Fire protection system for valve side sleeve of extra-high voltage converter transformer and using method

A converter transformer and protection system technology, applied in fire rescue and other directions, can solve problems such as damage to parts and explosion shock waves, threat to valve hall safety, unsuitable explosion risk, etc., achieve excellent anti-reburn performance, improve safety and reliability Sexual, fast and effective extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

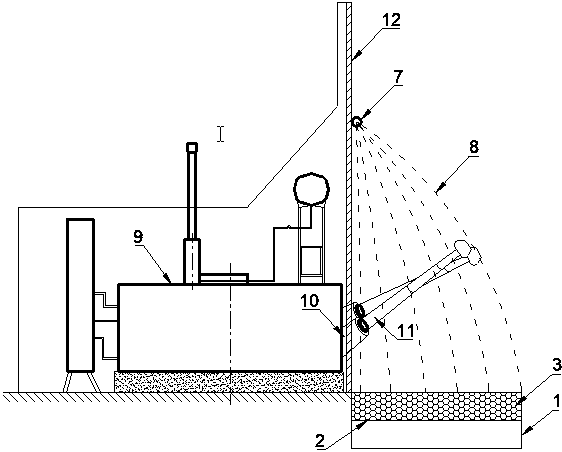

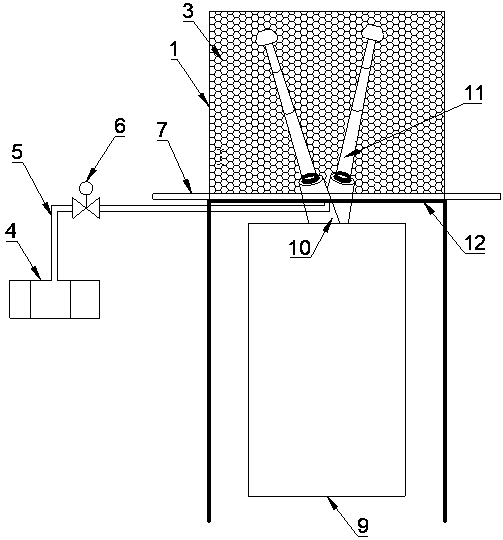

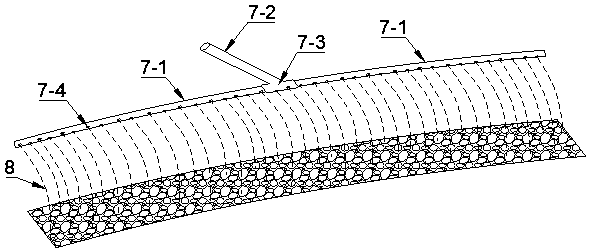

[0035] Such as Figure 1 to Figure 4 As shown, the UHV converter transformer valve side bushing fire protection system includes an oil sump 1, a compressed air foam generating device 4, a foam main pipe 5, a partition valve 6, a compressed air foam spray system 7, and the oil sump 1 is set Right below the valve side bushing 11 and the raised seat 10 where the converter transformer penetrates into the valve hall, a support grid 2 is fixed in the middle of the oil sump 1, and a pebble layer 3 is laid on the support grid 2, and the height of the pebble layer 3 is different. less than 250mm, and the diameter of a single pebble is not less than 38mm, which is used to collect the inflowing converter transformer oil; the compressed air foam spray system 7 is directly connected with the foam main pipe 5 through the partition valve 6, and the compressed air foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com