Thin water mist fire extinguishing system

A fire extinguishing system and fine water mist technology, applied in the field of fire extinguishing systems, can solve the problems of small space in power tunnels, arrangement on the top or side of cables, blocking, etc., to achieve convenient evacuation, good smoke removal effect, and slow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

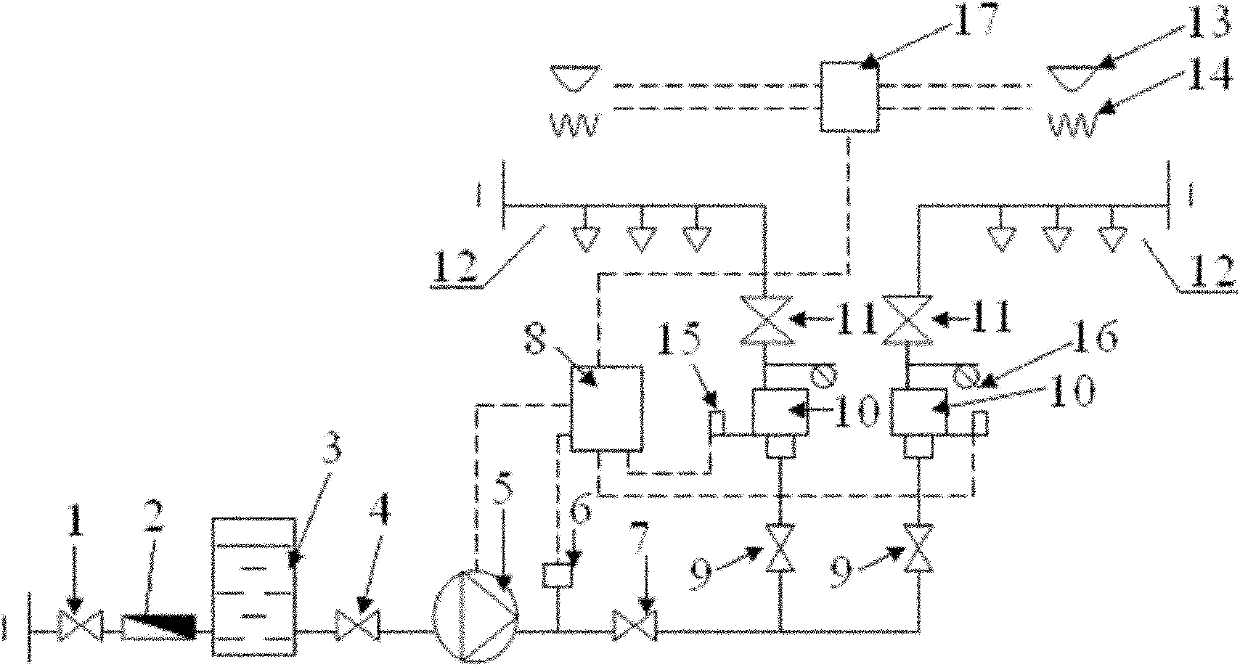

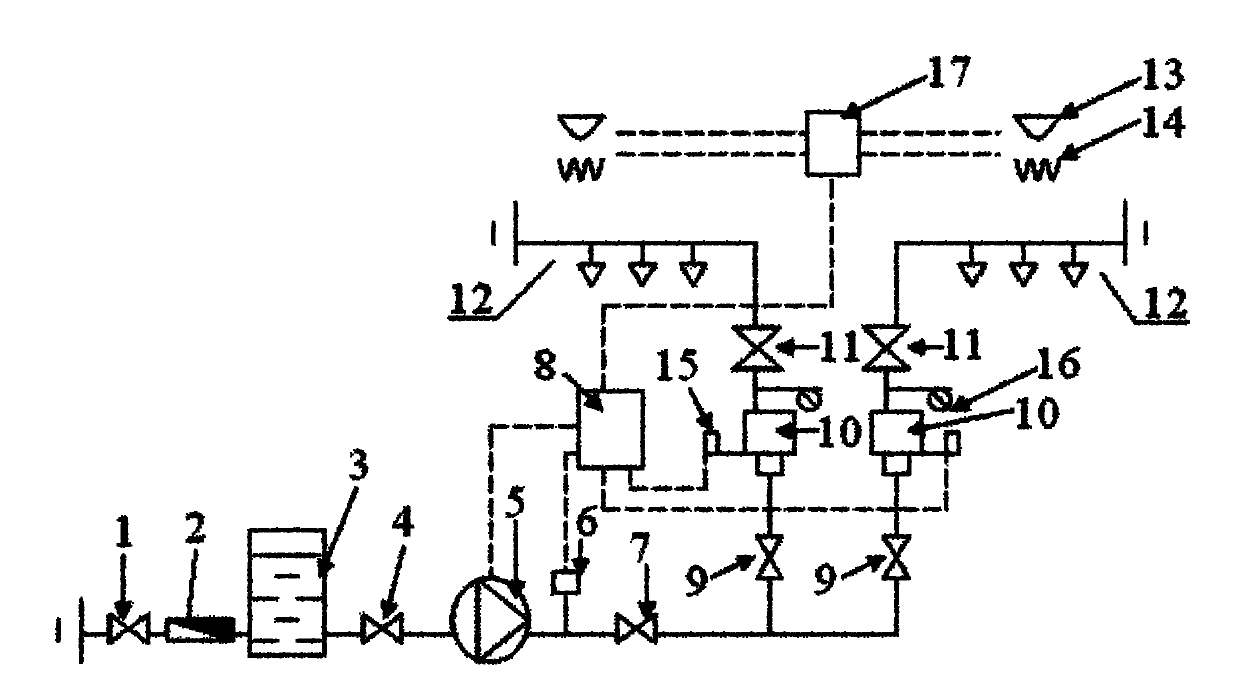

[0023] A kind of water mist fire extinguishing system, its structure is as follows figure 1 As shown, the fire extinguishing system includes a filter 2, a water tank 3, a water supply pump 5, a water pump control valve 8, a zone valve 10, an open water mist nozzle 12 and an alarm device, and one end of the filter 2 is connected to a water source through a water source valve 1 , through the water source valve 1 to control the size of the water flow, the other end of the filter 2 is connected to the water tank 3 through the pipeline, the filtered water can be stored in the water tank 3, one end of the water supply pump 5 is connected to the water tank 3 through the pipeline, and the other end The area valve 10 is connected through the pipeline, and the pump water inlet valve 4 is set between the water tank 3 and the water supply pump 5 to control the water intake. The pressure sensor 6, the pump outlet valve 7 and the water supply valve are set between the water supply pump 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com