Dual-chamber mixing device for syringes

A technology of mixing device and syringe, which is applied in the directions of syringes, hypodermic injection devices, infusion sets, etc., can solve the problems of complex structure, limitations on the ease of manufacture and operation of the mixing device, and difficulty in exhausting requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

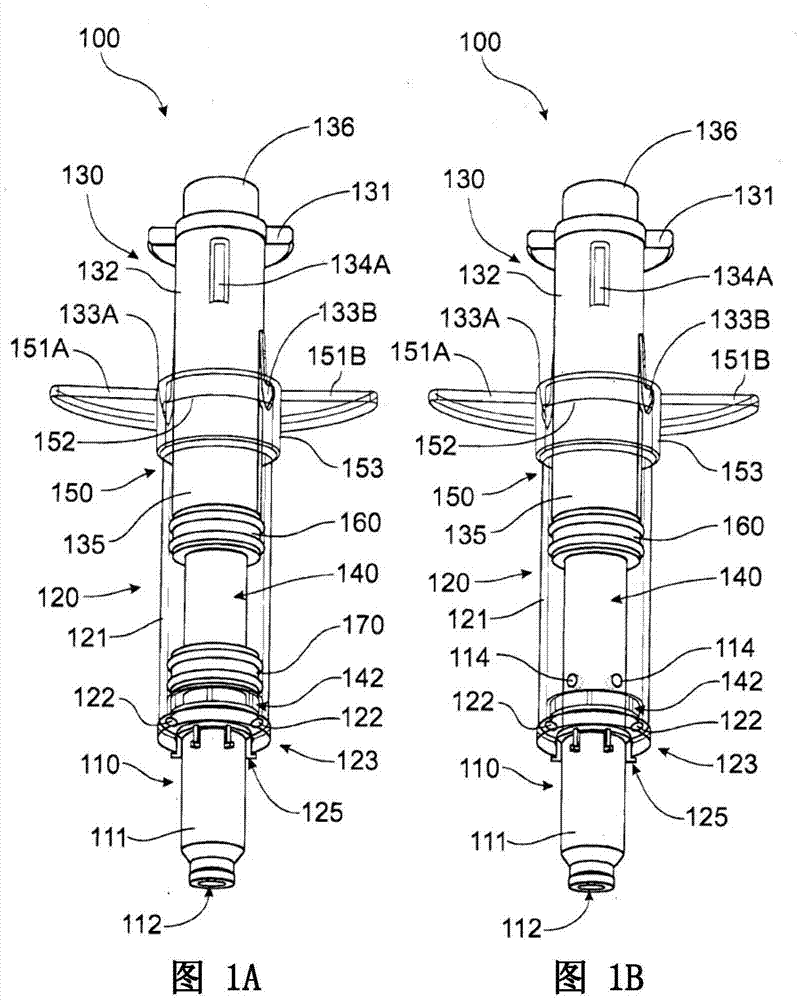

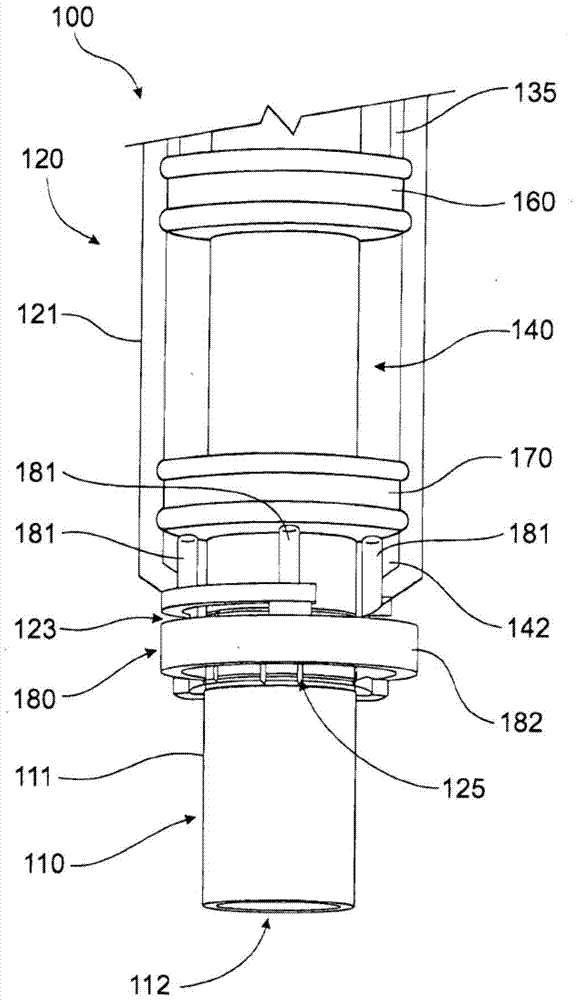

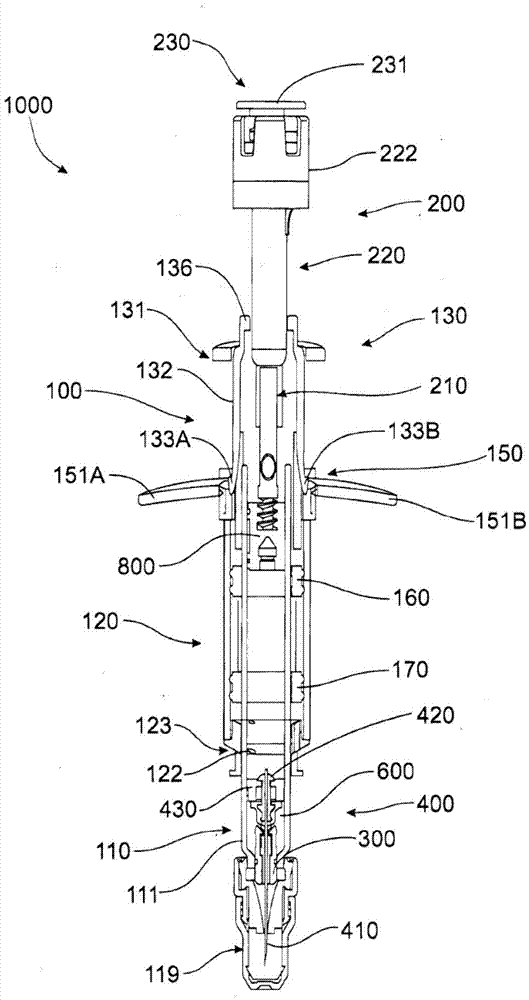

[0059] 1A and 1B, an embodiment of the mixing device 100 includes an inner barrel 110, an outer barrel 120 including a wall 121, and a mixing plunger 130. The inner barrel 110 includes a wall 111 and an inner cavity 112. The outer cavity 140 is formed between the wall 111 of the inner cylinder 110 and the wall 121 of the outer cylinder 120. The inner cylinder 110 and the outer cylinder 120 may be made of any number of materials, including plastic and glass, but are preferably made of glass. The inner cylinder 110 and the outer cylinder 120 are substantially in a concentric relationship, so that the inner cylinder 110 and the outer cylinder 120 have a substantially common central longitudinal axis. The inner cylinder 110 and the outer cylinder 120 are not rotatable relative to each other.

[0060] The outer cylinder extension 150 includes finger handles 151A, B to assist the user in grasping. The outer tube extension 150 may be integrally formed on the outer tube 120 or may be a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com