A roll changing bracket for a multi-axis textile winding device

A technology of a rewinding device and a roller bracket, which is applied in the directions of winding strips, transportation and packaging, and thin material processing, can solve problems such as reducing work efficiency, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

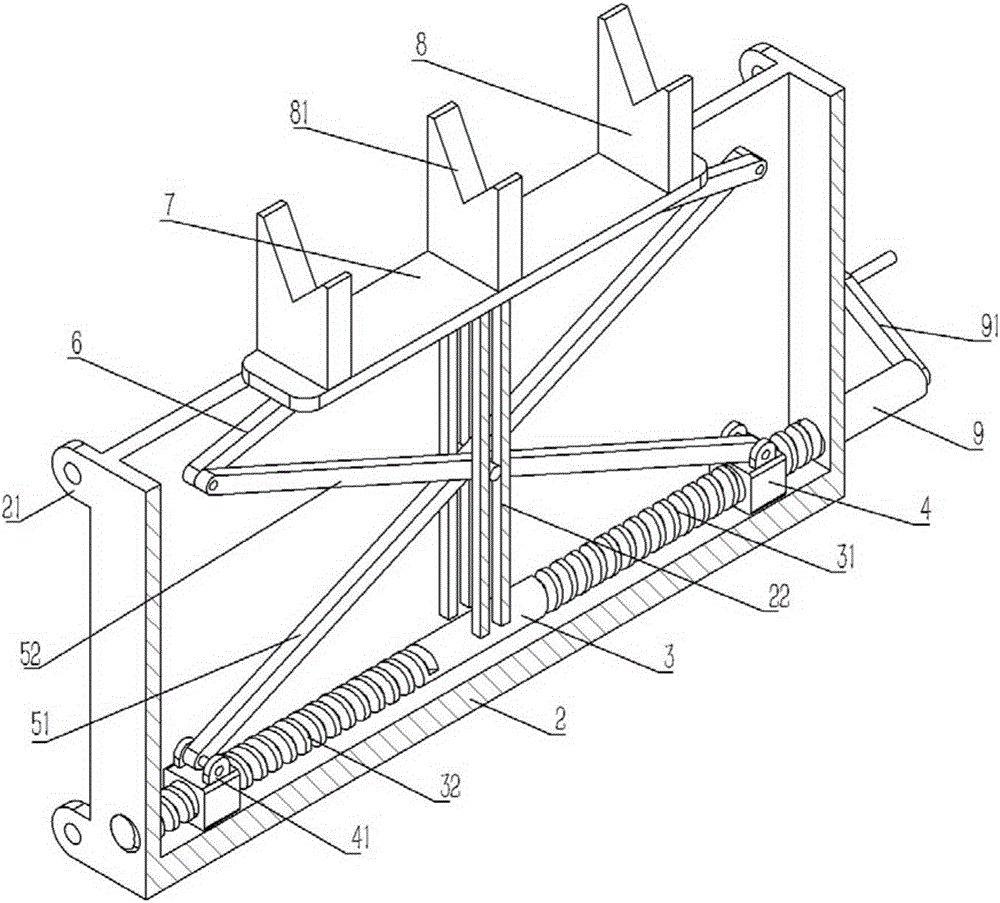

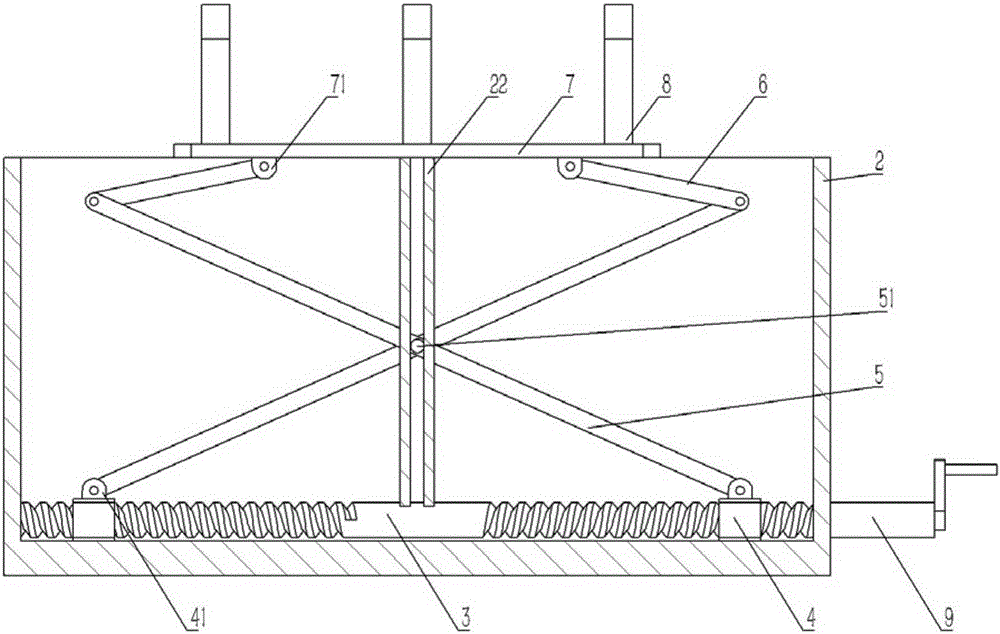

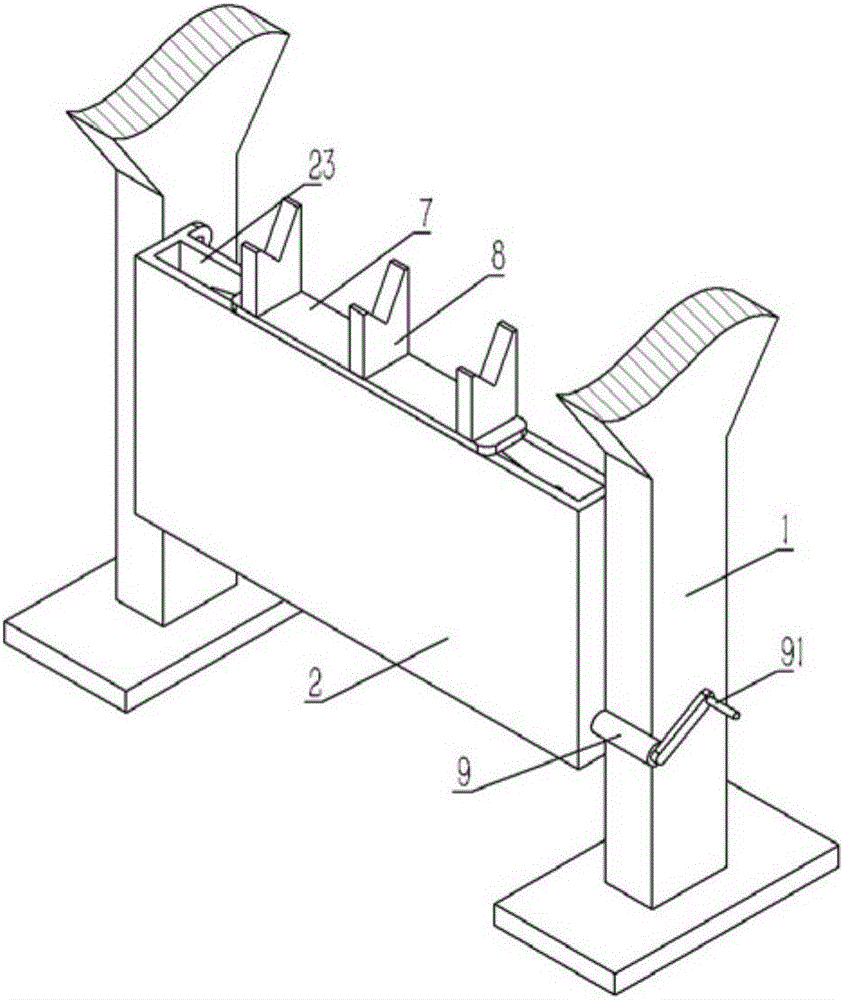

[0016] Example: see Figures 1 to 3 As shown, a roll changing bracket of a multi-axis textile winding device includes two pillars 1, a rectangular support 2 fixed between the pillars 1, a rotating shaft 3 is hinged in the rectangular supporting frame 2, and the two ends of the rotating shaft 3 are respectively formed There are left-handed threads 31 and right-handed threads 32, the two ends of the rotating shaft 3 are respectively screwed with rectangular sliders 4, and the rectangular sliders 4 are formed with a first hinged support 41, and the first hinged supports at both ends of the rotating shaft 3 41 are hinged with long connecting rods 5, and the middle parts of the two long connecting rods 5 are hinged together through a pin shaft 51. One end of the long connecting rods 5 is hinged on the first hinged support 41, and the other end is hinged There is a short connecting rod 6, and the short connecting rod 6 is hinged on the second hinged support 71, and the second hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com