Scaling equipment and waste disposal systems

A technology of waste disposal system and equipment, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of easy blocking, unloading in piles, and inability to achieve uniform material, so as to prevent piles of materials and prevent materials from blocking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

[0032] In the present invention, unless otherwise stated, the directional words used such as "up, down, left and right" generally refer to up, down, left and right as shown with reference to the accompanying drawings; "inside, outside" Refers to the inside and outside of the contour of each component itself.

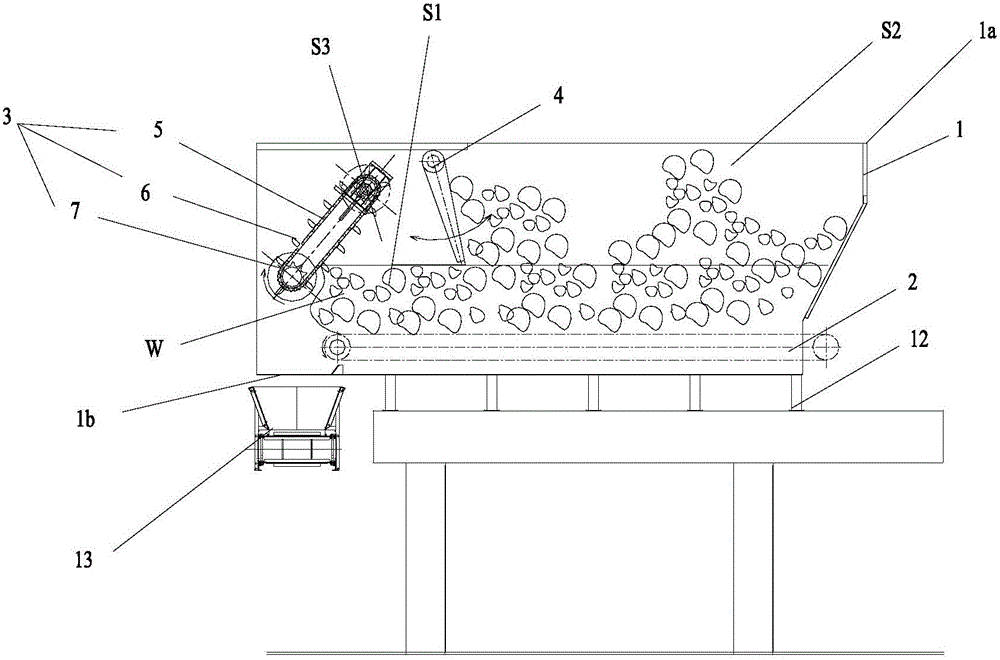

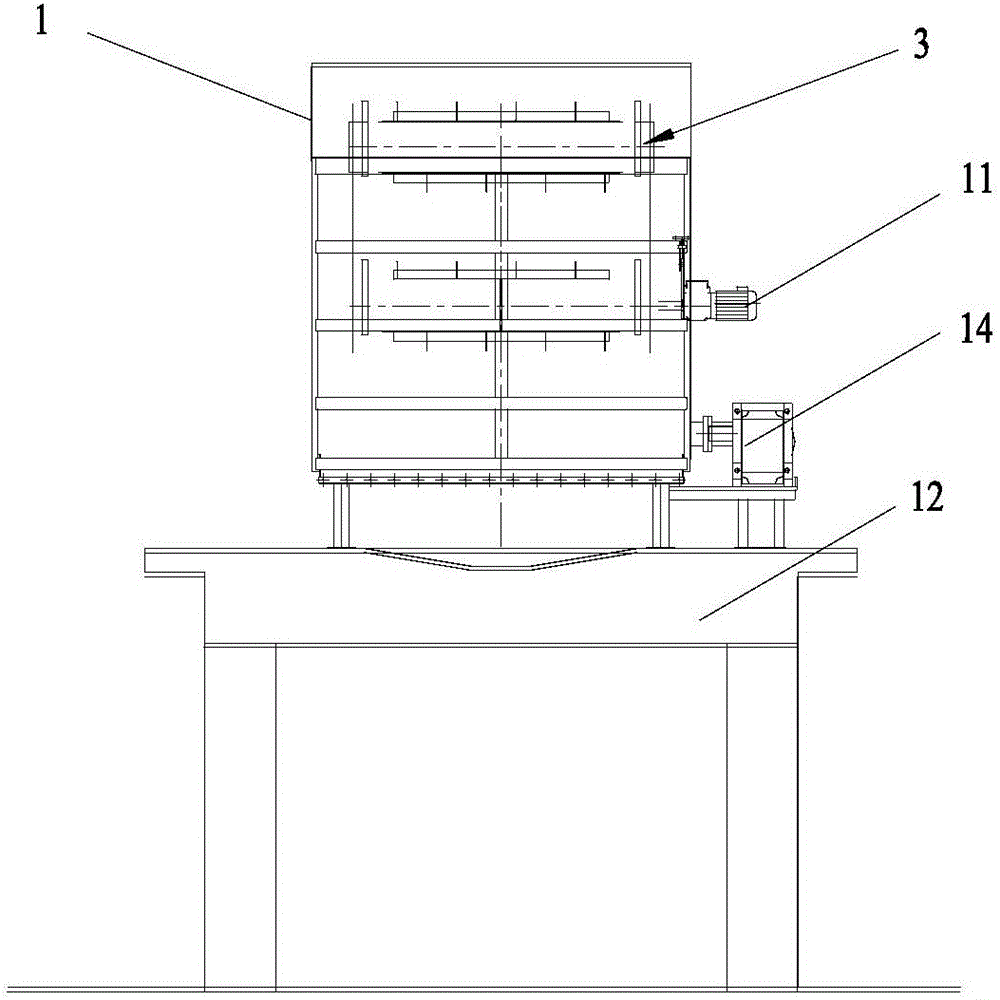

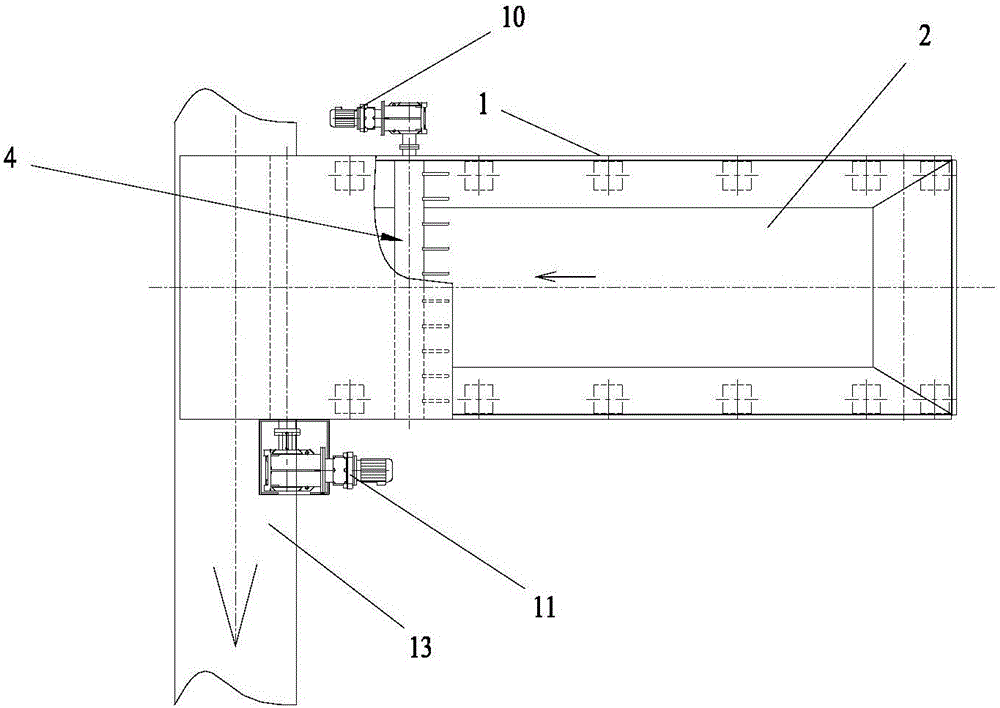

[0033] According to one aspect of the present invention, a screeding device is provided, wherein the screeding device comprises a hopper 1, a feeding device 2, a screeding device 3 and a blocking device 4, the feeding device 2, the screeding device 3 and the blocking device 4 The feeding device 4 is located in the hopper, and the feeding device transports the mate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap