Vacuum valve and closing member that closes the flow path in an airtight manner by linear movement

A technology of linear movement, flow path, applied in the direction of sliding valves, engine components, valve devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

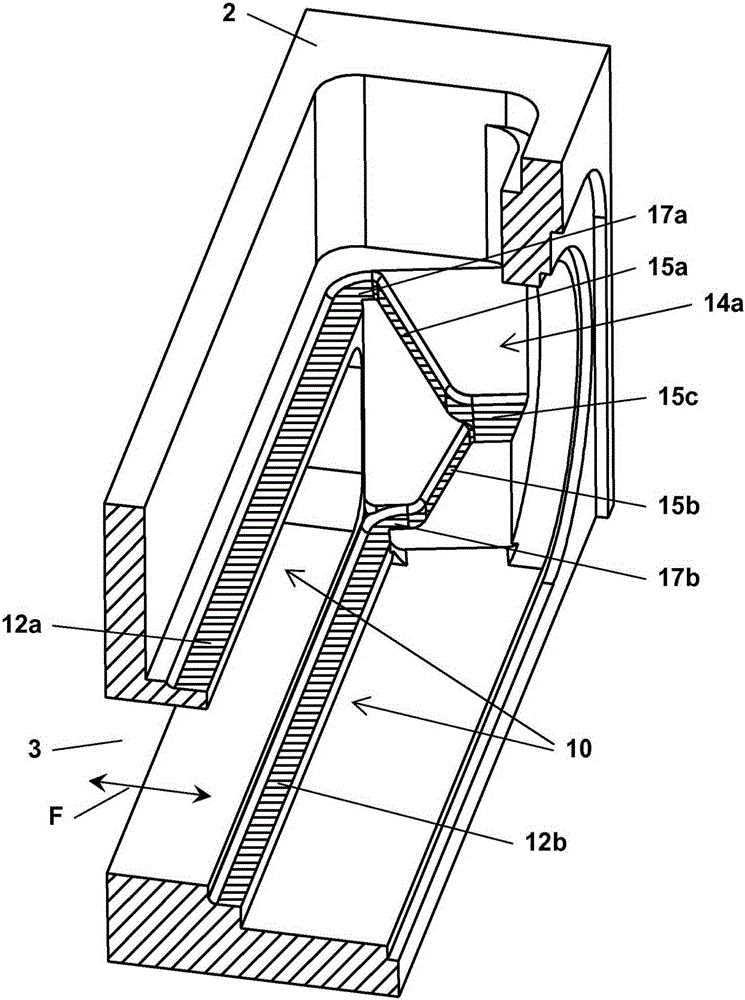

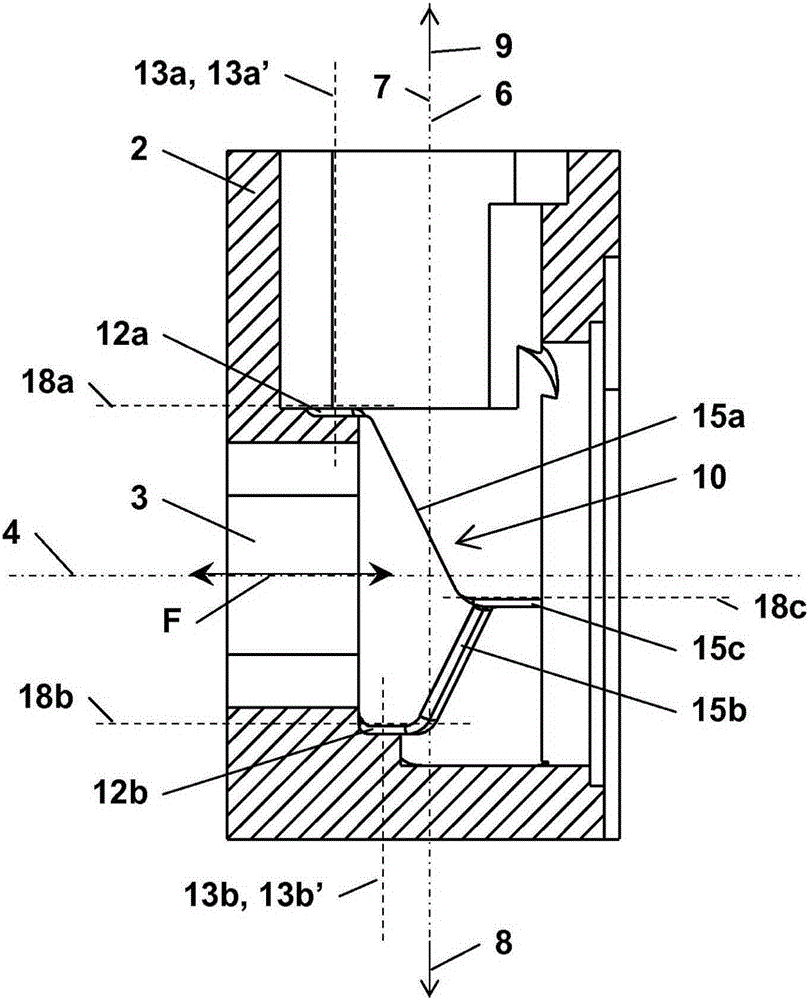

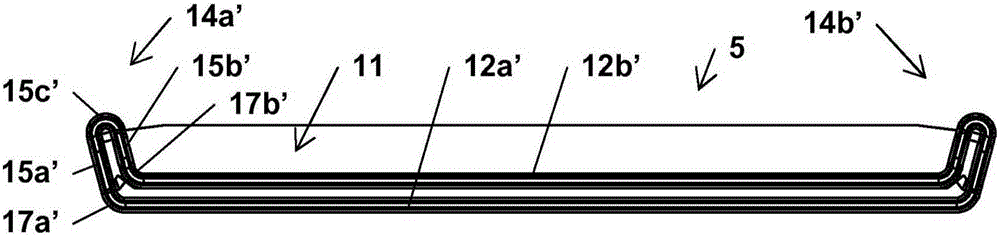

[0124] Figure 1a to Figure 2e , Figure 3a to Figure 3e with Figure 4a to Figure 5e Common exemplary embodiments of vacuum valves or closure members in various states, all as claimed in the present invention, are shown from various views and various levels of detail. Thus, in each case, the groups of figures are described together. according to Figure 2f with Figure 2g variants and based on Figure 4a to Figure 5e Exemplary implementation of and based on Figure 1a to Figure 2e with Figure 3a to Figure 3e The exemplary embodiments differ only in some features, which is part of the reason why only details of the differences between variants and embodiments are given. In part, details of references and features already explained in the previous figures will not be given. Figure 8a with Figure 8b It has been stated in detail in connection with the statements of the prior art.

[0125] Figure 1a to Figure 2e with Figure 3a to Figure 3e A first embodiment of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tilt angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com