enable a movable block to move up and down to drive a movable sleeve to move up and down, so that lifting work of the lamp is achieved, maintenance is facilitated, the lamp can quickly complete lifting, a hole or a slide way does not need to be formed in a lamp pole, the service life is ensured while the attractiveness is improved, and the lamp can be lifted to any position to stop and cannot fall off due to no fastening operation, so that the stability and the reliability are greatly improved.

Owner:江苏奥特斯建设集团有限公司

Novel multifunctional paint spraying equipment

InactiveCN107335570AImprove work efficiencyRealize lifting workSpraying apparatusAgricultural engineeringMultiple function

The invention discloses a novel multi-functional paint spraying equipment, which comprises corresponding brackets arranged on the left and right sides and a base fixed between the inner sides of the left and right brackets, and a paint spraying device is arranged between the inner sides of the left and right brackets above the base , the bottom end surface of the paint spraying device is provided with a first slide groove, the first slide groove is translated and connected with a paint spray slide block, the bottom end surface of the paint spray slide block is provided with a second slide groove, and the top of the second slide groove There is a connecting transmission chamber, and an upwardly extending partition board is provided between the second slide grooves. The top extension of the partition board is pushed into the transmission chamber and the tail side is fixedly connected to the top of the transmission chamber. The partition board will The second sliding groove is divided into a left guide groove and a right guide groove and the transmission cavity is divided into a left transmission cavity and a right transmission cavity, and the partition plate between the left guide groove and the right guide groove is provided with a first power device; The invention has the advantages of simple structure and reasonable design, which improves the work efficiency and the safety of equipment use.

Owner:深圳绿淋环保科技有限公司

A kind of material polishing equipment

ActiveCN107030580BImprove work efficiencyRealize lifting workGrinding carriagesPolishing machinesEngineeringEquipment use

The invention discloses material polishing equipment. The material polishing equipment comprises frames correspondingly arranged on the left and right sides and a chassis fixed between inner sides of the frames on the left and right sides; a polishing component is arranged above the chassis and between the inner sides of the frames on the left and right sides, a first sliding connection groove is formed in the end face of the bottom of the polishing component, a polishing sliding connection block is connected into the first sliding connection groove in a smooth fit manner, a second sliding connection groove is formed in the end face of the bottom of the polishing sliding connection block, and a through transferring connection cavity is formed in the top of the second sliding connection groove; a dividing plate extending upwards is arranged between parts of the second sliding connection groove, an extending part on the top of the dividing plate penetrates into the transferring connection cavity, and the tail end of the extending part is fixedly connected with the top end of the interior of the transferring connection cavity; and the second sliding connection groove is divided by the dividing plate into a left guide connection groove and a right guide connection groove, the transferring connection cavity is divided by the dividing plate into a left transferring connection cavity body and a right transferring connection cavity, and a first electric rotating machine is arranged in the position, between the left guide connection groove and the right guide connection groove, of the dividing plate. The material polishing equipment is simple in structure and reasonable in design, the working efficiency is improved, and the equipment using safety is improved.

Owner:NANTONG TONGYANG MECHANICAL & ELECTRICAL MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com