Apparatus and method for replacing existing actuator zone valves in an HVAC system with a ball valve

A valve device and actuator technology, which is applied to valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of expensive and large actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

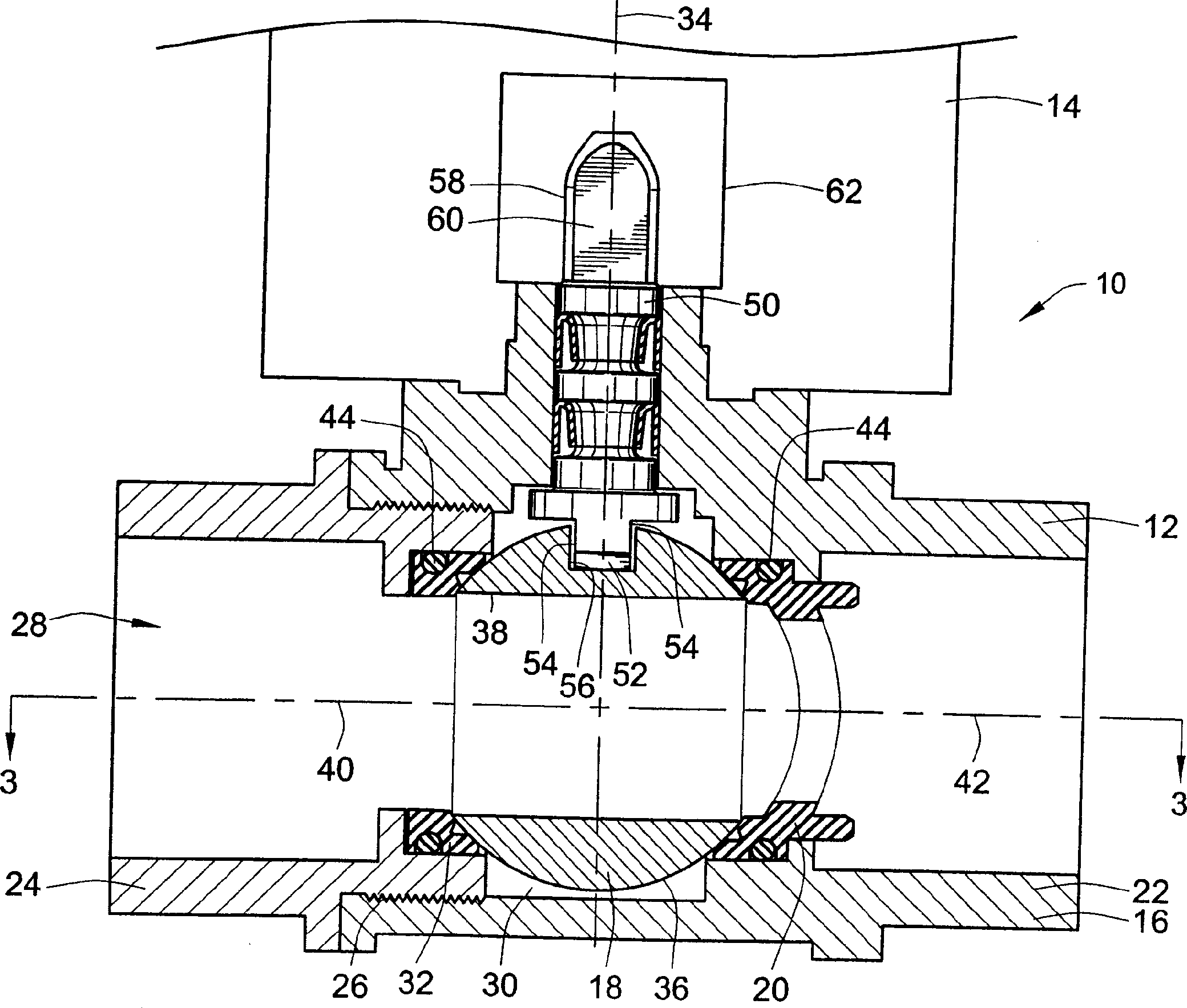

[0032] figure 2 A first exemplary embodiment of the invention is shown in the form of a valve arrangement 10 comprising a ball valve 12 and an actuator 14 operably connected to the ball valve 12 in a manner described in more detail below. The ball valve 12 includes a valve housing 16 , a valve member 18 and a ramp bearing 20 . The valve housing 16 includes a first portion 22 and a second portion 24 joined by a threaded connection 26 to define a flow path 28 extending through the housing 16 and a ball receiving chamber 30 within the flow path 28 .

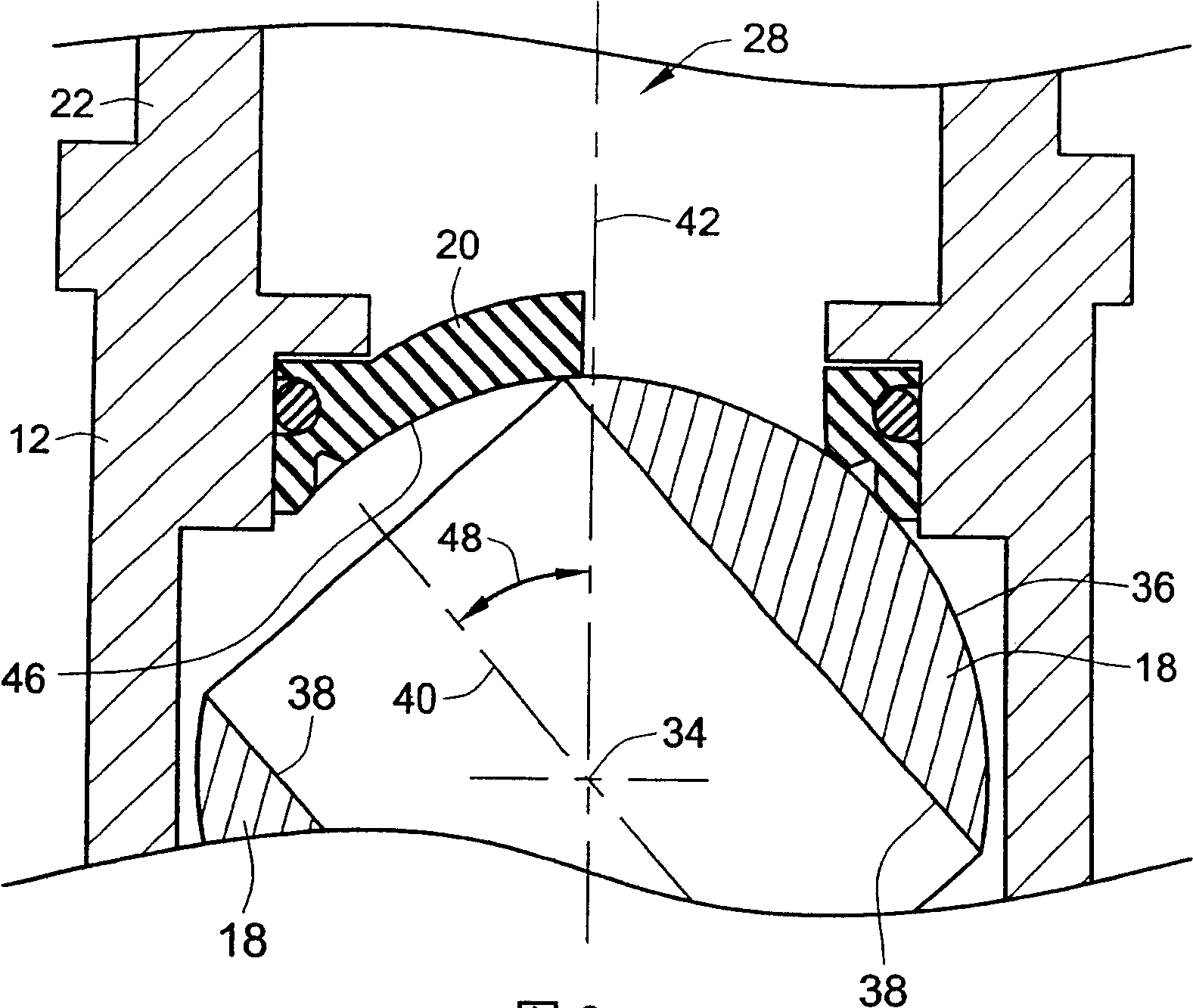

[0033] Valve member 18 of the exemplary embodiment is mounted between ramp bearing 20 and integral port inlet bearing 32 within ball housing 30 for optional rotation about axis of rotation 34 . The valve member of the exemplary embodiment is a generally spherical ball having a substantially spherical outer surface 36 . A through hole 38 extends through the valve member 18 to rotate the valve member 18 as figure 2 In the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com