Locomotive three-axis radial bogie

A shaft-radial and bogie technology, applied in the field of three-axle radial bogies for locomotives, can solve problems such as undeveloped and applied, and achieve the effects of improving curve passing performance, reducing wheel angle of attack, and reducing wheel-rail wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

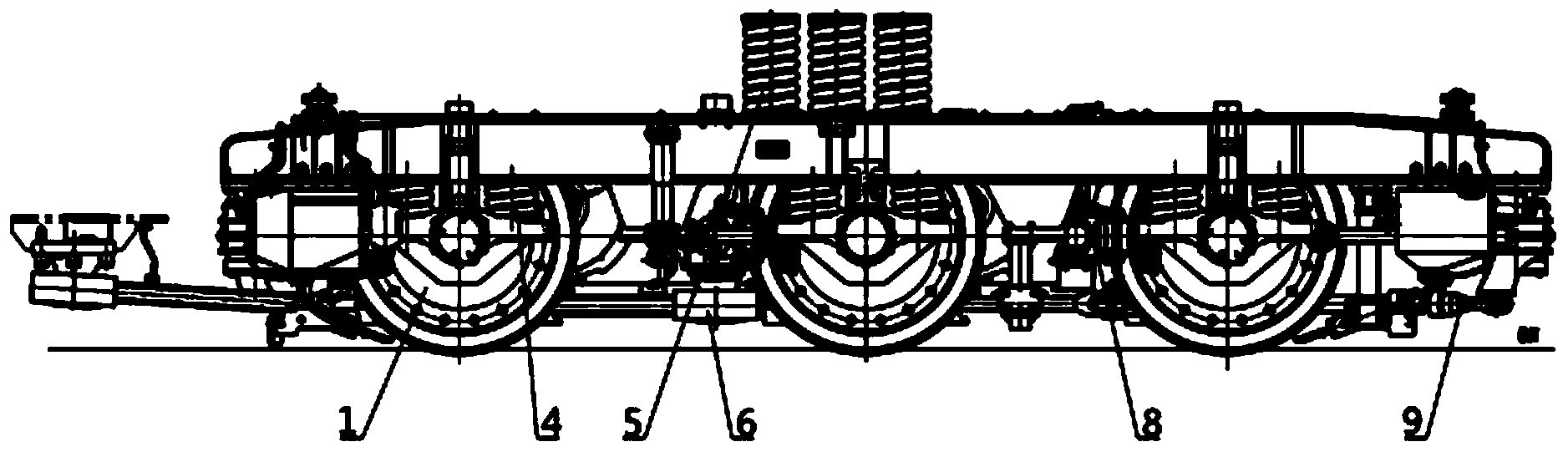

[0051] A three-axle radial bogie for an electric locomotive, such as figure 1 and 11 As shown, it is a three-axle structure, which is mainly assembled by three sets of wheel-to-axle boxes 1, three sets of drive units 2, a frame 3, a set of primary suspension devices 4, a set of secondary suspension devices 5, and a set of traction devices 6. It is composed of three sets of motor suspension devices 7, one set of brake devices 8, and one set of radial devices 9.

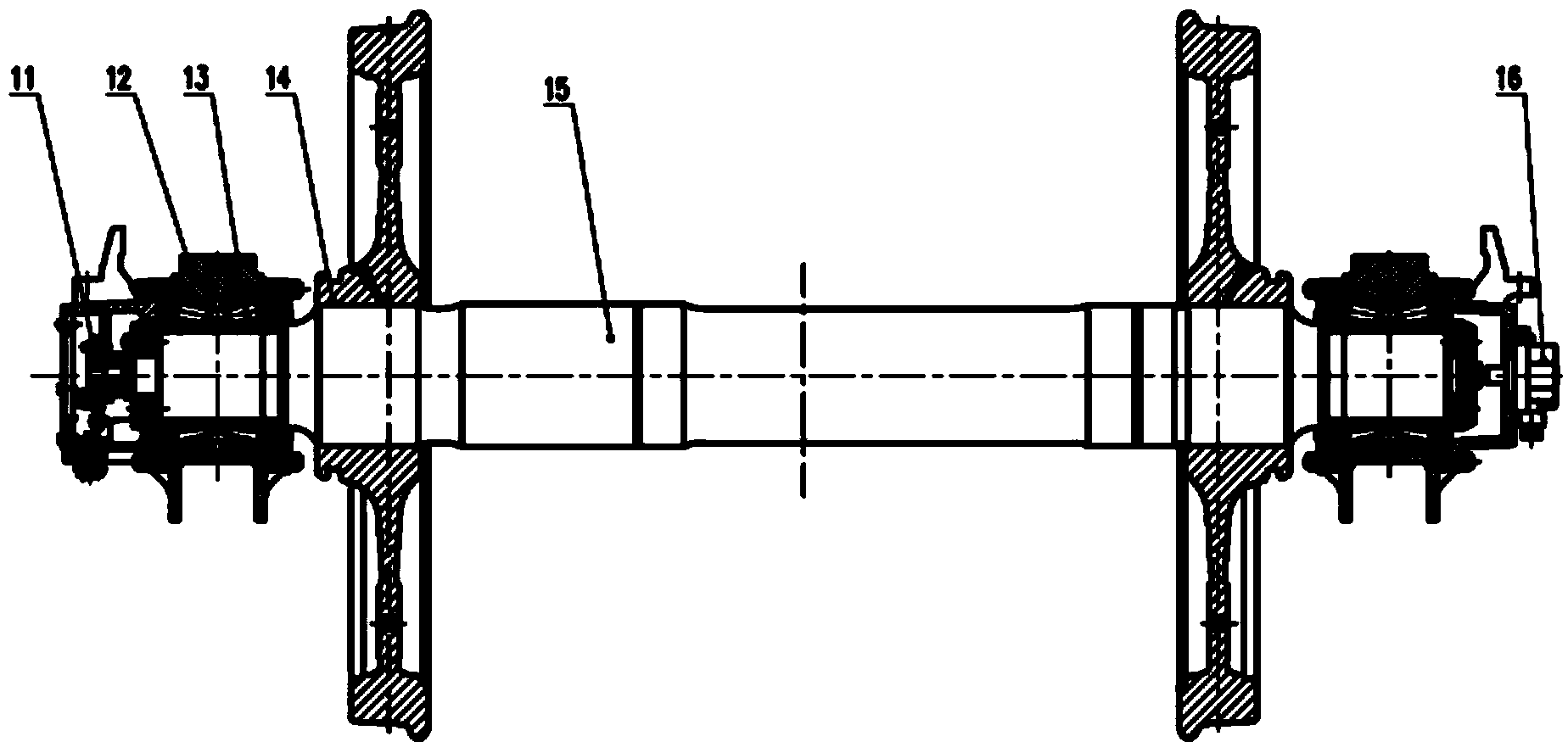

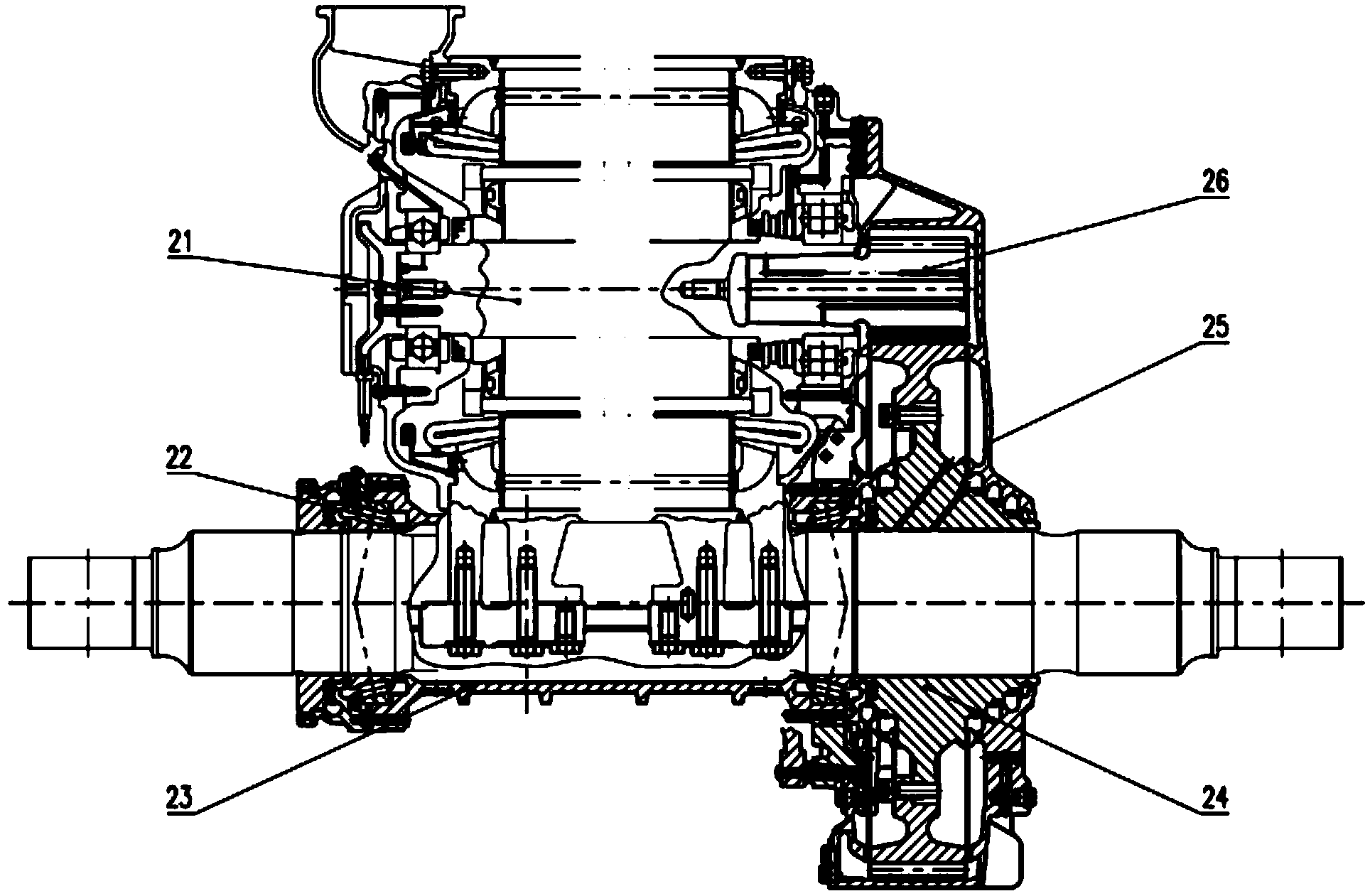

[0052] Such as figure 2 and 12 As shown, a kind of electric locomotive triaxial radial bogie wheel-to-axlebox assembly 1 provided by the embodiment of the present invention consists of grounding device 11, axlebox body 12, axlebox bearings 13, 17, wheels 14, axle shaft 15, speed sensor 16. Two wheels 14 are press-fitted on each axle 15; axle box bearings 13, 17 are also pressed on the journals at both ends of each axle 15, and the axle box bearing 13 is axially assembled with one wheel axle and three axles axially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com