Propeller with small duct, and ship

A propeller and duct technology, applied in the directions of rotating propellers, ship propulsion, ship parts, etc., can solve the problems of cavitation, large interference between large ducts and propellers, etc., and achieve the effect of low cost, small and lightweight friction resistance, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

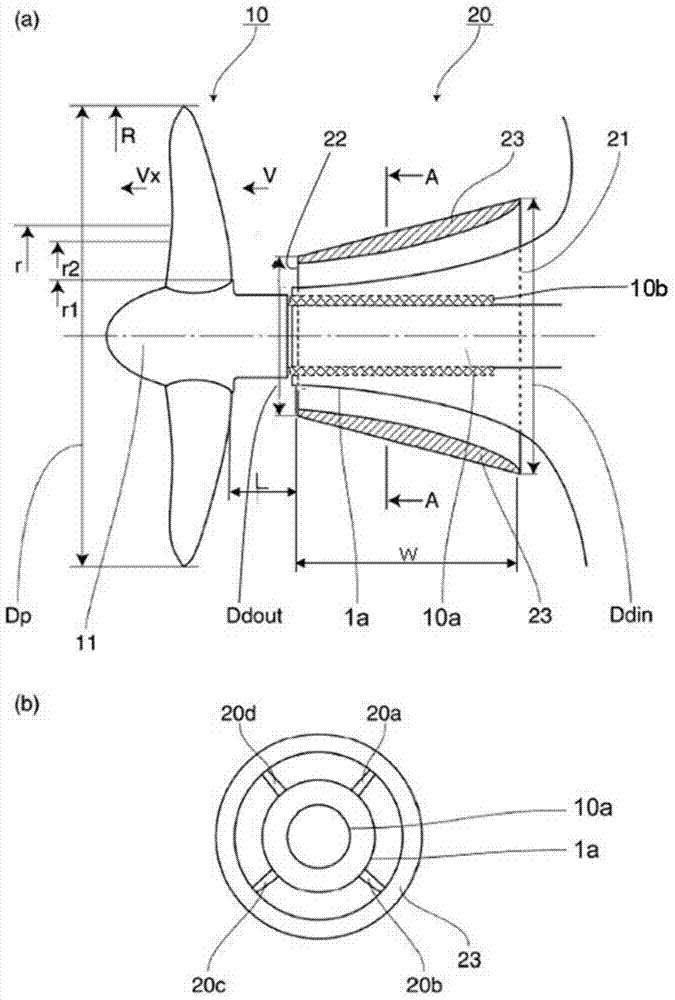

[0108] The thrust of embodiment 2 is increased compared with embodiment 1, and the thrust of embodiment 3 is increased compared with embodiment 2.

[0109] Such as Figure 8 As shown, the smaller the distance L between the front edge of the propeller 10 and the rear end 22 of the duct 20, the more the thrust increases.

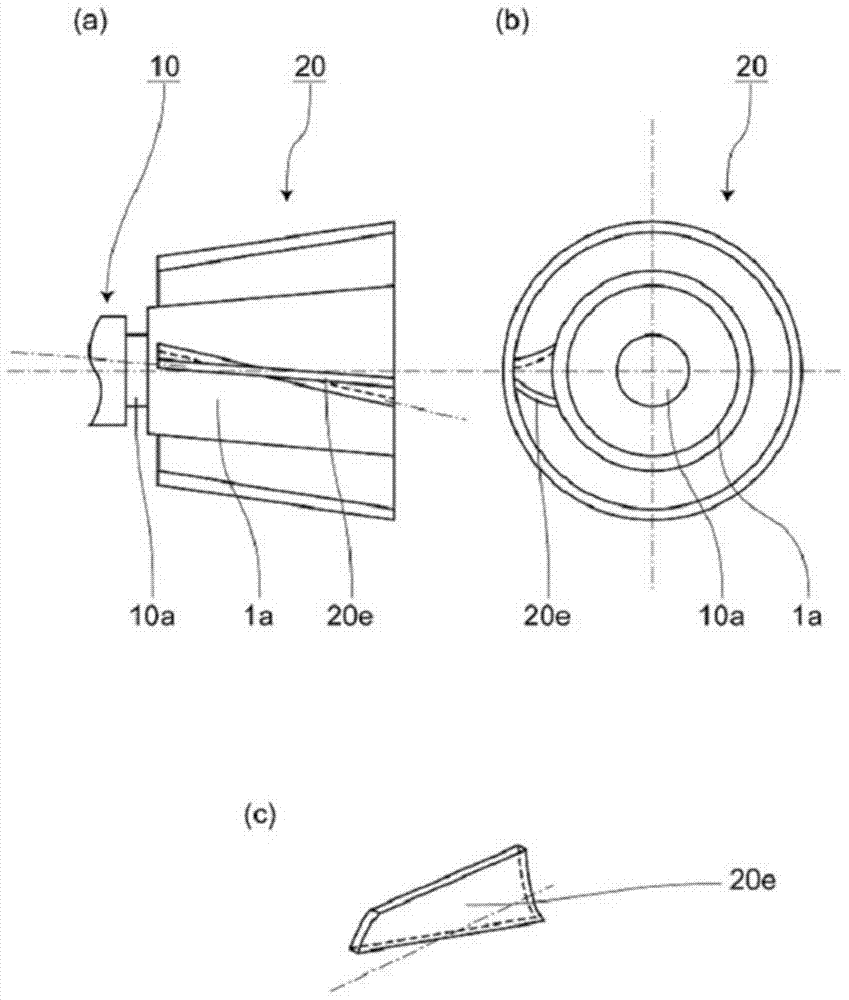

[0110] According to the propeller with a small duct according to the present embodiment, in the propeller with a small duct having the propeller 10 attached to the stern of the hull 1 and the duct 20 attached to the front of the propeller 10, the duct 20 and the propeller 10 of decreasing pitch In combination, the duct 20 can be downsized, the diameter Ddin of the duct 20 is 20% to 50% of the diameter Dp of the propeller 10, and the duct 20 can be brought close to the propeller 10 without causing cavitation. Therefore, by setting the pitch H of the propeller 10 to a decreasing pitch that decreases in the radial direction with a maximum value at the root of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com