Molding grinding machine for grinding intelligent loudspeaker magnet

A smart audio and speaker technology, applied in the manufacture of inductors/transformers/magnets, grinding racks, grinding machine parts, etc., can solve problems affecting work efficiency, unstable clamping, etc., and achieve the effect of lifting work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

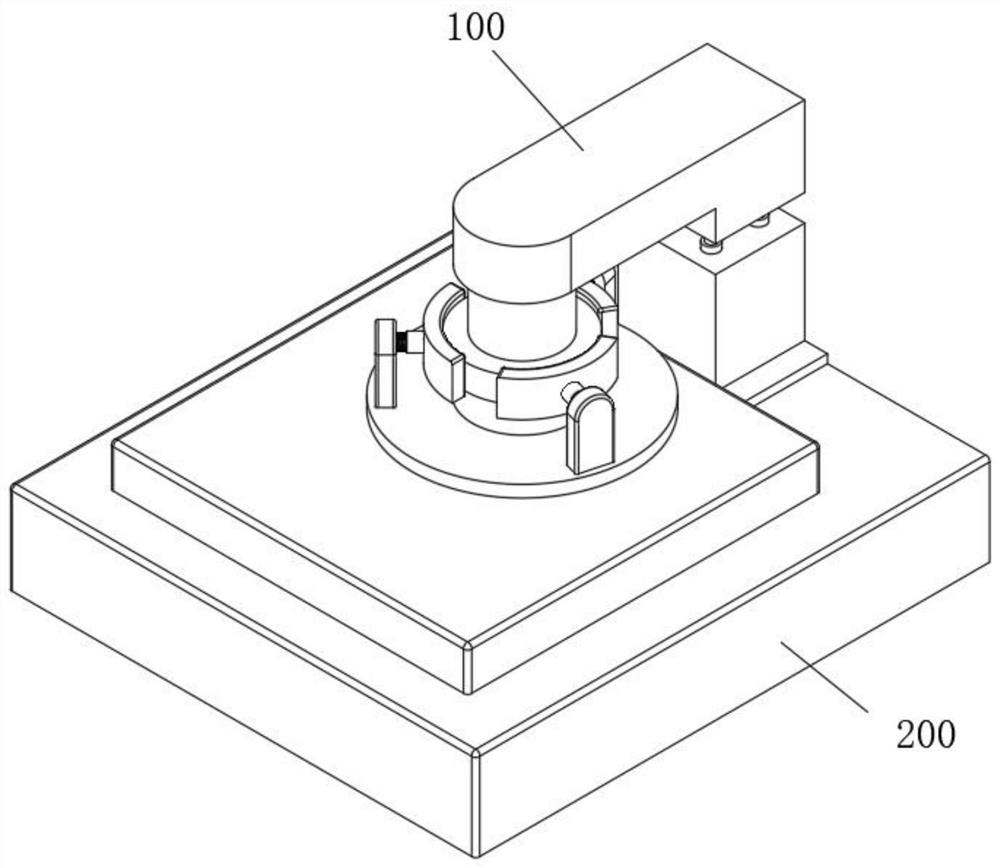

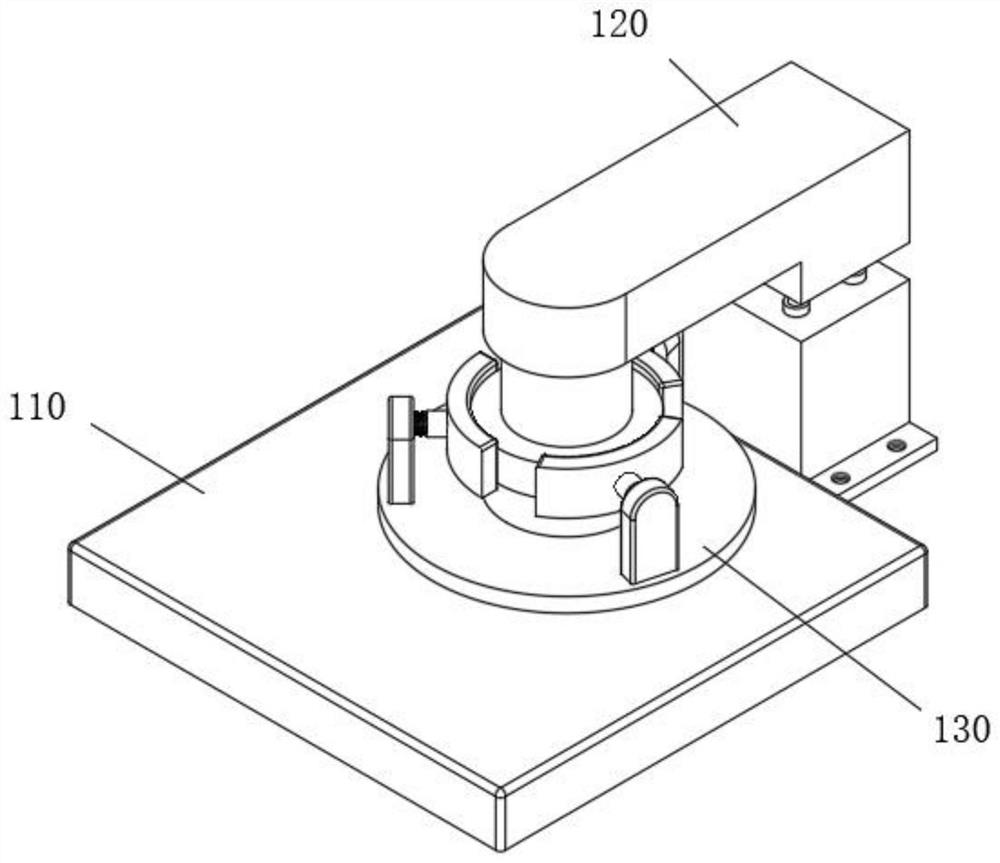

[0061] see Figure 1-Figure 16 As shown, the present embodiment provides a forming grinder for grinding smart audio speaker magnets, including a base 200 and a grinding mechanism 100 installed above the base 200. The grinding mechanism 100 at least includes:

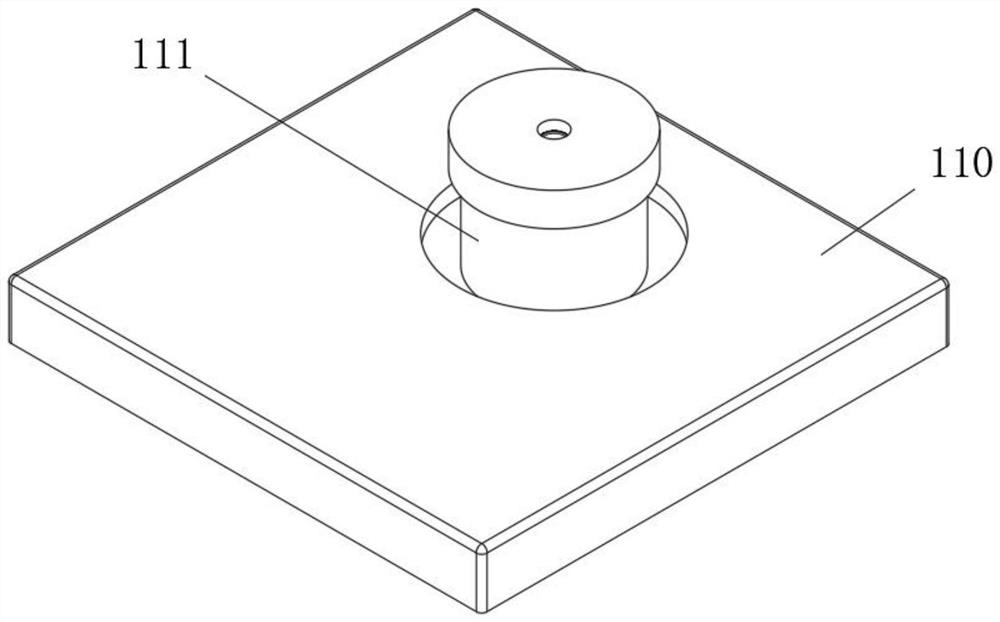

[0062] Operating table 110, the inside of operating table 110 is provided with a large gear slot 1100, the center of the bottom surface of the large gear slot 1100 is fixed with a placement column 111, and a magnetic block 112 is placed above the placement column 111, and a magnetic block hole 1120 is provided inside the magnetic block 112. A post 1111 is provided at the center of the upper surface of the post 111, and the post 1111 is mated with the magnetic block hole 1120, which is convenient for stabilizing the placed magnetic block 112 and is conducive to the later grinding work;

[0063] Clamping device 120, clamping device 120 comprises lifting base 122 and the clamping table 121 that is connected on the top of li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com