Clamp structure with three-dimensional machining function

A technology of functional fixtures and clamping mechanisms, which can be used in wood processing appliances, workbenches, manufacturing tools, etc., and can solve problems such as damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

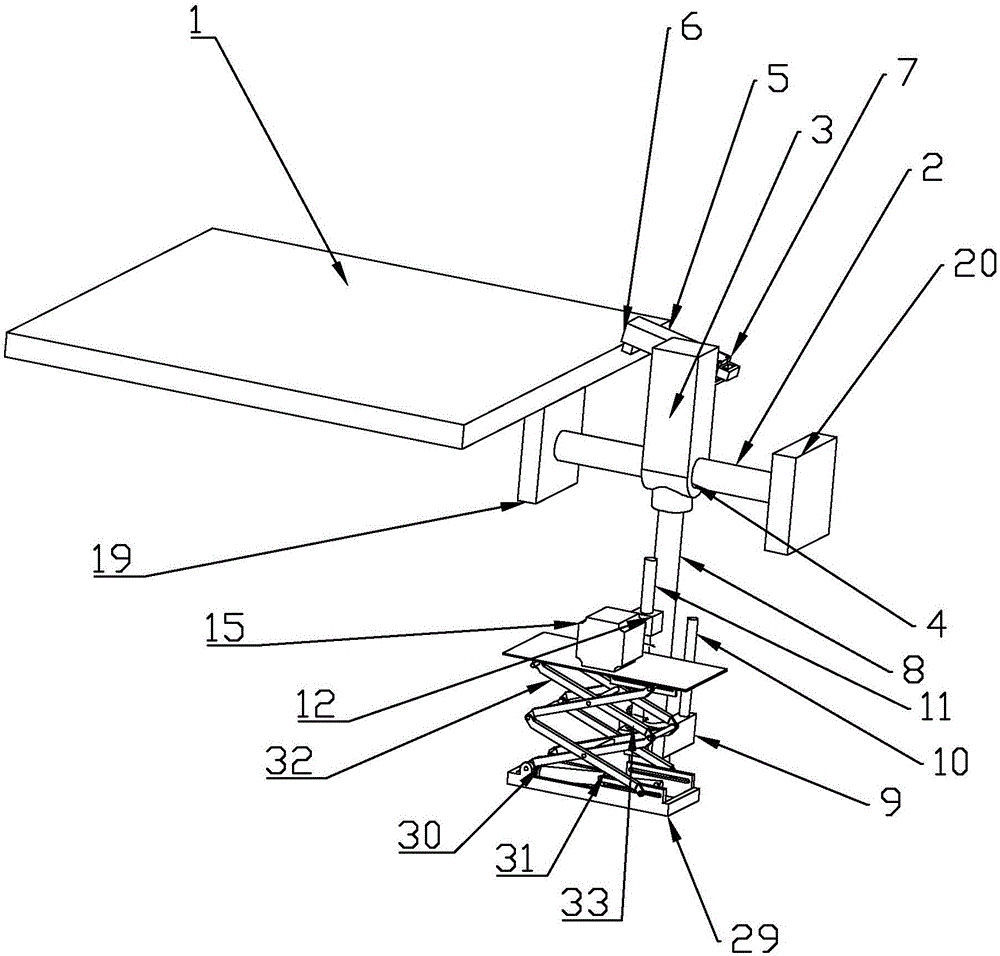

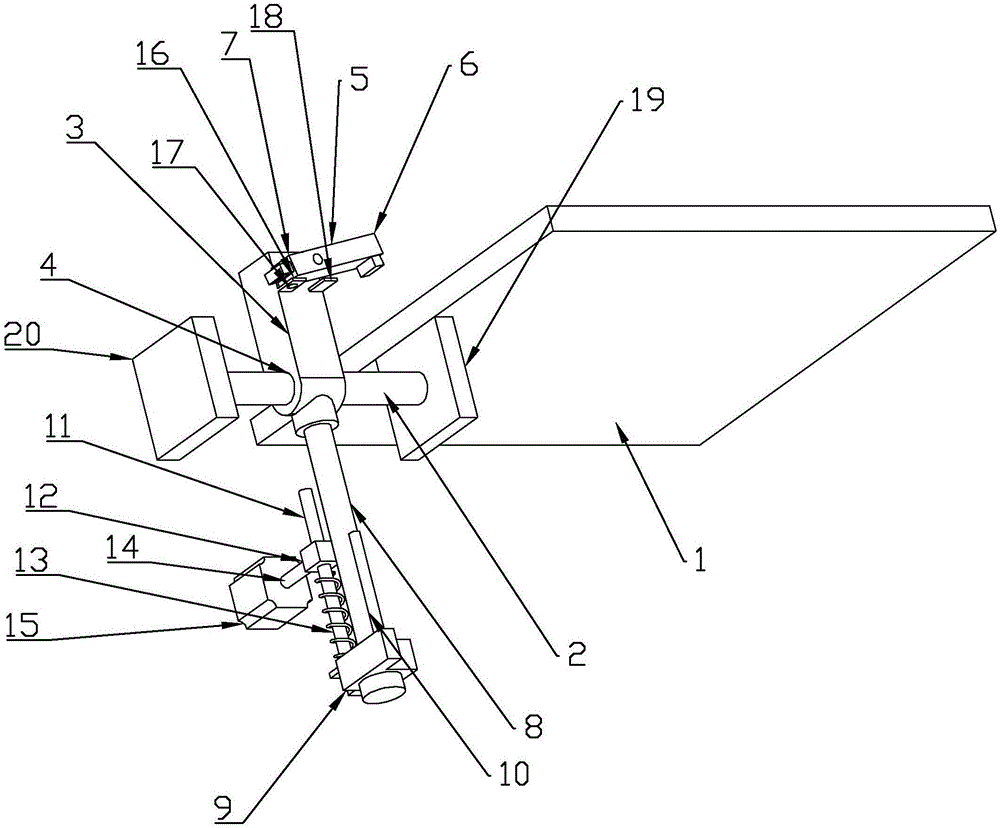

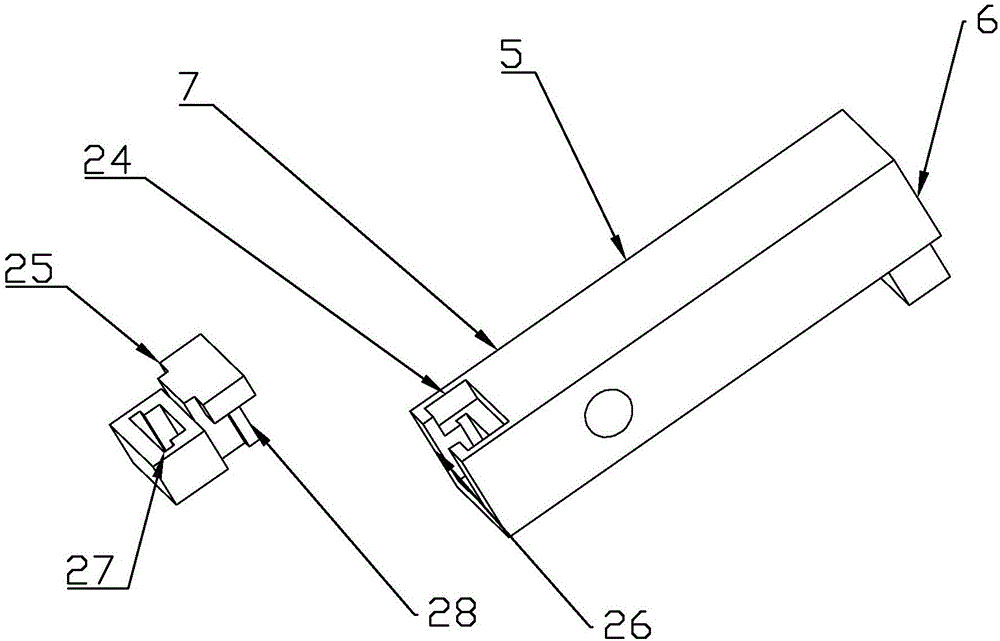

[0035] refer to Figures 1 to 7 As shown, a fixture structure with a three-dimensional processing function in this embodiment includes a mounting table 1 for placing planks, a clamping mechanism for clamping the planks, and a track bar 2 for the movement of the clamping mechanism. The clamping mechanism Including the first slider 3, the first slider 3 is provided with a slide hole 4, the track bar 2 passes through the slide hole 4, so that the first slider 3 is slidably connected to the track bar 2, the first track bar 2 A slider 3 is hinged with a clamping block 5, the clamping block 5 is provided with a clamping end 6 and a gravity end 7, the weight of the gravity end 7 is greater than that of the clamping end 6, and the clamping end 6 faces the installation The table 1 is set, the first slider 3 is provided with a slider 8, the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com