An empennage load applying device for aircraft structure strength test

A strength test and aircraft structure technology, which is applied in the direction of aircraft component testing, aircraft parts, ground installations, etc., can solve the problems of large replacement of test loading equipment, long design cycle of empennage structure, and difficulty in on-site installation, so as to save research and development funds , save installation space and time, and speed up the test progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

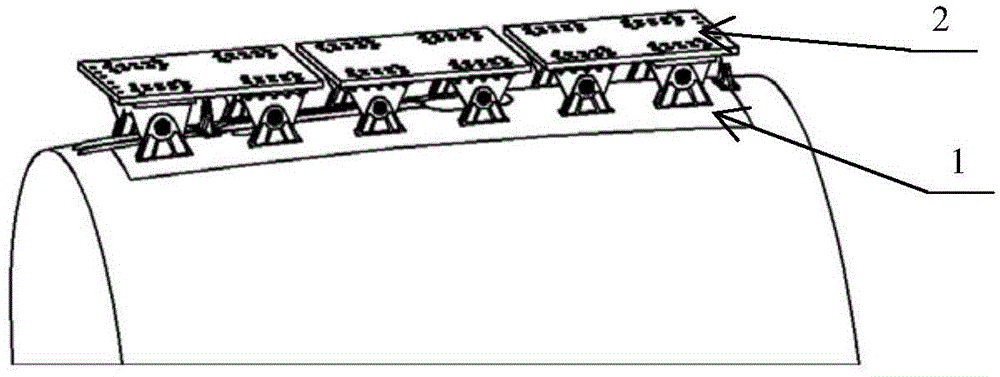

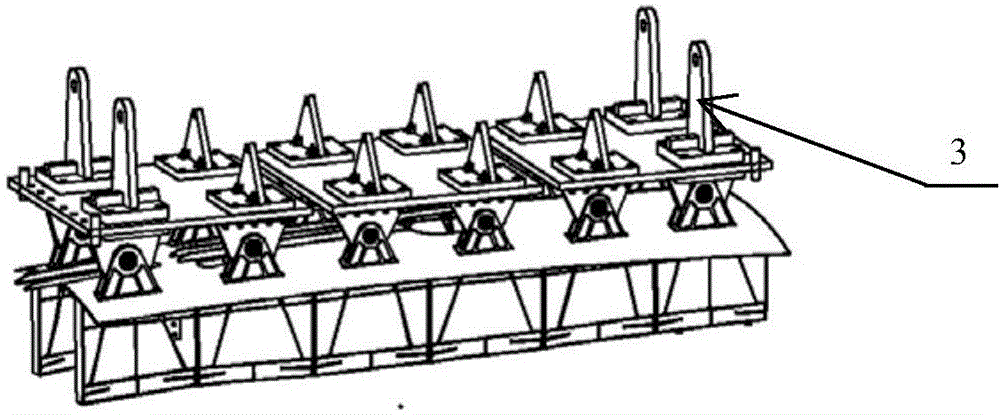

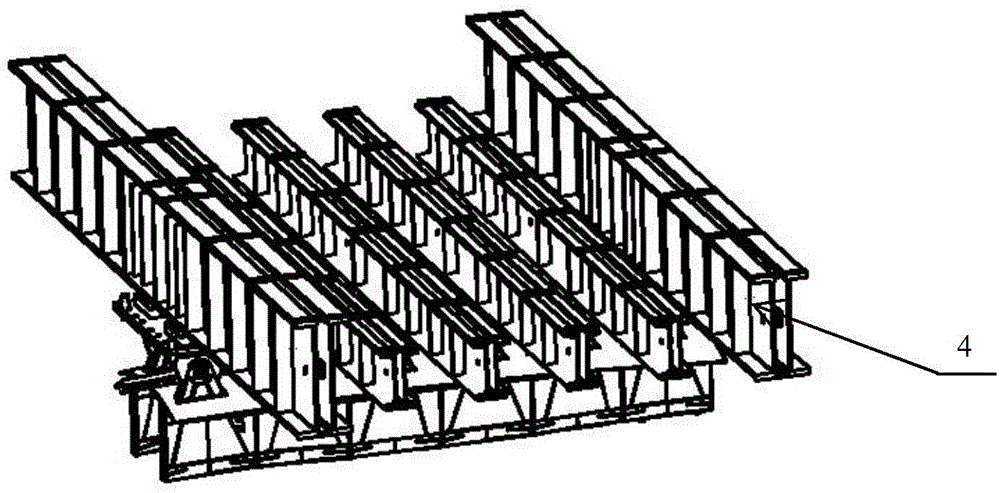

[0018] Please also see figure 1 , figure 2 and image 3 , the present invention is used for the empennage load applying device of aircraft structural strength test and comprises empennage dummy platform, connecting lug, loading beam, wherein, described empennage dummy platform surface is provided with connection hole, and the bottom is connected with fuselage empennage joint through single ear Hinged, the connecting lugs are arranged on the empennage dummy platform, and the loading beam is arranged on the empennage dummy platform through the connecting lugs.

[0019] The empennage dummy platform is connected with the fuselage empennage joint by bolts, simulating the real fuselage empennage load connection form. At the same time, room is left for the deformation of the fuselage during the load application process.

[0020] The loading beam is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com