Vibrating reed, vibrator, vibration device, sensor, and electronic device

A technology of electronic equipment and vibrating plates, applied in the direction of power oscillators, piezoelectric devices/electrostrictive devices, material selection for piezoelectric devices or electrostrictive devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach )

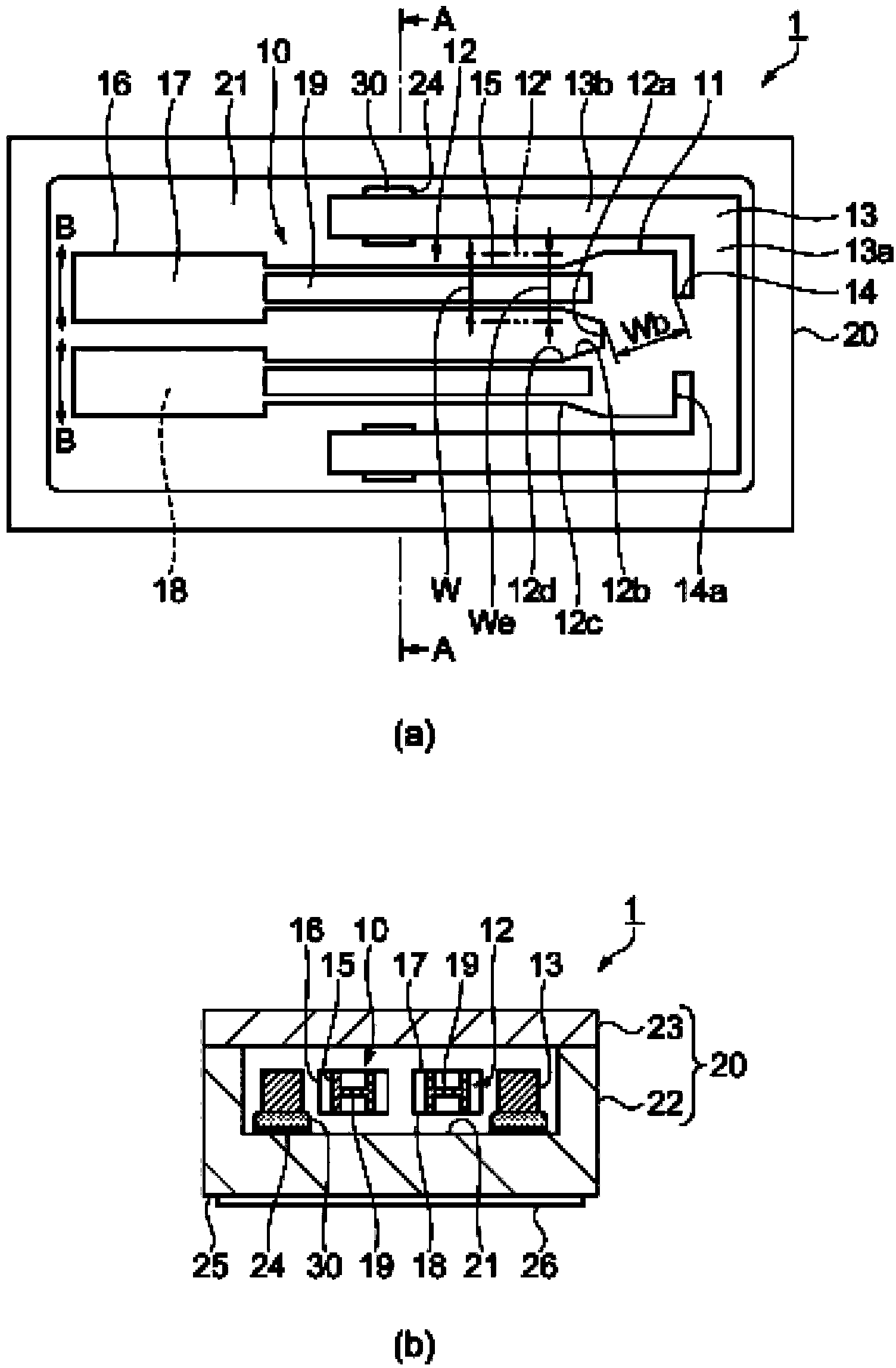

[0042] figure 1 It is a schematic diagram showing the schematic structure of a crystal resonator as a vibration device. figure 1 (a) is a plan view from the cover (cover body) side, figure 1 (b) is along figure 1 The sectional view of the AA line in (a). In addition, in the plan view, the cover is omitted for convenience.

[0043] like figure 1 As shown, the crystal resonator 1 includes a tuning-fork-type crystal resonator reed 10 as a resonator reed that flexibly vibrates in the arrow B direction, and a package 20 that accommodates and fixes the crystal resonator reed 10 therein.

[0044] The quartz vibrating piece 10 has: a base portion 11; a pair of vibrating arms 12 which are integrally formed with the base portion 11 and extend substantially parallel to each other from one end side of the base portion 11; and a support portion 13 which is integrally formed with the base portion 11 and which The other end side of 11 is connected.

[0045] The base 11 of the quartz vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com