Patents

Literature

43 results about "Zone valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

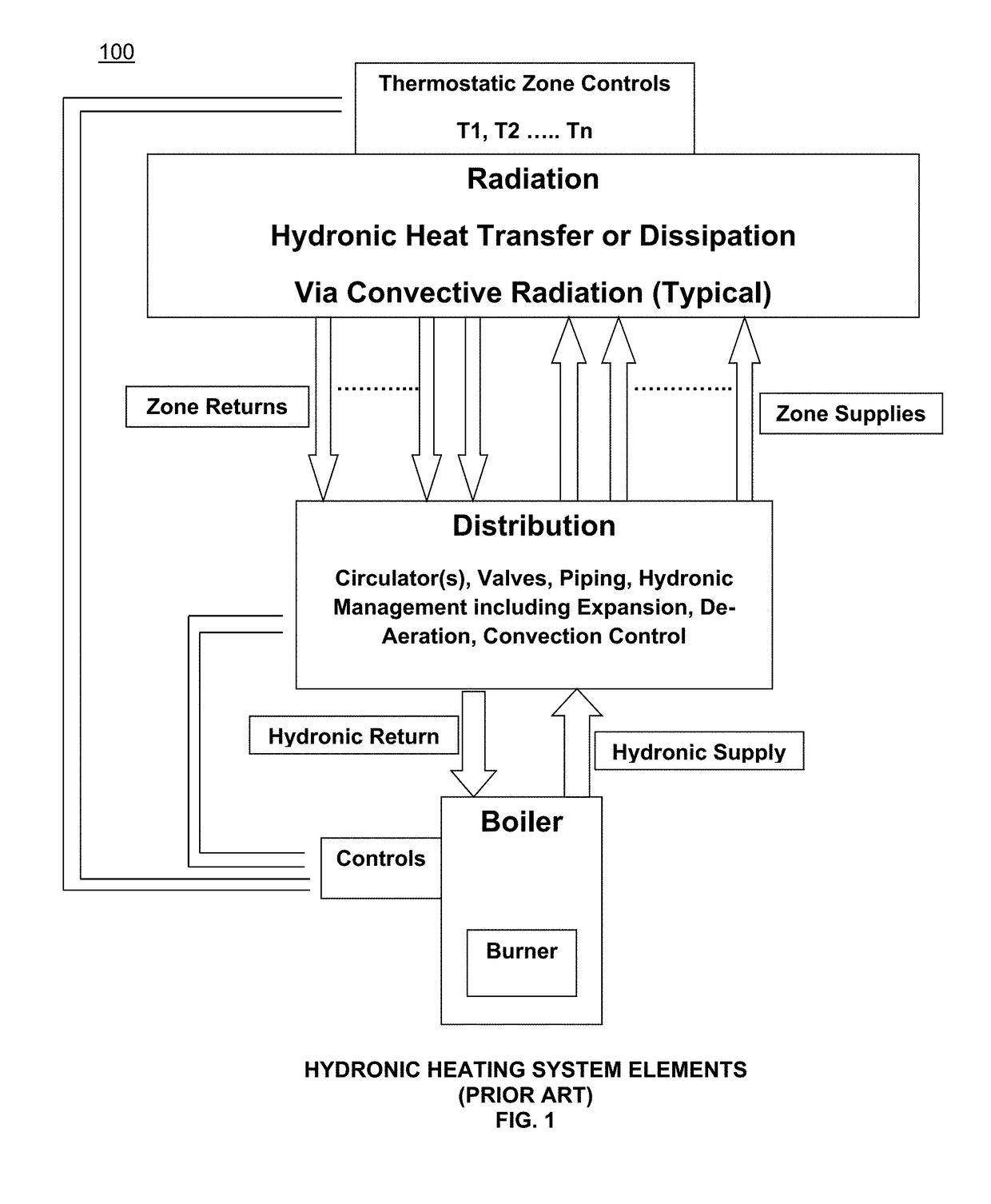

A zone valve is a specific type of valve used to control the flow of water or steam in a hydronic heating or cooling system. In the interest of improving efficiency and occupant comfort, such systems are commonly divided up into multiple zones. For example, in a house, the main floor may be served by one heating zone while the upstairs bedrooms are served by another. In this way, the heat can be directed principally to the main floor during the day and principally to the bedrooms at night, allowing the unoccupied areas to cool down.

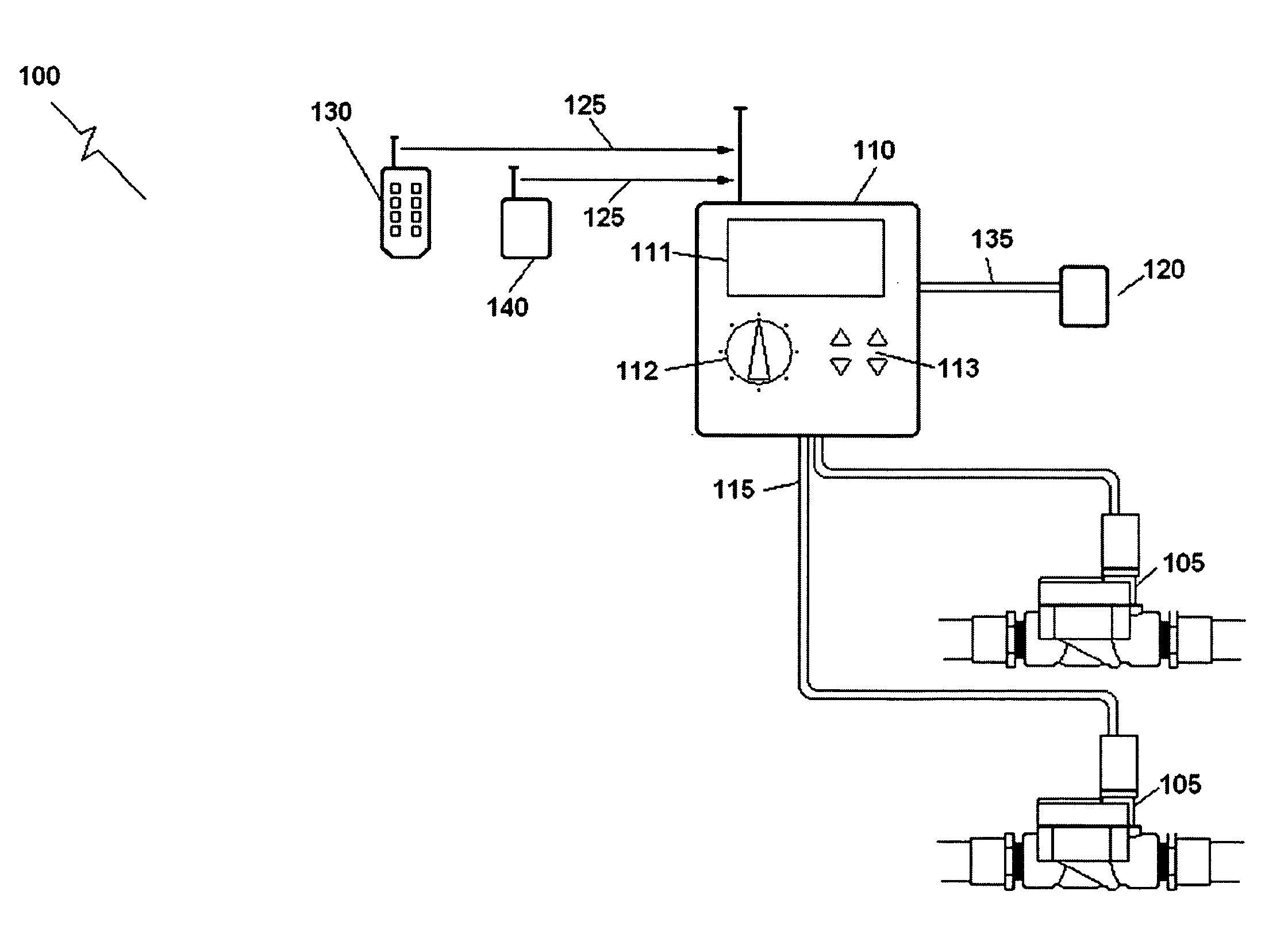

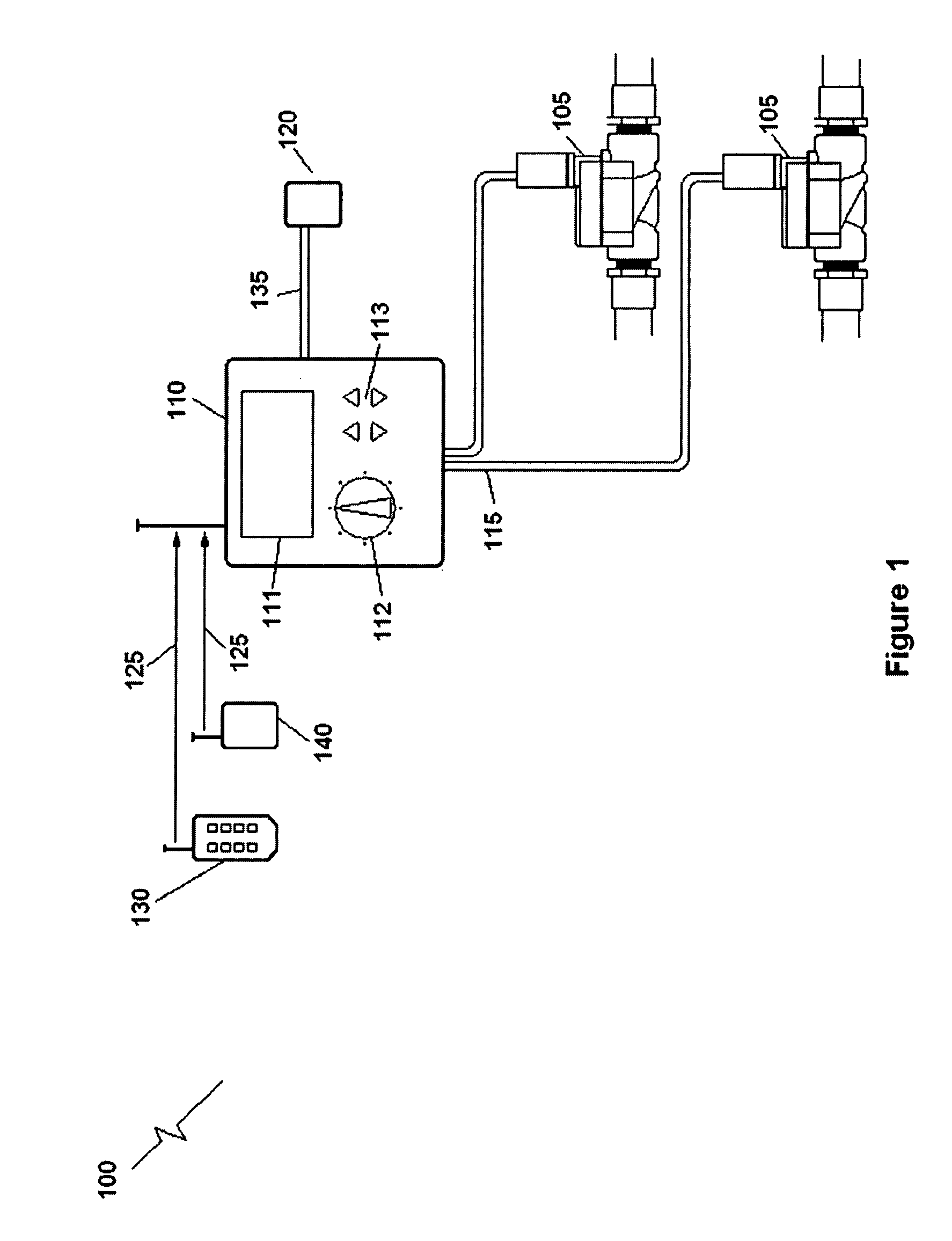

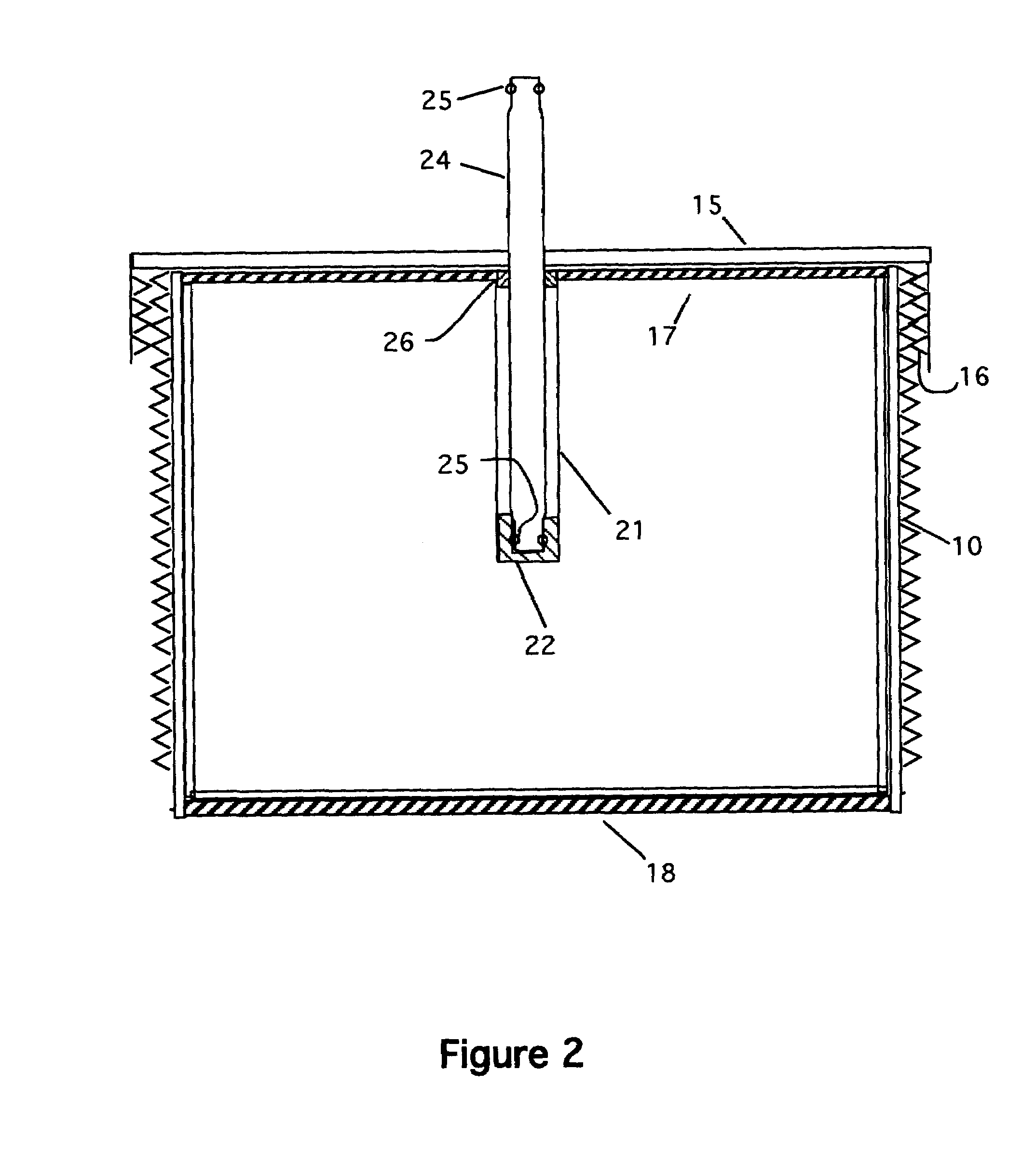

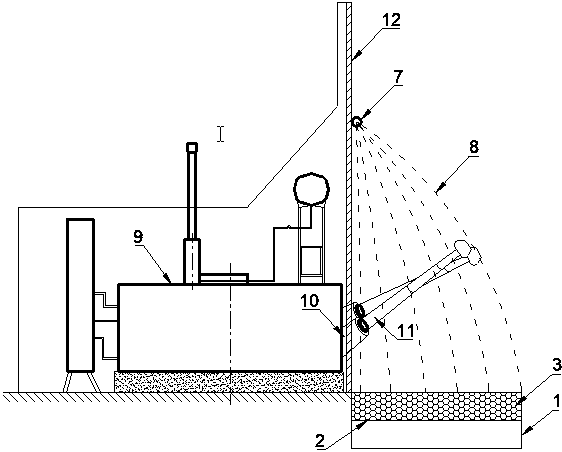

Wireless Irrigation and Trespasser Deterrent Control System (WITDCS)

InactiveUS20080251602A1Cost effectiveEliminate needSelf-acting watering devicesClimate change adaptationMotion detectorEngineering

A Wireless Irrigation and Trespasser Deterrent Control System used for controlling a remote irrigation system comprising a plurality of sprinklers connected by water pipes to one or more electric zone valves having wireless valve controllers. Included is a wireless system controller that communicates with the remote wireless valve controllers when a signal is received from a sensor such as a motion detector in order to turn the sprinklers on or off. Other sensors are possible such as soil moisture sensors and rain sensors. A handheld remote controller is also included.

Owner:LEGGETT CURTIS STEPHEN +1

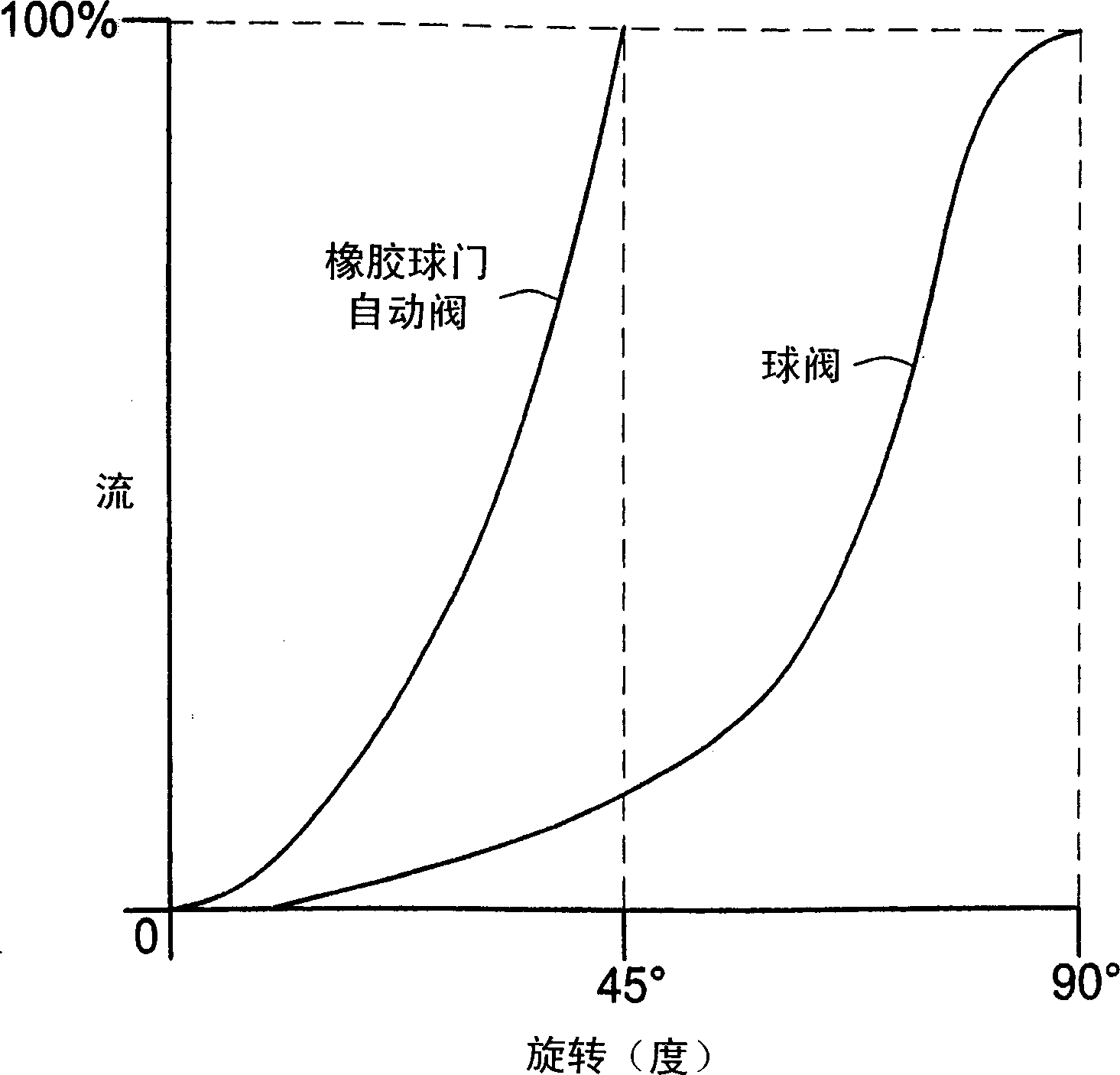

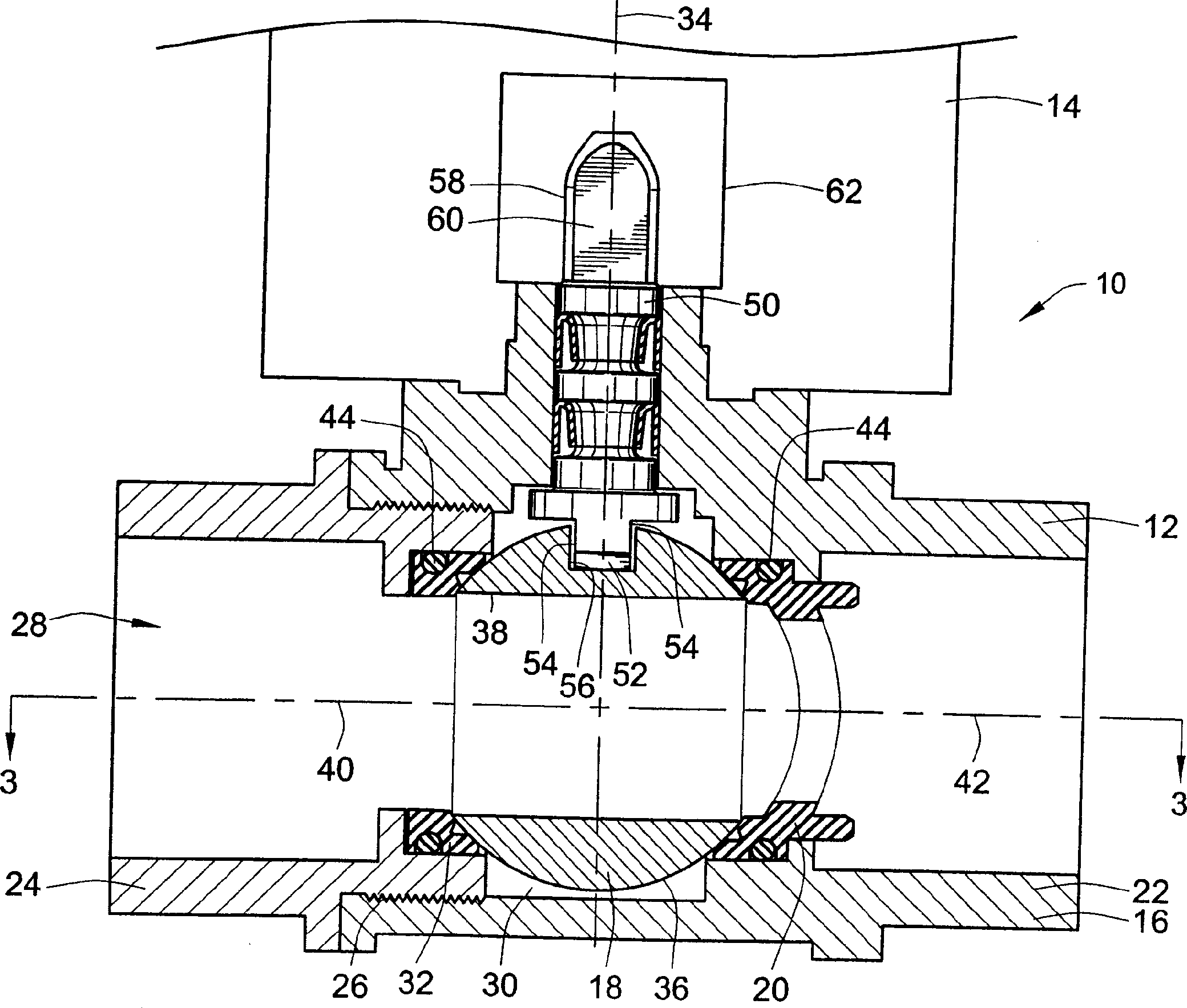

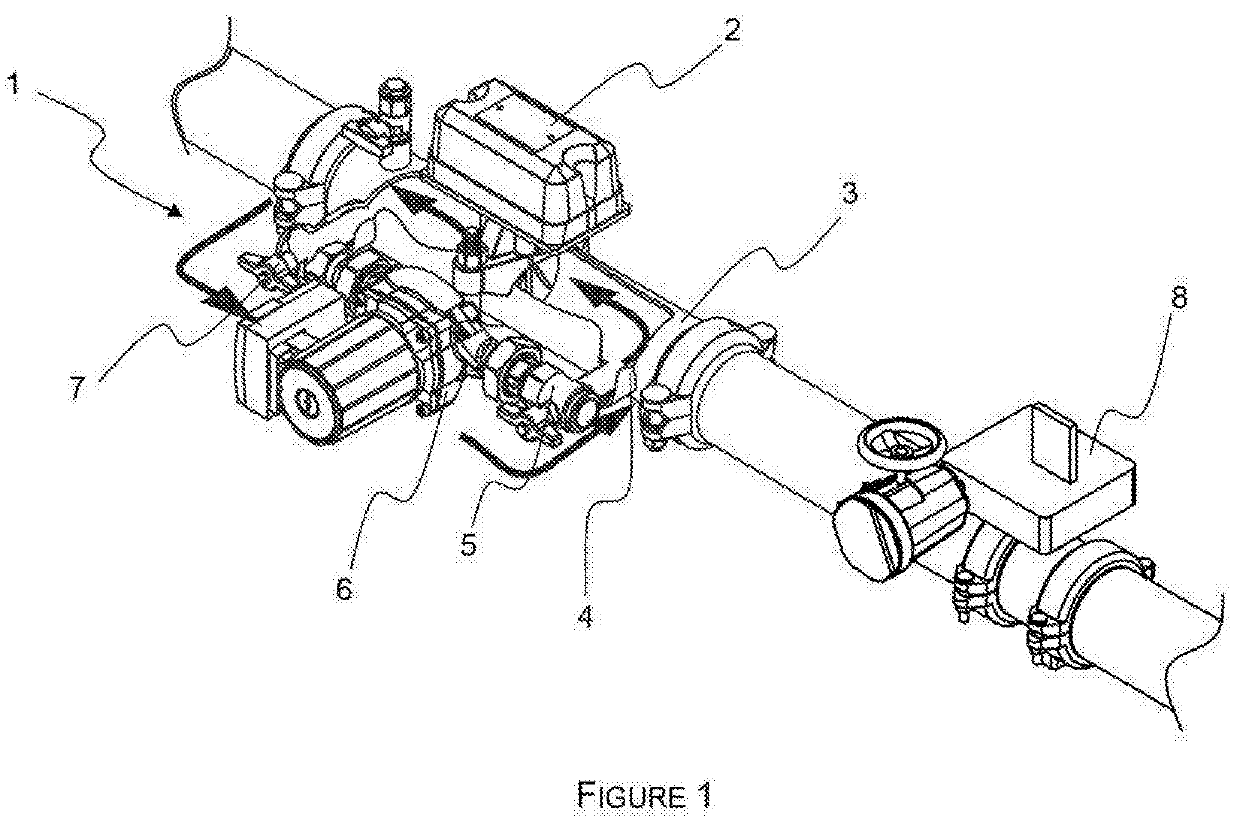

Apparatus and method for replacing existing actuator zone valves in an HVAC system with a ball valve

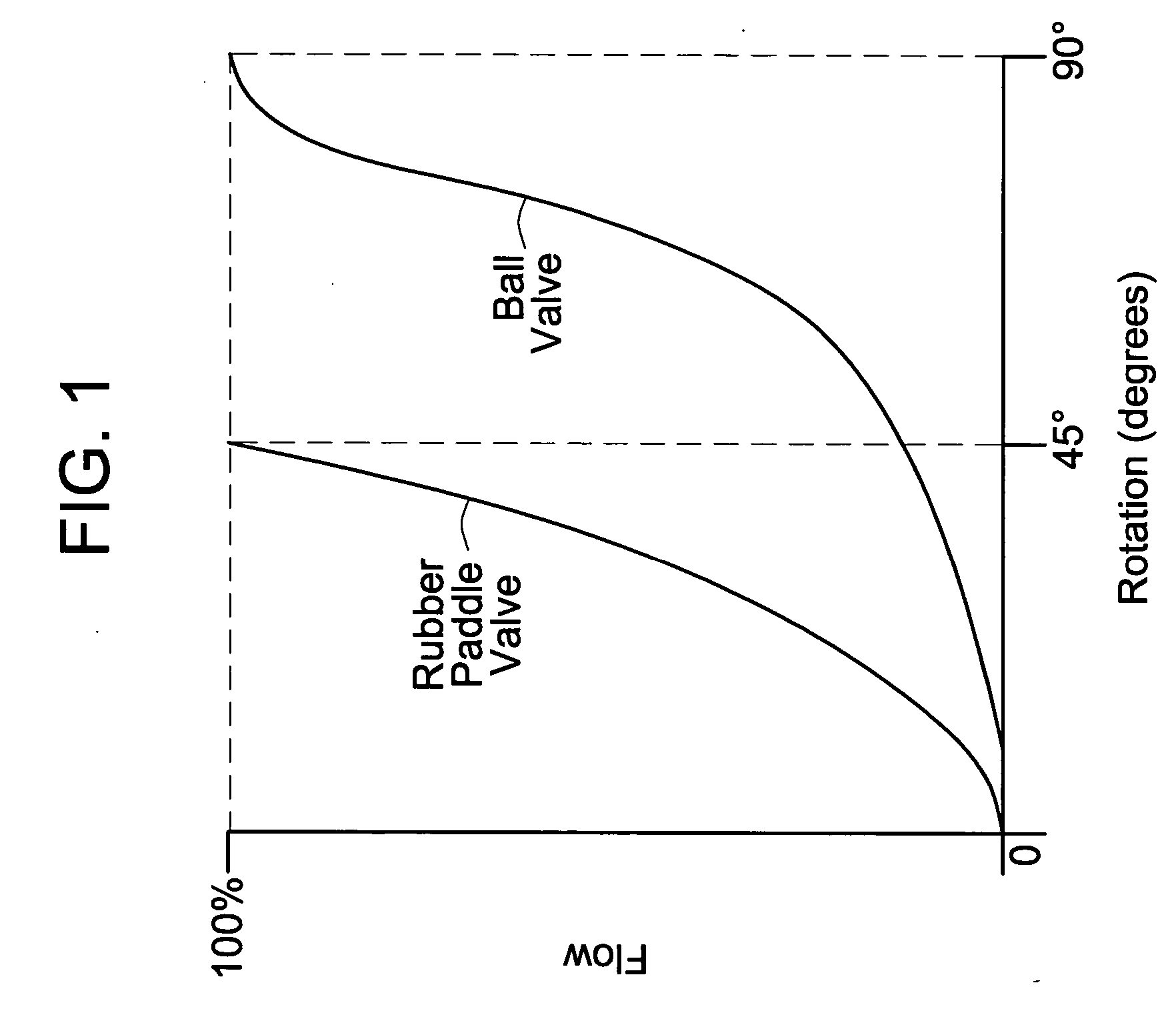

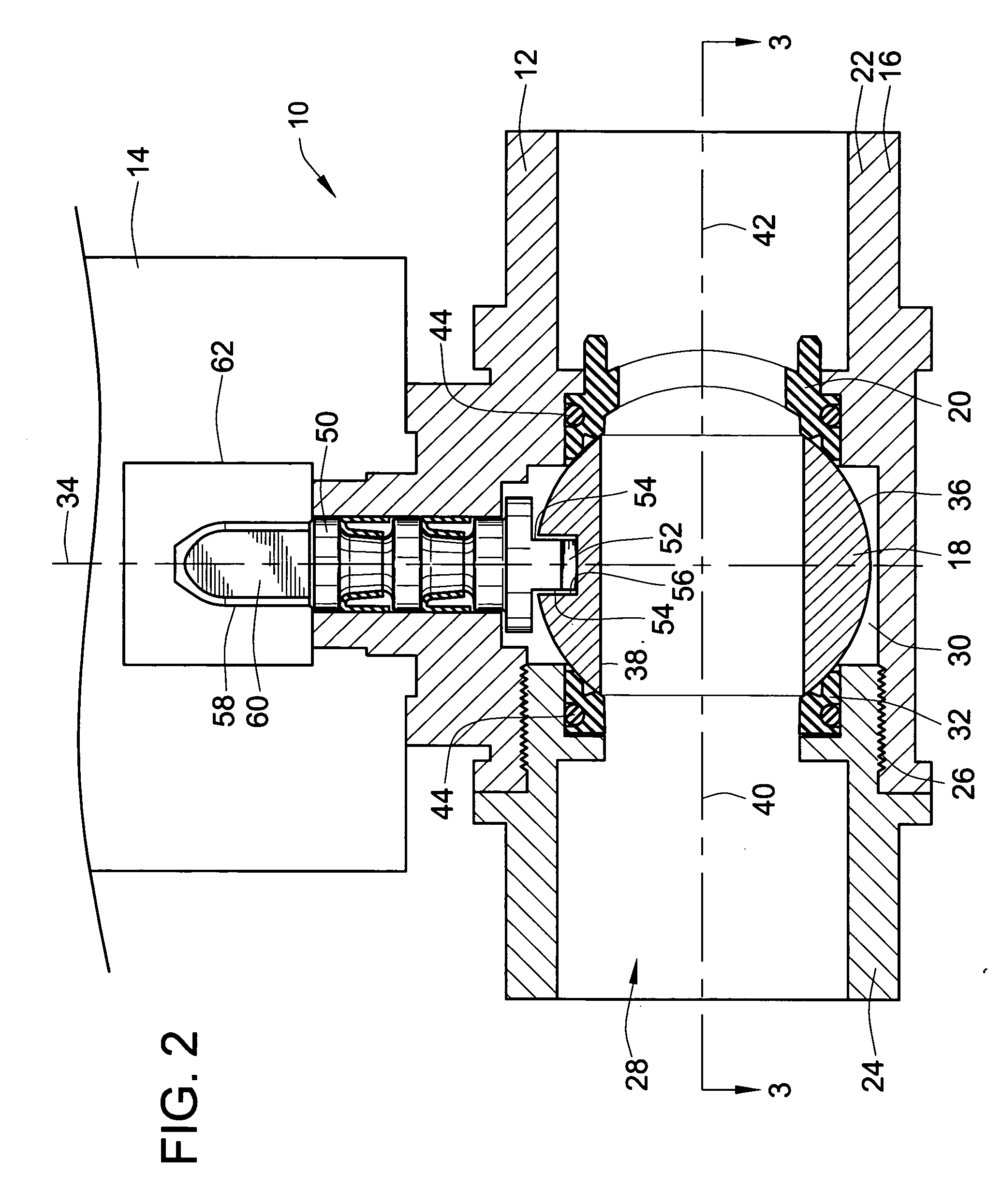

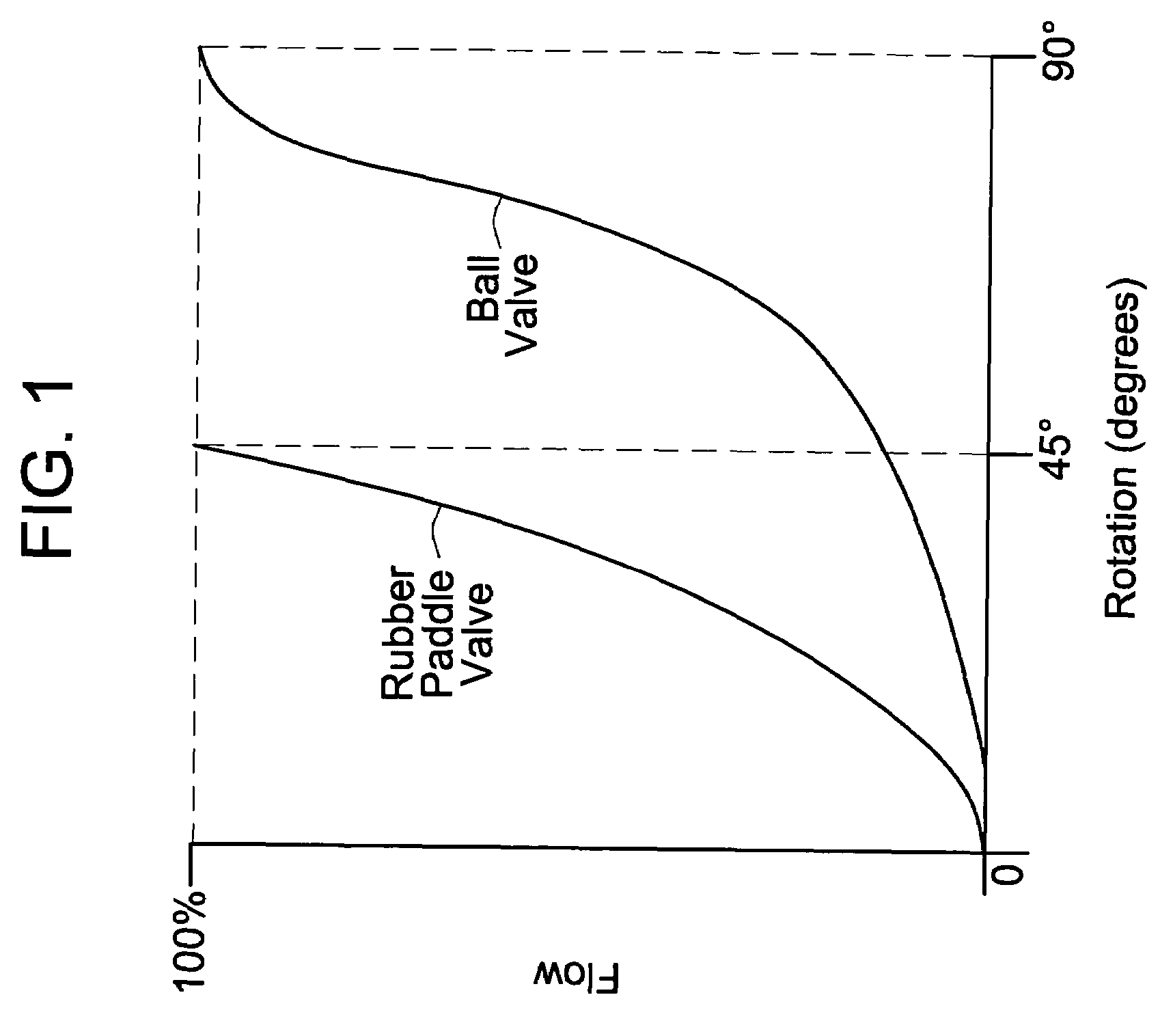

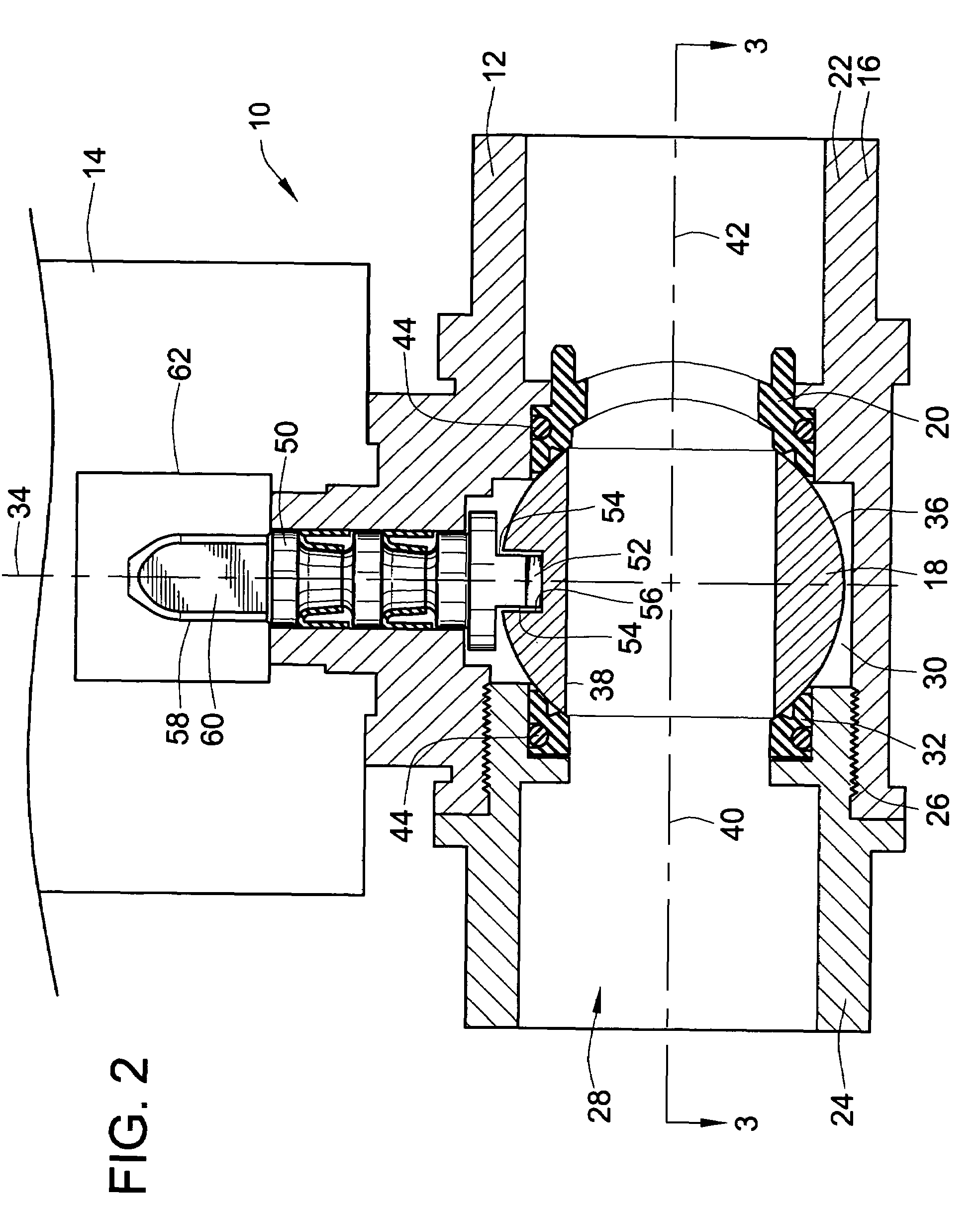

An apparatus and method are provided for replacing existing actuator driven zone valves in an HVAC system, and particularly valves of the rubber paddle type having actuators providing less than 90 degrees of rotation, with a ball valve including a skewed seat bearing that blocks flow through the flowpath when a valve member of the ball valve is rotated through an angle of substantially less than 90 degrees from a fully open position of the valve at which a bore in the valve member is substantially fully aligned with the flowpath. The actuator from the existing zone valve being replaced may be used with the provided ball valve apparatus and method.

Owner:TAC LLC

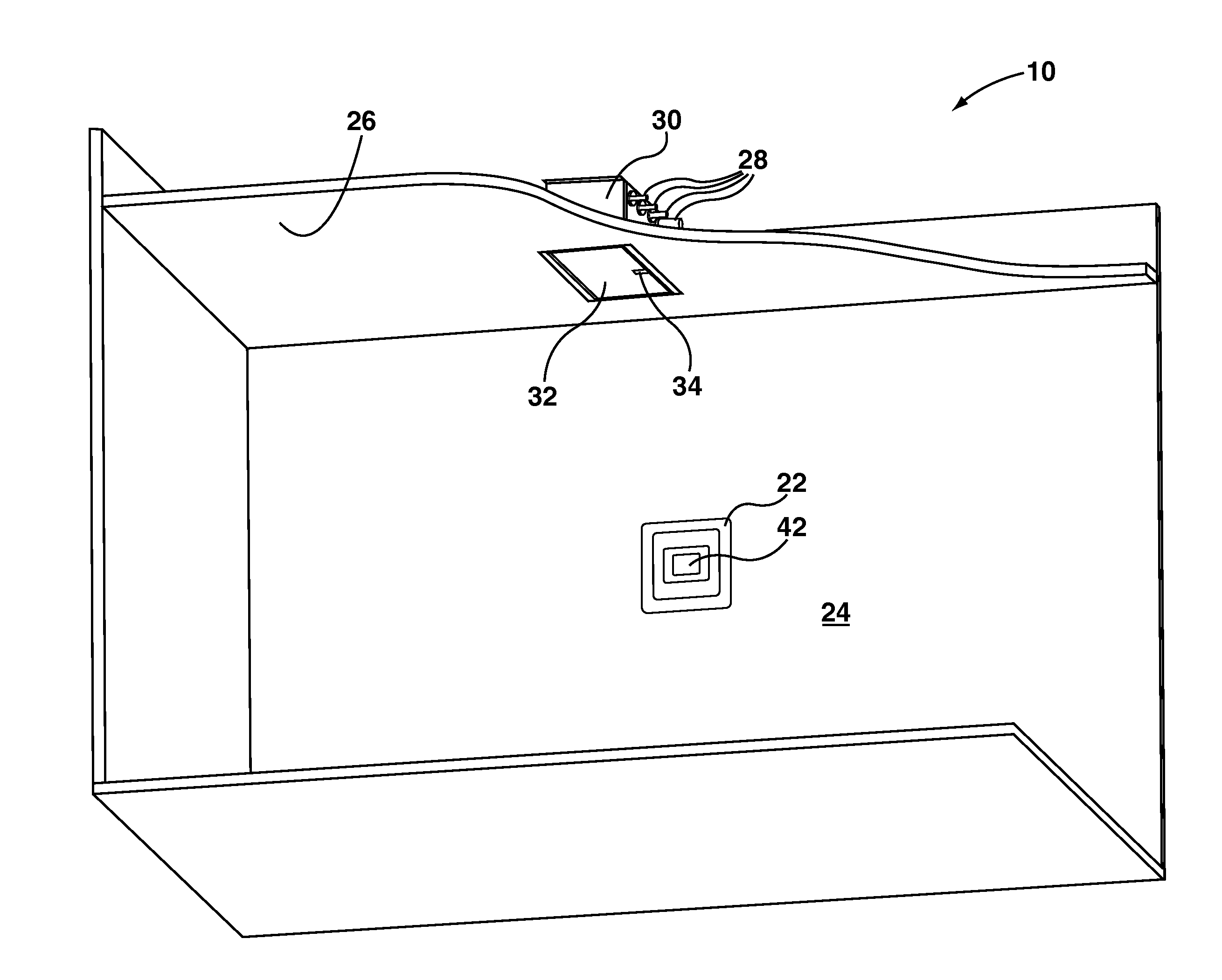

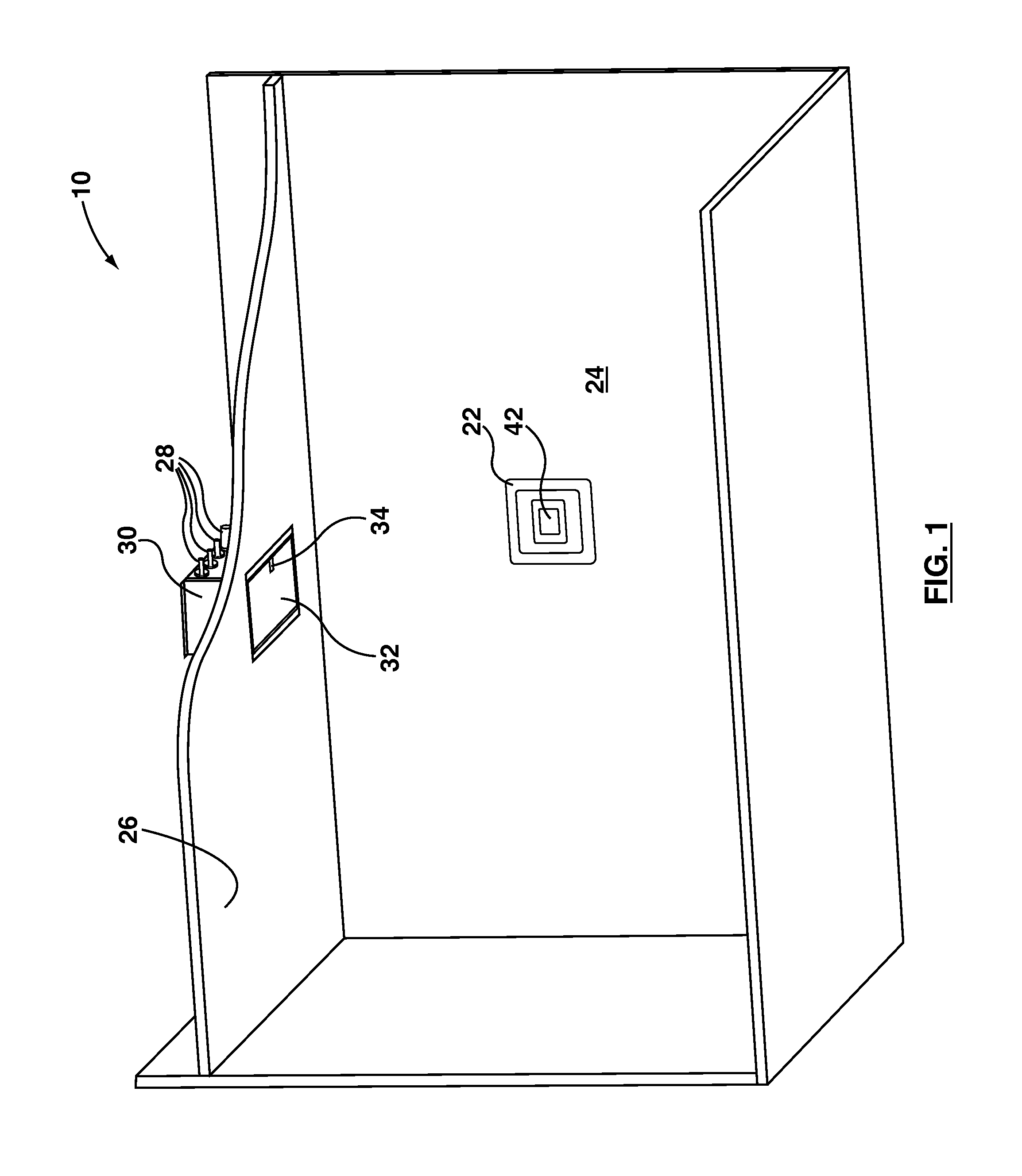

Methods and apparatus for controlling fluid flow in medical facilities

An apparatus for controlling fluid flow in a medical facility includes a plurality of remotely controlled zone valves. Each zone valve is coupled to a respective fluid conduit for opening and closing the fluid conduit to control fluid flow therethrough. The apparatus also includes an access terminal installed in a user-accessible location that is located remotely from the zone valves. For example, the zone valve may be located in a ceiling, and the access terminal may be located on a wall. The access terminal has an input interface for receiving instructions to open and close the zone valves, an output device for communicating with the zone valves to remotely open and close each zone valve based on the received instructions, and an alarm for indicating when at least one of the zone valves is closed.

Owner:CLASS 1

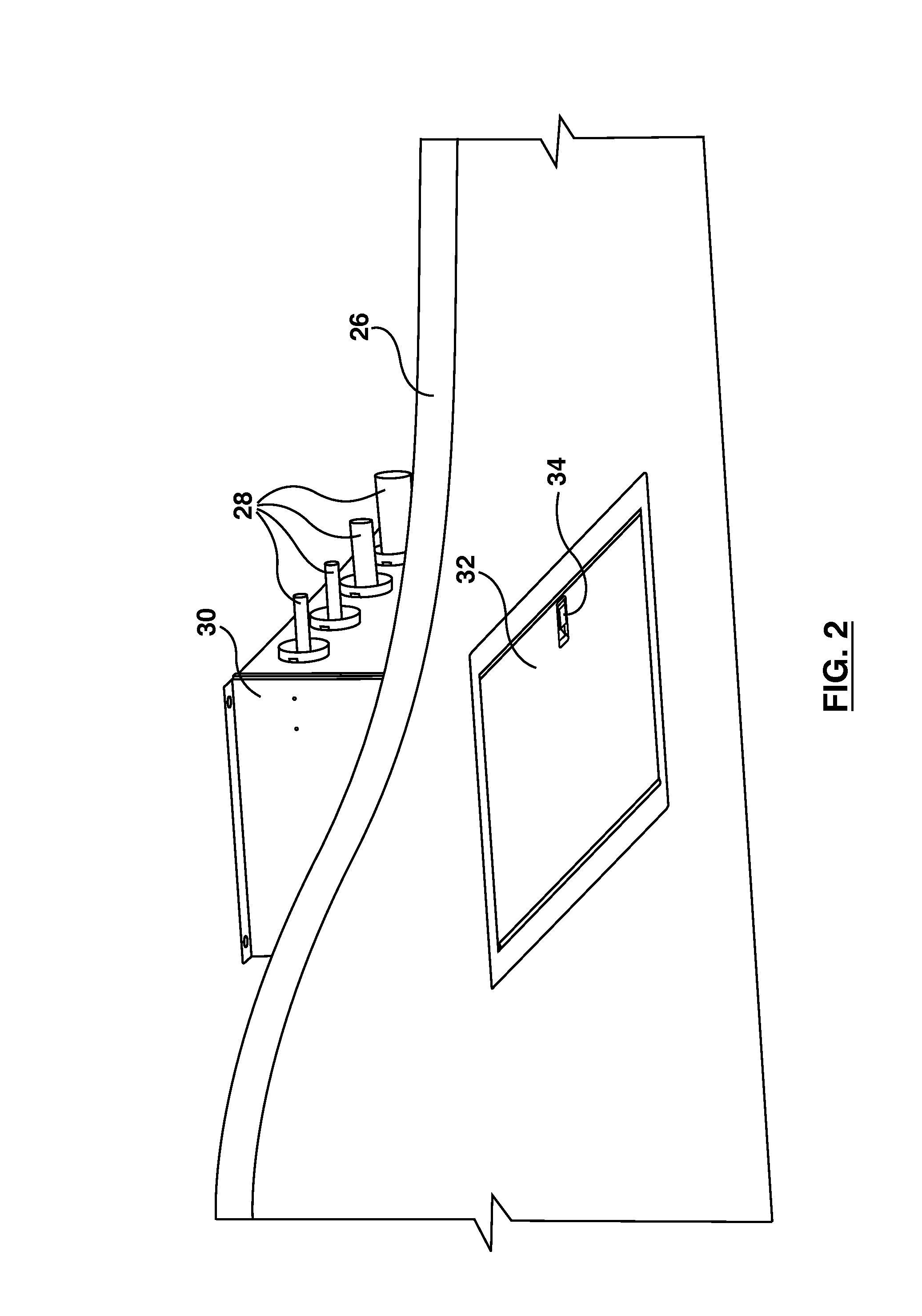

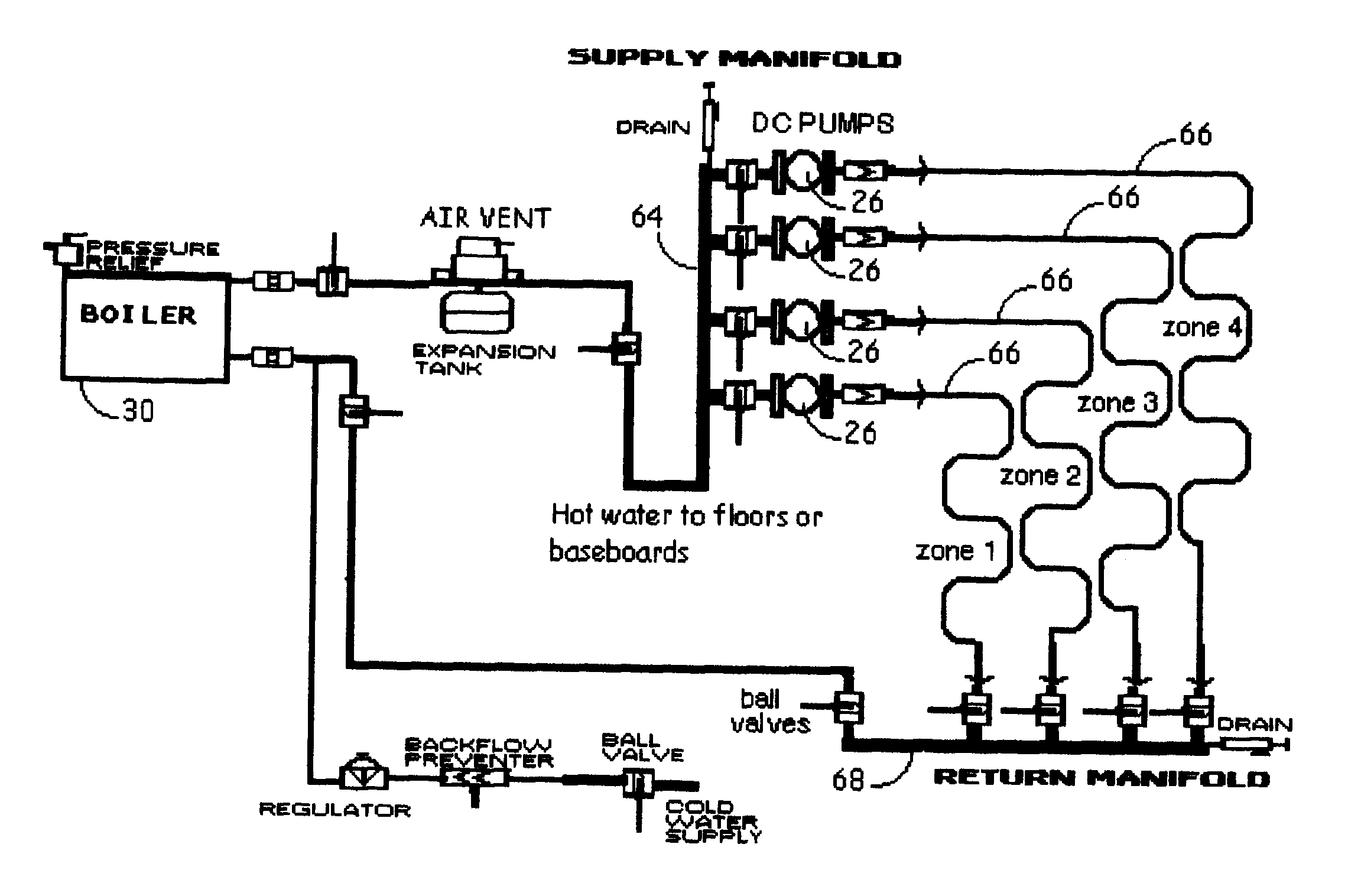

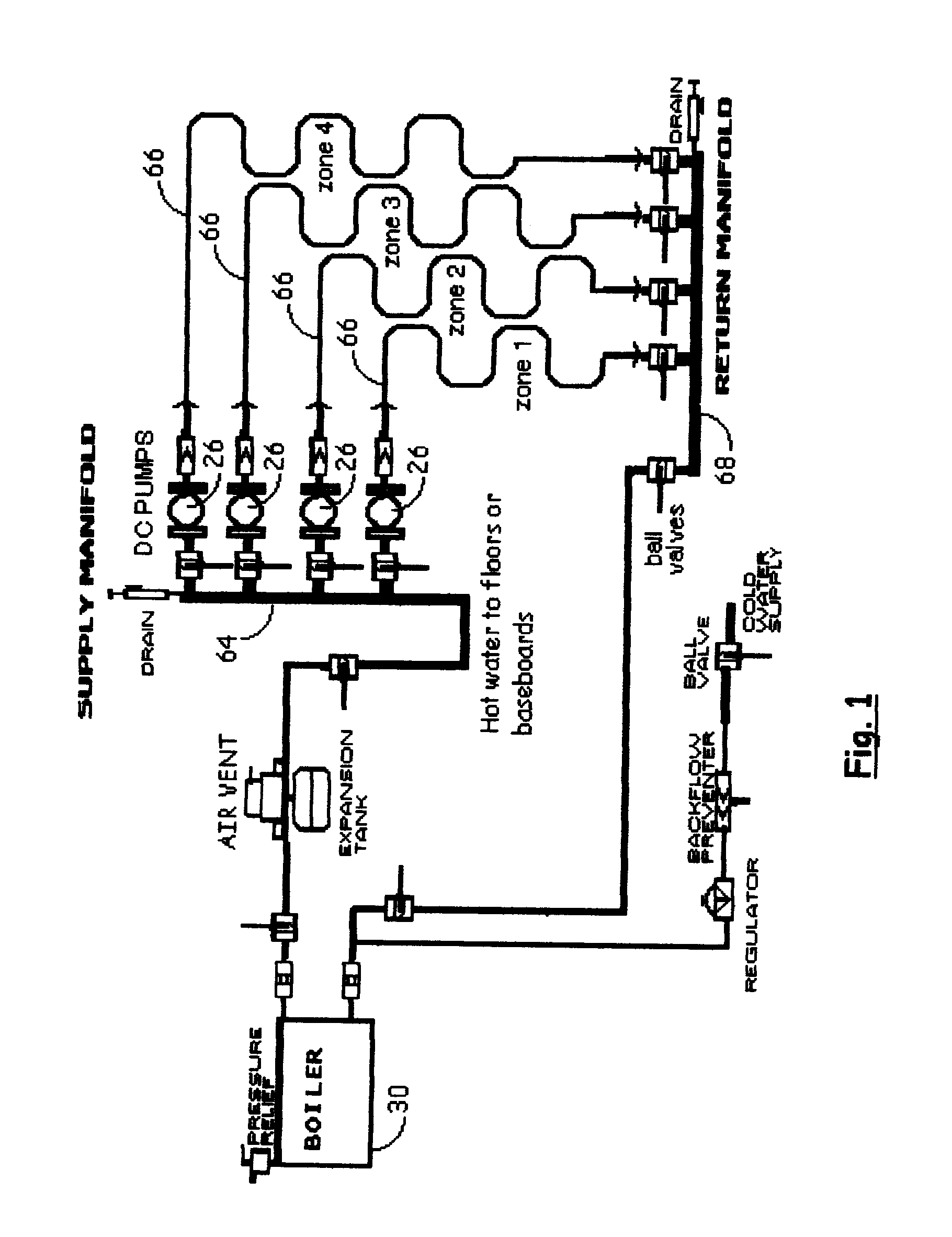

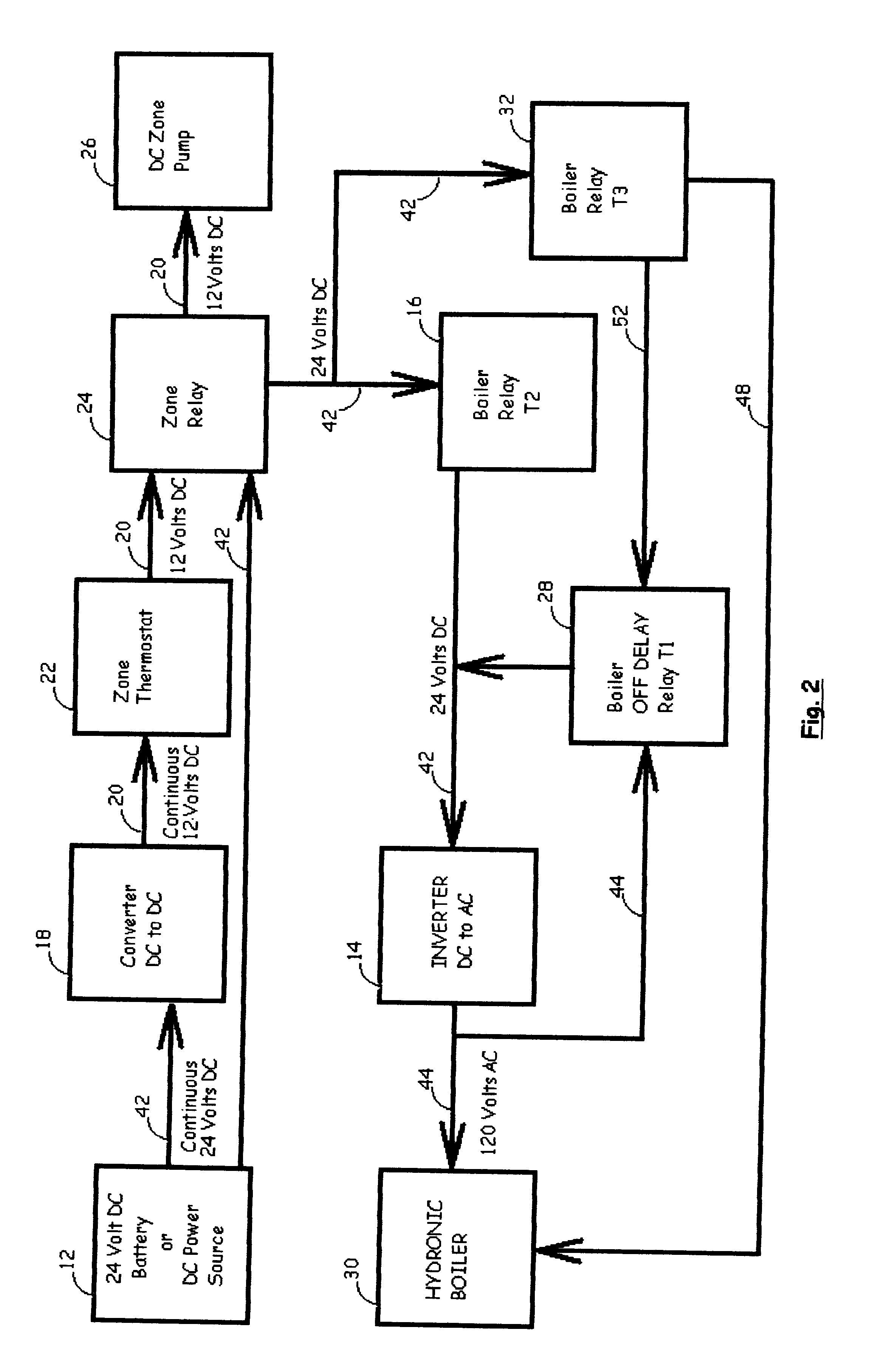

Direct current electrical controls for heating systems

InactiveUS6237855B1Extend battery lifeReduce eliminateAir-treating devicesLighting and heating apparatusZone SystemElectrical battery

A method and apparatus for controlling the normal operation of a hydronic heating system, (including AC powered, gas-burning hot water boiler, multi-zone systems) using a DC power source, such as battery power, as the primary continuous source of electricity. Control functions minimize the consumption of electric power during normal operation, and eliminate standby electric consumption in order to extend the life of the batteries and maximize the run-time of the heating system. A DC to DC converter supplies low voltage DC power to the zone thermostats, and also supplies the proper voltage through zone relays to operate DC zone pumps. By allowing the use of DC power for the thermostats and zone pumps, the system eliminates the need for transformers, zone valves, and AC circulators, resulting in a large savings in electrical consumption and the elimination of the standby electric demand ("phantom load") common in conventional hydronic heating systems. A DC to AC inverter is dedicated to supply AC power for a hydronic (hot water) boiler. The inverter is switched on by relays only when needed, thereby eliminating the "phantom electric load" consumed by most boilers when standing by. A time delay relay circuit allows the boiler to go through its proper shutdown sequence before power is removed. This control system does not require any internal modification to the other heating system components.

Owner:STICKNEY BRISTOL L +1

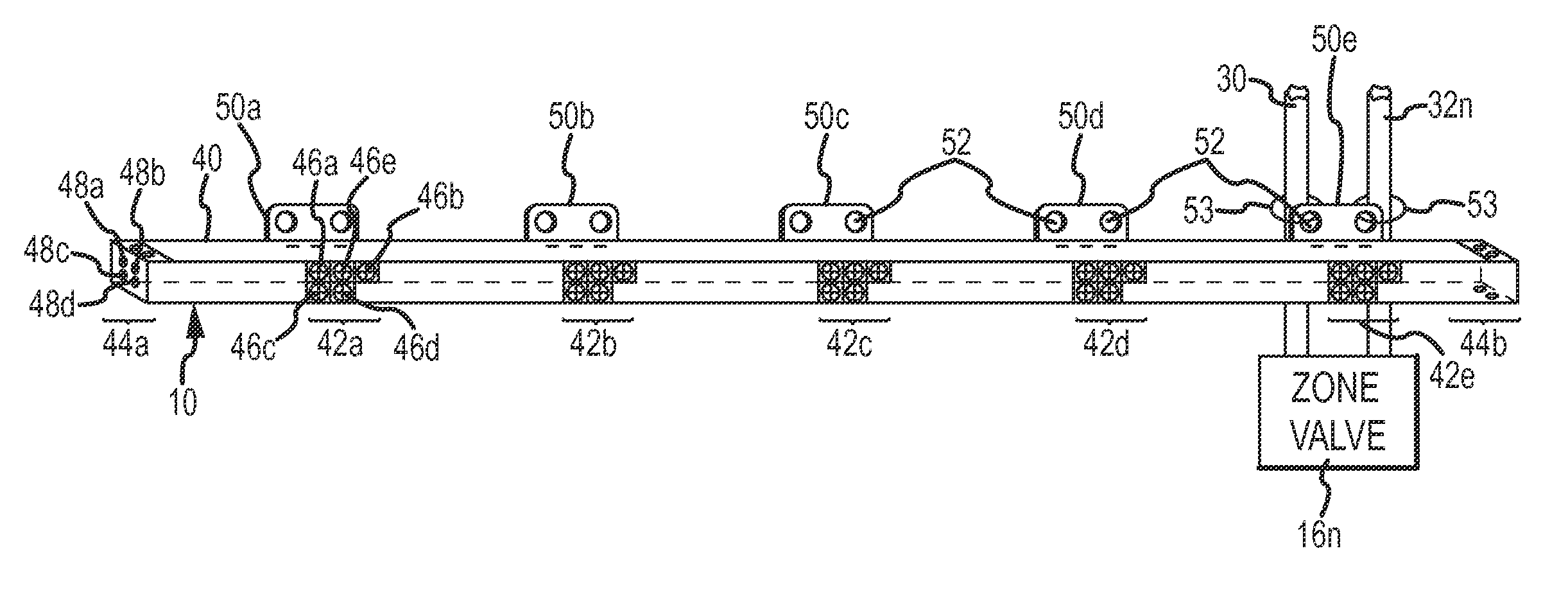

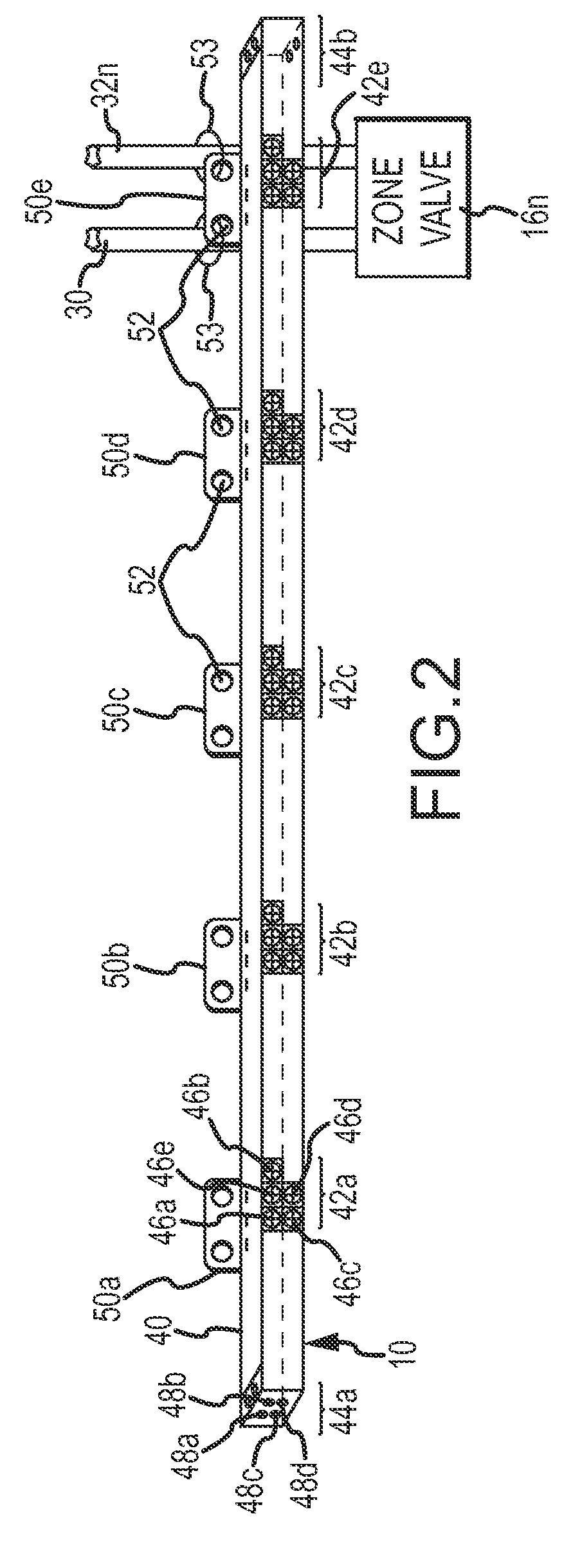

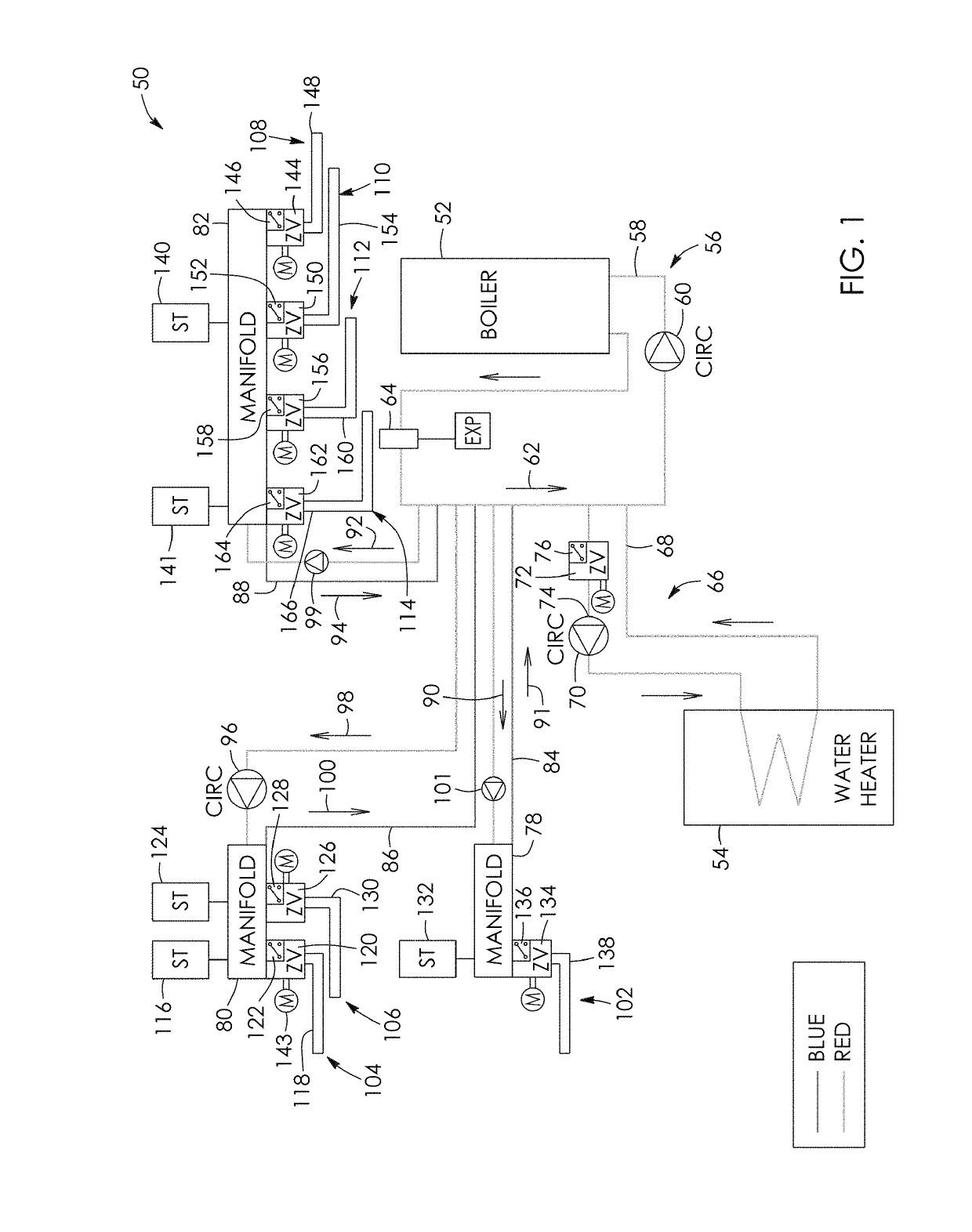

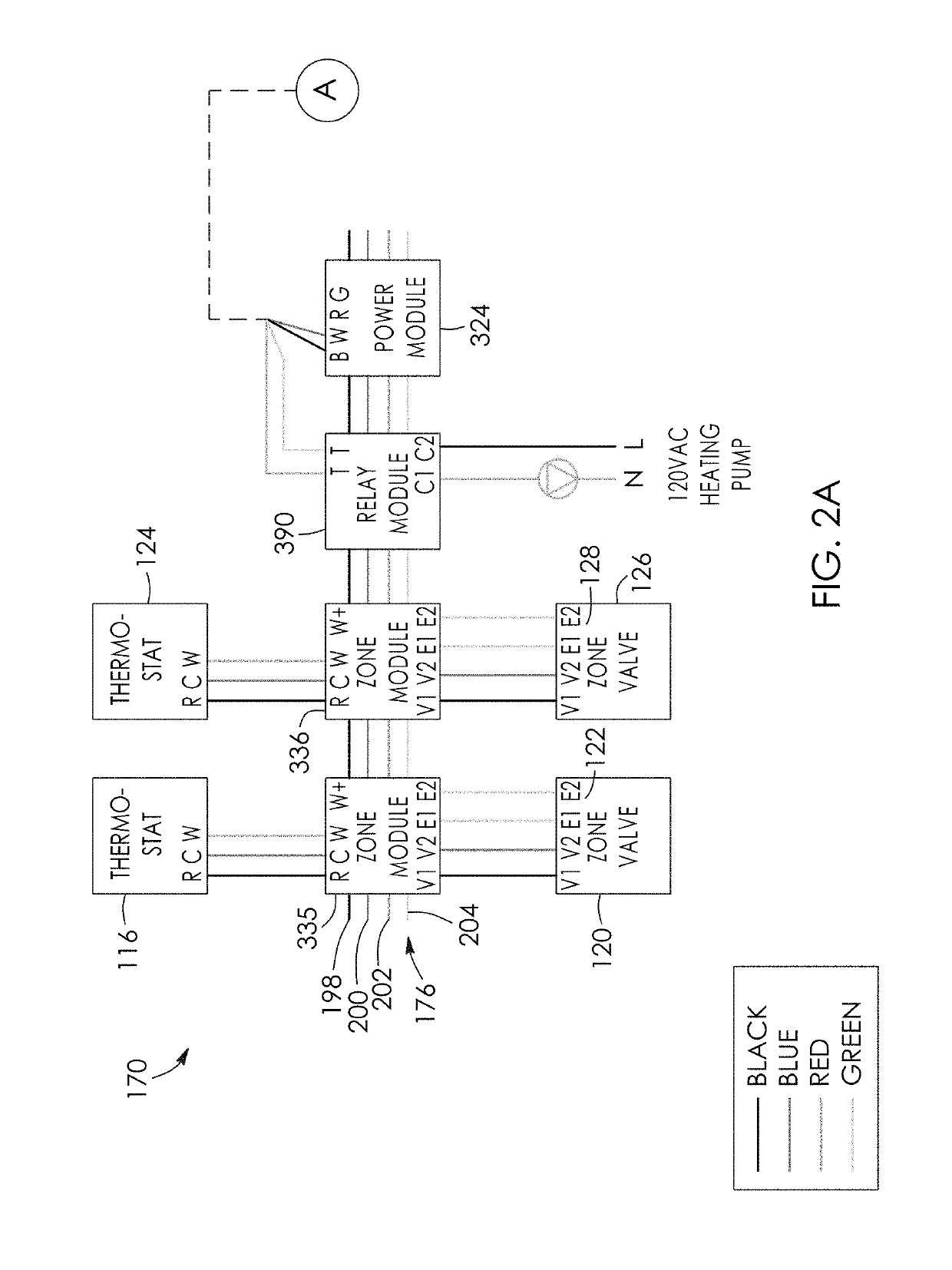

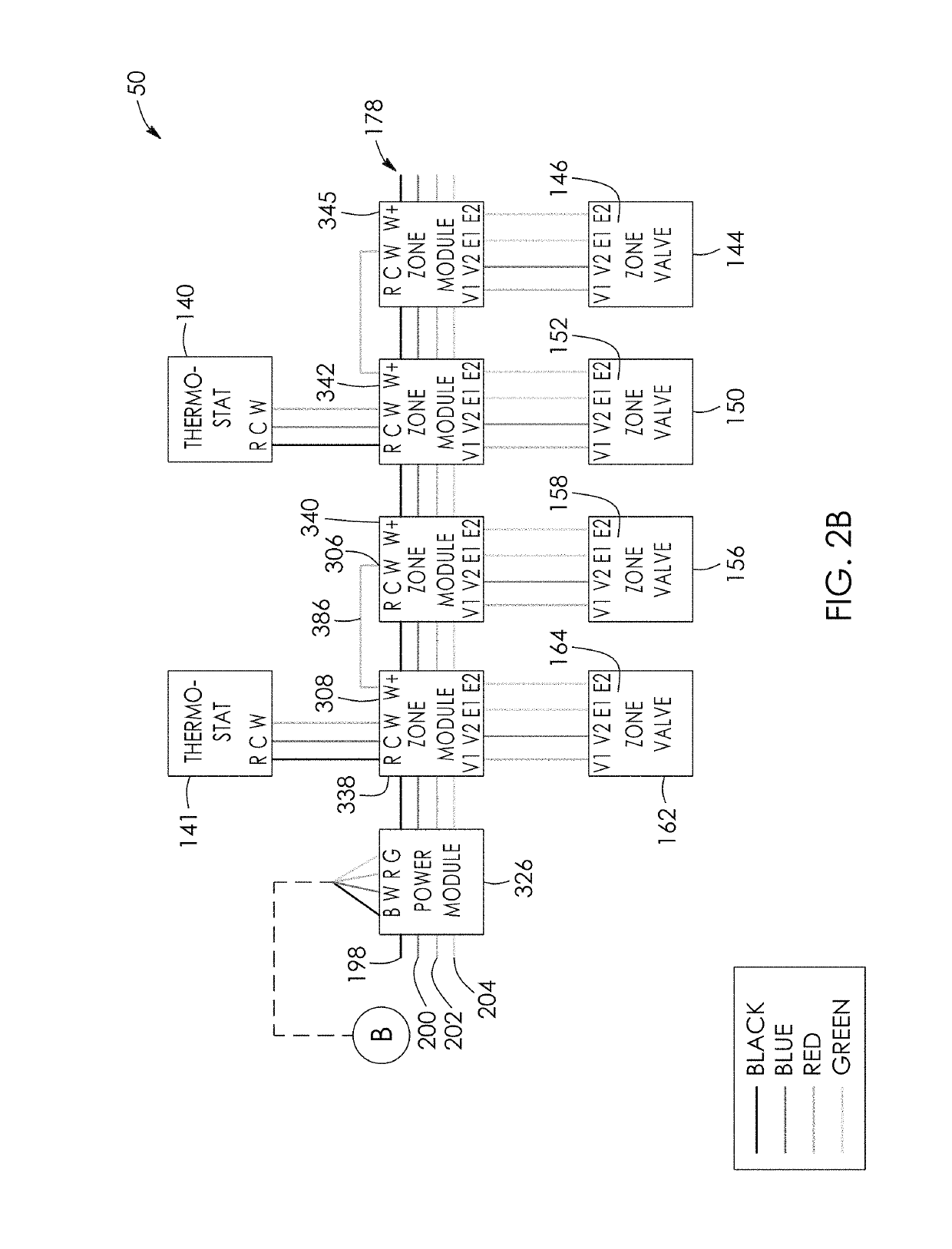

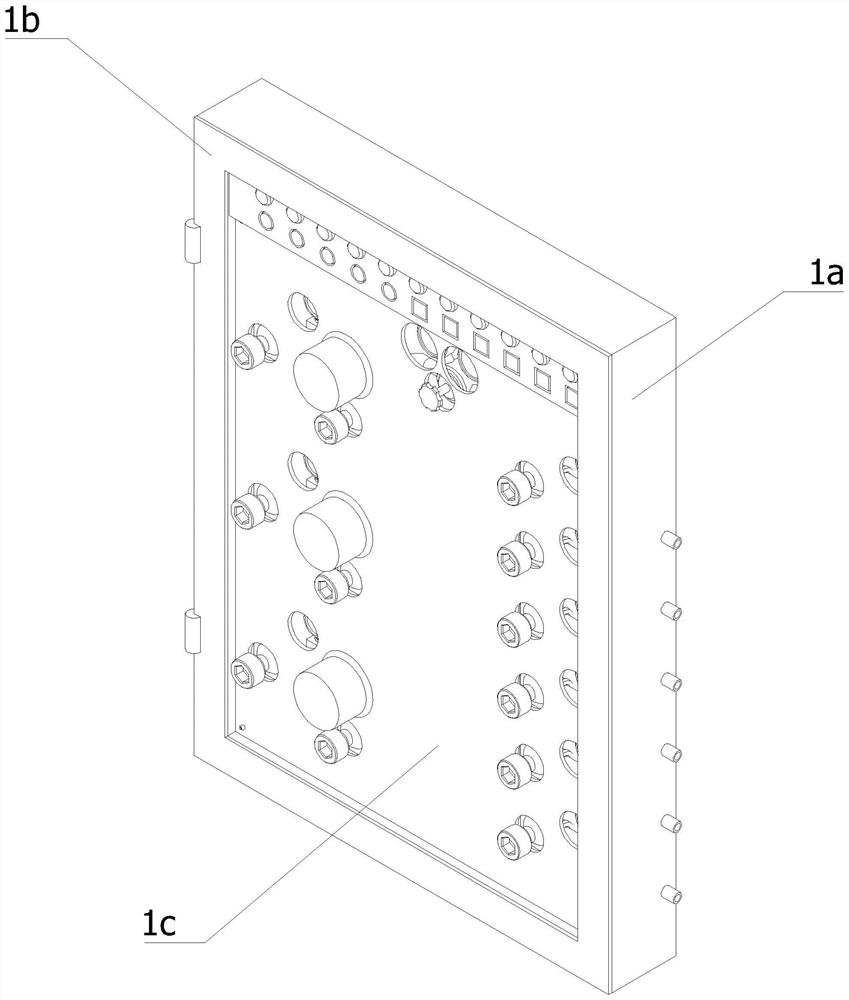

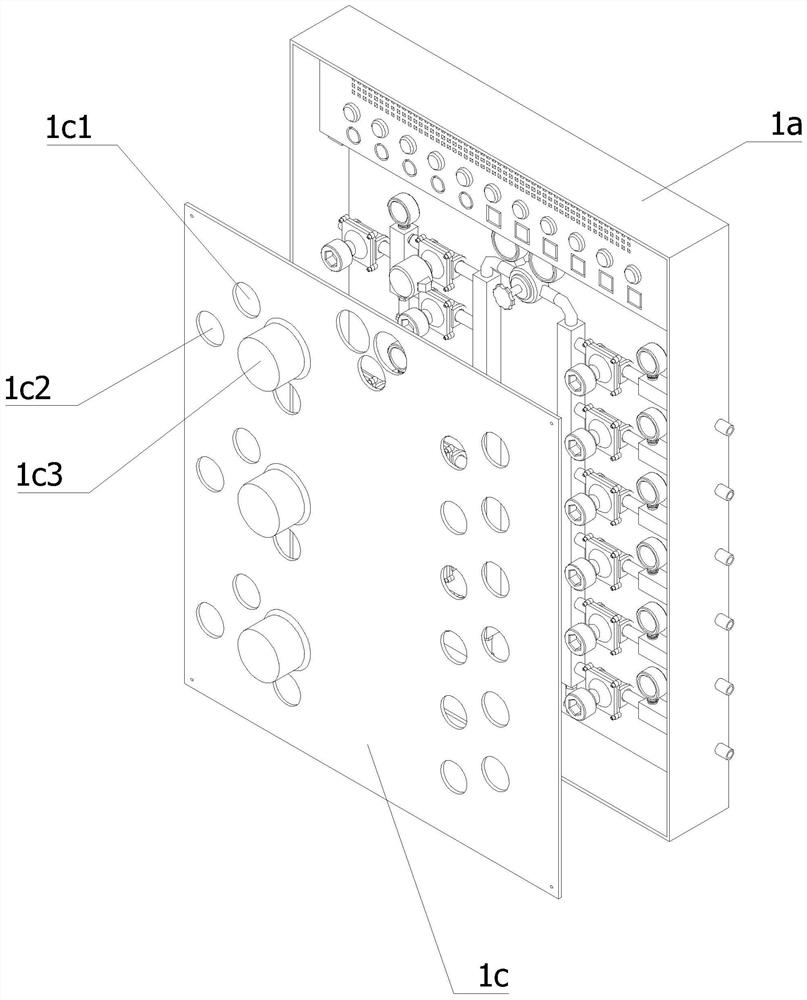

Modular track wiring assembly for a hydronic system

ActiveUS20170030593A1Coupling device connectionsLighting and heating apparatusElectrical conductorZone valve

There is provided a hydronic system for a plurality of zones. The system includes a wiring track. The track has a pair of power conductors for supplying electrical energy therealong and a pair of signal conductors. The signal conductors are in communication with a heat / cold source. The system includes a plurality of zone modules, each corresponding to a respective one of the zones. Each of the zone modules includes leads which connect to respective ones of the conductors. Each of the zone modules includes terminals and conductors configured to selectively connect respective thermostats and zone valves of their zone together, receives signals therefrom and conveys the signals via the signal conductors to the heat / cold source for selectively heating / cooling respective ones of the zones.

Owner:B2 PROD LTD

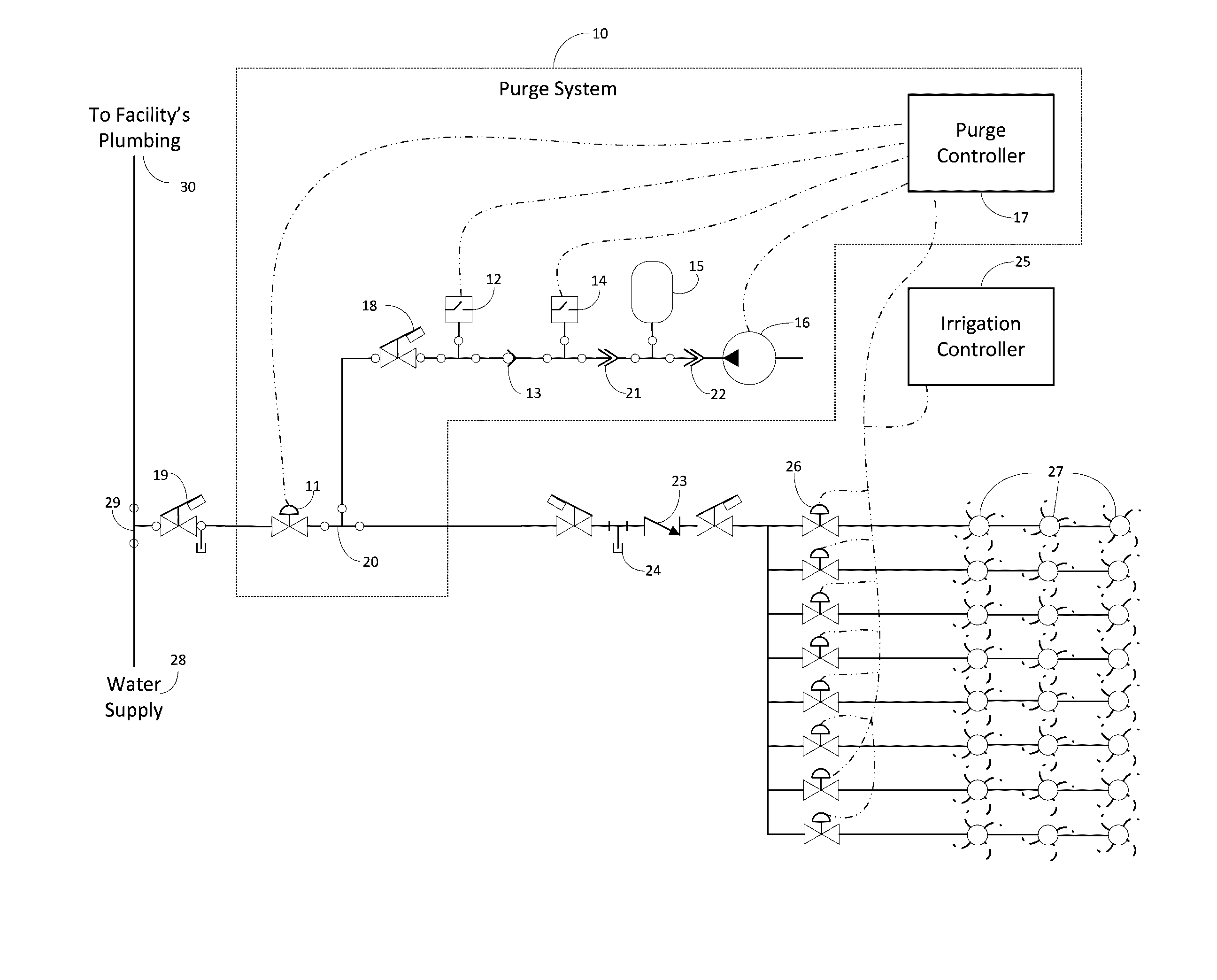

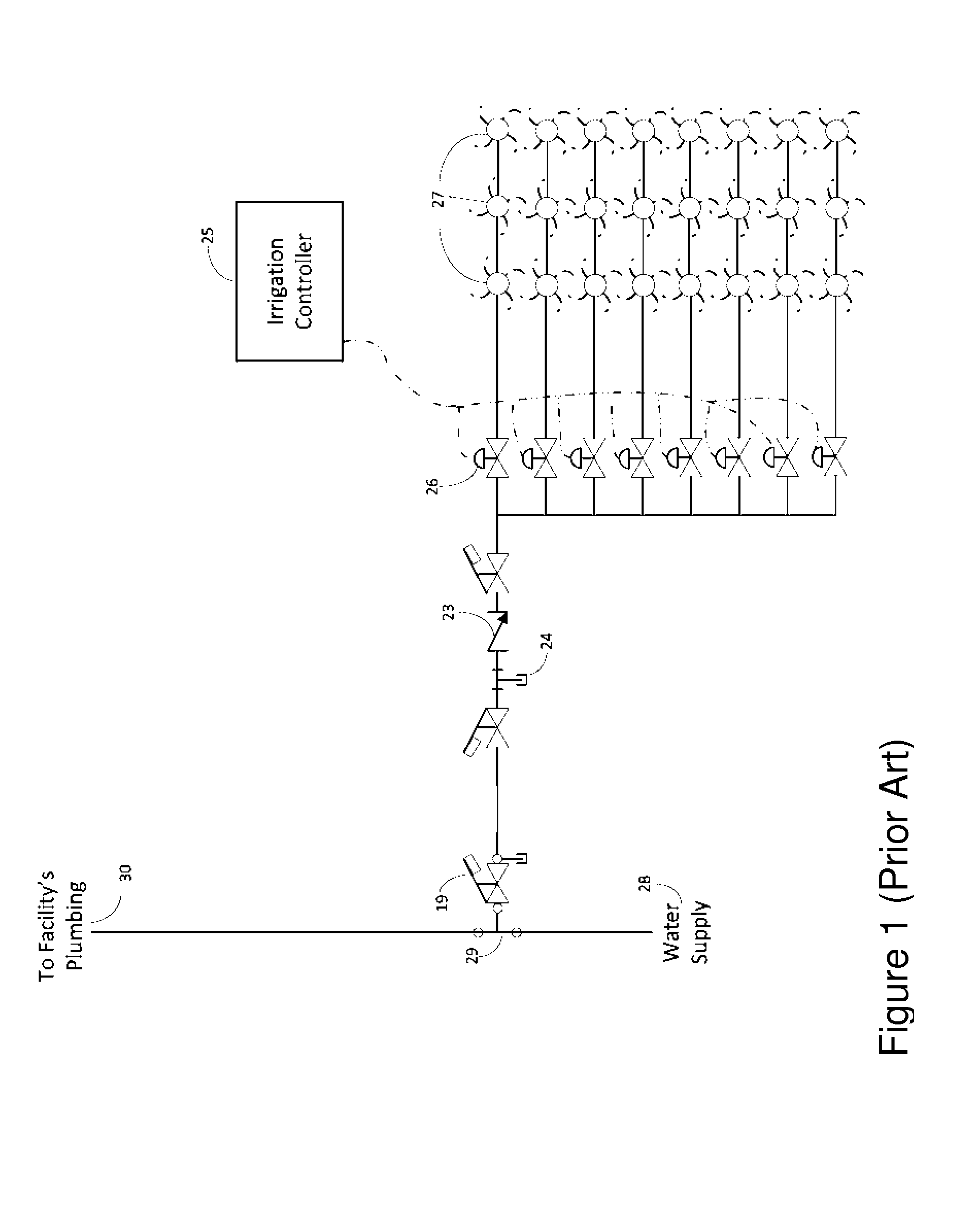

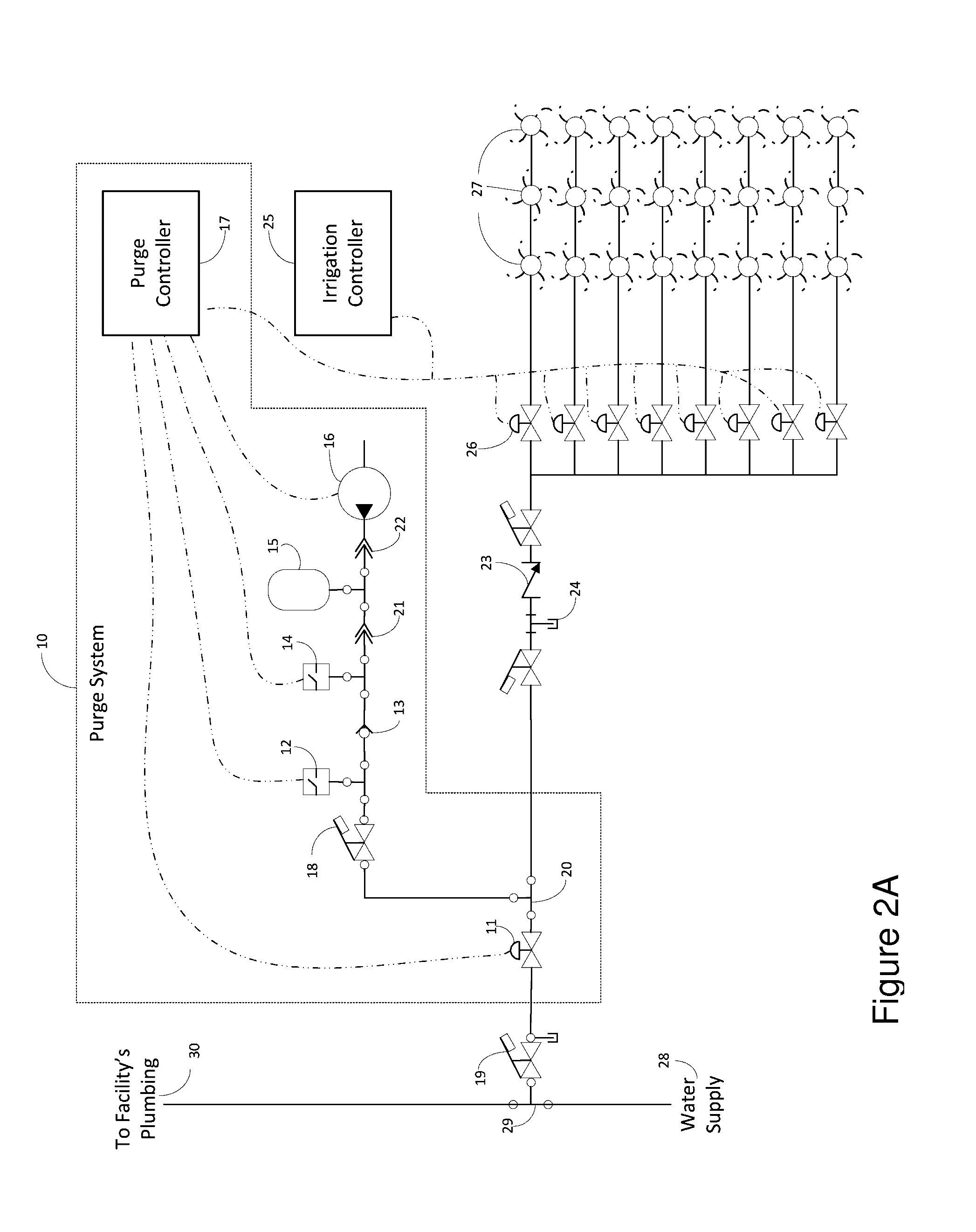

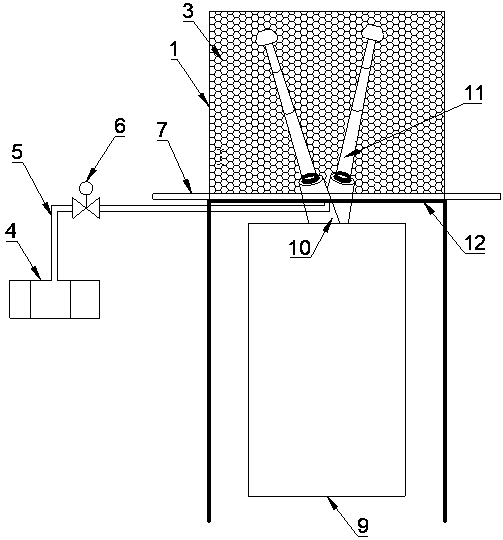

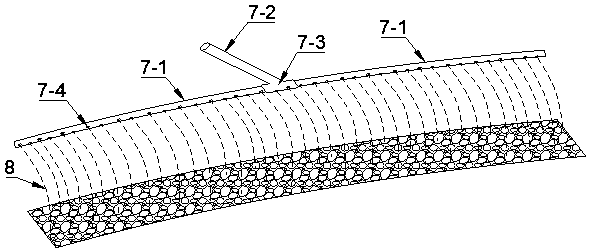

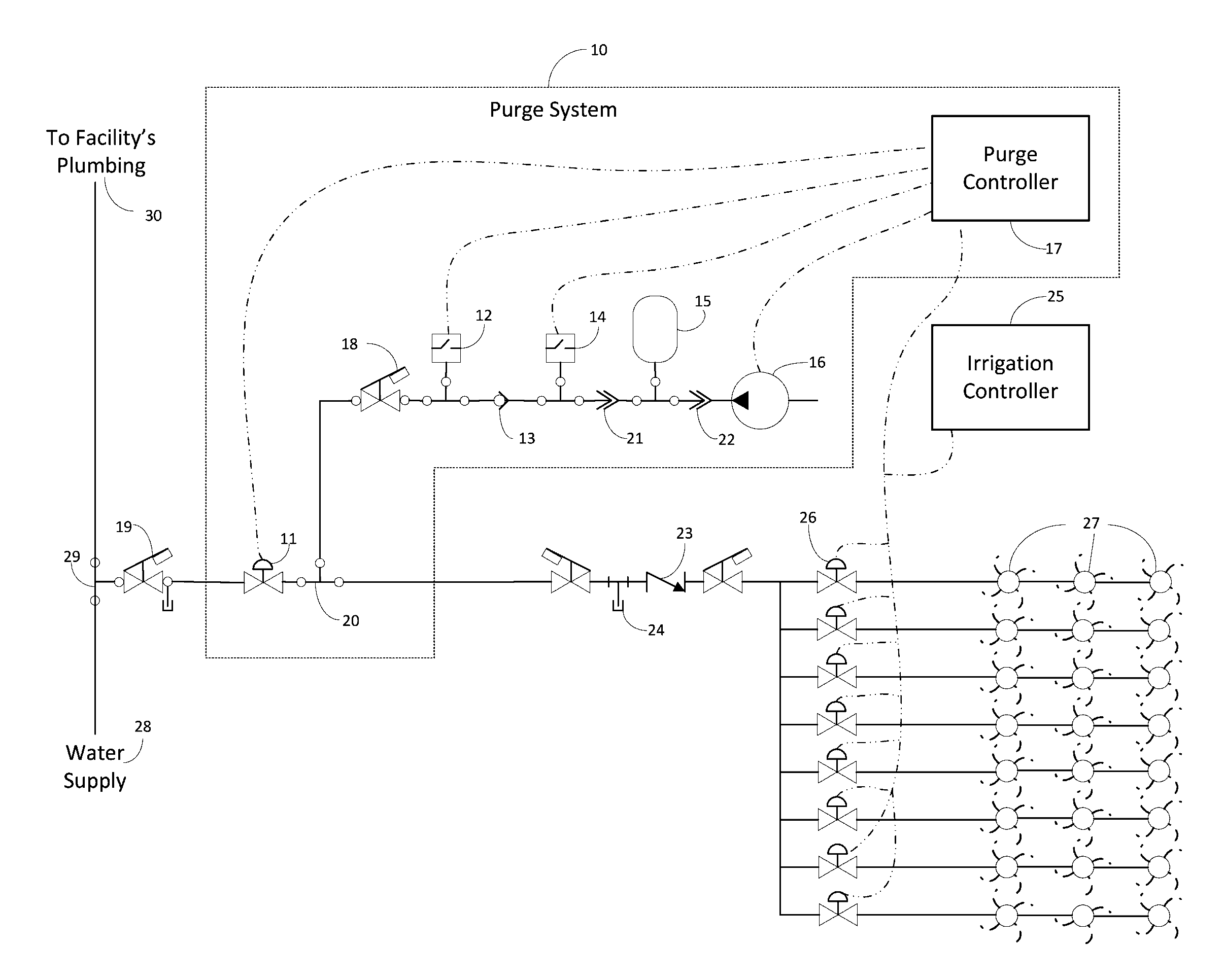

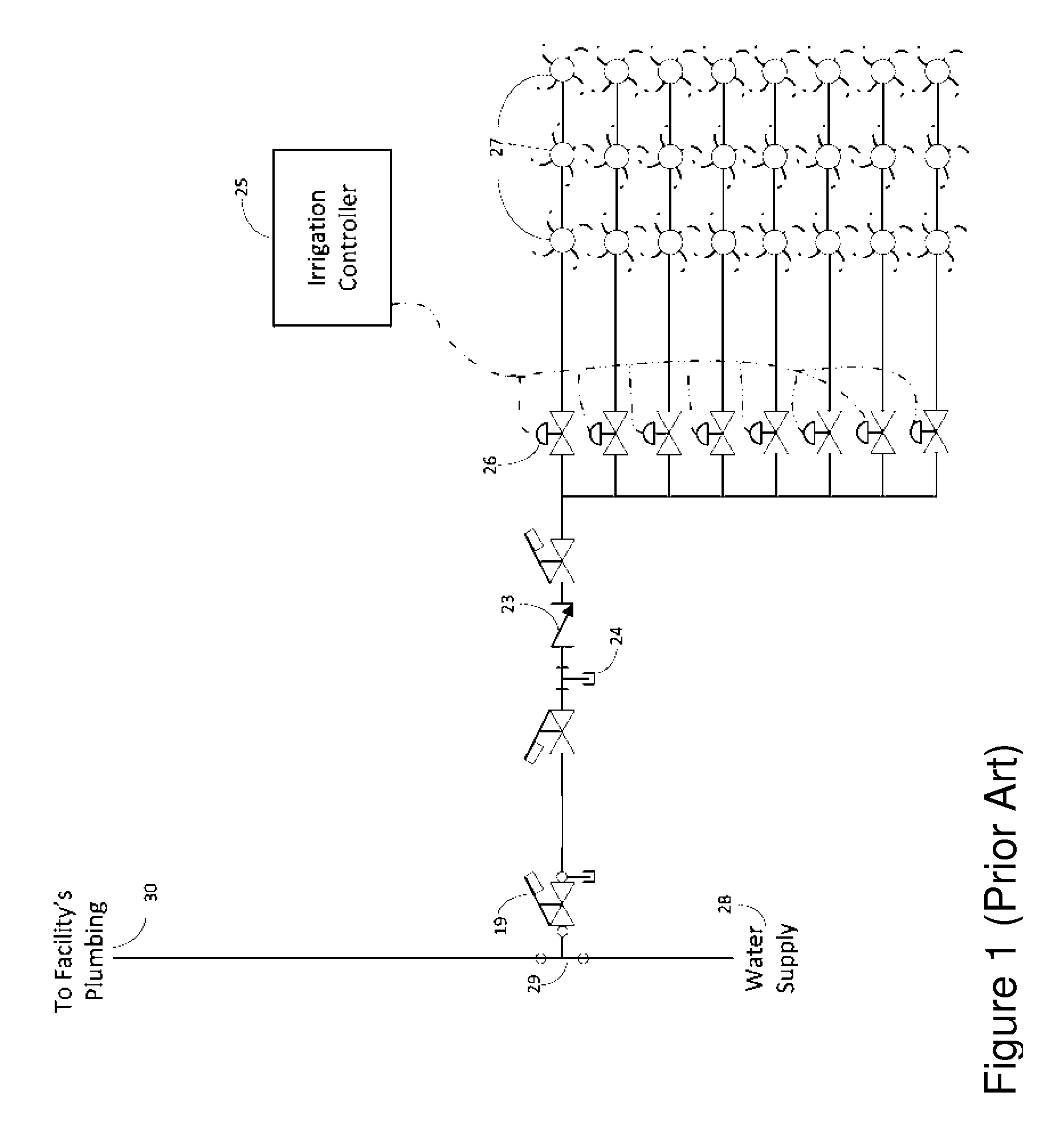

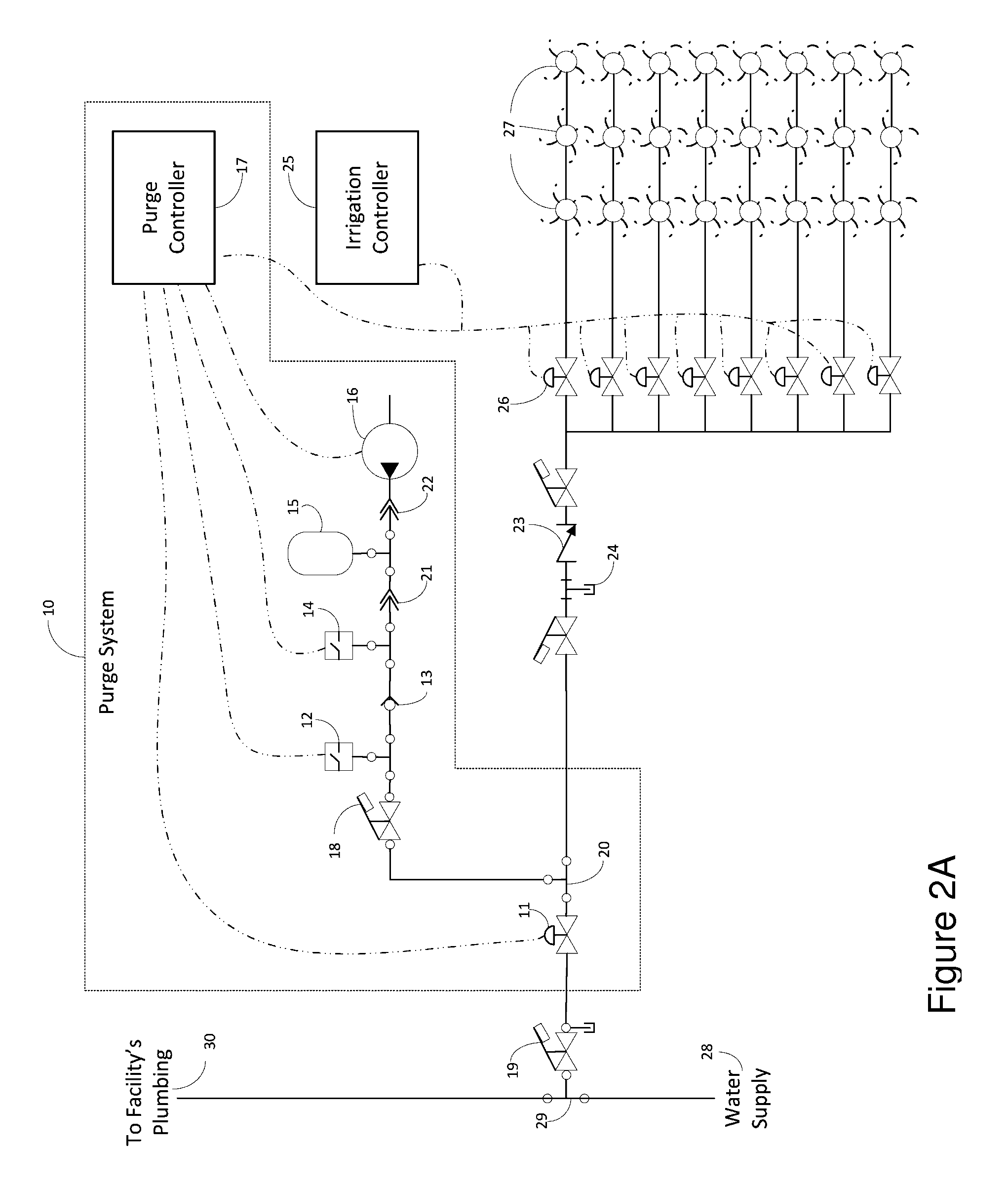

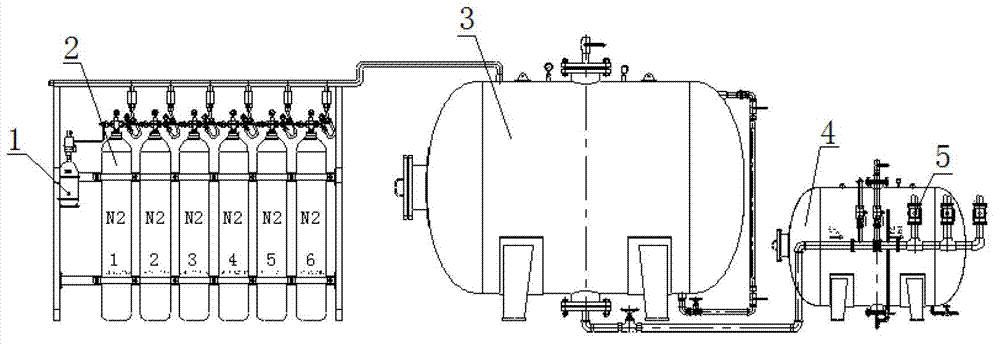

Automatic irrigation system purging

An automated irrigation purge system utilizes a pressure purge method of discharging compressed air from a reservoir through selected irrigation zones with feedback from pressure switches to determine when to open and close each zone valve. No programming or user interaction is required beyond starting the system. The system can operate with a wide variety of irrigation systems, with varying number of zones, pipe lengths, pipe diameters, number and variety of sprinkler heads or outlets, and terrain slope. The system tracks the pressure transition time from high pressure to low pressure for each zone as it is blown out. When the current transition time is within a specified range from the previous transition time, the system knows the water has been sufficiently purged from that zone. The purge system can protect the irrigation system from high-pressure conditions, handle multiple error conditions, and maintain water valve settings during power loss.

Owner:PELLAERO

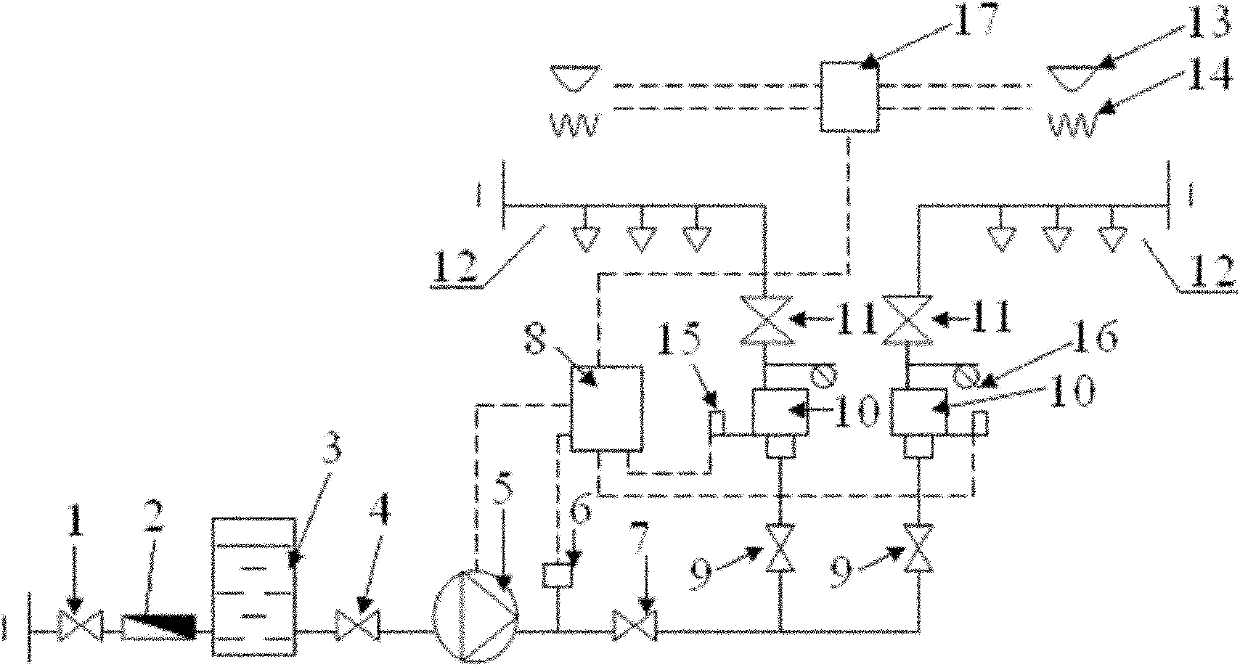

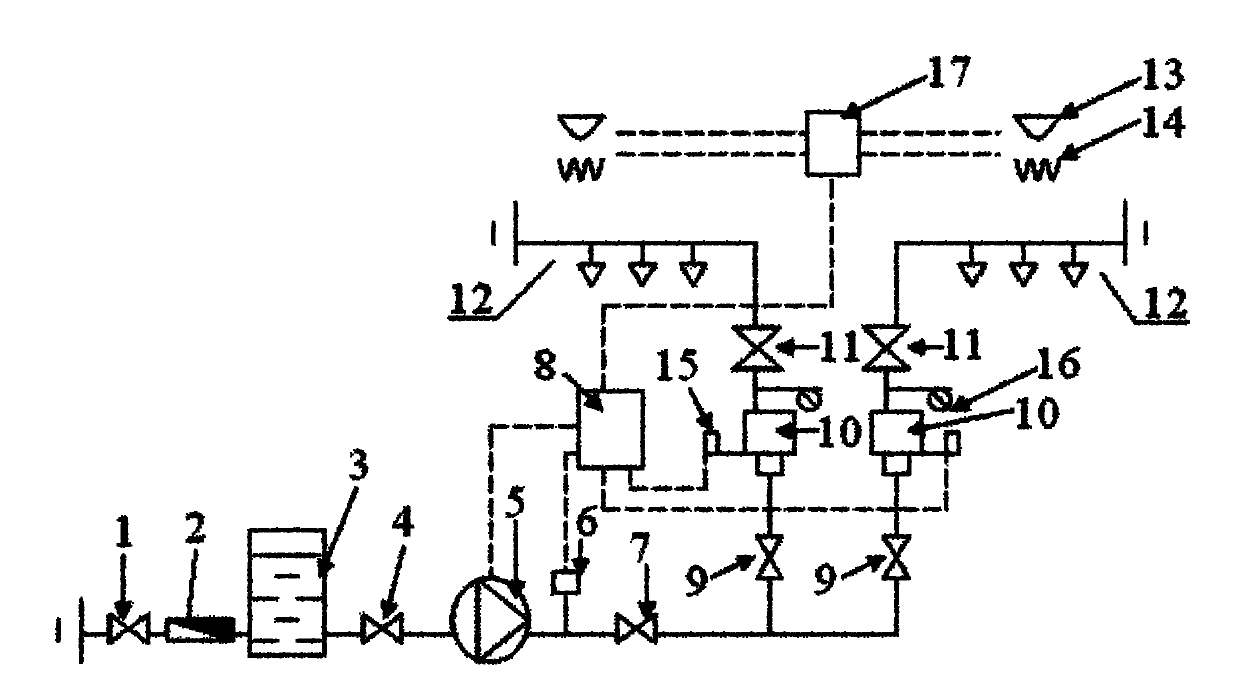

Thin water mist fire extinguishing system

InactiveCN102553116AImprove smoke removal effectLarge specific surface areaFire rescueFire alarmsHigh densityZone valve

The invention relates to a thin water mist fire extinguishing system comprising a filter, a water tank, a water supply pump, a water pump control valve, zone valves, water mist spray nozzles and an alarm device. One end of the filter is connected with a water source through a water source valve, and the other end of the filter is connected with the water tank through a pipeline. One end of the water supply pump is connected with the water tank through the pipeline, and the other end of the water supply pump is connected with the zone valves through the pipelines. The water pump control valve is connected with the water supply pump, the zone valves and the alarm device respectively through electric signals. The water mist spray nozzles are connected with the zone valves through the pipelines. Compared with the prior art, the sum of the volume of water particles with the diameters of less than 200 MMum in water mist jet flow sprayed by the thin water mist fire-extinguishing system is not less than 90% of the total volume, the size of water drops of the thin water mist is small, and the thin water mist has large specific surface area, high density and good smoke-removing effect.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

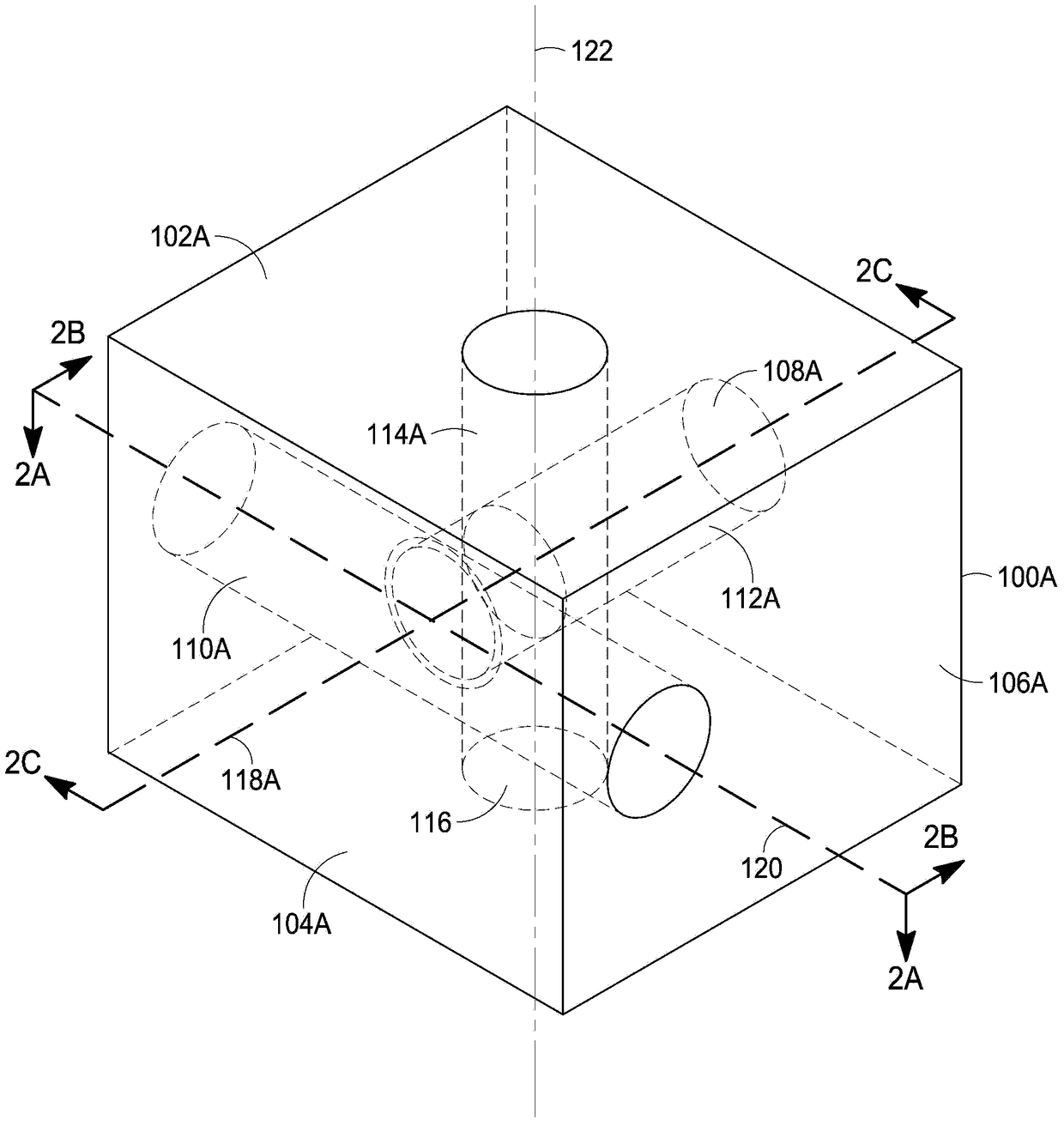

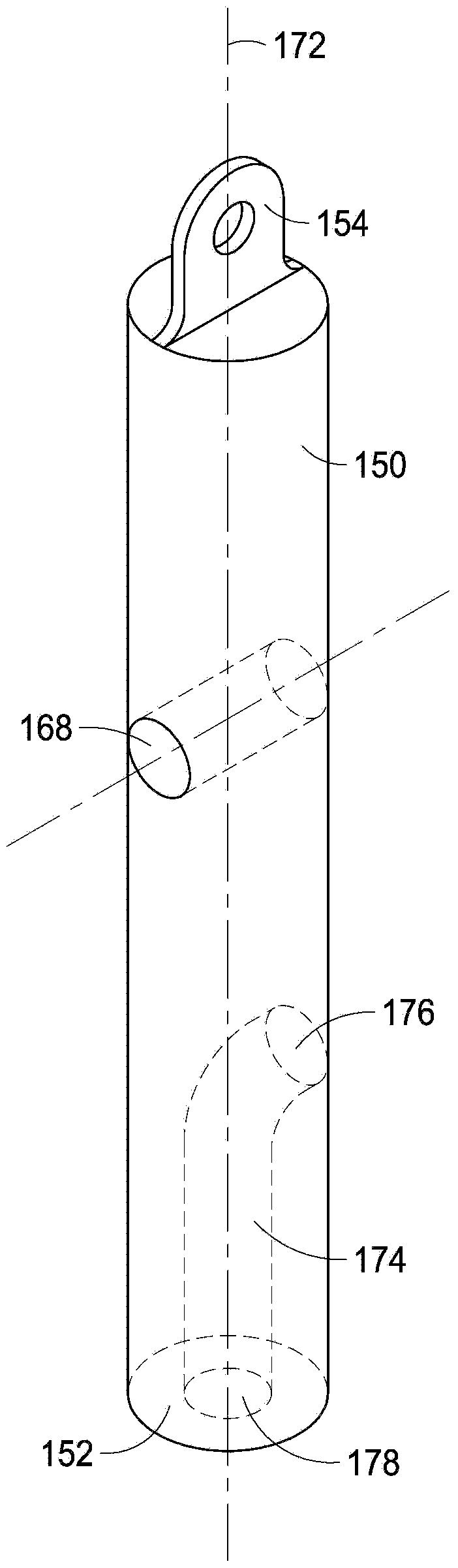

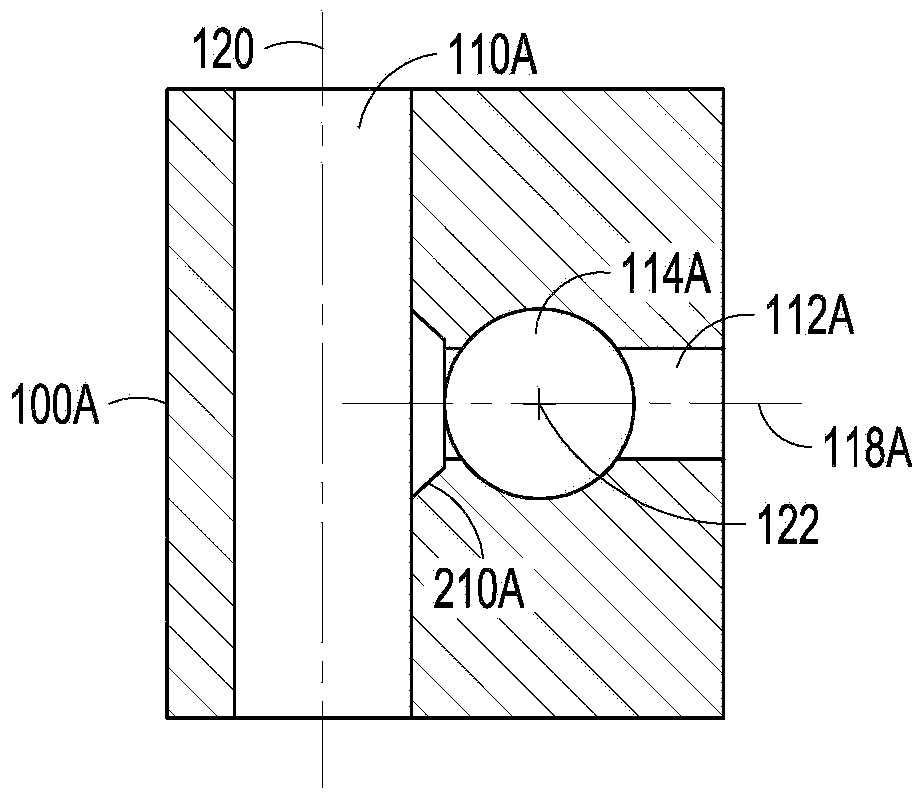

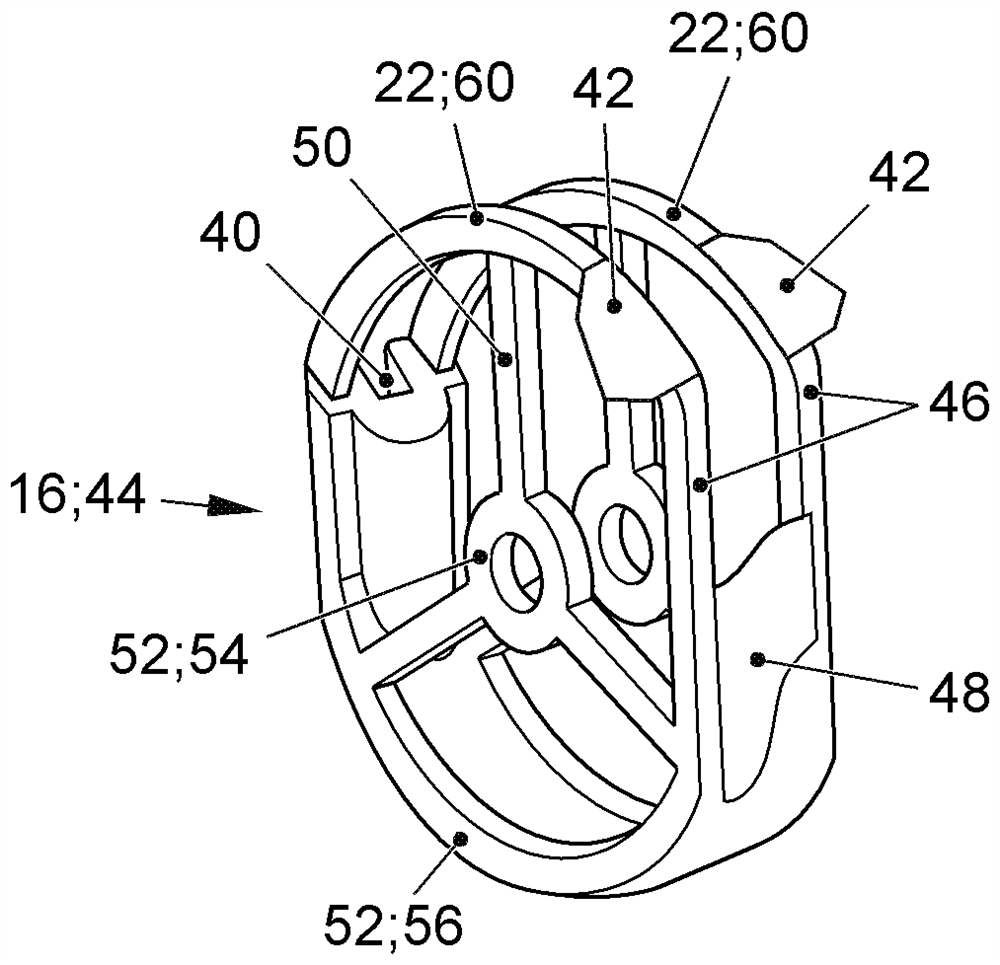

Additive injection zone valve

A valve includes a valve body and a bolt. The valve body has an input port and an output channel coupled by a primary passageway. The valve body has a bolt bore aligned to intersect the primary passageway. The valve body has a divert port disposed at an end of the bolt bore. The valve body has an intersection at the output channel and the primary passageway including a gradual transition. The bolt has a first end and a second end aligned on a longitudinal axis. The bolt has a through passageway aligned transverse to the longitudinal axis and has a divert passageway disposed between a side aperture and the first end. The bolt is configured for slidable engagement with the bolt bore.

Owner:INVISTA TEXTILES (U K) LTD

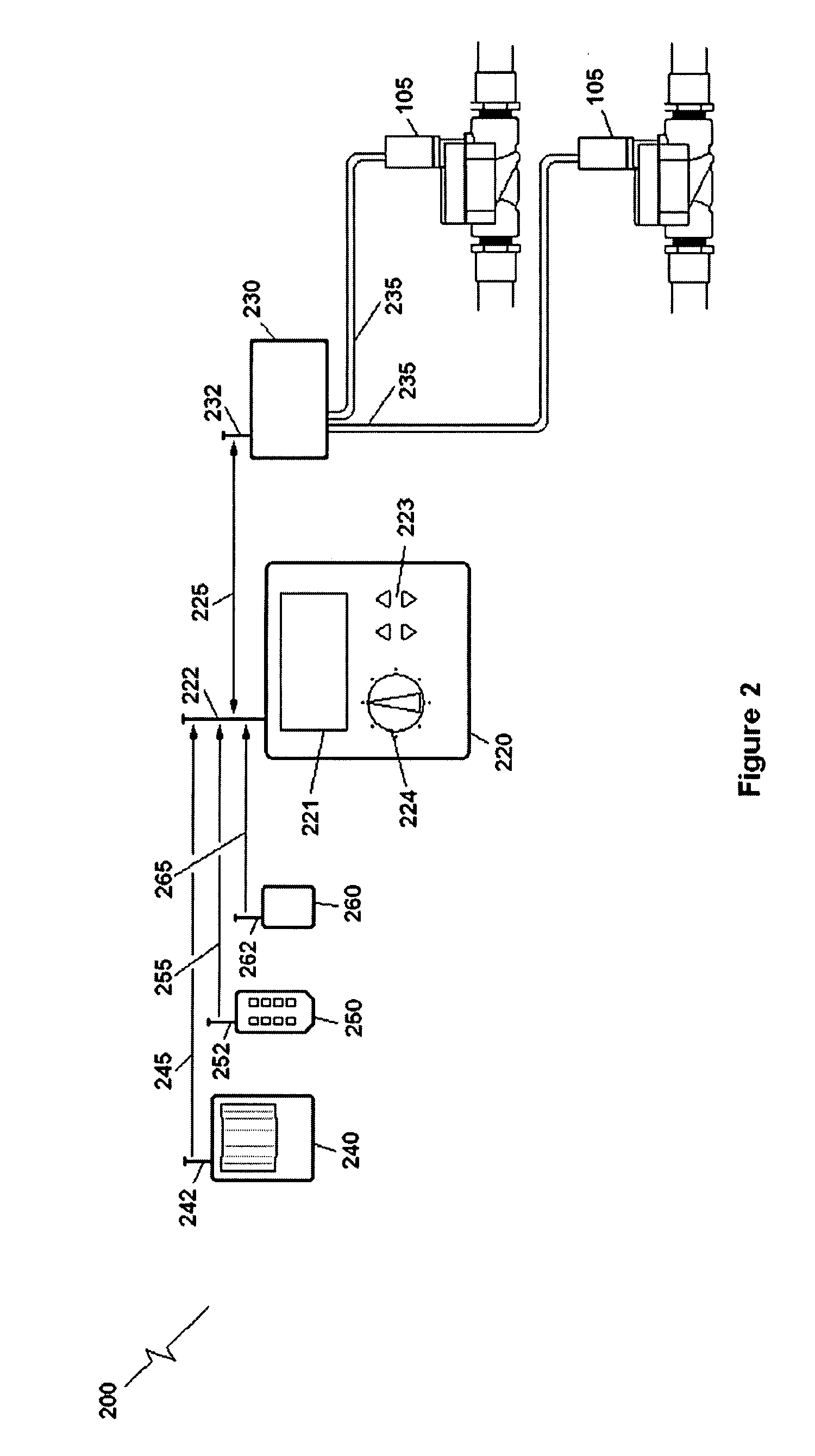

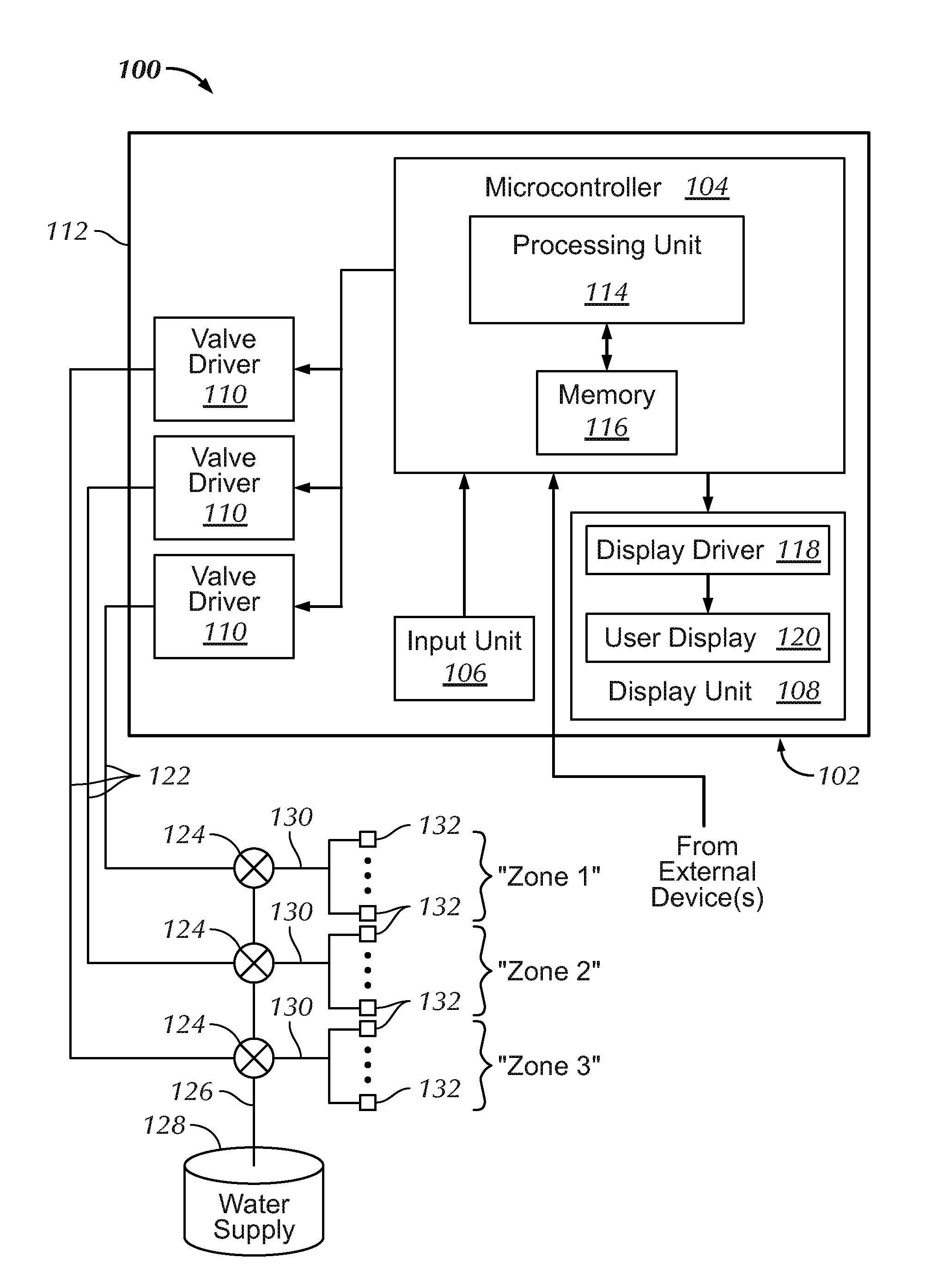

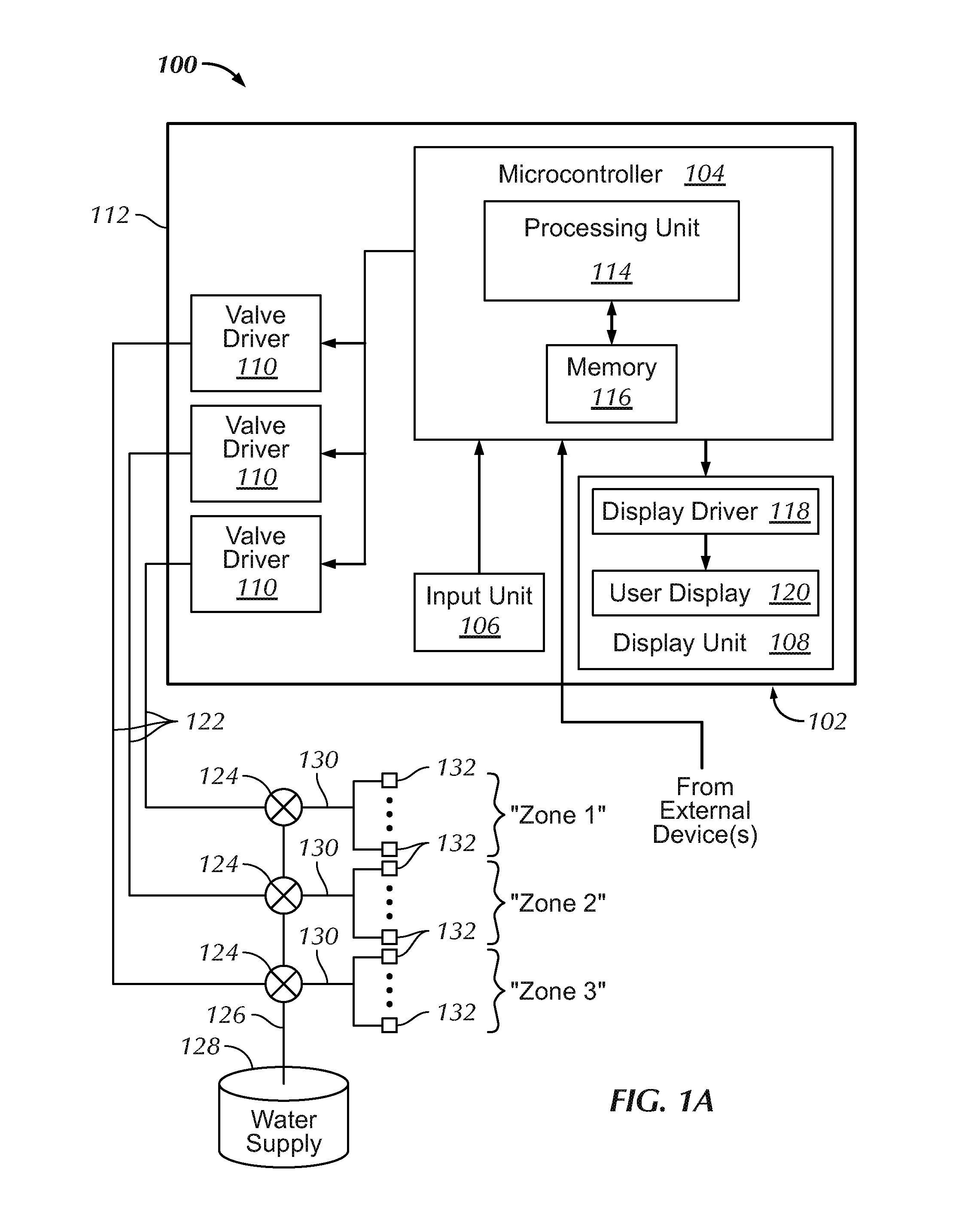

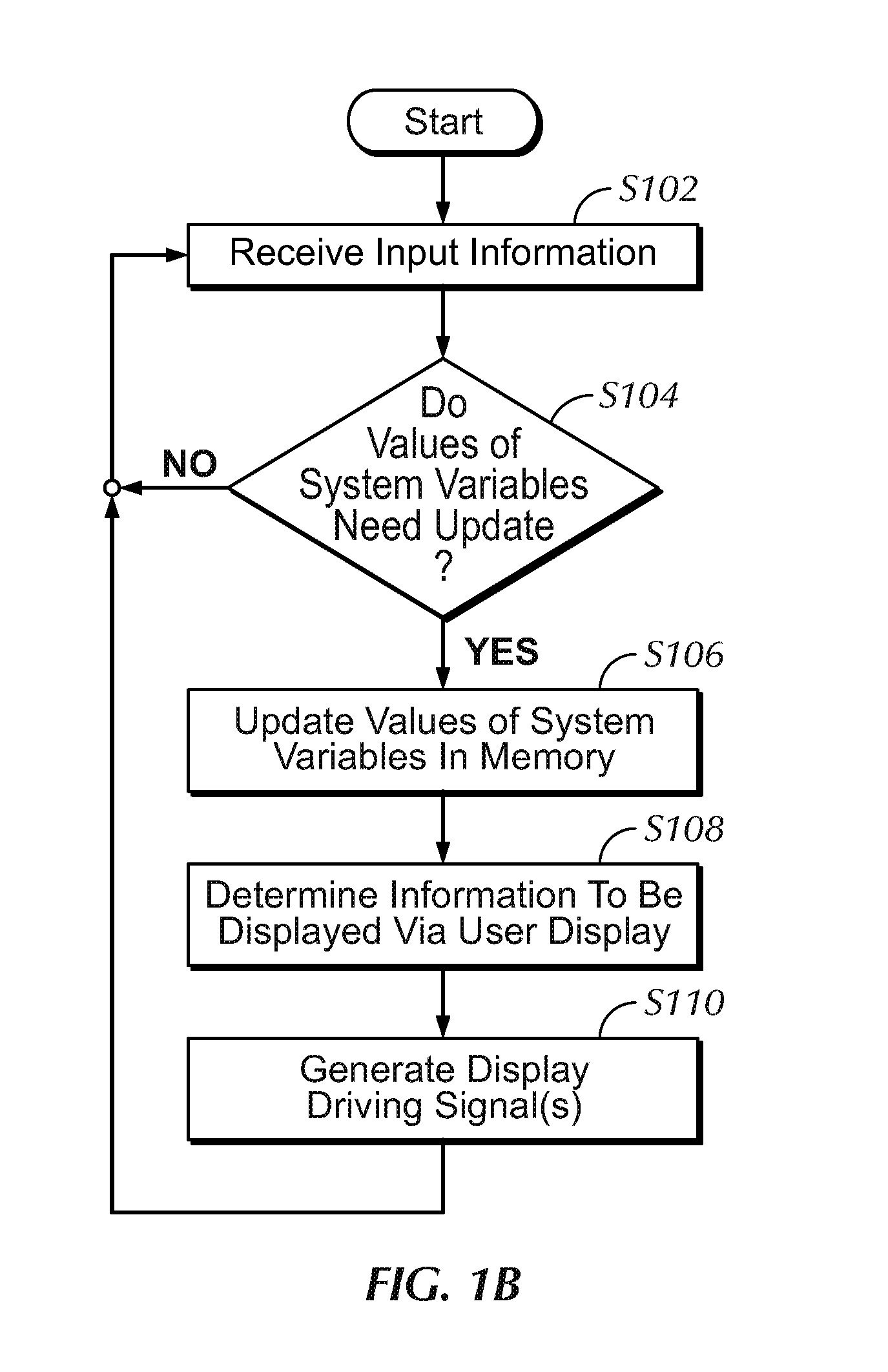

Programmable irrigation controller having user interface

An irrigation controller, includes a housing, a microcontroller within the housing and configured to store and execute an irrigation schedule, a valve driver coupled to the microcontroller and configured to output a zone activation signal to an actuatable zone valve in response to signaling from the microcontroller, and a user interface. The user interface includes a plurality of user input devices coupled to the microcontroller and configured to provide signaling to the microcontroller based upon a user's engagement therewith, the plurality of user input devices configured to allow the user to create an irrigation schedule; and a user display coupled to the microcontroller and configured to display irrigation parameters associated with the irrigation schedule. The microcontroller is configured to cause the user display to display at least one of a next irrigation start day, a next irrigation start time, and a next zone to irrigate associated with the irrigation schedule.

Owner:RAIN BIRD CORP

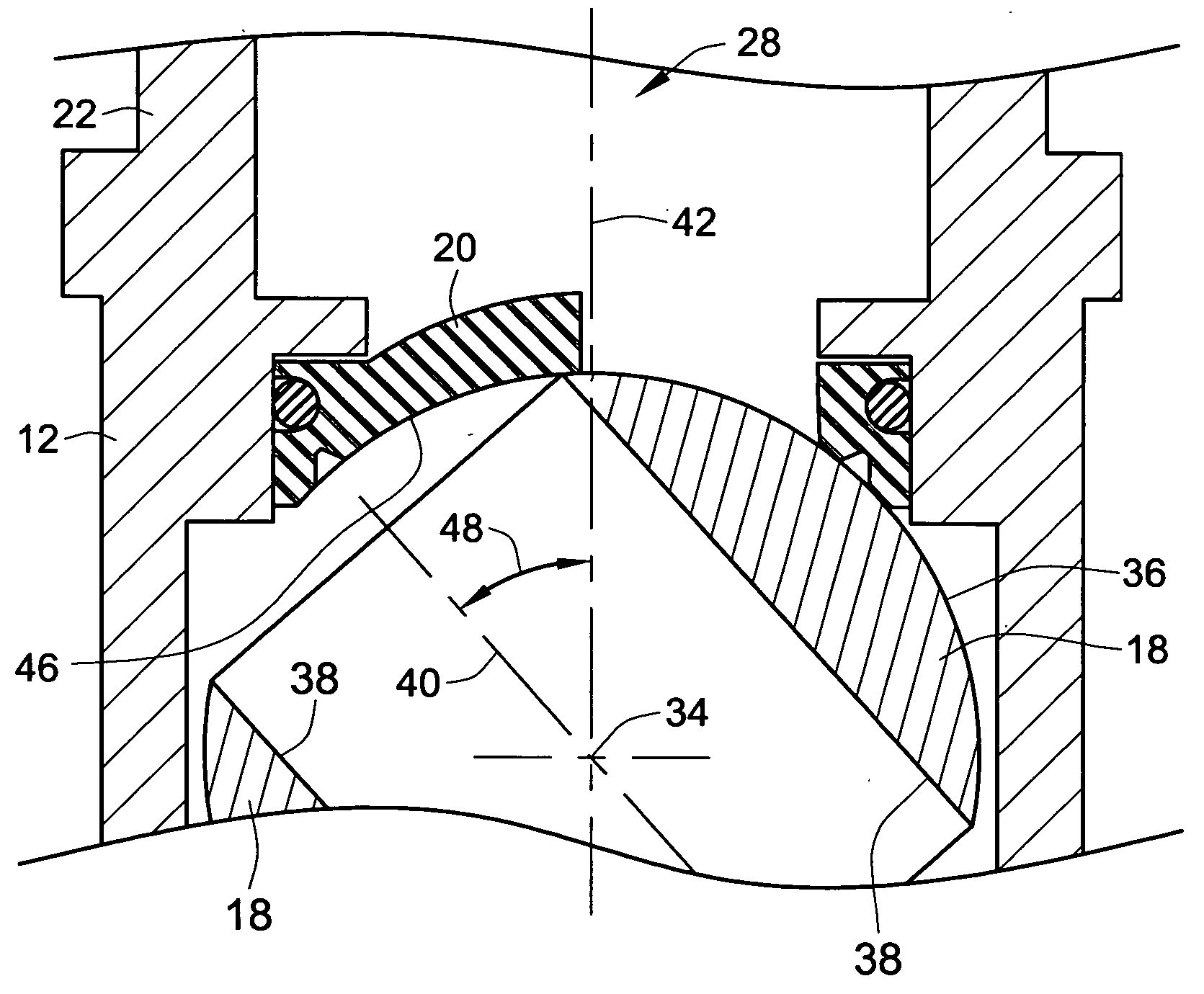

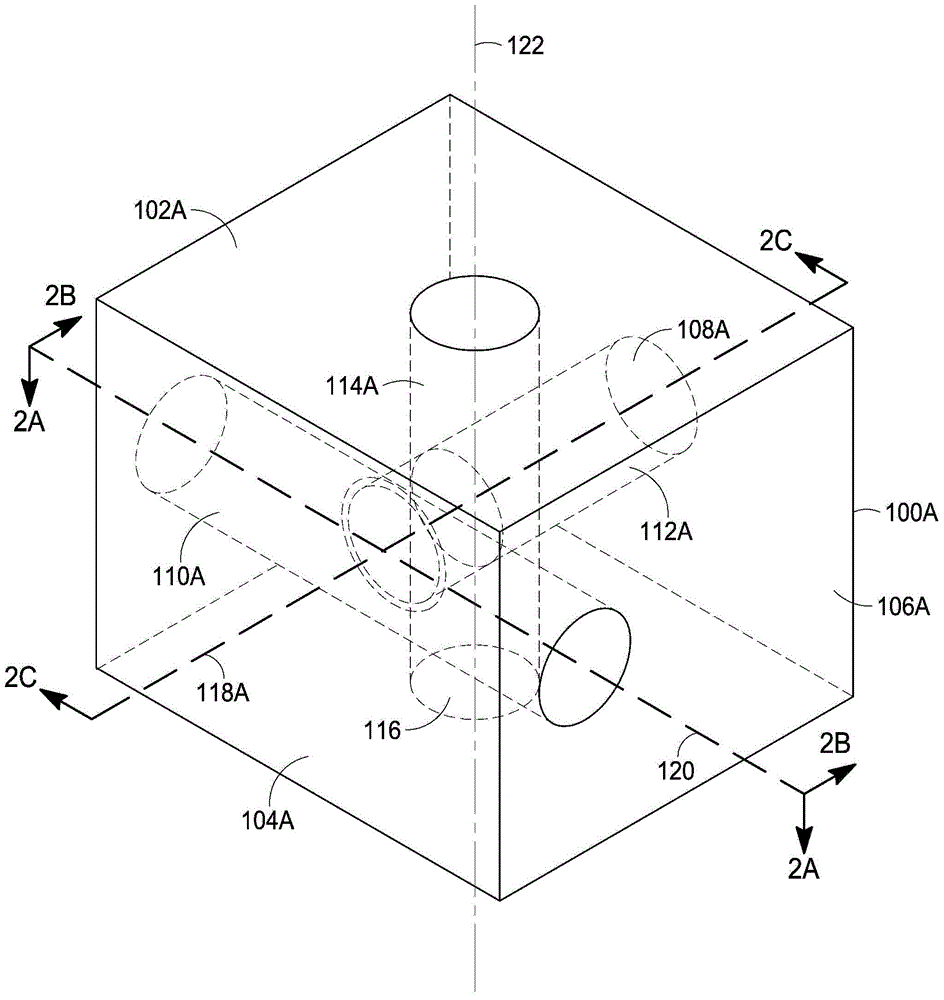

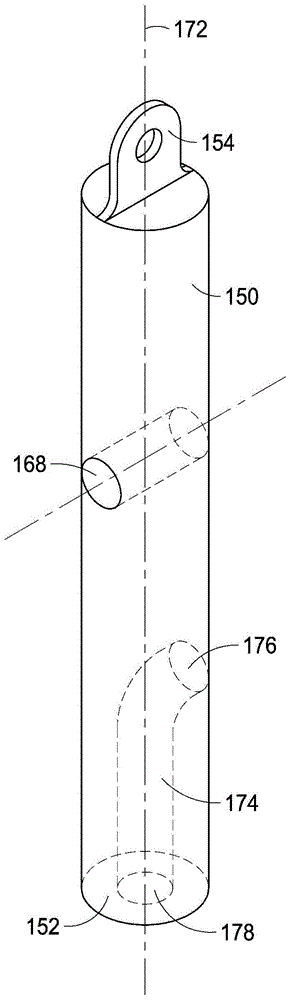

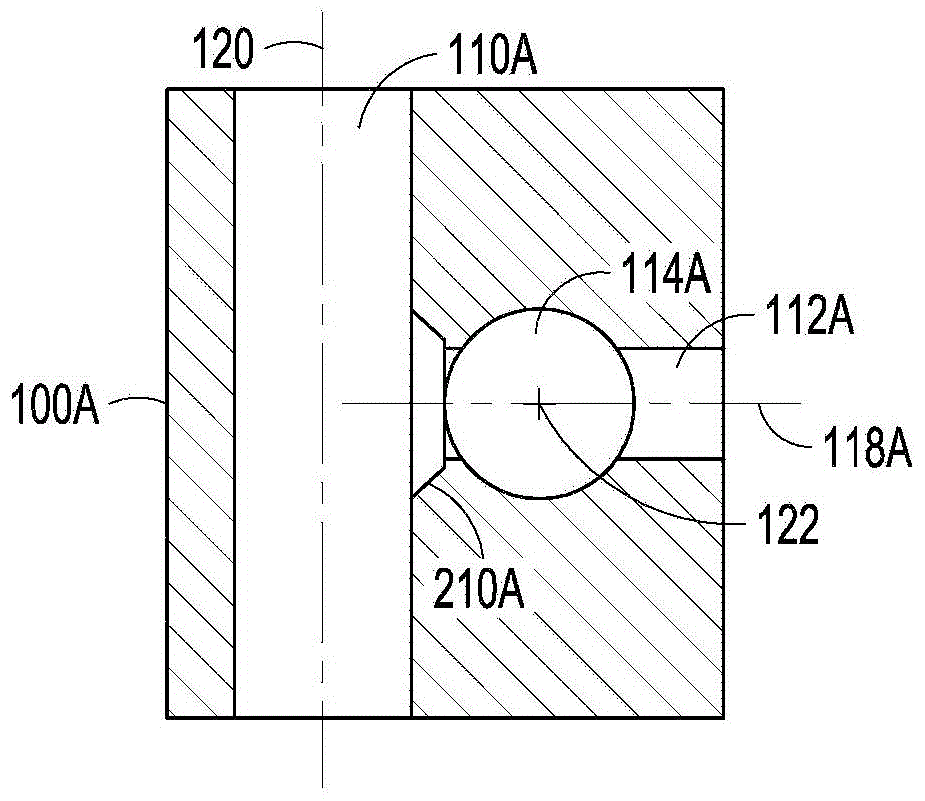

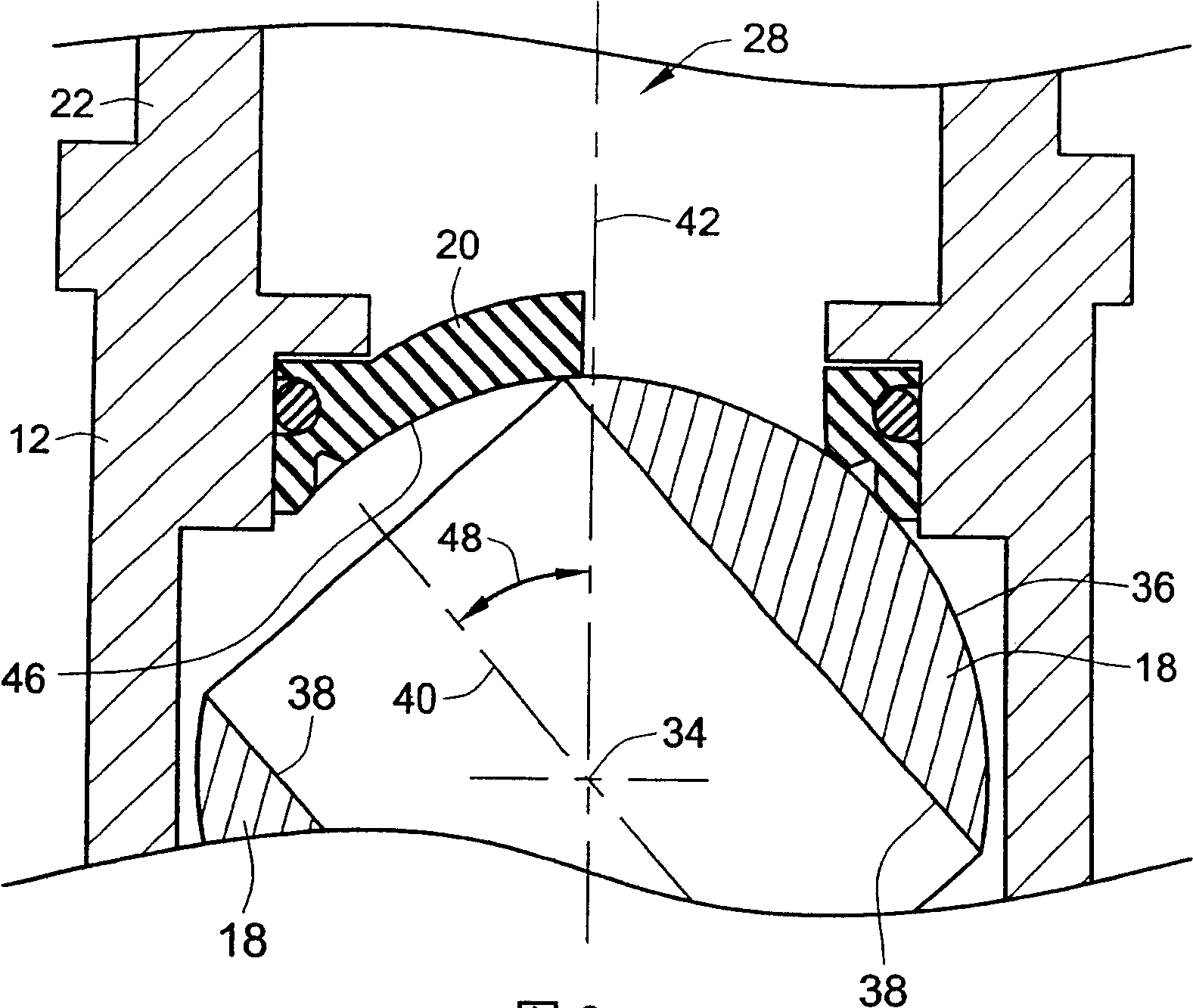

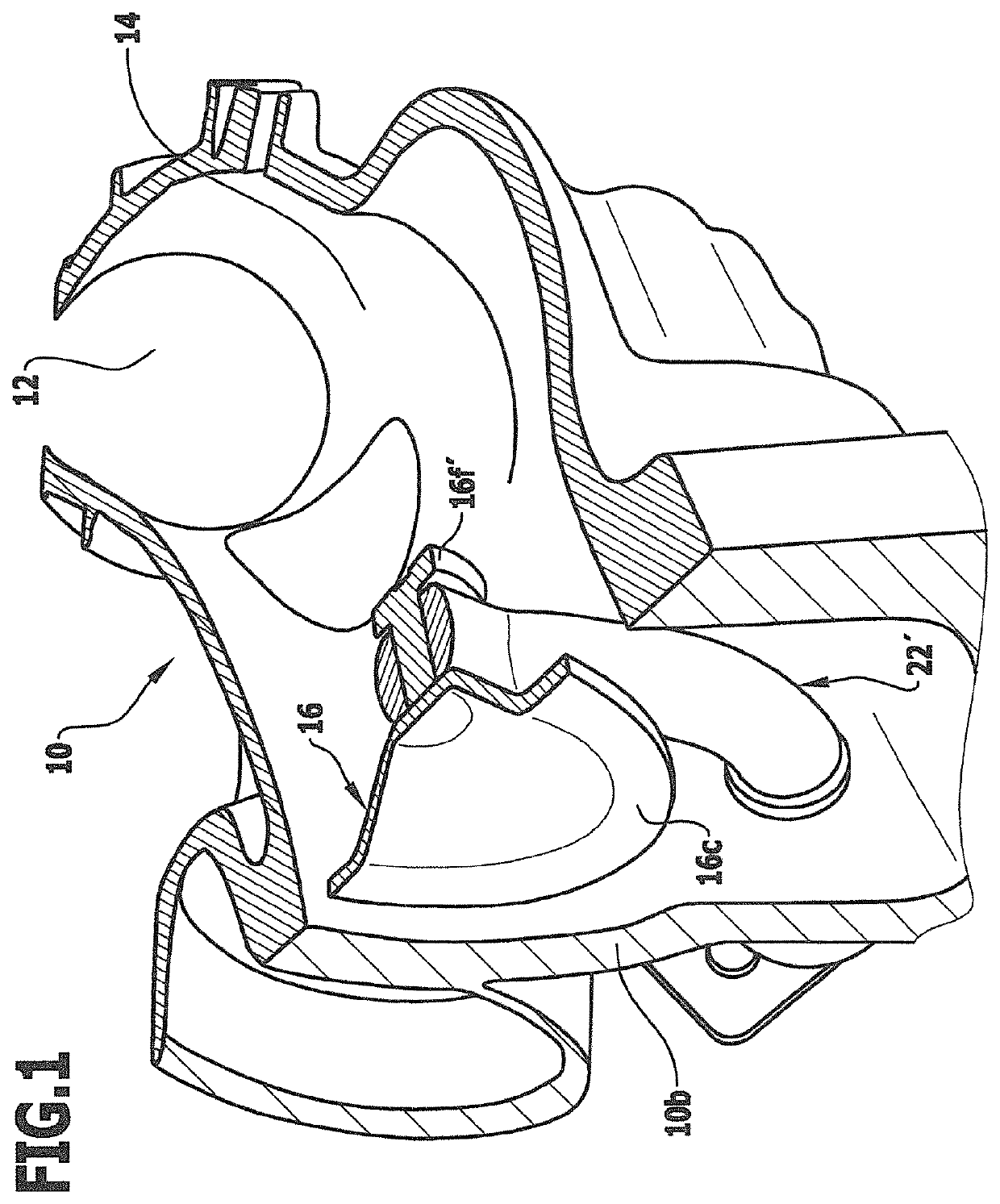

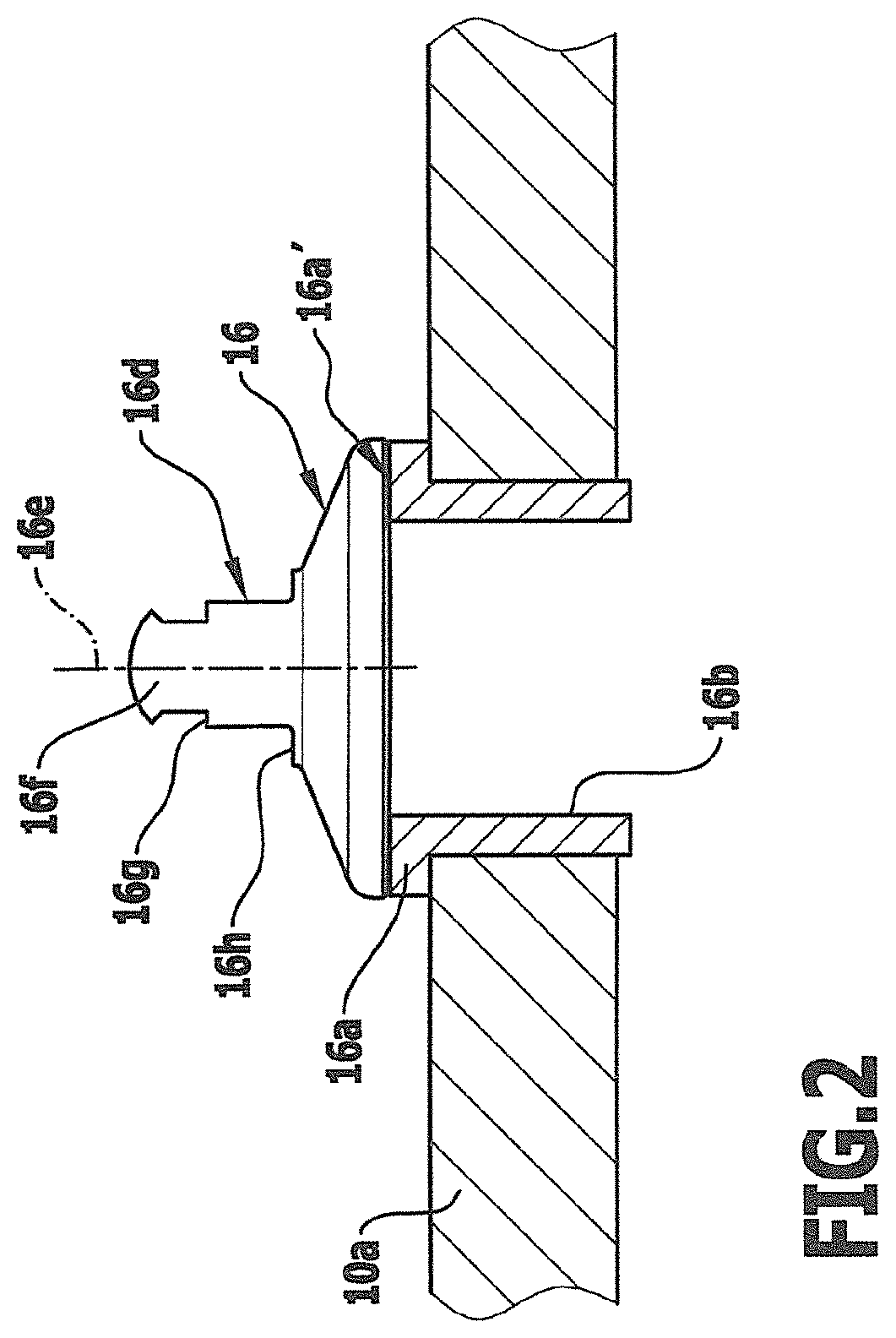

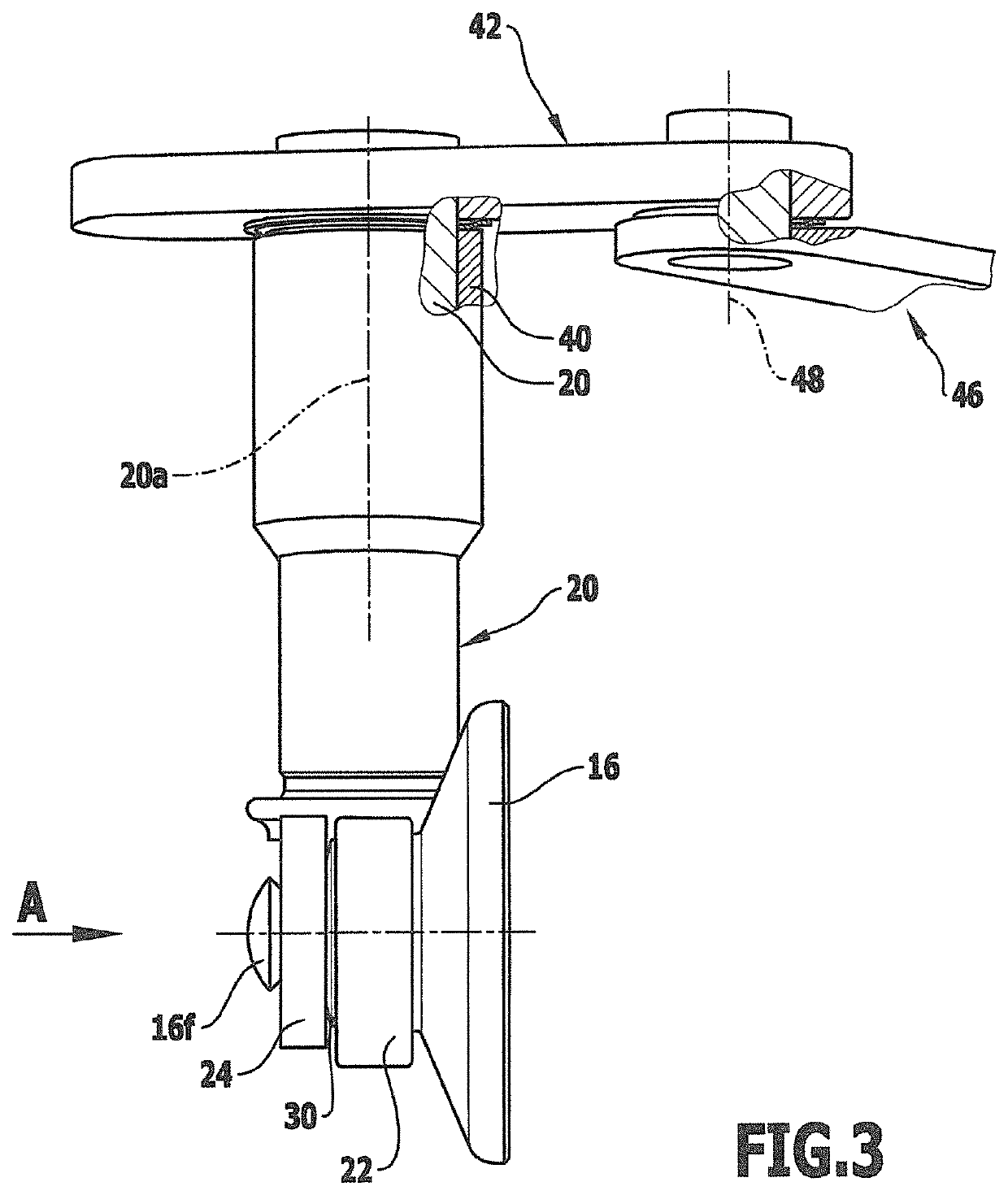

Apparatus and method for replacing existing actuator zone valves in an HVAC system with a ball valve

An apparatus and method are provided for replacing existing actuator driven zone valves in an HVAC system, and particularly valves of the rubber paddle type having actuators providing less than 90 degrees of rotation, with a ball valve including a skewed seat bearing that blocks flow through the flowpath when a valve member of the ball valve is rotated through an angle of substantially less than 90 degrees from a fully open position of the valve at which a bore in the valve member is substantially fully aligned with the flowpath. The actuator from the existing zone valve being replaced may be used with the provided ball valve apparatus and method.

Owner:TAC LLC

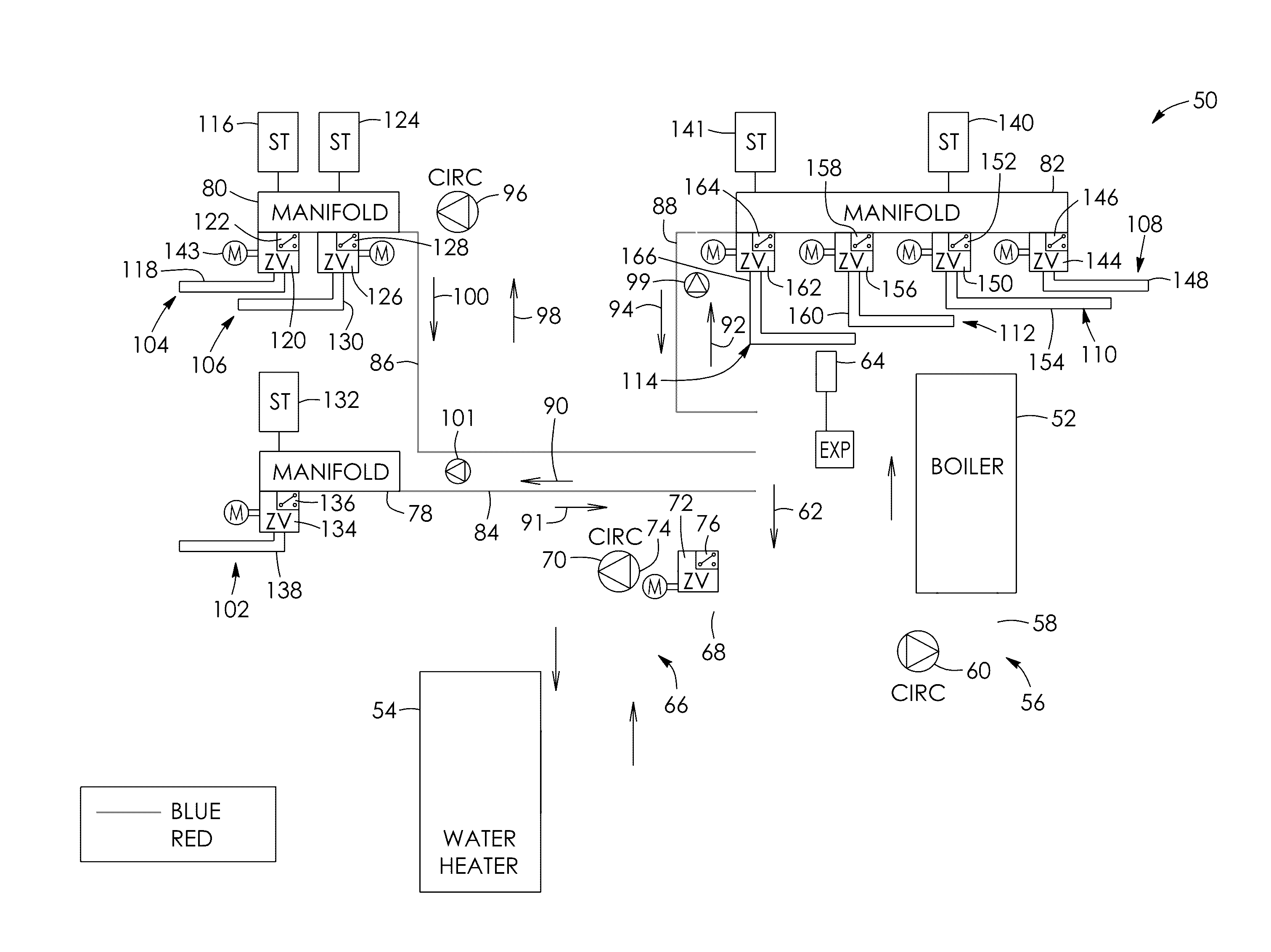

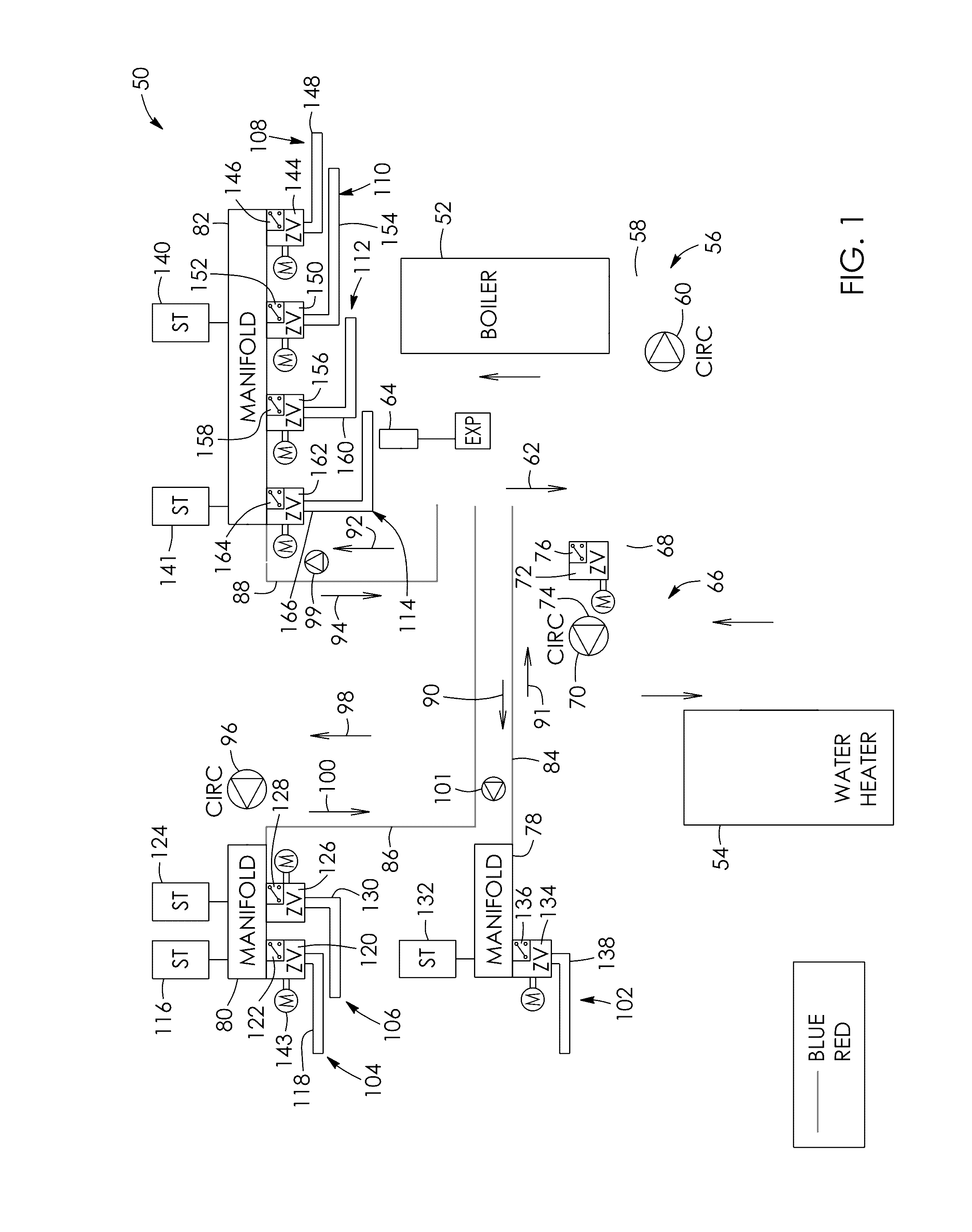

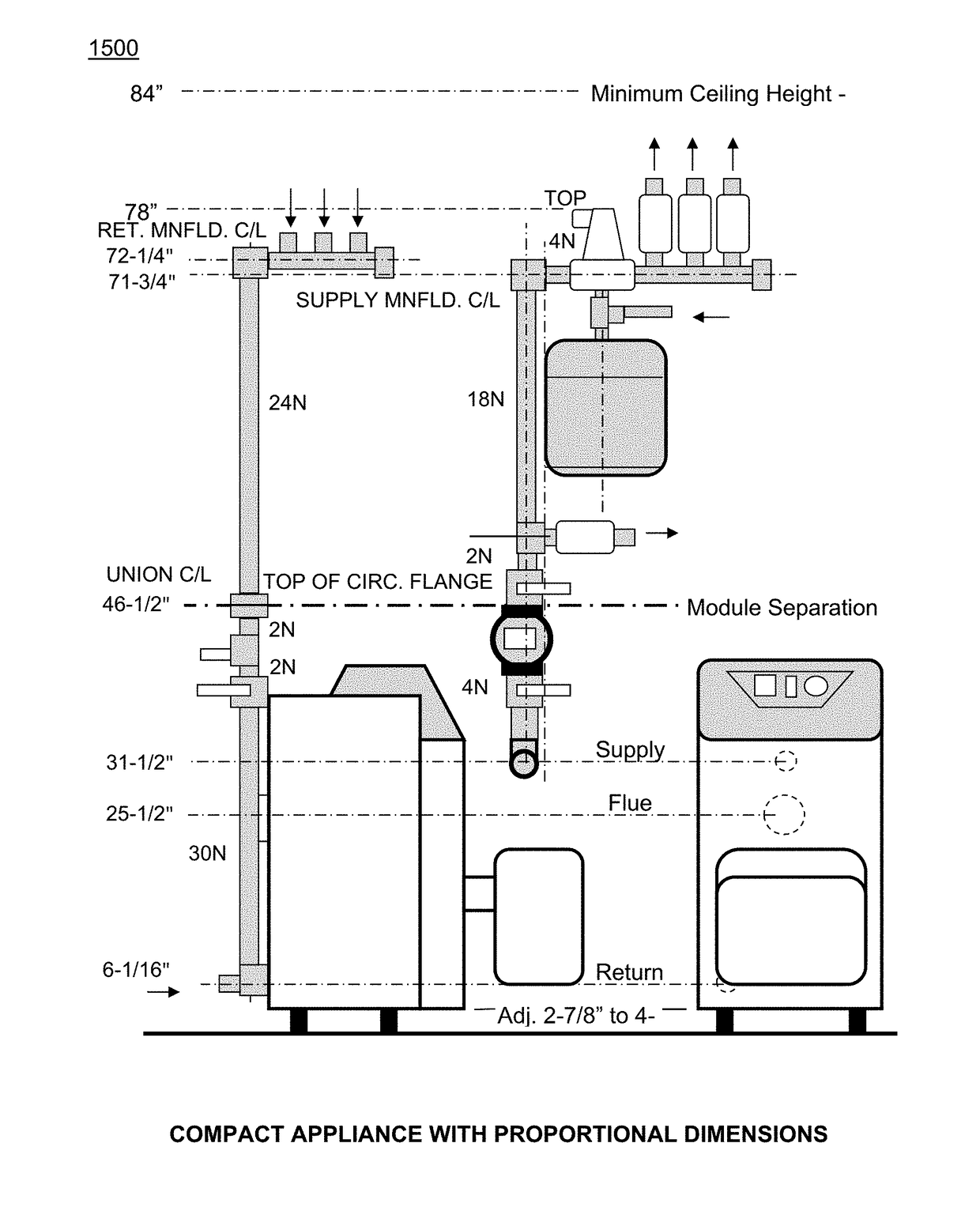

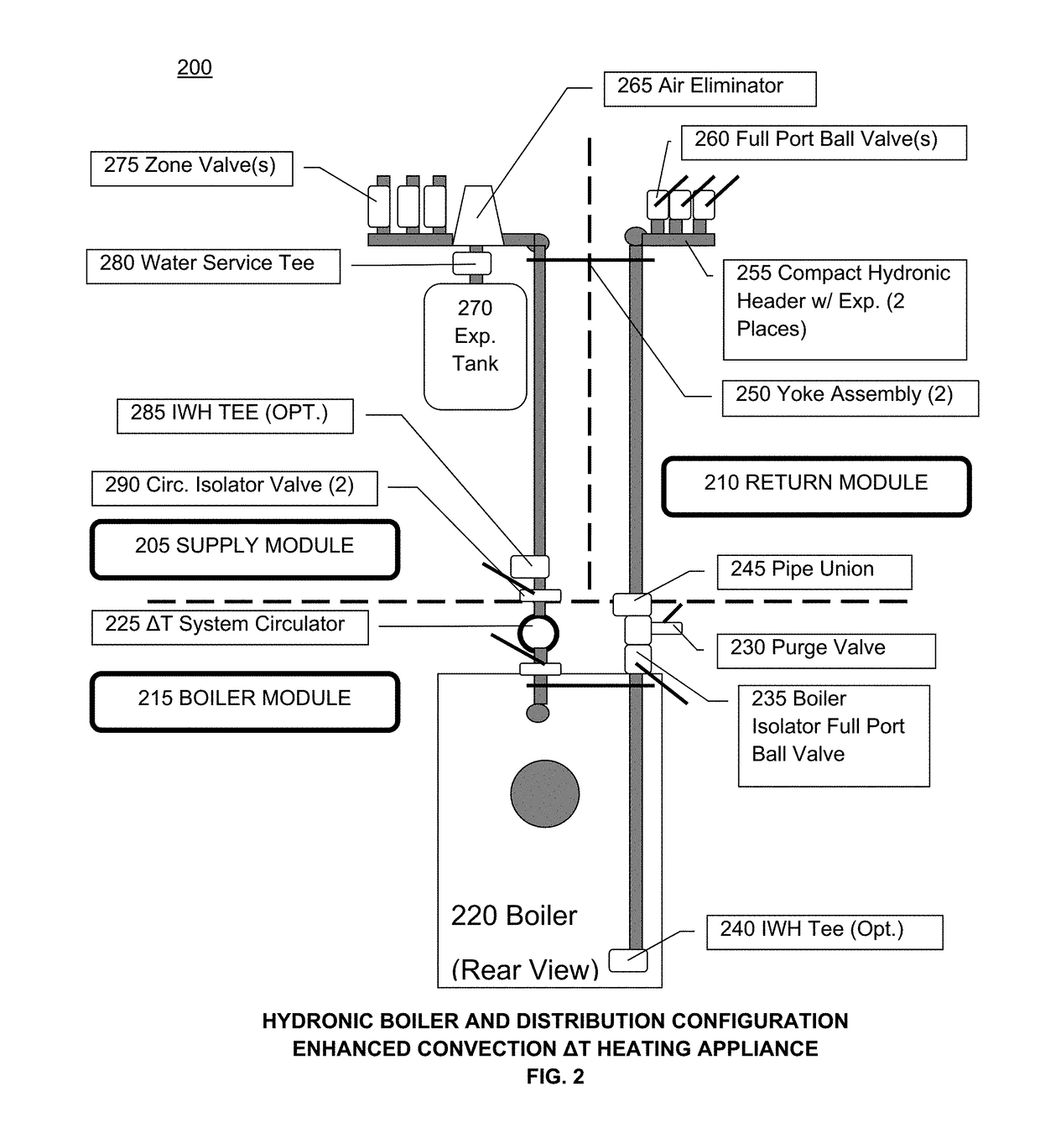

Enhanced convection, differential temperature managed, hydronic heating appliance

ActiveUS20170299200A1Lower system operating temperatureReducing “ stand-by ” lossLighting and heating apparatusCentral heating componentsReflux valveZone valve

A system, apparatus, and method for a differential temperature managed integral, free standing, hydronic heating appliance uses a high-mass heat source coupled to a single, highly-efficient, variable speed, Electronically Commutated Motor (ECM)-driven Delta-T stand-alone system circulator which feeds one or more zone valves governing flow to one or more hydronic zones. Components are integrated into simplified, compact, assemblies. Zone valve packaging of a compact header improves hydronic performance (head pressure reduction and increased flow), complementing zone valve performance and reducing zone valve wiring labor and material content. Returns have full port valves and the boiler includes isolation valves. All manually activated valves are full port. This can include full port boiler isolation valves, circulator isolation valves and return valves. Paralleled, ganged, alignment of state-indicating-lamped zone valves provides rapid, functional indication of component and system performance while the need for a zone valve panel commonly found on hydronic heating systems is negated.

Owner:MERCIER SR PAUL D

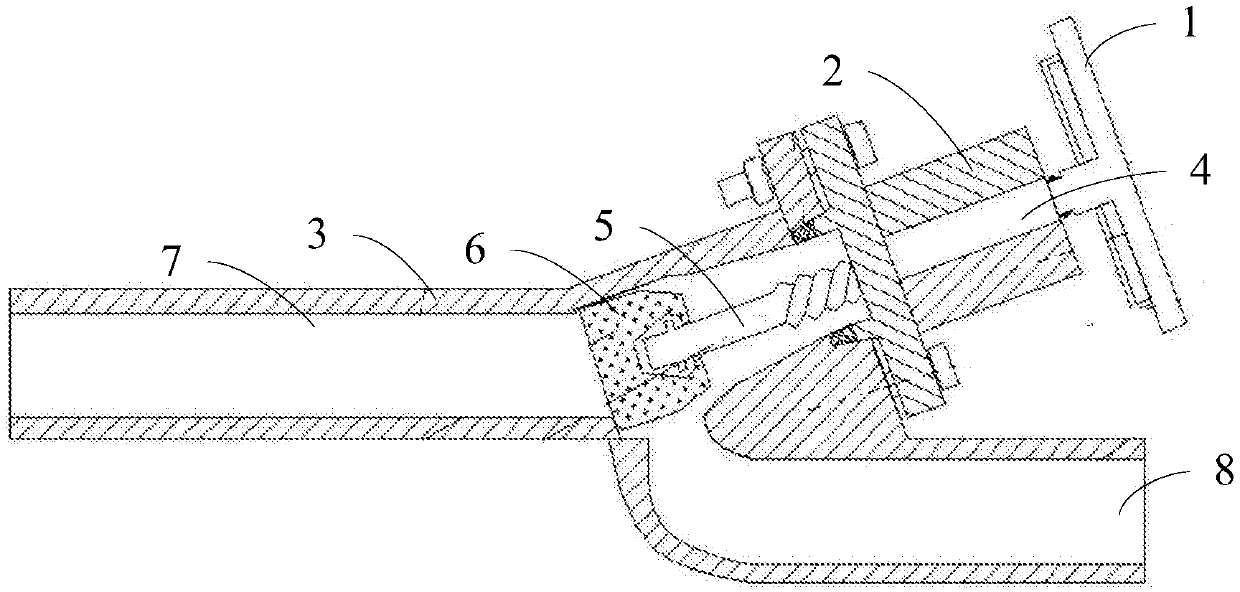

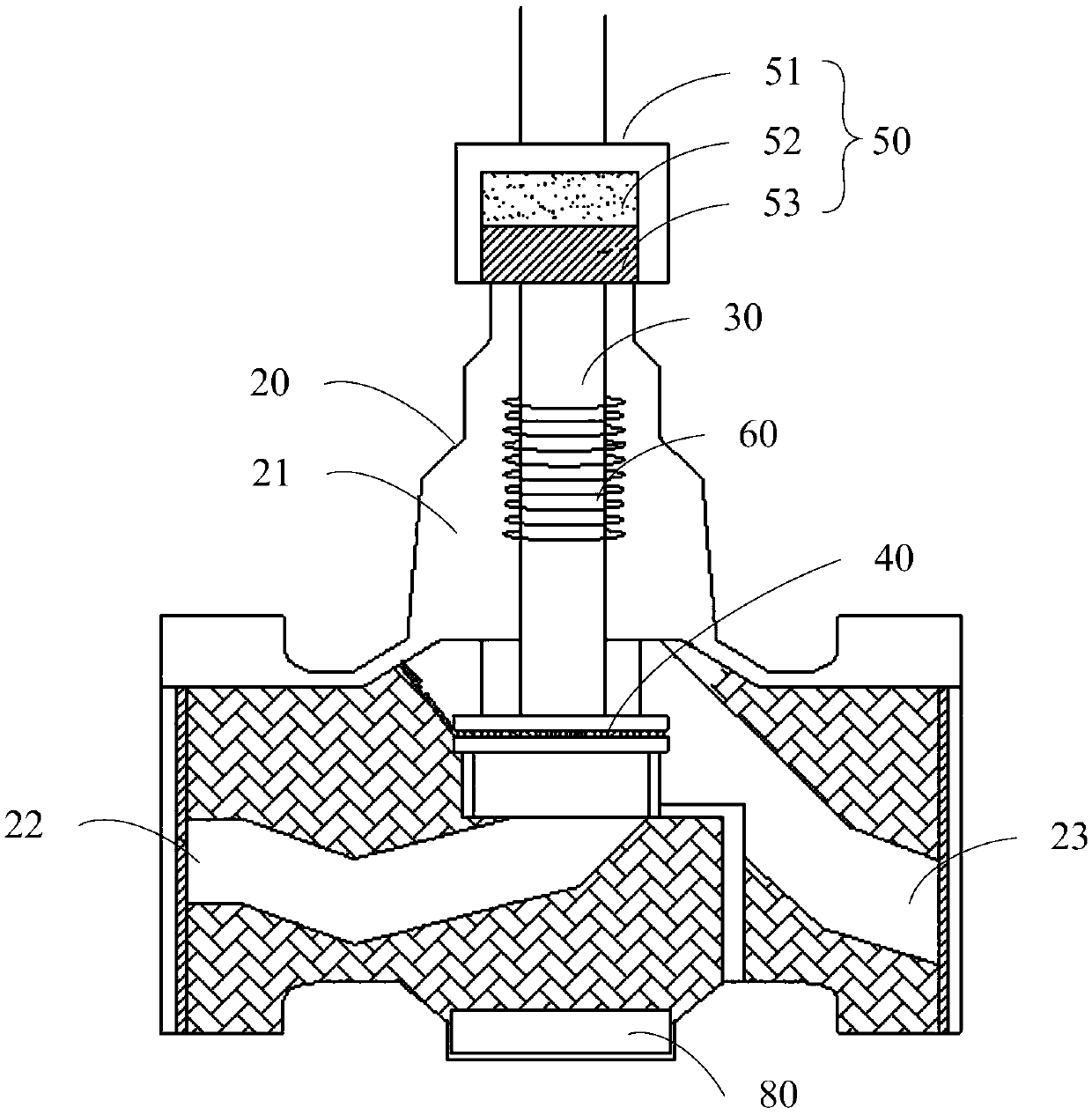

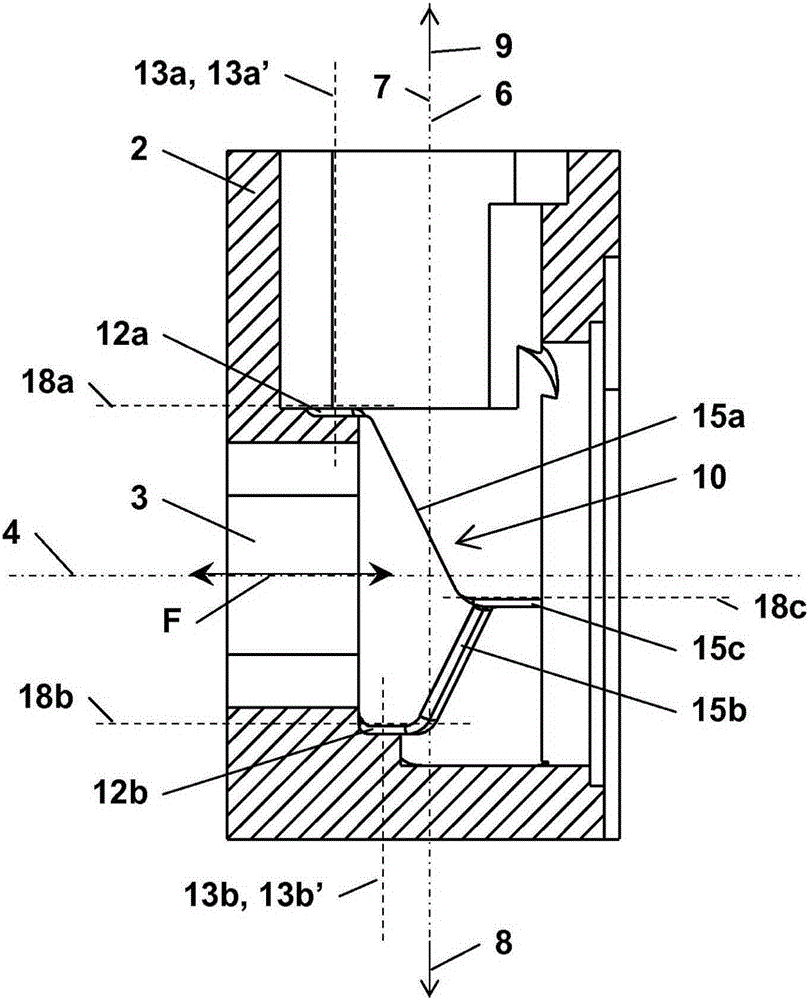

Valve with material having modifiable degree of penetrability

ActiveUS20120126154A1Long life-timeEasy to manufactureOperating means/releasing devices for valvesSoldering apparatusEngineeringMechanical engineering

Owner:SIEMENS HEALTHINEERS NEDERLAND BV

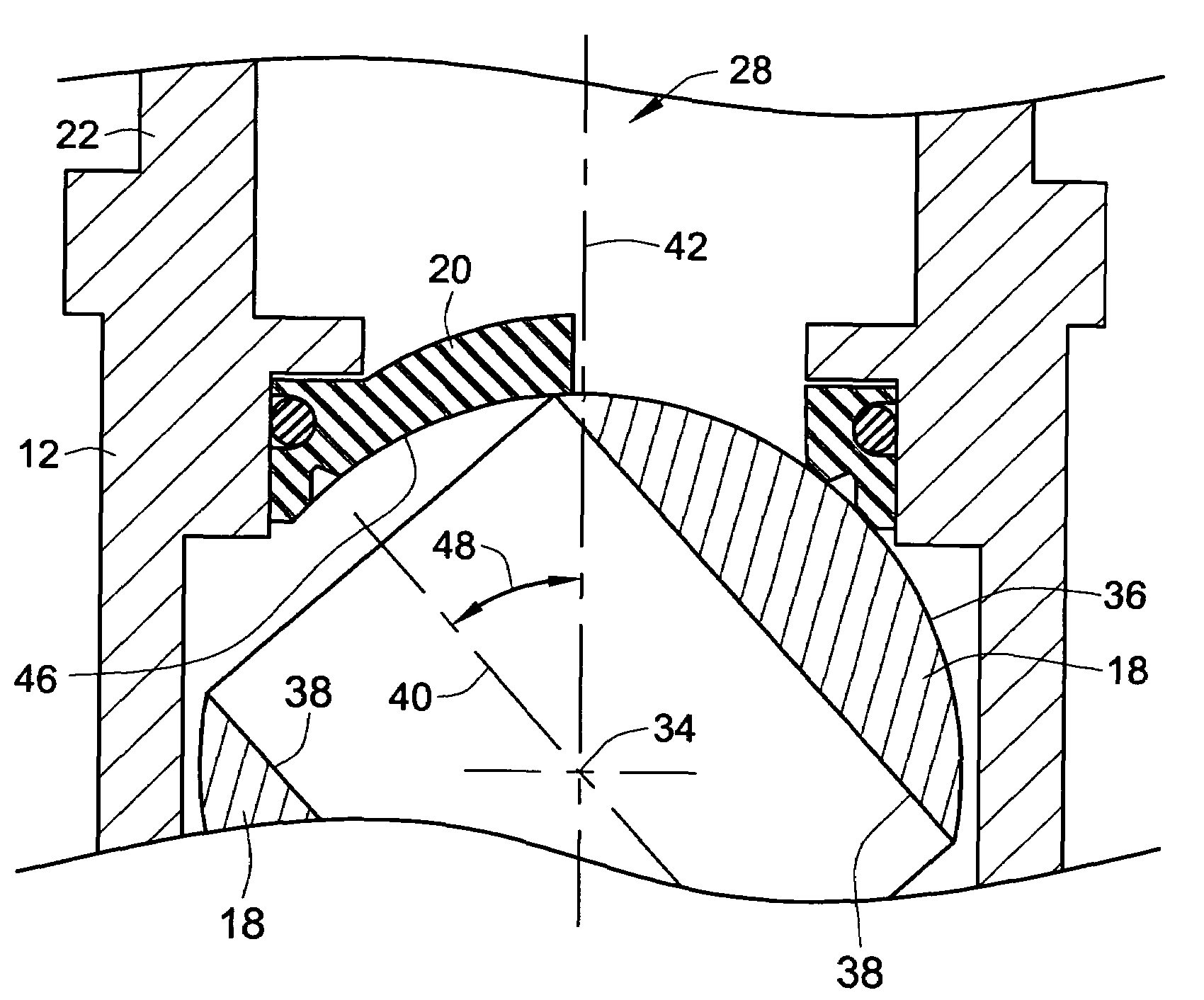

Apparatus and method for replacing existing actuator zone valves in an HVAC system with a ball valve

An apparatus and method are provided for replacing existing actuator driven zone valves in an HVAC system, and particularly valves of the rubber paddle type having actuators providing less than 90 degrees of rotation, with a ball valve including a skewed seat bearing that blocks flow through the flowpath when a valve member of the ball valve is rotated through an angle of substantially less than 90 degrees from a fully open position of the valve at which a bore in the valve member is substantially fully aligned with the flowpath. The actuator from the existing zone valve being replaced may be used with the provided ball valve apparatus and method.

Owner:SCHNEIDER ELECTRIC BUILDINGS AMERICAS INC

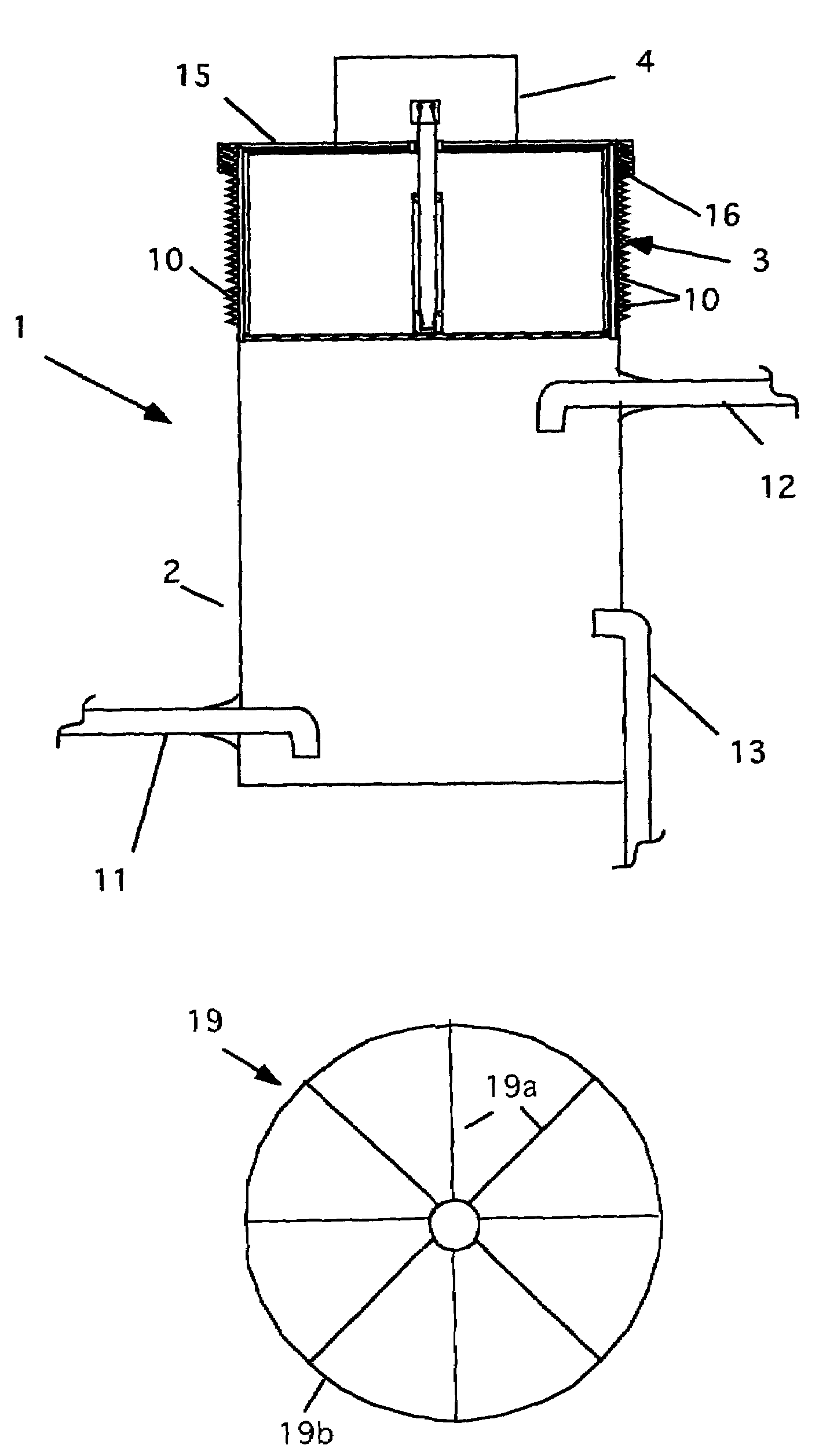

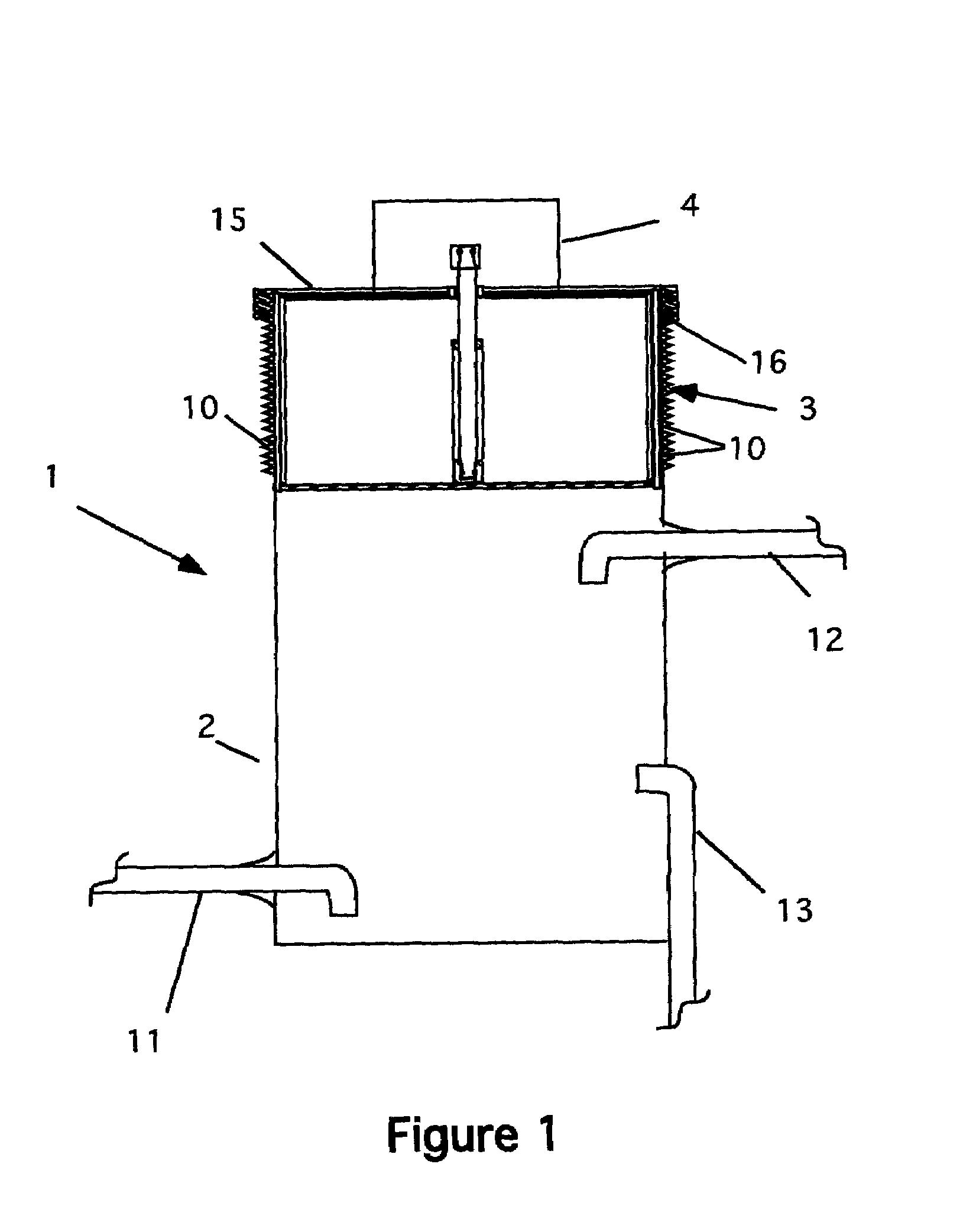

Automatic dispenser for underground sprinkler-systems

An automatic fertilizer that is designed to be used with a yard / lawn / garden sprinkler system. This unit is placed before the zone valves of the sprinkler system. The unit is designed to disperse fertilizer into a tank chamber below a discharge tray. The fertilizer dissolves in the water and is distributed / dispersed to the appropriate sprinkler system zone. The discharge tray has multiple chambers based on the number of zones in the sprinkler system. The chambers in the discharge tray can hold various capacities based on the area covered by each zone within the sprinkler system. The discharge tray turns to dispense the fertilizer as the sprinkler system changes from zone to zone. The discharge tray is automatically moved. The chambers are manually refilled based on the frequency of yard fertilization. The unit has an access from the top to the discharge tray for filling chambers with fertilizer material.

Owner:WALTER DAMIAN

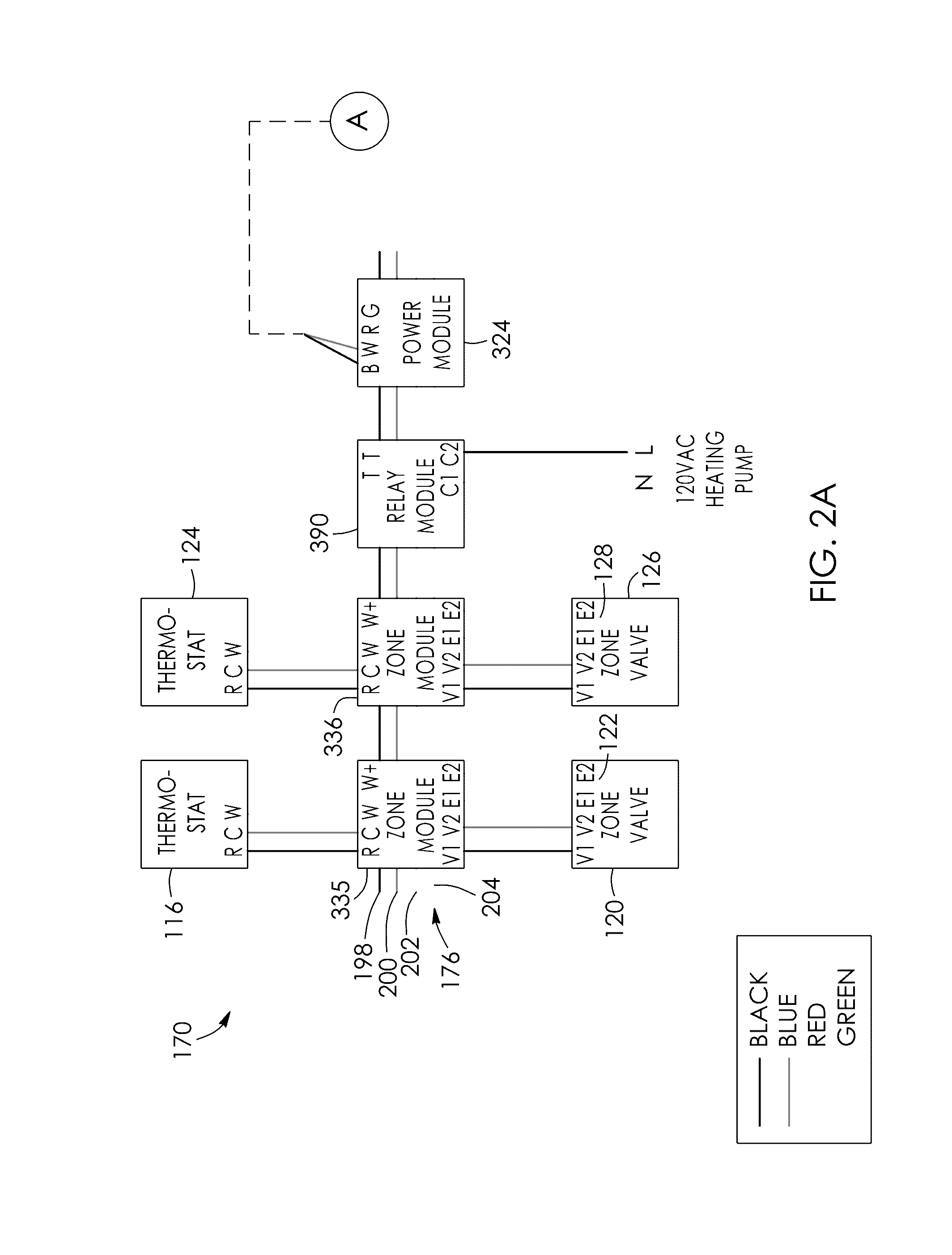

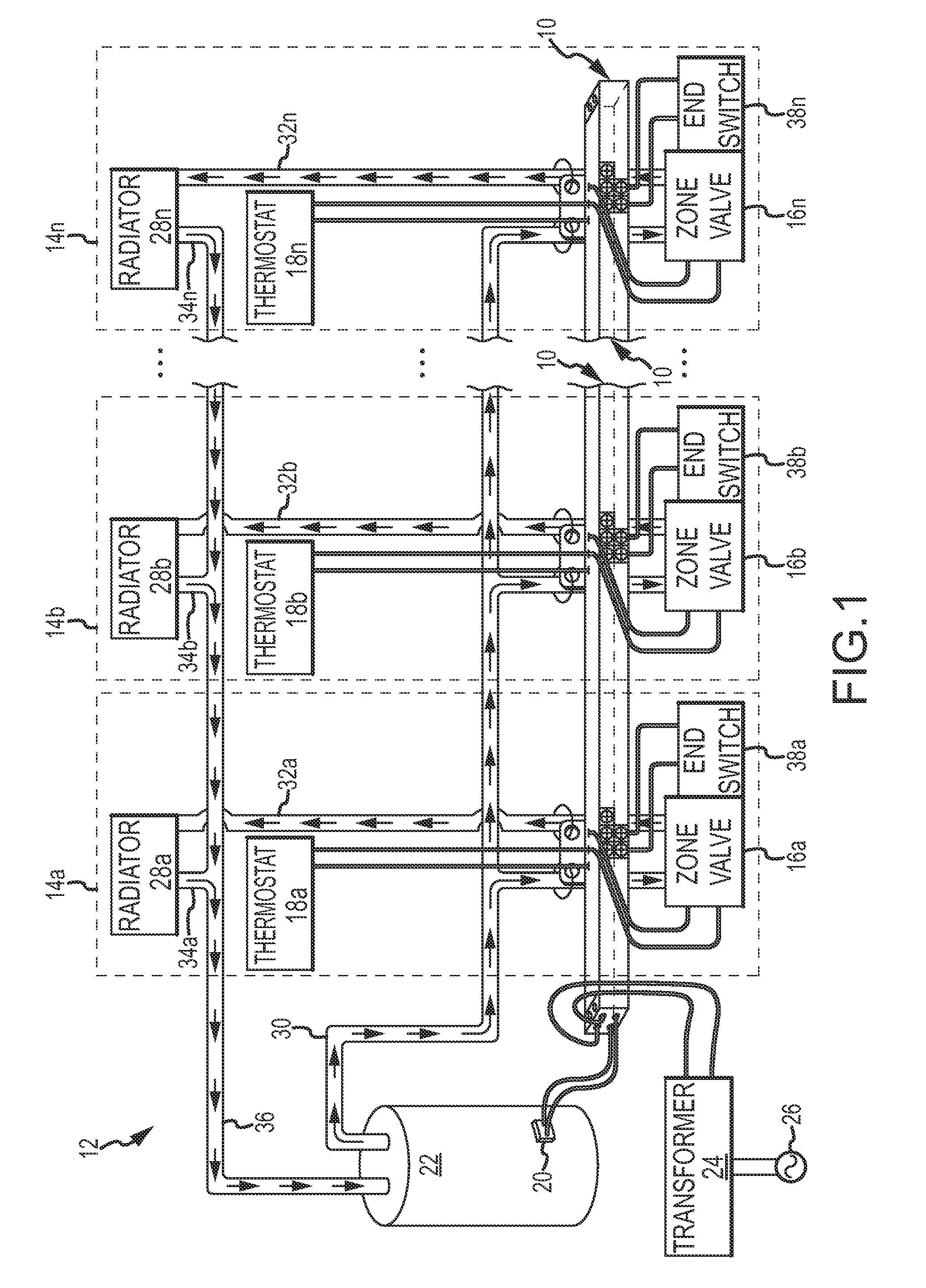

Integrated boiler component wiring assembly and method

InactiveUS8326134B2Reliable electrical connectionShorten the timeDough treatmentMilk preservationElectricityZone valve

An integrated wiring assembly electrically connects components of a multi-zone boiler heating system. The integrated wiring assembly includes a plurality of connection terminals which are commonly connected to facilitate connecting thermostats and zone valves for each zone, end switches of each zone valve to a start switch of the boiler, and a transformer to supply electrical power to the components, in such a way that the complexity of the electrical connections is simplified.

Owner:HARPER JAMES T

Fire protection system for valve side sleeve of extra-high voltage converter transformer and using method

The invention discloses a fire protection system for a valve side sleeve of an extra-high voltage converter transformer and a using method. The system comprises an oil collecting pit, a compressed airfoam generating device, a foam dry tube, a zoning valve and a compressed air foam spray system. The fire protection system adopts the independent oil collecting pi filled with pebble beds, effectively retrains the valve side sleeve, a valve side lifting base and transformer oil flow spread after an accident occurs, reduces a fire scale to the greatest extent, reduces fire loss, and protects safety of adjacent facilities and a valve hall. The compressed air foam spraying system adopts a spray tube without a spray head and a branch tube, and clings to a fireproof wall, so that damages, on a foam release device, of valve side sleeve explosion impact are reduced to the greatest extent, and safety reliability of the system is improved, and therefore, the technical problem of fire control of the valve side sleeve of the extra-high voltage converter transformer is completely solved, the fire protection system can be used for the extra-high voltage converter transformer, and also can be usedfor other converter transformers.

Owner:应急管理部天津消防研究所 +1

Automatic irrigation system purging

Owner:PELLAERO

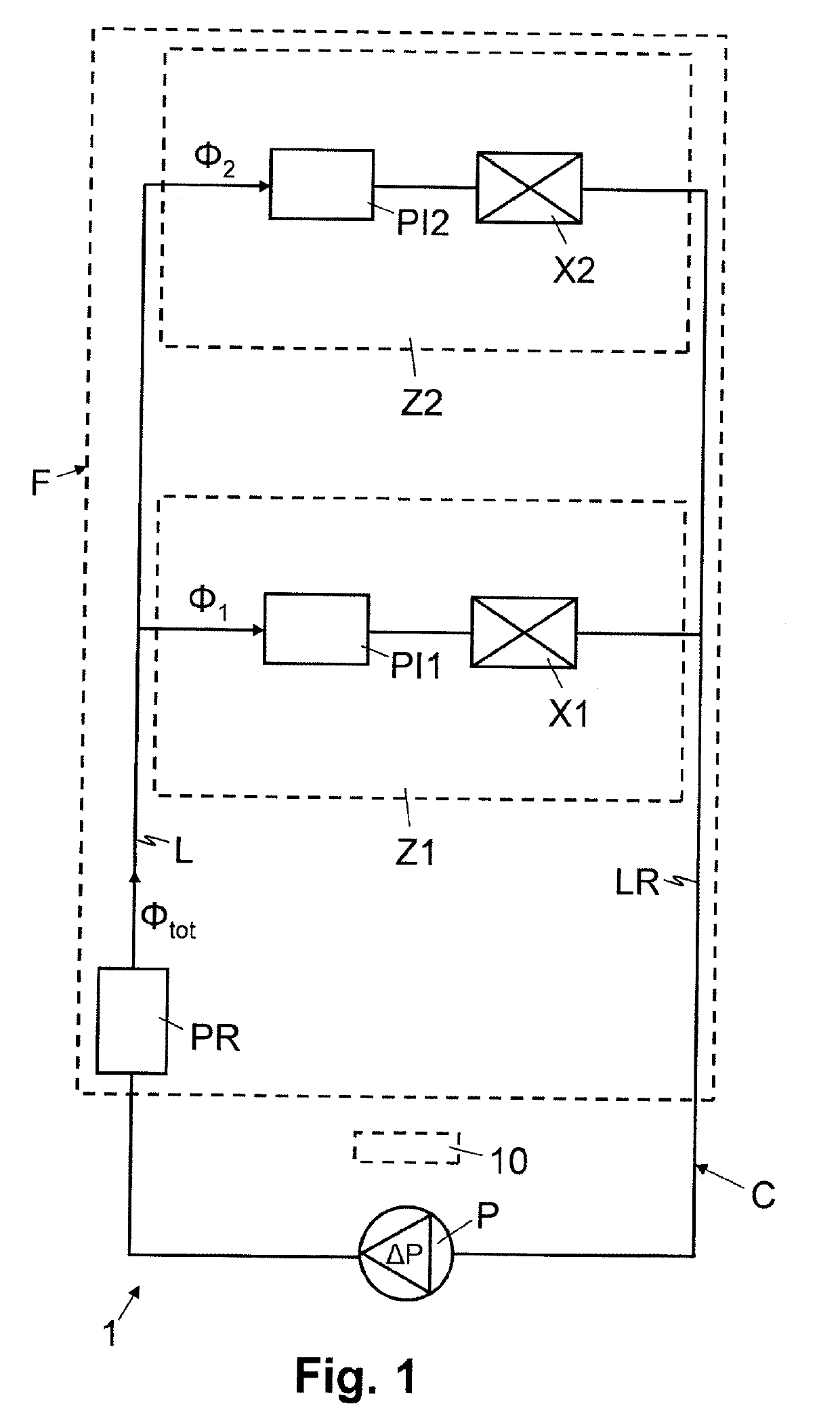

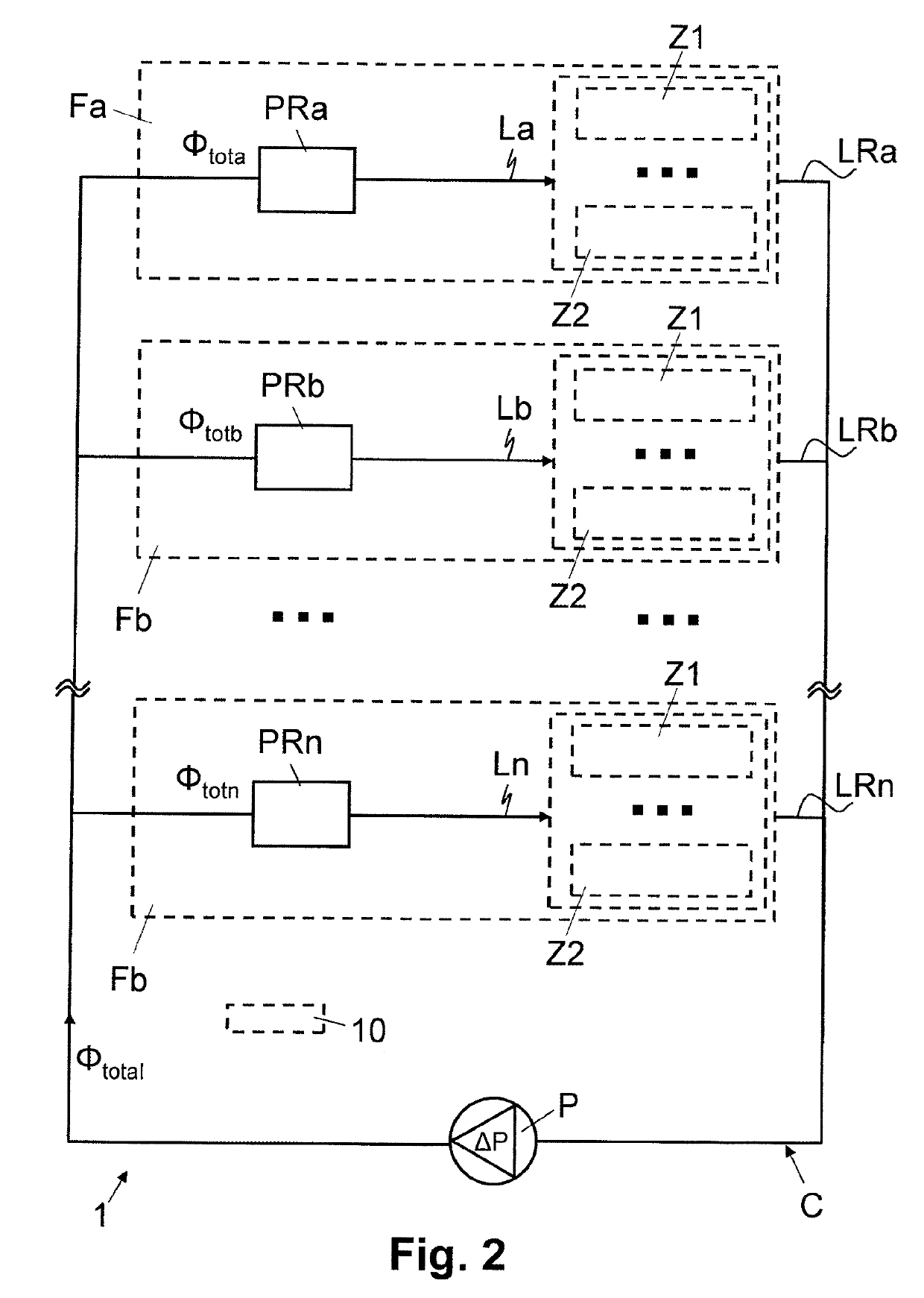

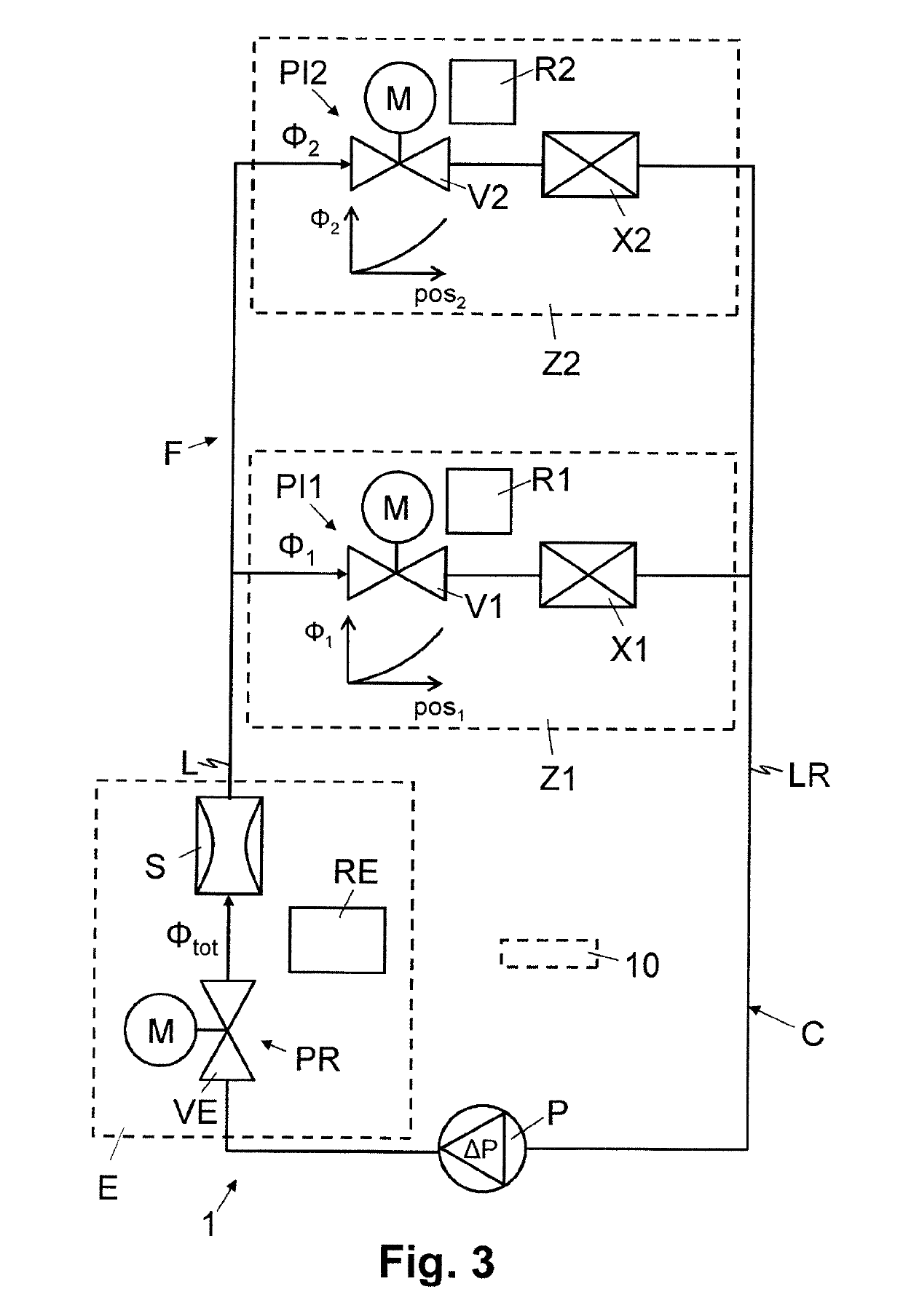

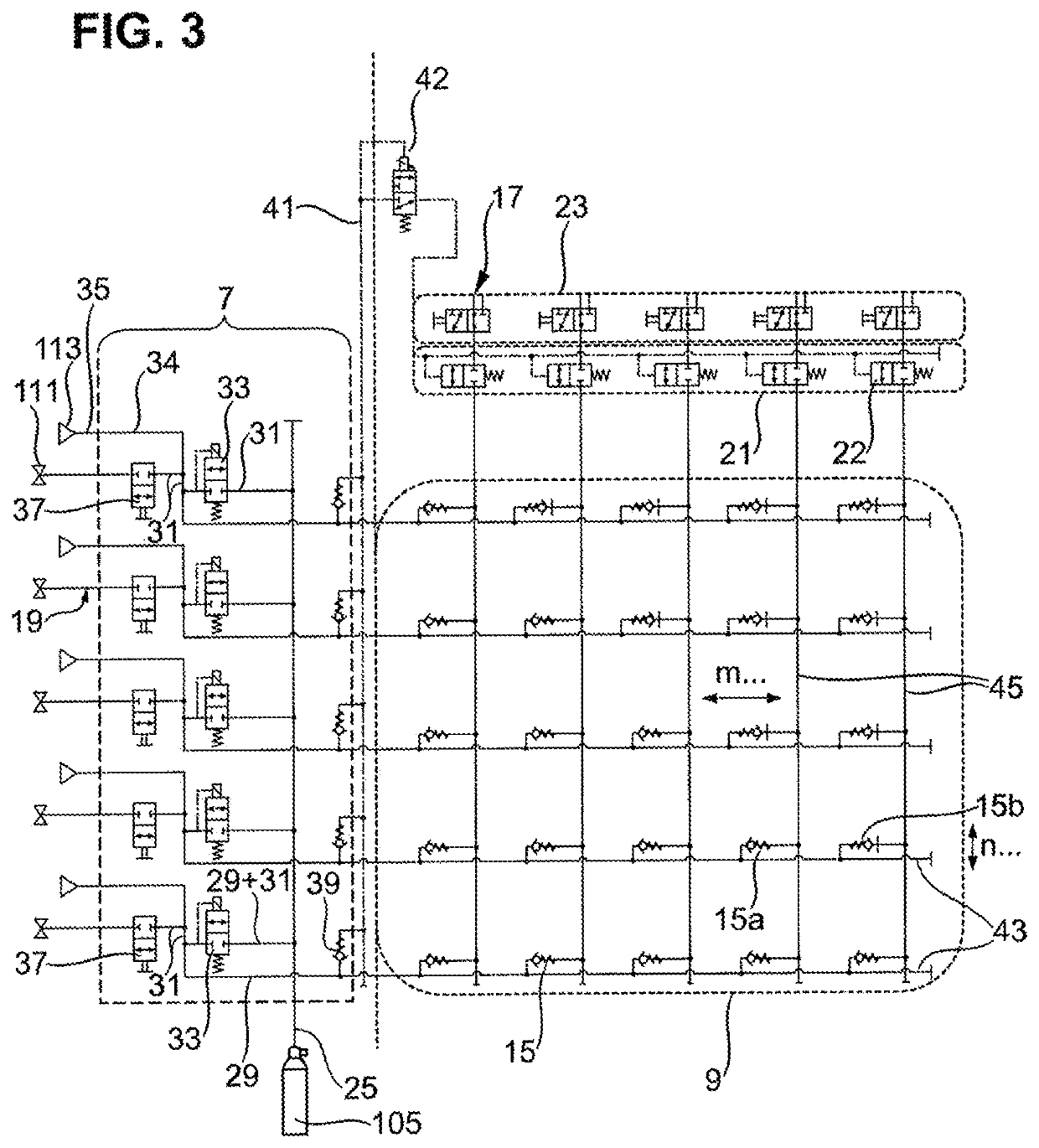

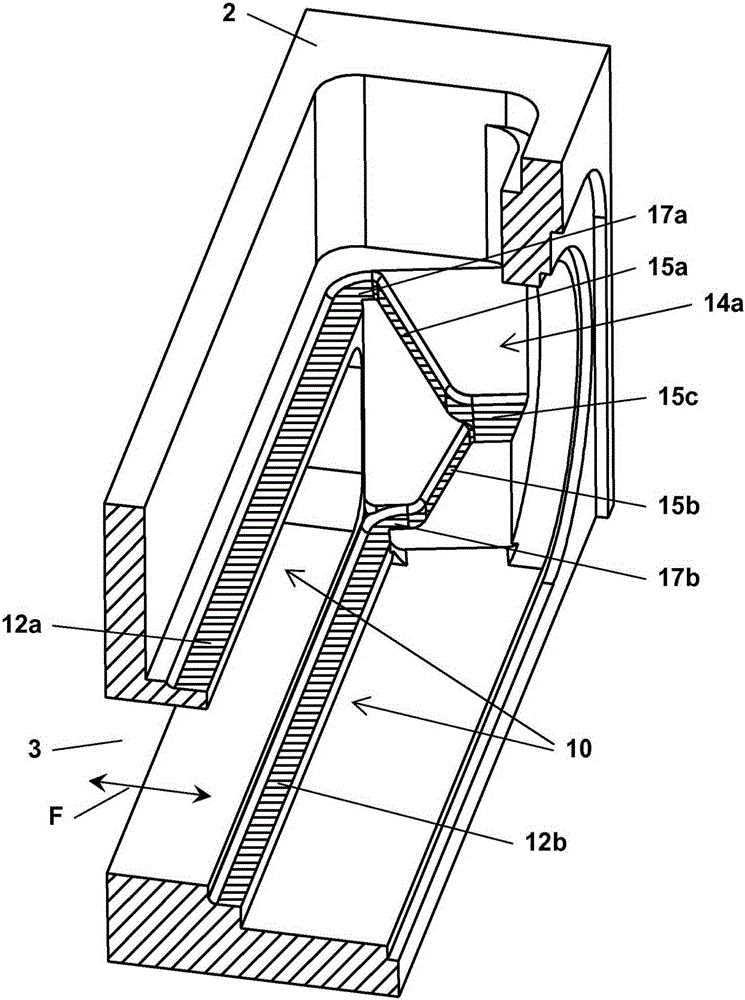

Method and devices for controlling a fluid transportation network

ActiveUS20190107292A1Reduce hardware overheadImprove energy efficiencyDistrict heating systemLighting and heating apparatusZone valveEngineering

A fluid transportation network (1) comprises a plurality of parallel zones (Z1, Z2), fed by a common supply line (L), with a regulating zone valve (V1, V2) in each zone (Z1, Z2) for regulating a flow of fluid (ϕ1, ϕ2) through the respective zone (Z1, Z2). A processing unit (RE) receives valve positions (pos1, pos2) of the regulating zone valves (V1, V2) and determines and sets an adjusted valve position for a line valve (VE) arranged in the supply line (L), depending on the valve positions (pos1, pos2) of the regulating zone valves (V1, V2). A processing unit (RE) further receives a measurement of a total flow of fluid (ϕtot) through the supply line (L) and determines and sets adjusted valve positions for the regulating zone valves (V1, V2), depending on the measurement of the total flow of fluid (ϕtot) through the supply line (L).

Owner:BELIMO HOLDING AG

Modular track wiring assembly for a hydronic system

ActiveUS10465919B2Coupling device connectionsLighting and heating apparatusElectrical conductorZone valve

There is provided a hydronic system for a plurality of zones. The system includes a wiring track. The track has a pair of power conductors for supplying electrical energy therealong and a pair of signal conductors. The signal conductors are in communication with a heat / cold source. The system includes a plurality of zone modules, each corresponding to a respective one of the zones. Each of the zone modules includes leads which connect to respective ones of the conductors. Each of the zone modules includes terminals and conductors configured to selectively connect respective thermostats and zone valves of their zone together, receives signals therefrom and conveys the signals via the signal conductors to the heat / cold source for selectively heating / cooling respective ones of the zones.

Owner:B2 PROD LTD

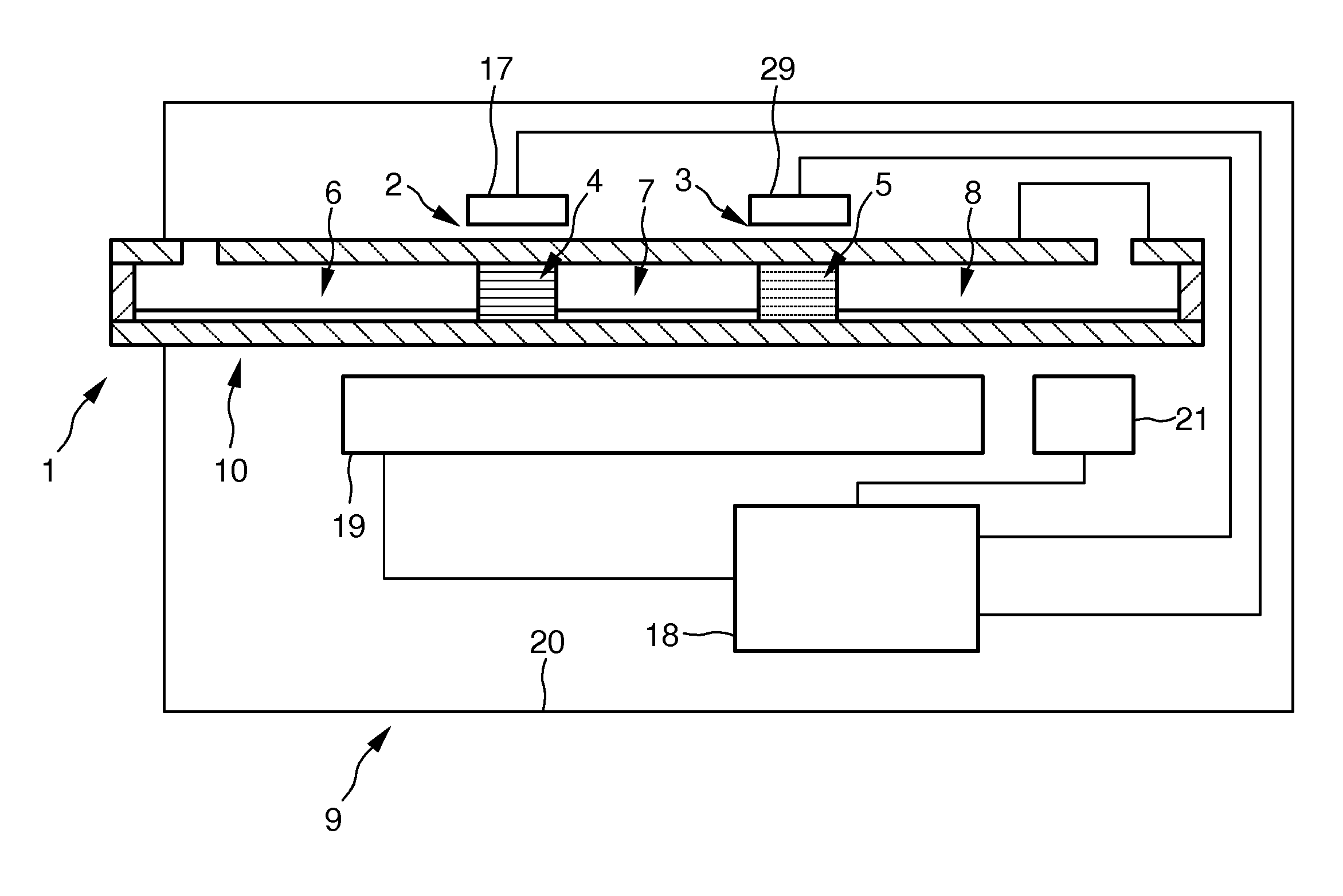

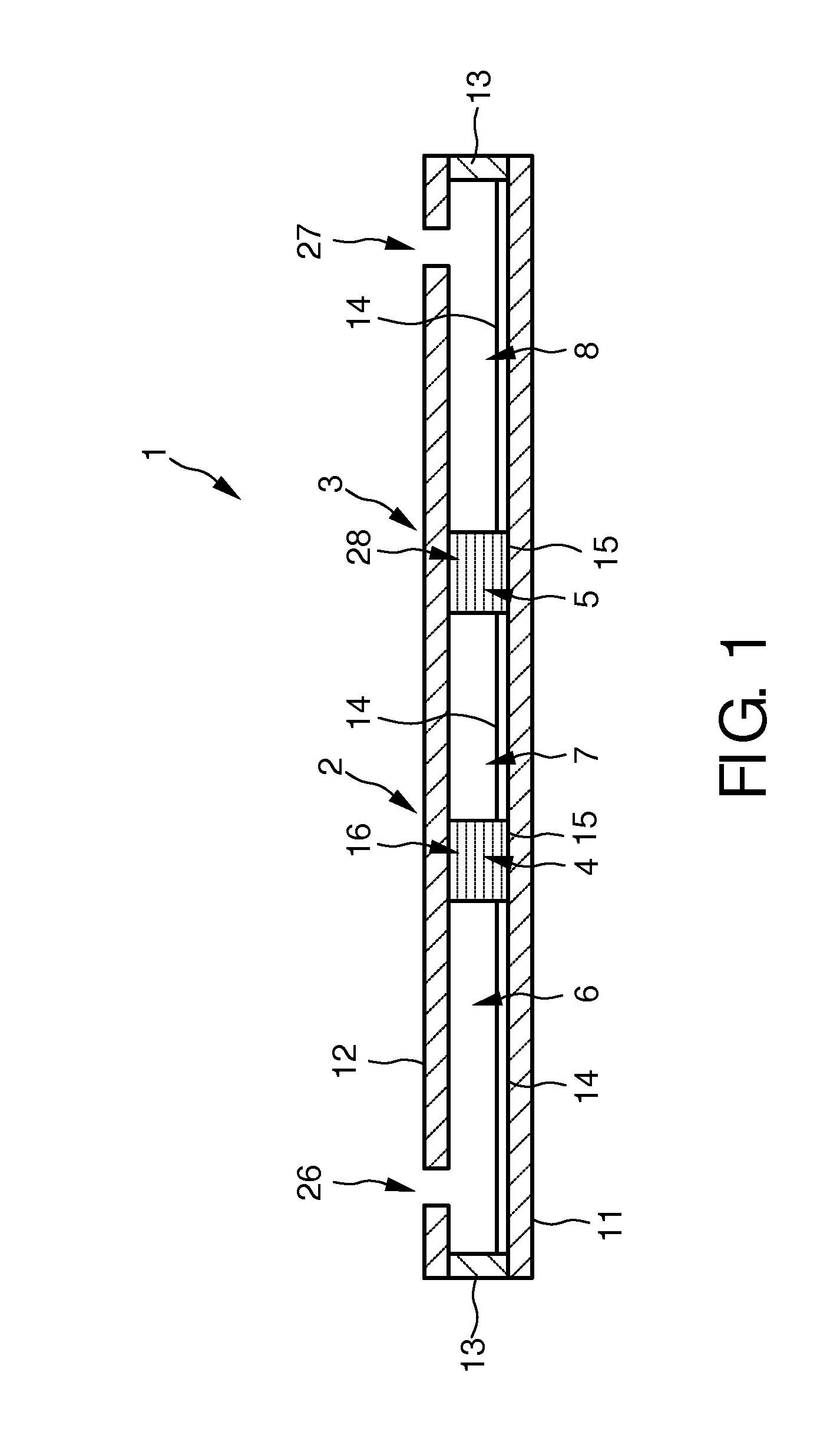

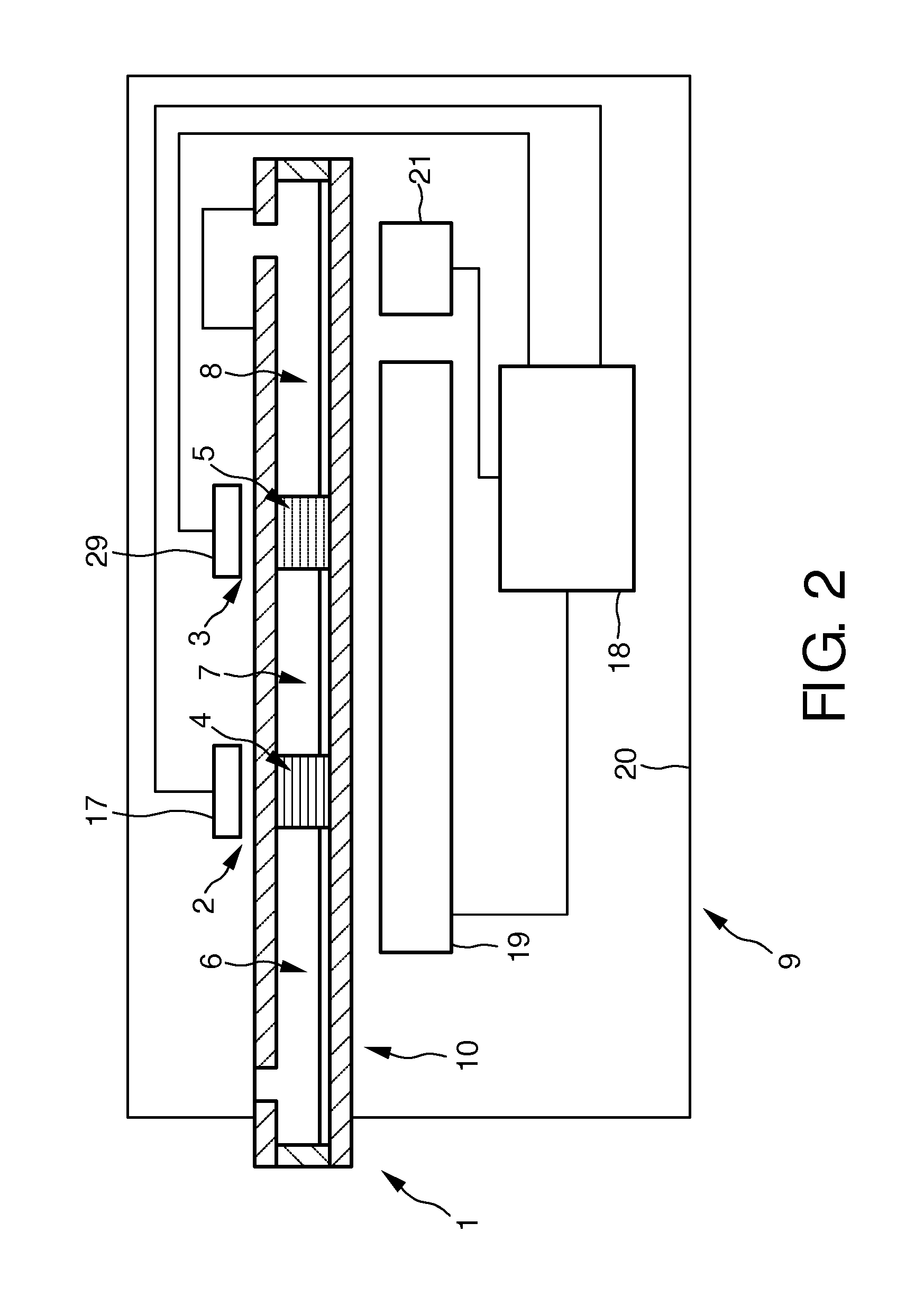

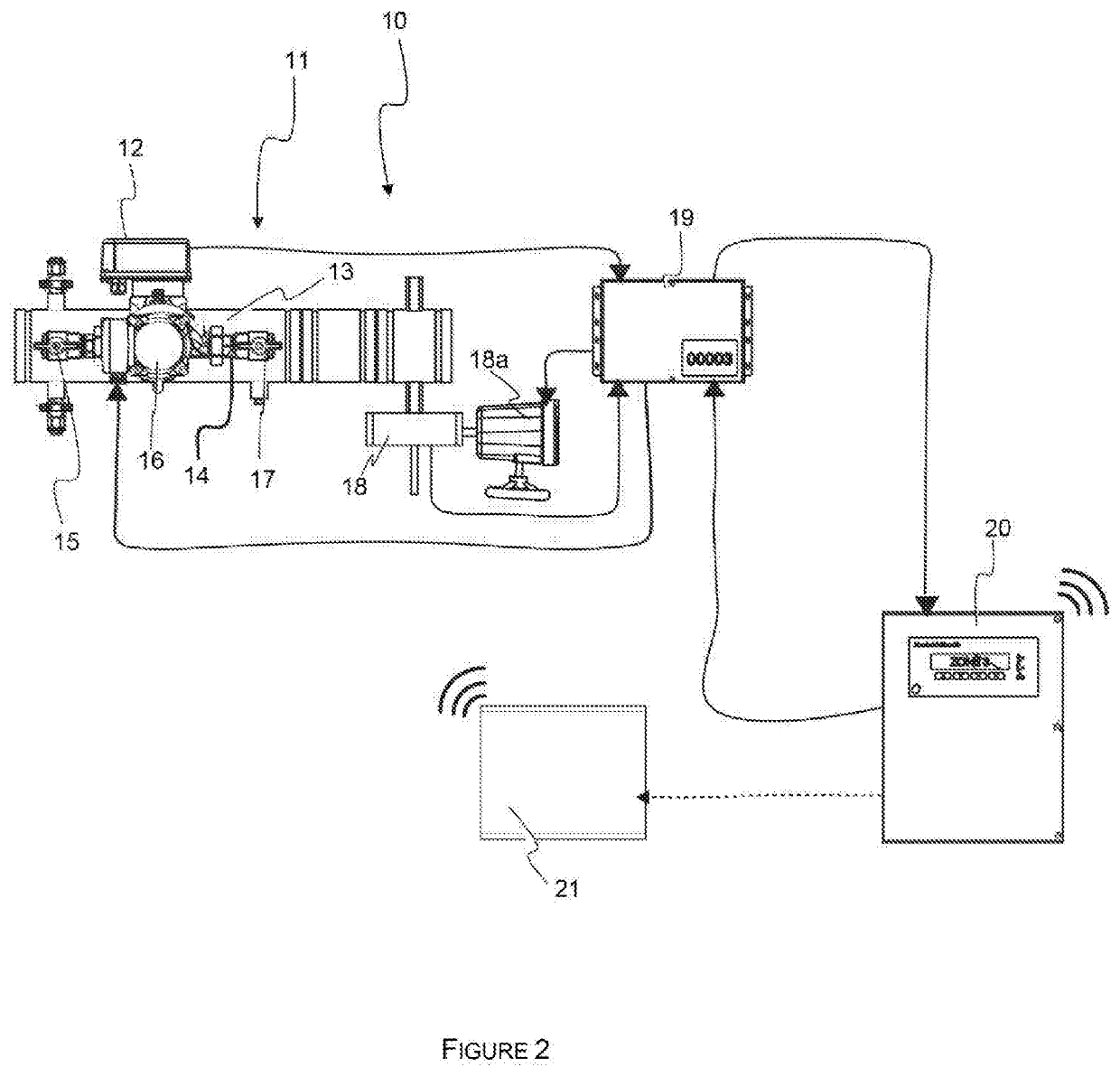

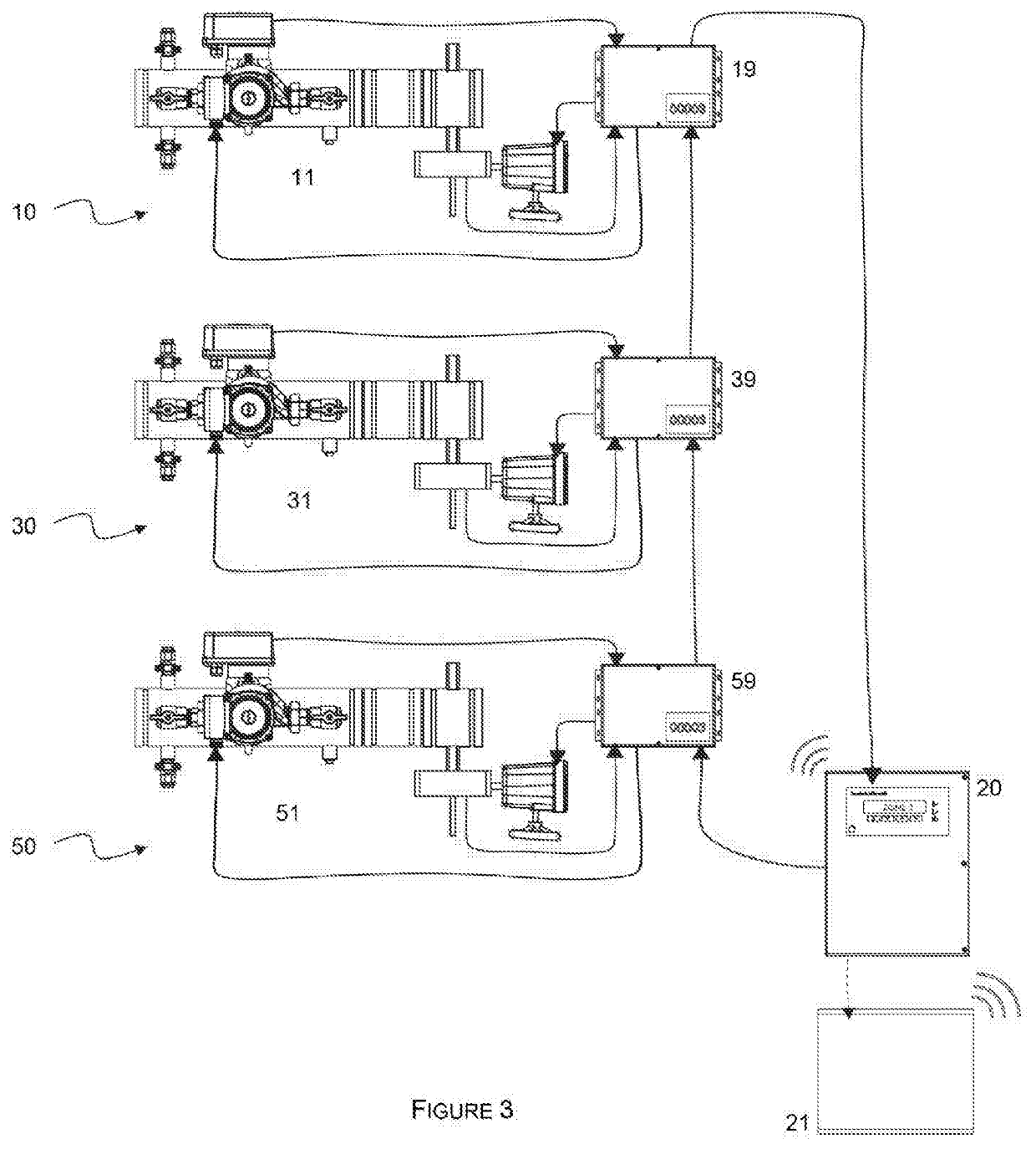

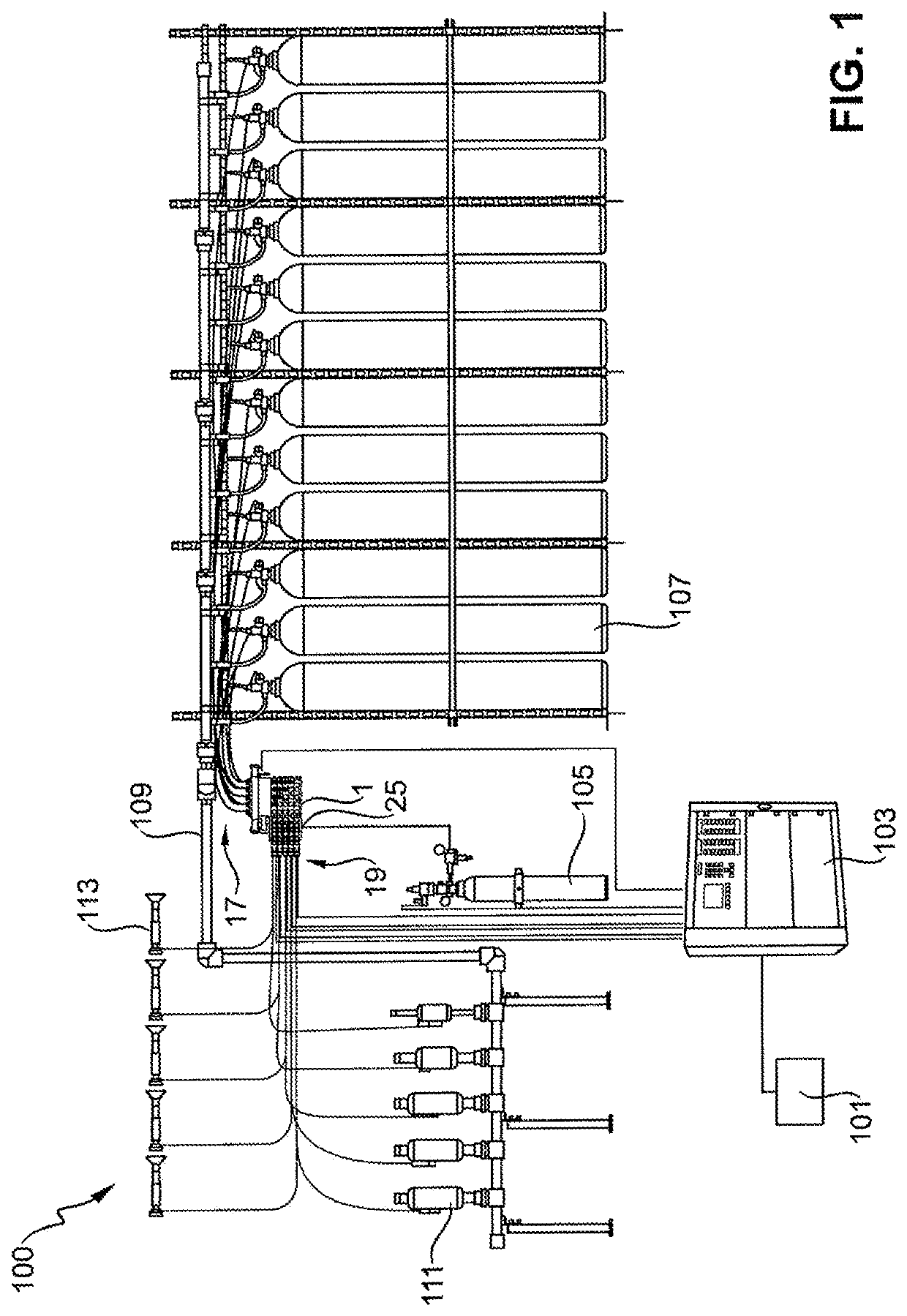

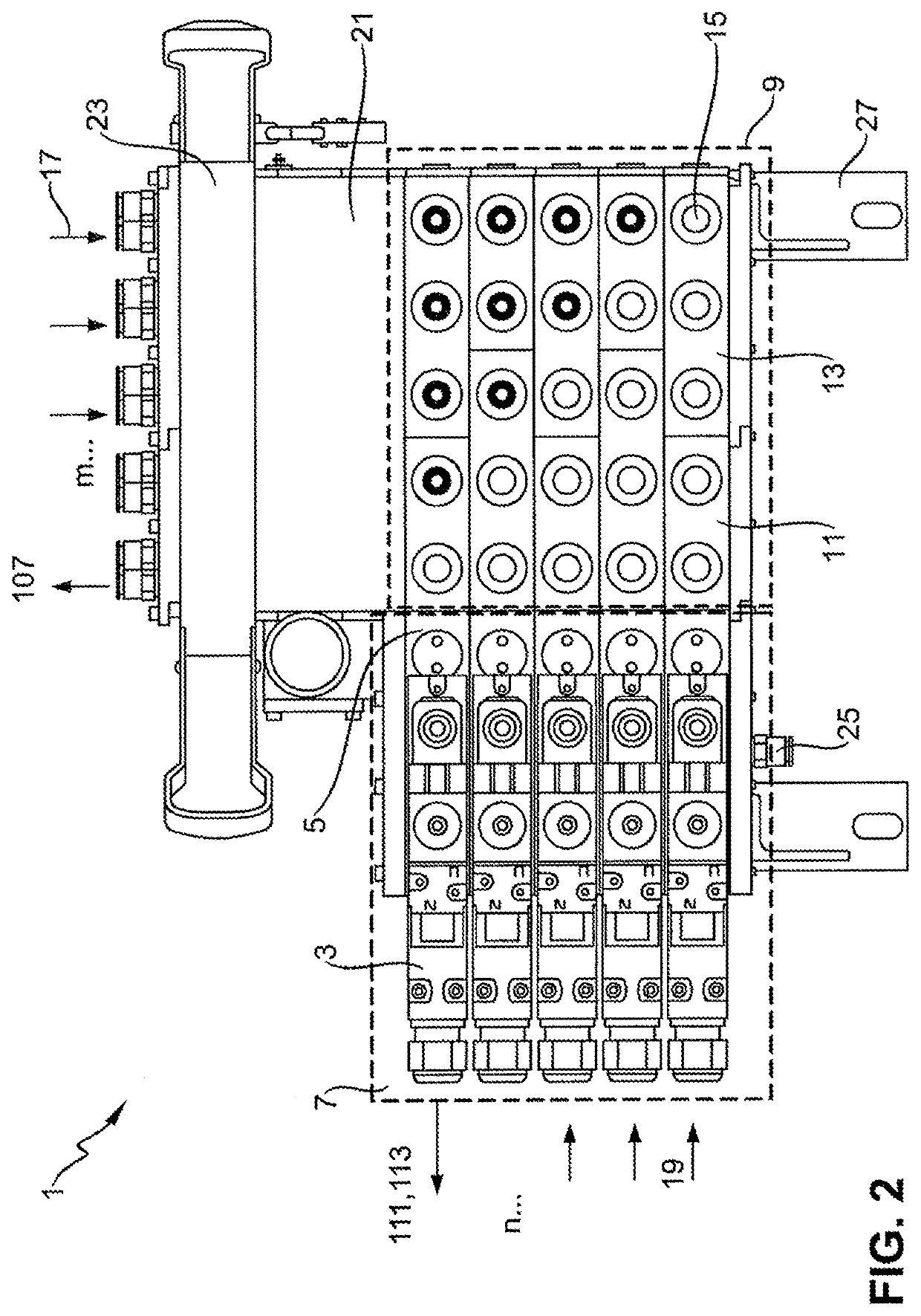

Assembly, system and method for testing a sprinkler system

A testing apparatus (11) for testing a fire sprinkler system combines components for testing both the function of a tamper switch (not shown) incorporated into local zone valve (18) and the working of a flow switch (12) that detects flow in a pipe (13). The assembly (10) also comprises a module (19) which is connected to the flow switch (12), the pump (16) and the local zone valve (18) to monitor their performance. A master controller (20) is provided for reading data from the module (19) and for instructing the module (19) to control the operation of the various components of the testing apparatus (11) connected thereto. Information received by the master controller (20) can be relayed to a building's fire alarm panel (21). In normal use, the module (19) will transmit signals to the master controller (20) to activate the fire alarm via the fire alarm panel (21) in response to monitoring of the flow switch (12) and zone valve (18). In test mode, the module (19) is operable to disable the alarm being activated. This allows testing to take place without generating false alarms. The module (19) can also correlate the date and time of the test with the outcome of the test (i.e. pass or fail) and send this information to the master controller (20) for printing or archiving.

Owner:PROJECT FIRE GLOBAL HLDG

Foam spray fire extinguishing device

The invention discloses a foam spray fire extinguishing device, which comprises a power bottle set, a driving device, a water storage device, a foam stock solution storage device and a zoning valve, wherein the power bottle set is connected with the water storage device through a collecting pipe; an output pipeline of the water storage device is divided into two paths through the zoning valve, and the two paths are communicated with two independent tank bodies of the foam stock solution storage device; and a capsule filled with a foam stock solution is arranged in one tank body of the foam stock solution storage device, and the other tank body is communicated with the capsule and provided with a spray outlet. Fire fighting water and the foam stock solution are separately filled in the fire extinguishing device, so that the storage time of consumables is prolonged, and the using cost of a fire fighting person is reduced; the problem of corrosion is not considered in a water tank (the water storage device), and a common normal pressure storage tank can be adopted, so that the manufacturing cost is reduced; and after being used up, the foam solution and the water can be filled in a ratio, so that continuous fire extinguishment can be realized.

Owner:WUHU SHIJI KAIXUAN FIRE EQUIP

Valve device for a turbocharger

ActiveUS11047296B2Eliminate playLess spaceBelleville-type springsInternal combustion piston enginesZone valveTurbocharger

A valve device for an exhaust-gas bypass path of a turbocharger, including: a plate-like valve element, movable between a closed position and an open position and which has a shaft, which is connected to a valve element carrier for limited movement in the shaft direction; a rotatably held spindle, to which the valve element carrier is fixedly connected; a valve seat for the valve element, which valve seat surrounds an exhaust-gas through-opening; and an annular sheet-metal spring element, which has an opening through which the valve element shaft extends, an outer ring region, an inner ring region, which is axially offset relative to the outer ring region and adjoins the spring element opening, and an annular transition region therebetween; the width of the spring element transition region being variable around the spring element opening such that the valve element can be adapted to the valve seat as easily as possible.

Owner:ELRINGKLINGER AG

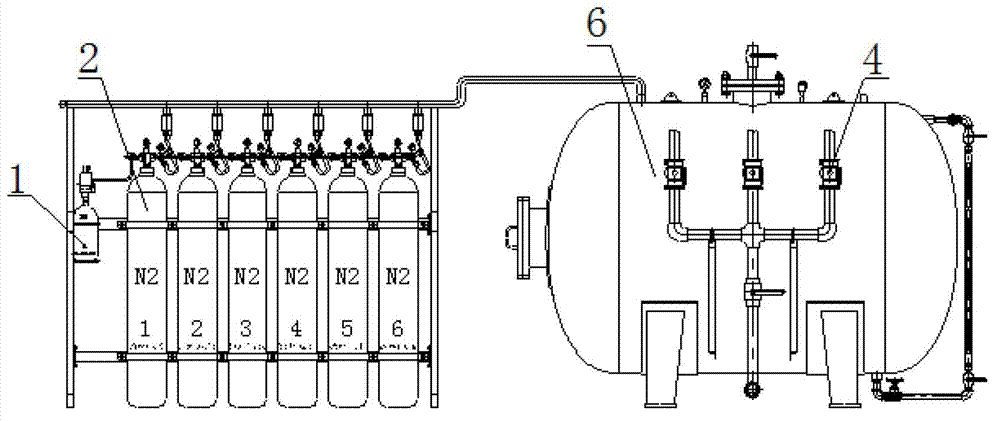

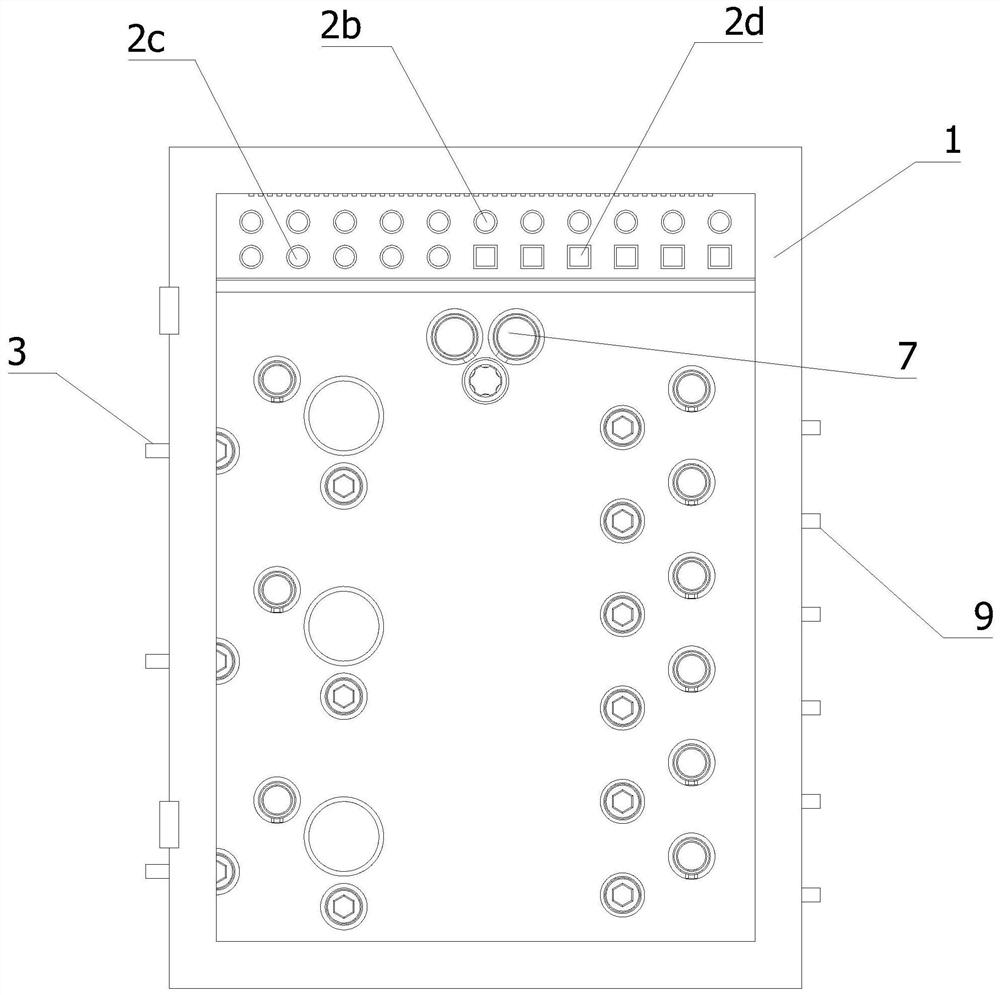

Pneumatic Control Device for Multi-Zone Fire Extinguishing Systems, and Multi-Zone Fire-Extinguishing Systems Having Same

PendingUS20210069539A1Considerable effectLow degree of diversityFire rescueZone valveElectrical control

Owner:MINIMAX LIMITED

A medical gas area valve box

ActiveCN110440035BRealize uninterrupted gas supplyReduce air pressureMultiple way valvesZone valveGas supply

Owner:宁波奉天海供氧净化成套设备有限公司

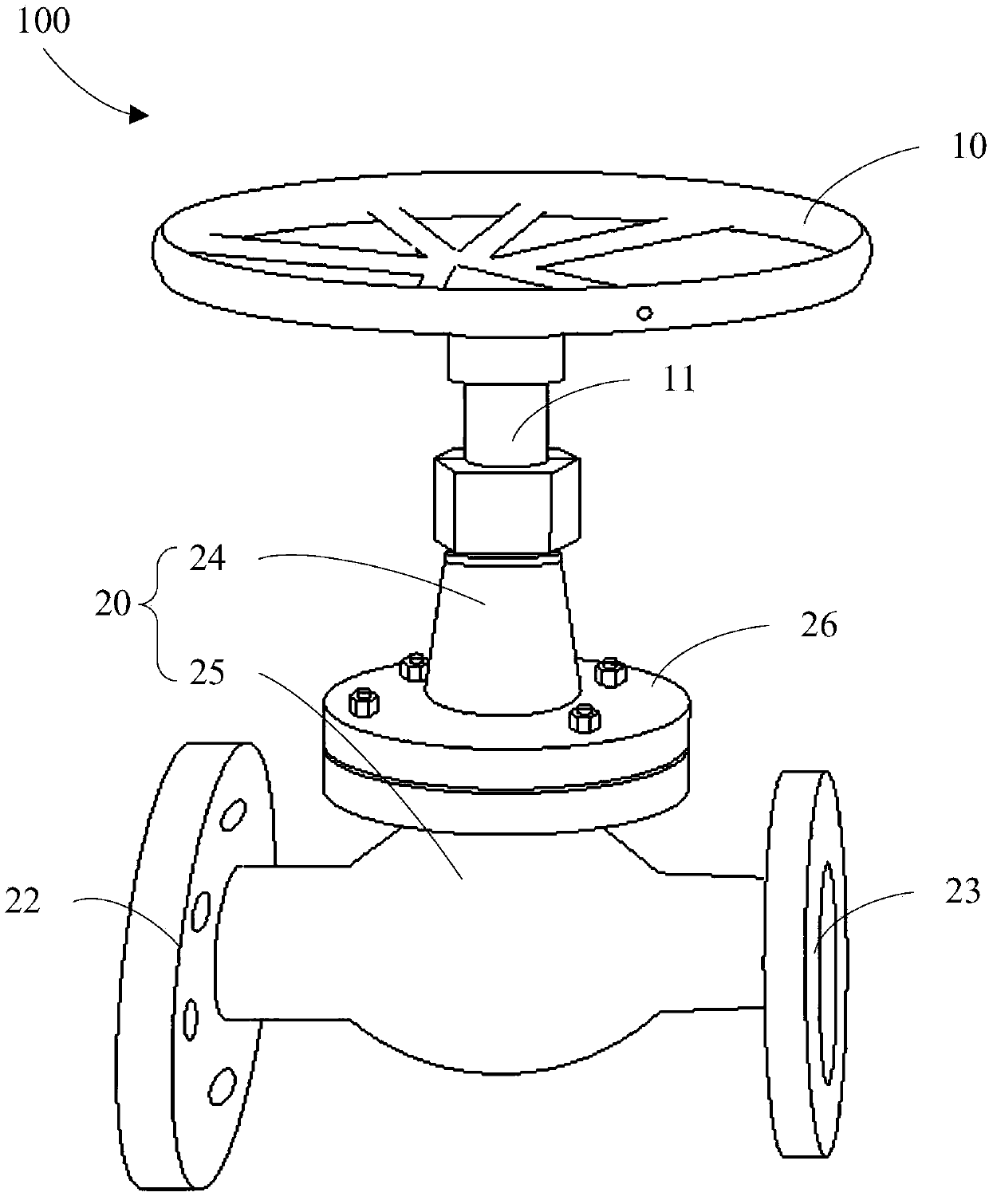

Petroleum pipeline stop valve and petroleum conveying system

PendingCN110873189AImprove sealingQuality improvementSpindle sealingsOperating means/releasing devices for valvesZone valveMarine engineering

The invention provides a petroleum pipeline stop valve and a petroleum conveying system. The petroleum pipeline stop valve comprises a hand wheel, a valve body, a valve rod and a valve flap, wherein avalve cavity for allowing an oil body to circulate is formed inside the valve body, a mounting opening is formed in one end of the valve cavity, and a liquid inlet pipeline and a liquid outlet pipeline which communicate with the valve cavity are arranged at the other end of the valve cavity; a wheel shaft of the hand wheel is connected with one end of the valve rod, the other end of the valve rodis provided with the valve flap, and the other end of the valve rod extends into the valve cavity through the mounting opening, so that the valve flap is located in an communication area between theliquid inlet pipeline and the liquid outlet pipeline; the hand wheel is used for rotating and driving the valve rod to reciprocate in the direction extending into the valve cavity, and the valve flapis used for blocking or conducting the communication area under the driving of the valve rod; and a sealing assembly is further arranged between the valve rod and the mounting opening, and the sealingassembly is used for sealing a gap between the valve rod and the mounting opening. According to the petroleum pipeline stop valve, the sealing performance of the stop valve can be improved, the leakage of the stop valve is prevented, and the safe and efficient conveying performance of a petroleum pipeline is ensured.

Owner:PETROCHINA CO LTD

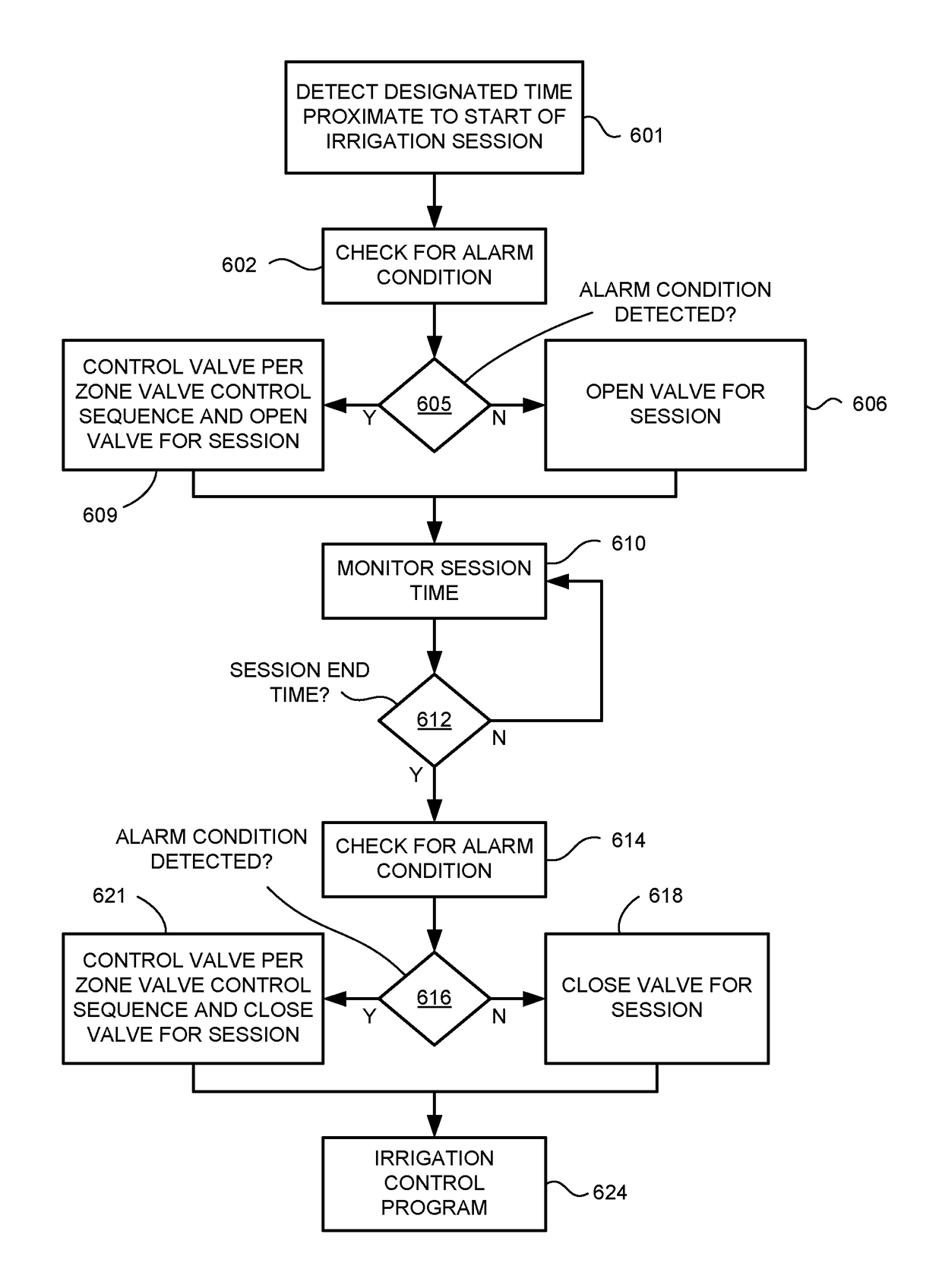

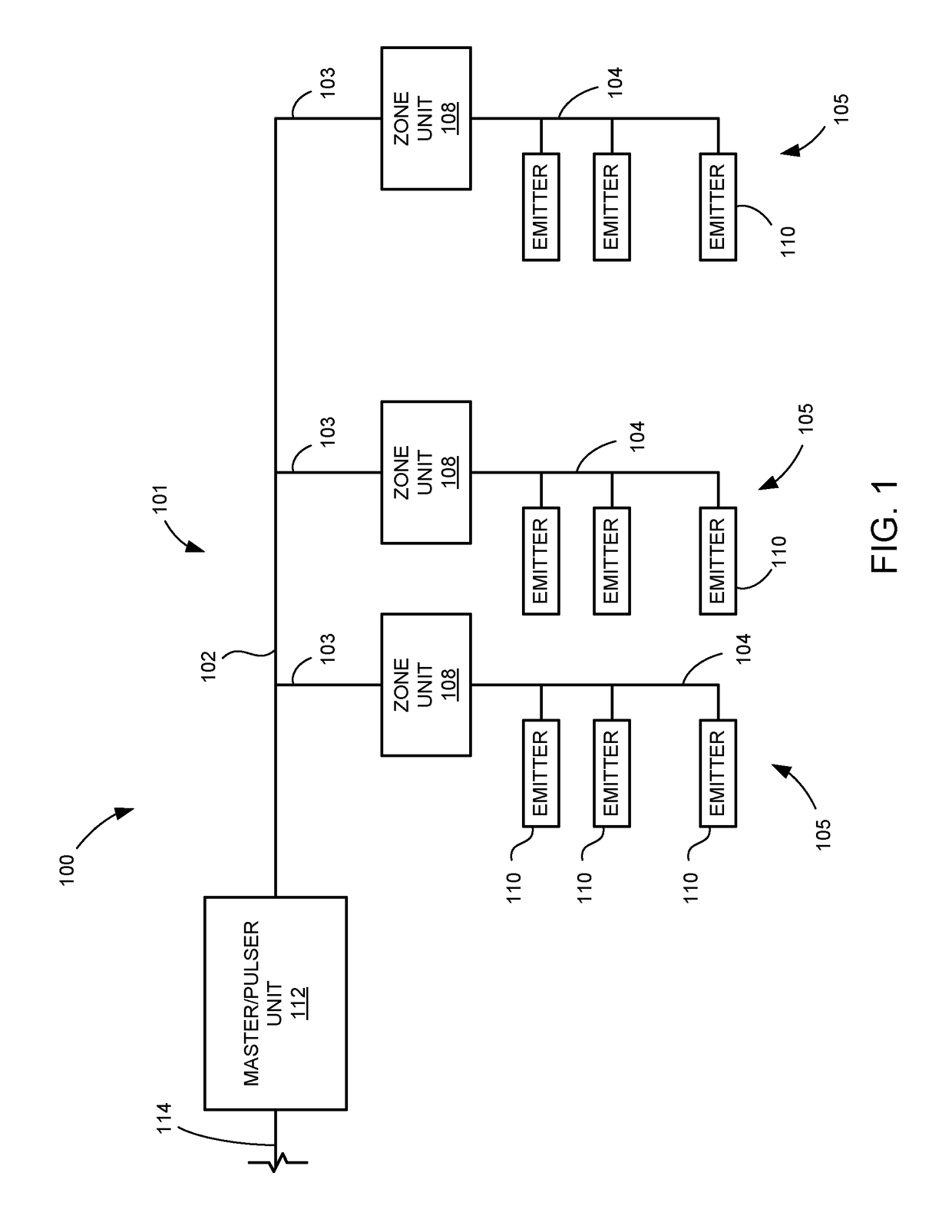

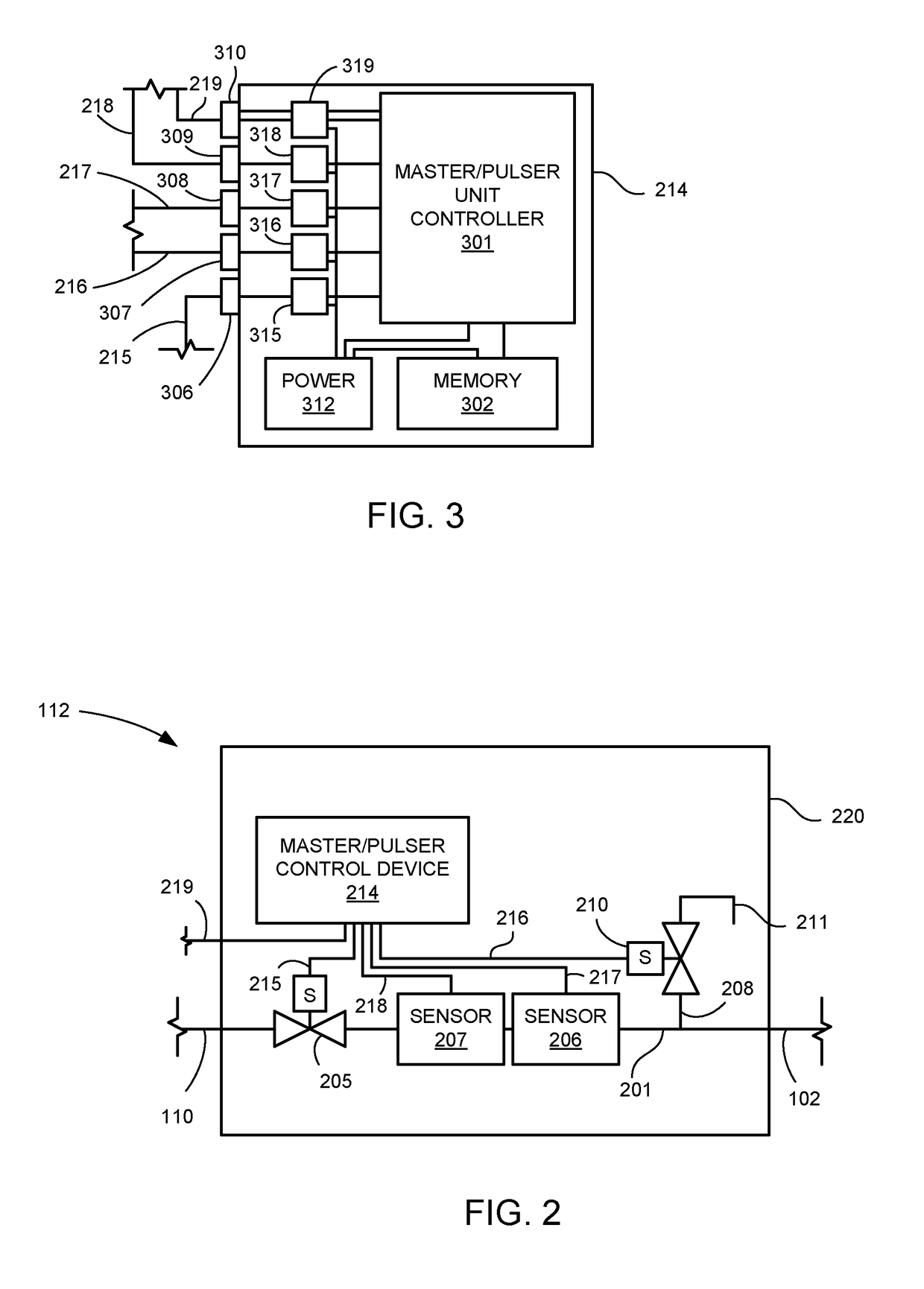

Apparatus and Methods for Wireless Transmission of Alarm Condition Information from Zones in an Irrigation System

InactiveUS20170347543A1Convenient wireless transmissionPromote disseminationWatering devicesCultivating equipmentsSequence controlWireless transmission

A method of wirelessly transmitting alarm condition information is applicable to an irrigation zone including a zone input conduit connected to a main distribution conduit of the irrigation system. The zone further includes a zone distribution conduit, a zone valve connected between the zone input conduit and the zone distribution conduit, and at least one irrigation emitter connected in the zone distribution conduit. The method includes detecting an alarm condition at the irrigation zone, and at a designated time proximate to one of a start time and an end time for to an irrigation session for the irrigation zone, controlling the zone valve according to a zone valve control sequence corresponding to the detected alarm condition. The zone valve control sequence comprises a predefined pattern of open and closed states of the zone valve over time.

Owner:RAINBOXX INC

Additive injection zone valve

Owner:INVISTA TEXTILES (U K) LTD

Vacuum valve and closing member that closes the flow path in an airtight manner by linear movement

Owner:VAT HLDG AG

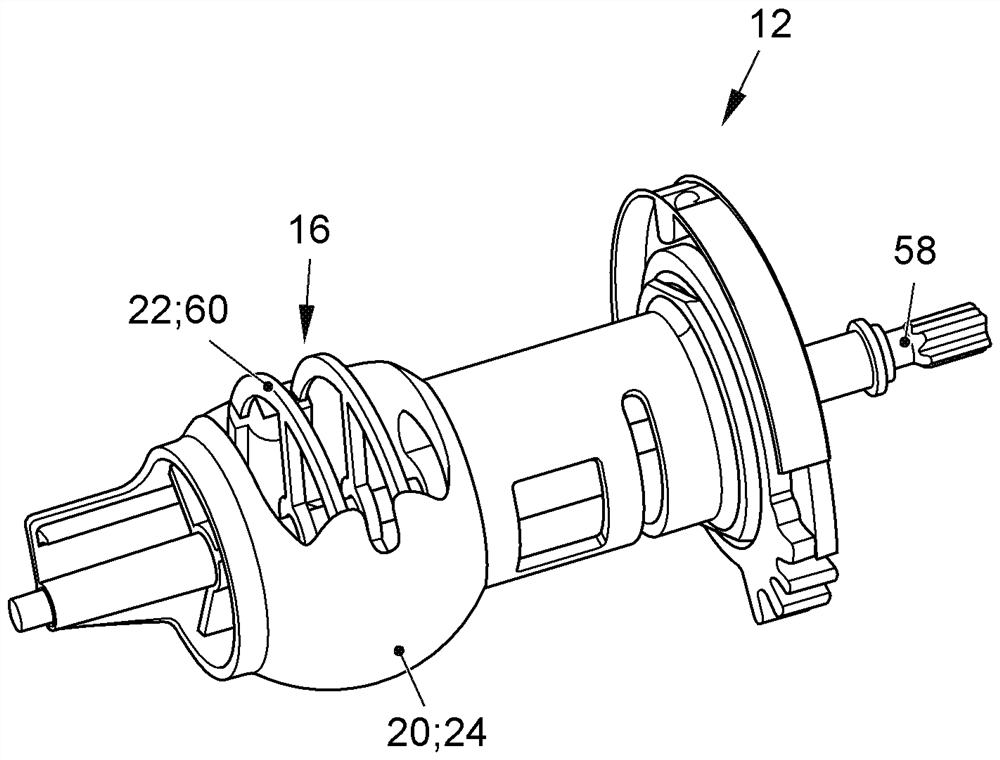

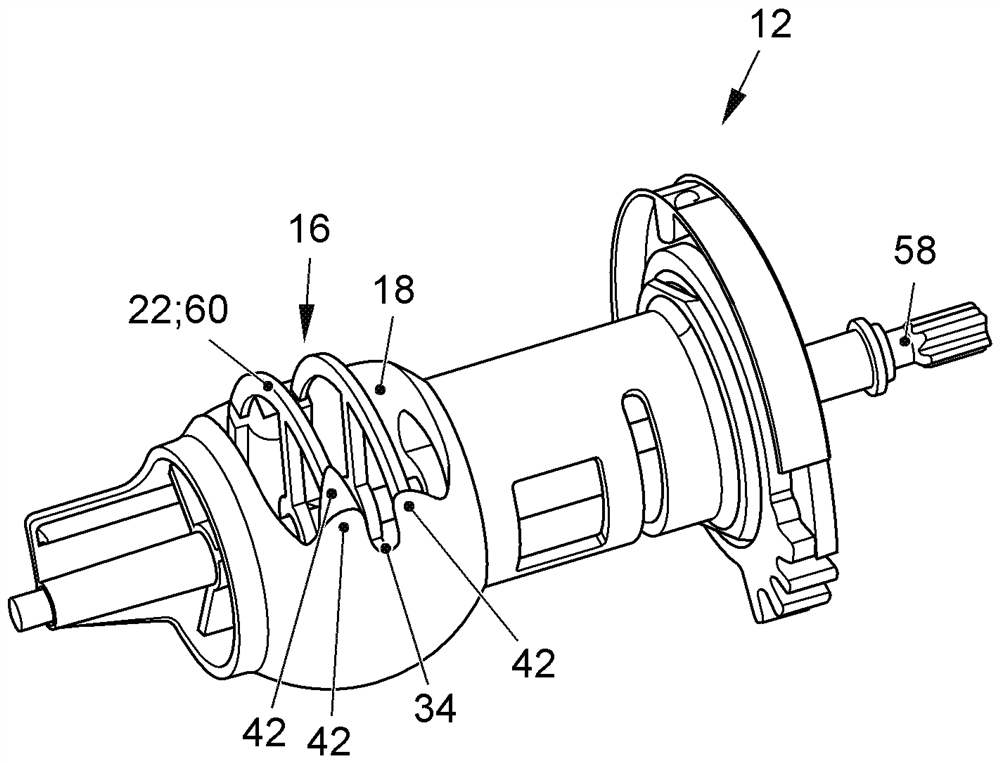

Valve Assembly with Retainer

ActiveCN108204464BEasy to slideSeamless transitionPlug valvesLift valveZone valveInternal combustion engine

The present invention relates to a valve assembly with a retainer, and more particularly to a valve assembly (10), particularly a regulating valve for regulating a coolant circuit of an internal combustion engine. The valve assembly (10) is provided with a valve unit (12) for directing fluid through an opening (18) and a sealing element (14) for sealing a transition between the valve unit (12) andthe fluid passage. Furthermore, the valve assembly (10) is provided with a retainer (16) for preventing the sealing element (14) from sinking into the opening (18) of the valve unit (12), wherein theretainer (16) is arranged in the valve unit (12). Furthermore, the retainer (16) has an exposed area (22) at the opening (18). The contour (24) of the valve unit (12) continues at the exposed area (22) of the retainer (16).

Owner:VOLKSWAGEN AG

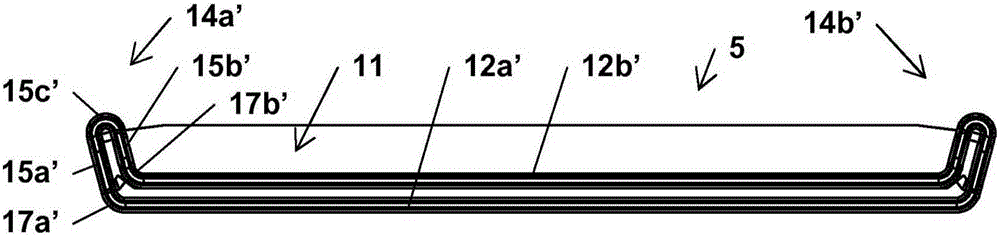

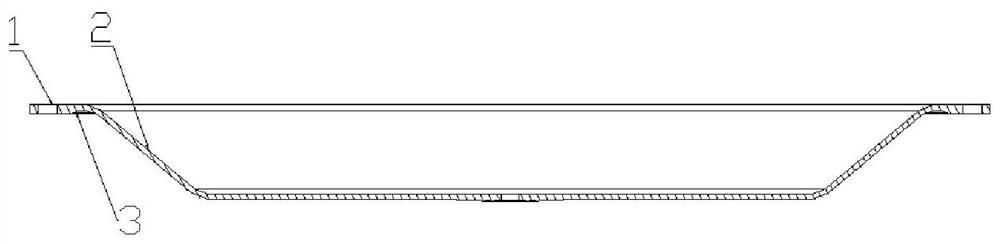

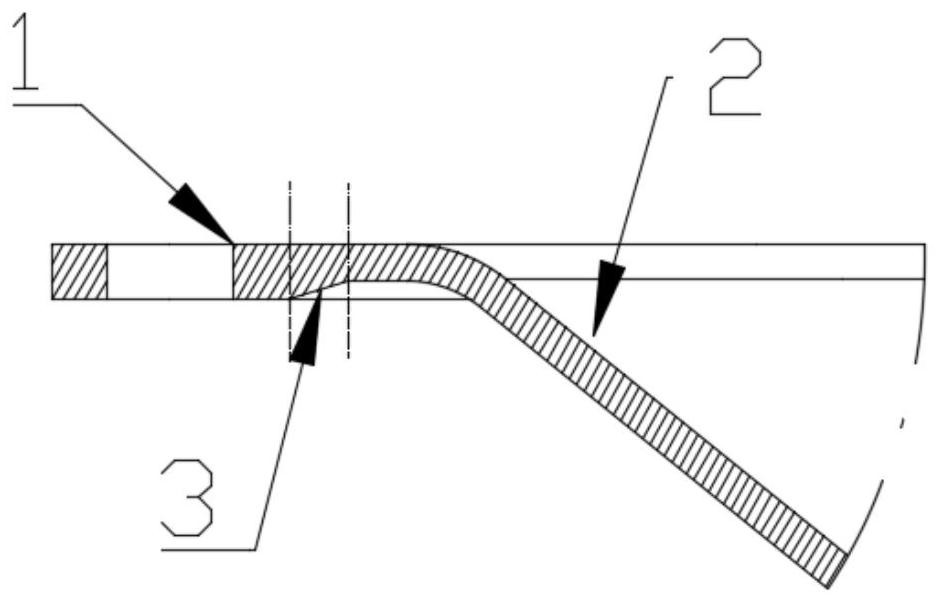

Valve diaphragm with high fatigue performance

InactiveCN112283395AImprove sealingImprove fatigue lifeDiaphragm valvesOperating means/releasing devices for valvesZone valveReciprocating motion

The invention discloses a valve diaphragm with high fatigue performance, and belongs to the technical field of regulating valves. The edge of the valve diaphragm is provided with an installation sealing area (1) fixedly connected with the periphery of an upper diaphragm capsule and the periphery of a lower diaphragm capsule, and the center of the valve diaphragm is a reciprocating flexing area (2)capable of moving in a reciprocating mode after being stressed; the thickness of the installation sealing area (1) is larger than that of the reciprocating flexing area (2), and a transition step (3)is formed between the installation sealing area (1) and the reciprocating flexing area (2) of the valve diaphragm; the installation sealing area (1) of the valve diaphragm is fixed to the periphery of the upper diaphragm capsule and the periphery of the lower diaphragm capsule, and the space between the upper diaphragm capsule and the lower diaphragm capsule is sealed; the inner side of the transition step (3) does not make contact with the upper diaphragm capsule and the lower diaphragm capsule when the valve diaphragm is not in the working state; and when the valve diaphragm works, the reciprocating flexing area (2) does reciprocating movement under the action of valve air pressure. The valve diaphragm is provided with the step, so that the fatigue performance of the valve diaphragm canbe remarkably improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com