Bridge construction equipment

A bridge construction and equipment technology, applied in metal processing equipment, drilling/drilling equipment, manufacturing tools, etc., can solve the problems of poor safety performance, complicated use and operation, low work efficiency, etc., to achieve reasonable design and improve safety. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

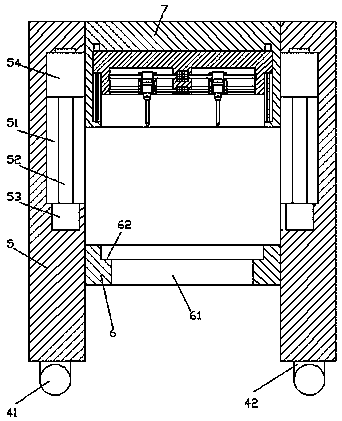

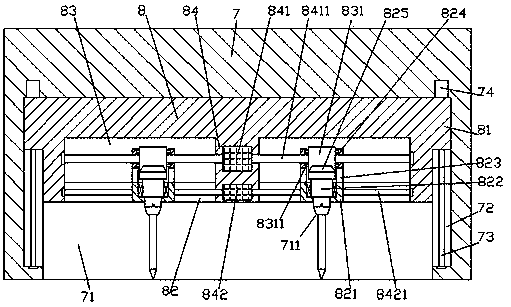

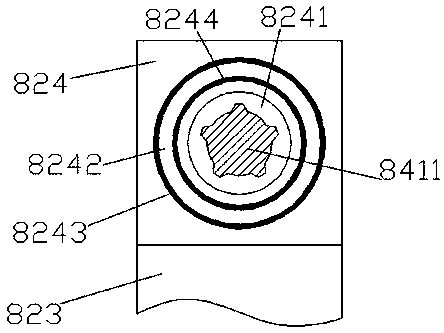

[0026] Such as Figure 1-Figure 9 As shown, a kind of bridge construction equipment of the present invention comprises the stand 5 that is arranged oppositely on the left and right sides and the abutment 6 that is fixed between the inner sides of the stand 5 on the left and right sides, and the bottom of the stand 5 is fixedly arranged with A pole 42, the bottom of the pole 42 is rotatably provided with a roller 41, the roller 41 is used to facilitate the adjustment of the position of the stand 5, between the insides of the stand 5 on the left and right sides above the abutment 6 A drilling element 7 is provided, and a first sliding cavity 71 is arranged in the bottom end surface of the drilling element 7, and a drilling slider 8 is movably connected in the first sliding cavity 71, and the bottom of the drilling slider 8 A second sliding chamber 82 is provided in the end face, and a transmission chamber 83 arranged in communication is provided on the top of the second sliding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com