Spraying device with front heat-sensitive mechanism

A spraying device and heat-sensitive technology, which is applied in fire rescue and other directions, can solve the problems of spray nozzle shape and structure limitation, damage spray, spray head can not be atomized, etc., to achieve diversified spraying forms, improved response ability, and strong fire extinguishing power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

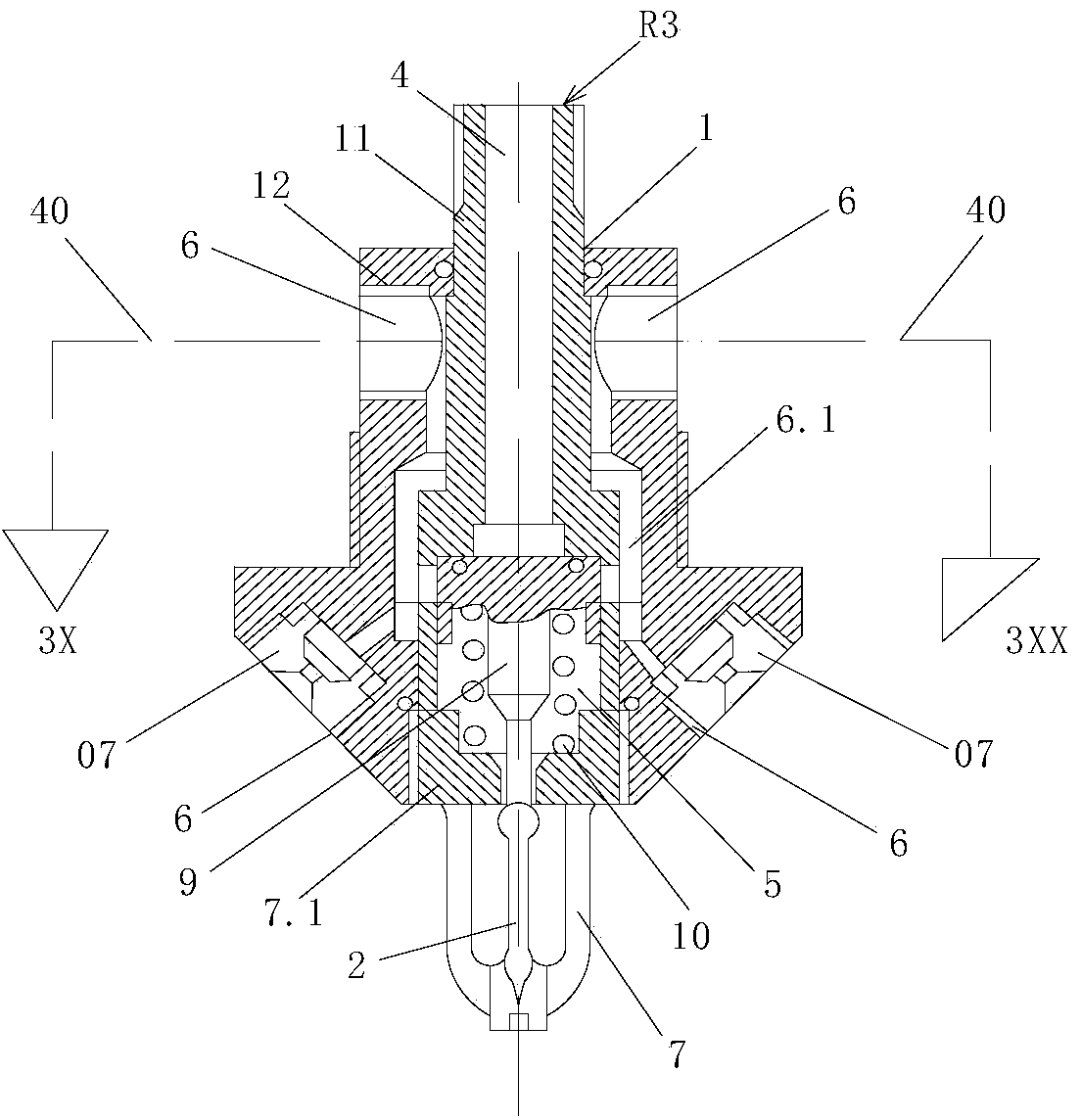

[0027] see figure 2 , and the difference from the existing conventional spraying device with a front thermal mechanism is that the valve body 1 of the normally closed valve R3 is a split-type combined valve body, and the valve body 1 is sleeved by an outer body 12 on the inlet port 4 The intermediate body 11 and the end cap 7.1 are formed. The annular cavity 6.1 formed between the intermediate body 11 and the outer body 12 surrounds the outer periphery of the control cavity 5 formed between the intermediate body 11 and the end cap 7.1. The bracket 7 supports the thermosensitive element 2 , and the thermosensitive element 2 and the spring 10 jointly press against the blocking member 9 to block the passage from the inlet chamber 4 to the control chamber 5 . Grooves are provided on the outer body 12 and the intermediate body 11, and the holes make the control cavity 5 and the annular cavity 6.1 communicate with each outlet cavity 6 arranged around the outer body 12, and each ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap