Valve Assembly with Retainer

A technology of valve components and retaining rings, applied in the direction of lift valves, valve devices, engine components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

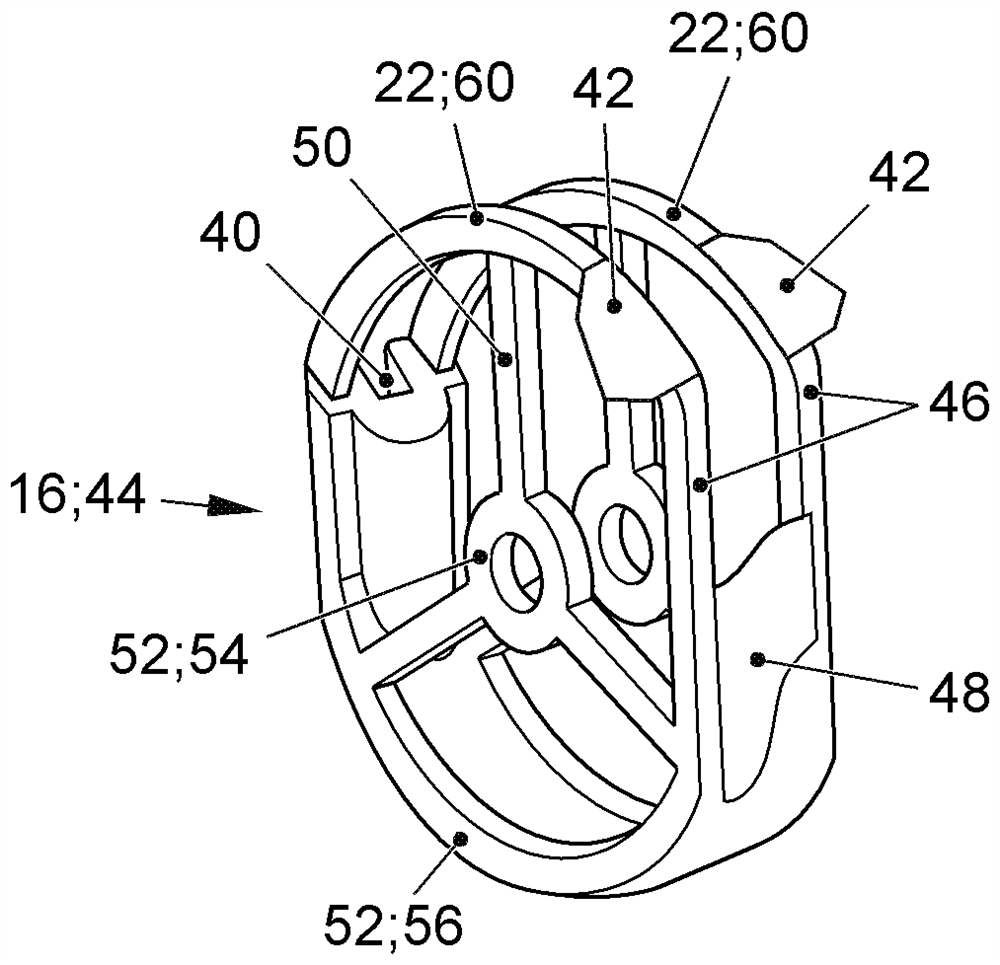

[0065] In the figures, identical or functionally identical elements are provided with the same reference signs. Furthermore, it should be noted that the illustrations in the figures are not necessarily drawn to correct scale.

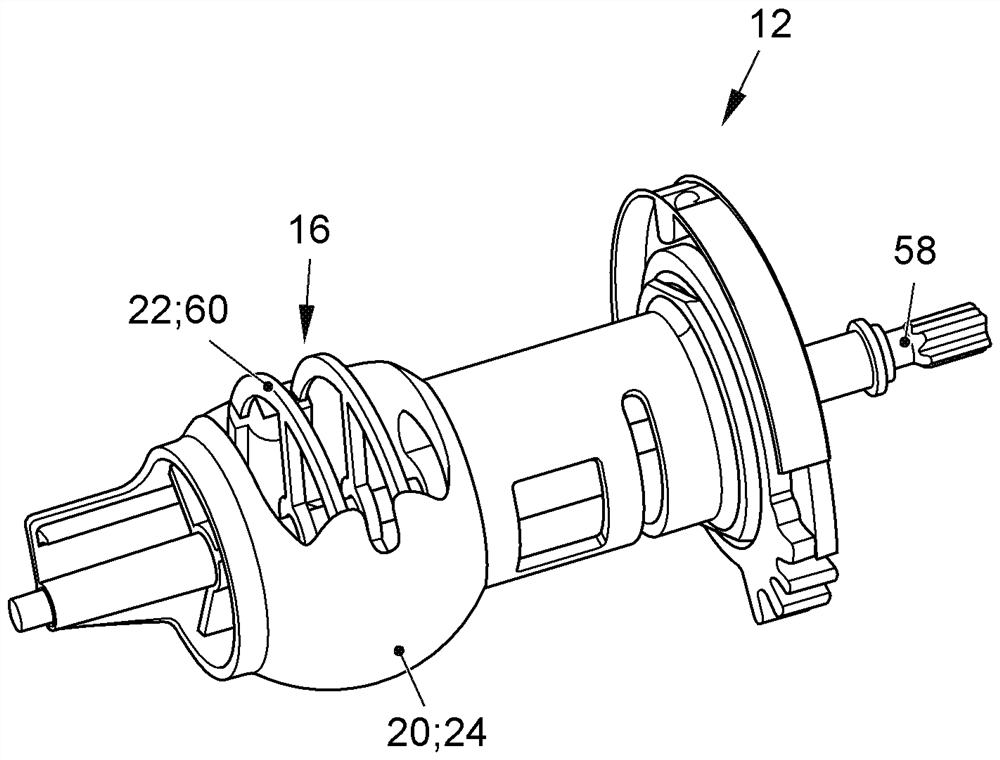

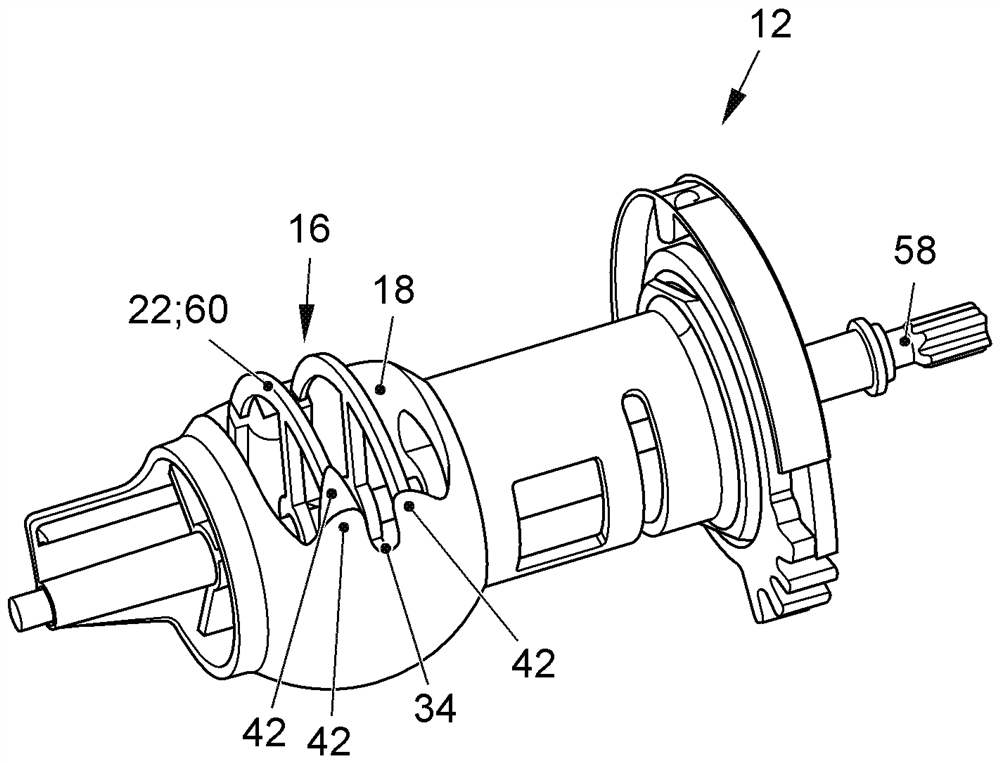

[0066] figure 1 An exploded view of the valve assembly 10 according to the invention is shown. The valve assembly 10 may in particular be a regulating valve for regulating a coolant circuit of an internal combustion engine. The valve assembly 10 has a valve unit 12 , a sealing element 14 and a retaining ring 16 . The valve unit 12 serves to guide fluid. Fluid can escape or enter at the opening 18 in the peripheral surface 20 of the valve unit 12 . In contrast, the sealing element 14 serves to seal the transition between the valve unit 12 and the fluid channel ( figure 1 not shown). A fluid channel is formed through the housing adjoining the sealing element. The transition is the area between the valve unit 12 and the fluid channel.

[0067] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com