Valve diaphragm with high fatigue performance

A fatigue performance and valve technology, which is applied in the field of valve diaphragms with high fatigue performance, can solve problems such as poor sealing performance and fatigue life that cannot meet the technical index requirements, and achieve the effect of improving sealing and fatigue life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

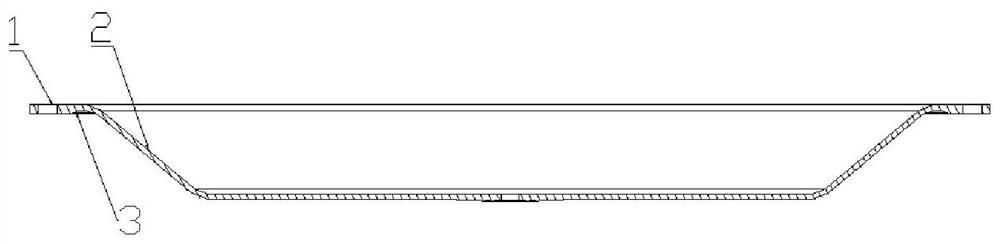

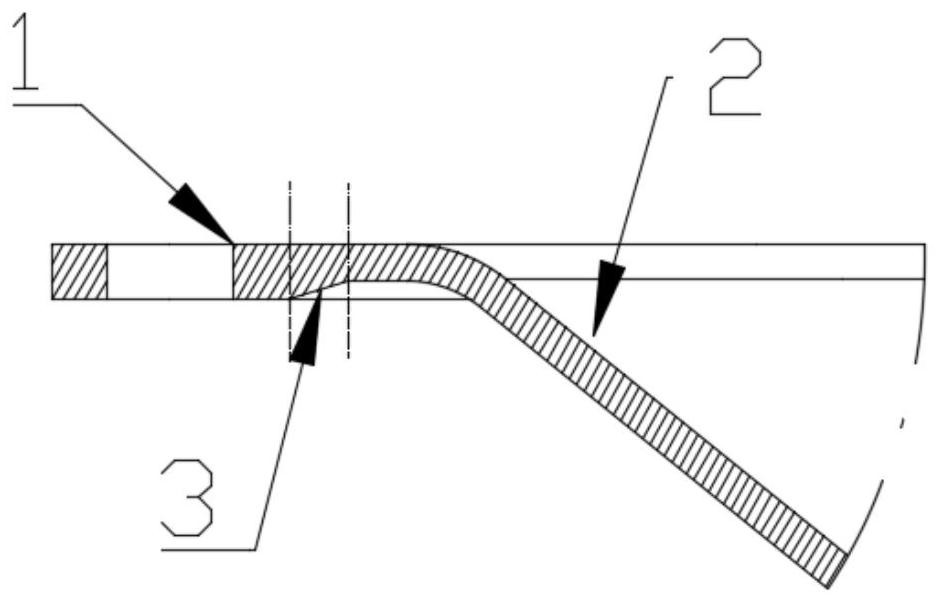

[0033] Select the included angle between the inclined plane and the central plane of the reciprocating flexing area (2) to be 135°; select the transition fillet radius between the central plane and the inclined plane of the reciprocating flexing area (2) to be 16 mm, and the inclined plane and the connecting surface The transition fillet radius between them is 16mm.

[0034] The thickness of the installation sealing area (1) is selected as 6mm, and the thickness of the reciprocating flexing area (2) is respectively selected as 4, 5, and 6mm, so the fatigue life ratio of the valve diaphragm is 28:23:19.

Embodiment 2

[0036] The thickness of the installation sealing area (1) is selected to be 6mm, and the thickness of the reciprocating flexing area (2) is respectively selected to be 4mm; The transition fillet radius between the connecting faces is 16mm.

[0037] The included angles between the inclined plane and the central plane of the reciprocating flexing area (2) are 135°, 138°, 140°, and 143° respectively, and the fatigue life ratio of the valve diaphragm is 27.5:22:14:12.

Embodiment 3

[0039] The included angle between the slope of the reciprocating flexing area (2) and the central plane is 135°; the thickness of the installation sealing area (1) is selected to be 6 mm, and the thickness of the reciprocating flexing area (2) is respectively selected to be 4 mm.

[0040] The transition fillet radius between the central plane and the inclined plane of the reciprocating flexing area (2) is the same as the transition fillet radius between the inclined plane and the connecting surface, respectively select 9:11:14:16mm, then the fatigue of the valve diaphragm The life ratio is 26:27:28:30.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com