Direct current electrical controls for heating systems

a technology of direct current and electrical control, which is applied in the direction of heating types, lighting and heating apparatus, transportation and packaging, etc., can solve the problems of inability to disclose dc control units, inability to control devices for heating systems, and inherently inefficient systems, etc., to reduce or eliminate the associated constant electrical demand of heating components, prolong battery life, and reduce the effect of reducing or eliminating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

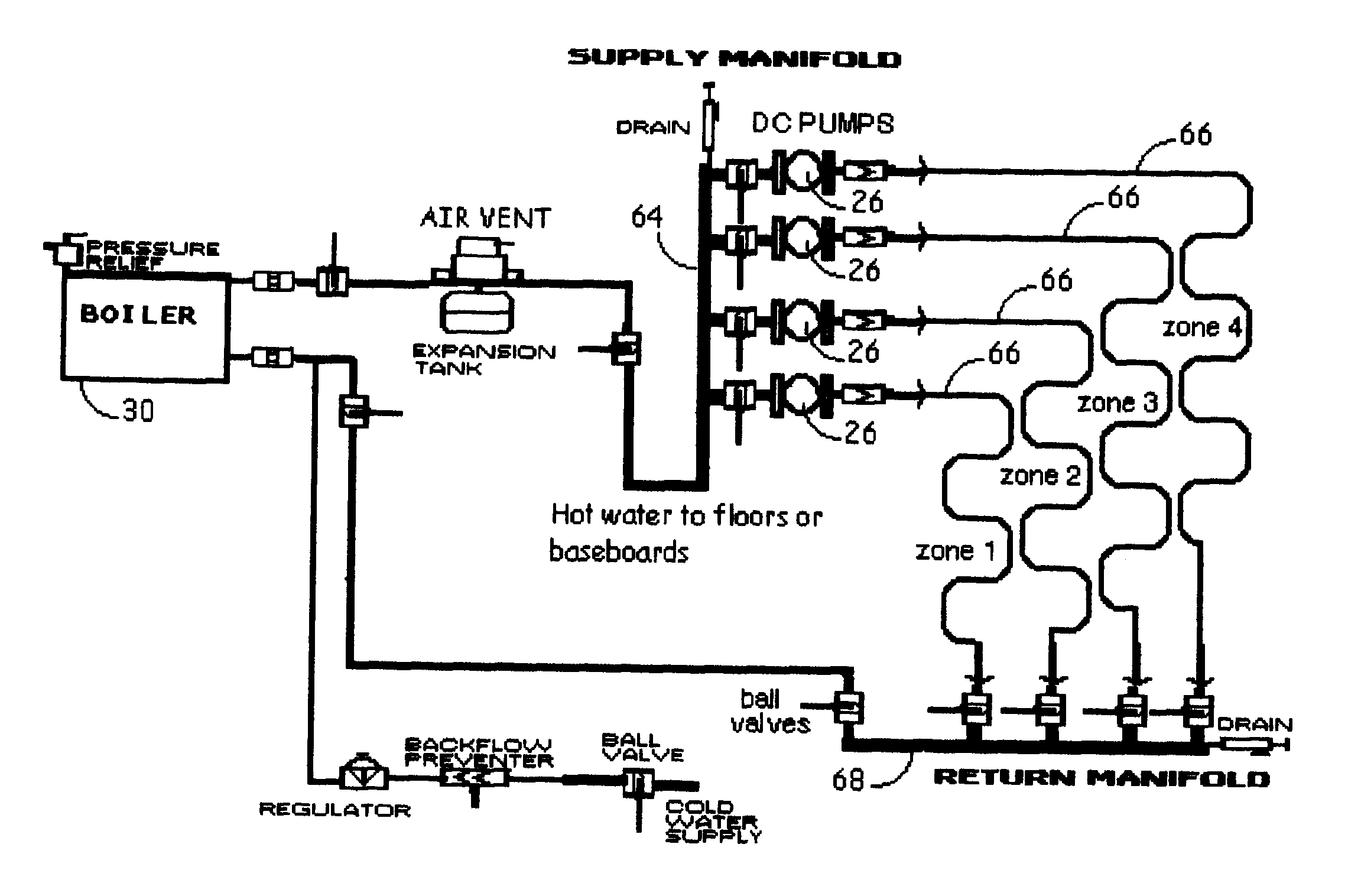

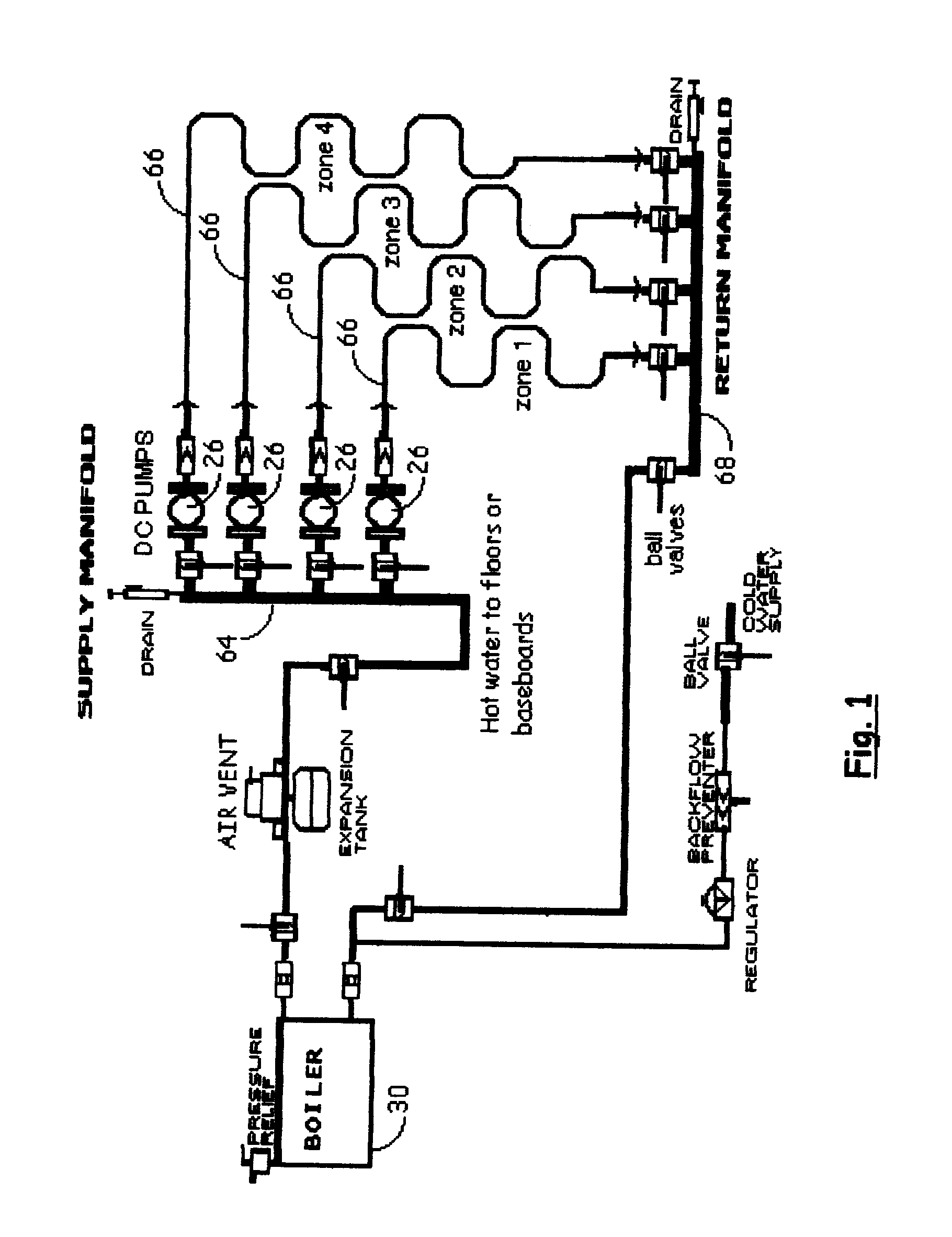

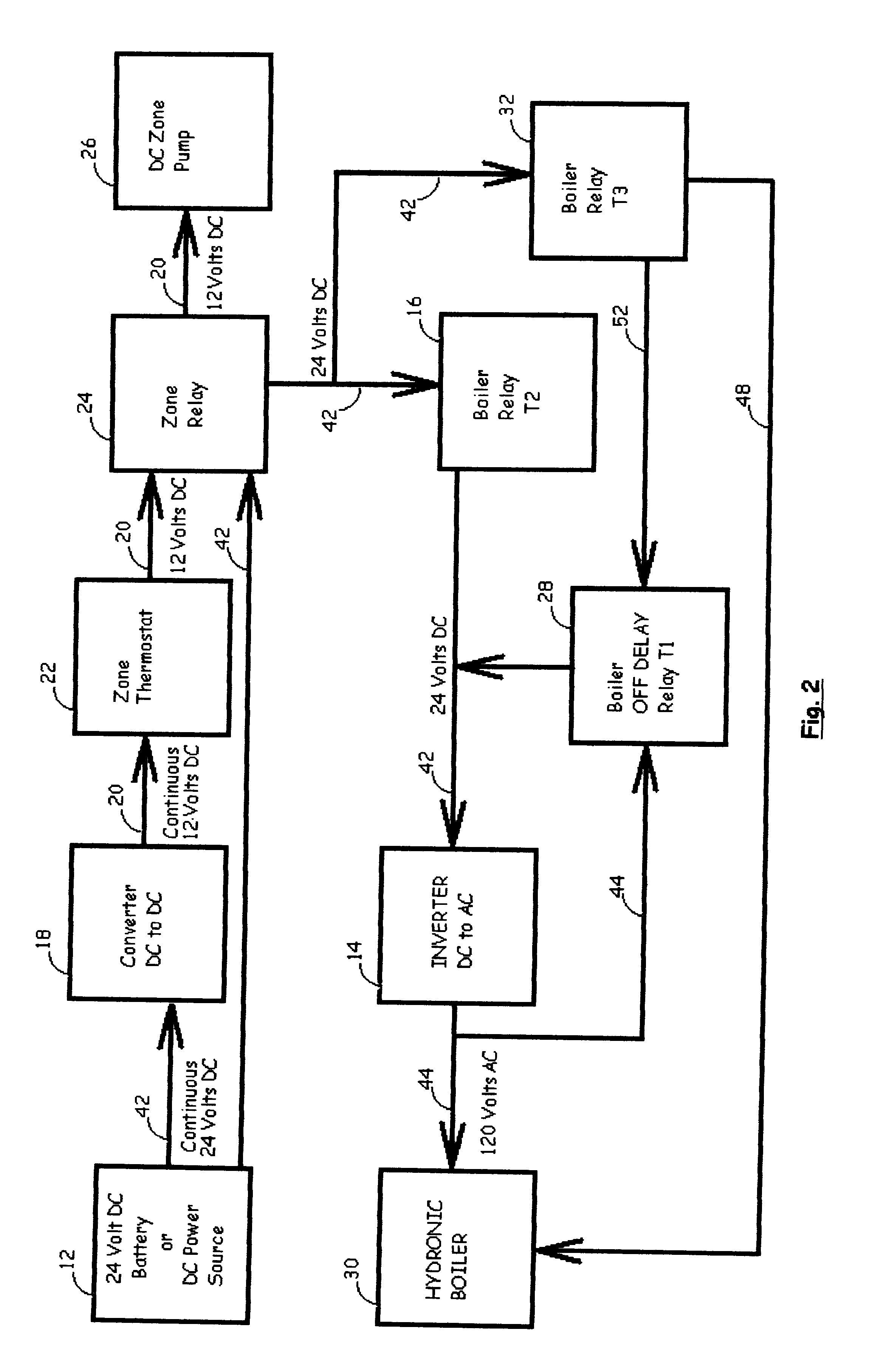

The preferred embodiment of the hydronic boiler system control is shown in FIGS. 1, 2, and 3. The invention comprises a method and apparatus for controlling the normal operation of a heating system, (including AC powered, gas-burning hot water boiler, multi-zone systems) using DC battery 12 power or a DC power source as the primary continuous source of electricity, that provides control functions which minimize the consumption of electric power, in order to extend the life of the batteries and maximize the run-time of the heating system.

The apparatus contains a small DC to AC inverter 14 such as Tumbler Technologies Model 24-15013, or the like, dedicated to provide AC power to boiler 30. DC to AC inverter 14 is switched on by inverter relay 16 only when needed, thereby eliminating the "phantom electric load" consumed by most boilers when they are standing by.

A DC to DC converter 18 is included in the apparatus to provide 12 volts DC 20 power to zone thermostats 22, thereby eliminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com