Automobile appearance detection and repair workstation

A technology of appearance inspection and workstation, which is applied in vehicle maintenance/repair, manufacturing tools, vehicle maintenance, etc. It can solve problems that are difficult to achieve, and achieve the effects of improving deployment efficiency, controlling pollution and improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

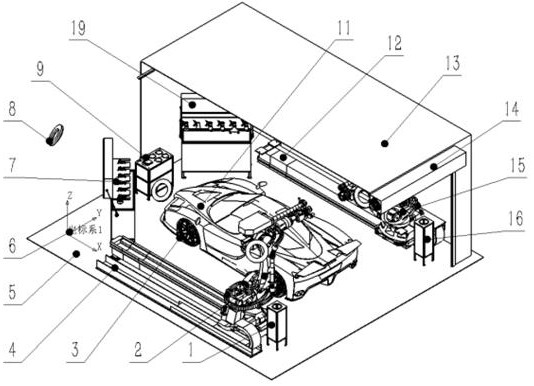

[0041] Examples of the present invention are Figure 1 to Figure 4 As shown, an automobile appearance inspection and repair workstation includes a base plate 5 and a work station body 13. The work station body 13 is detachably mounted on the base plate 5, which is convenient for installation, disassembly and transportation. In this embodiment, the material of the substrate 5 is Q235, the mechanical properties meet the relevant requirements of GB / T700-2006, the size of the steel plate meets the requirements of GB / T709-2006, and the size of the supporting square tube under the steel plate meets the requirements of GB / T3094-2000.

[0042] The workstation body 13 is provided with a lighting lamp 8 , a tool library, a robot and a track for the robot to slide. The track can increase the working space of the robot and make the workstation body 13 more adaptable and versatile.

[0043] The robot includes a first robot 2 and a second robot 15; the tool library includes a first tool lib...

Embodiment 2

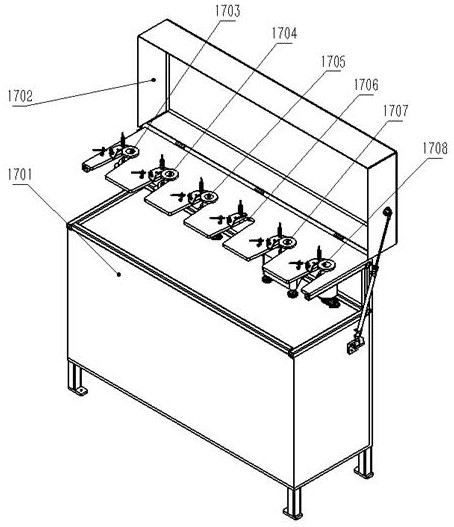

[0057] like Figure 5 As shown, this embodiment discloses a new sand tearing device, which is different from the common device that uses a clamping method to tear off the waste sandpaper. For reasons such as too large, sometimes the sandpaper will be torn or even directly clamped. At this time, the clamping operation is difficult to be carried out automatically, and the production can only be continued after the machine is stopped and manually torn off. like Figure 5 As shown, the sand tearing device 10 of this embodiment includes an installation bracket 1001, a sand tearing plate 1002, a bearing 1003, a rubber 1004 and a roller 1005. The installation bracket 1001 is provided with a number of rollers 1005 in parallel, and the rollers 1005 are parallel to the sand storehouse. The main body 901 is arranged in the width direction; the roller 1005 is rotatably arranged on the mounting bracket 1001 through the bearing 1003, and the roller 1005 can rotate freely; , there is a gap...

Embodiment 3

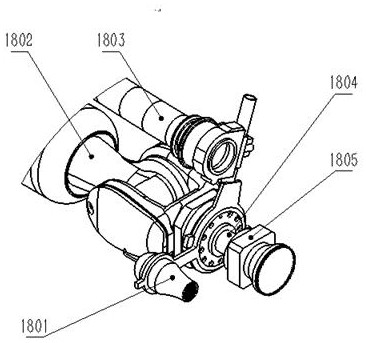

[0064] like Image 6As shown in the figure, similar to Embodiment 2, the difference is that: the bottom of the raised portion 1010 is provided with a groove 1011 with one end opening in the raised portion 1010, and an insertion plate 1012 is arranged in the groove 1011. One end of the plate 1012 protrudes from the convex part, and the insert plate 1012 is first inserted between the grinding wheel and the waste sandpaper when tearing the sandpaper to separate the grinding wheel and the waste sandpaper; the bottom of the groove 1011 is provided with a pressure sensor 1013. When the device 1013 senses that the pressure received by the inserting plate 1012 deviates from the normal pressure range, it will send a signal to restart the sandpaper tearing operation. Normal pressure means that when the inserting plate 1012 is normally inserted between the grinding wheel and the waste sandpaper, due to the dynamic range of the sum of the resistance on the front end of the inserting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com