Ship propulsion vertical permanent magnet motor

A permanent magnet motor, vertical technology, applied to synchronous motors with stationary armatures and rotating magnets, electromechanical devices, electrical components, etc. Requirements, low reliability of permanent magnet motors, etc., to achieve the effect of increasing the cross section, increasing the air gap flux density and power density, and reducing tooth expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

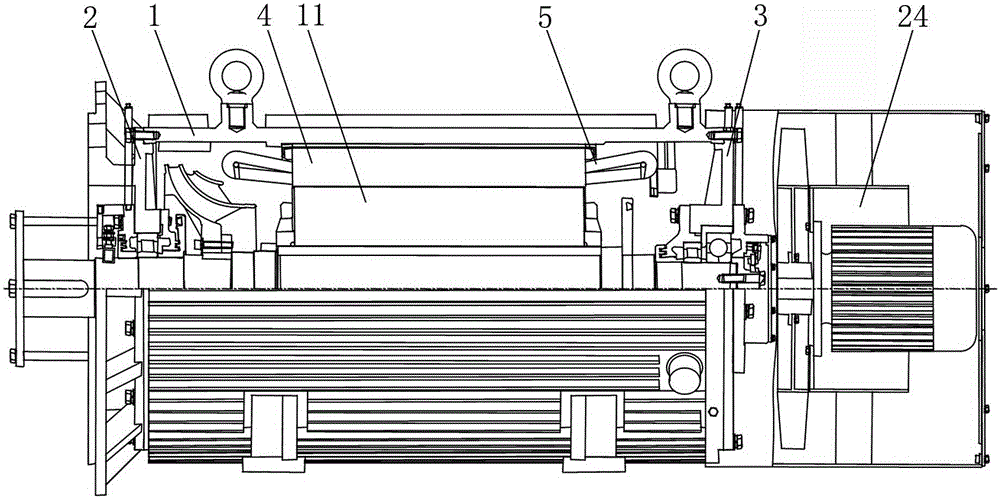

[0014] Ship propulsion vertical permanent magnet motor, including machine base 1, front end cover 2, rear end cover 3, stator structure, rotor structure, three-bearing structure, and air-cooled structure; wherein, front end cover 2 is fixedly assembled on the front surface of machine base 1 ;The rear end cover 3 is fixedly assembled on the rear end surface of the base 1;

[0015] The stator structure includes a stator core 4 and a stator coil 5; the stator core 4 is fixedly assembled on the inner surface of the base 1; the stator coil 5 is embedded on the stator core 4;

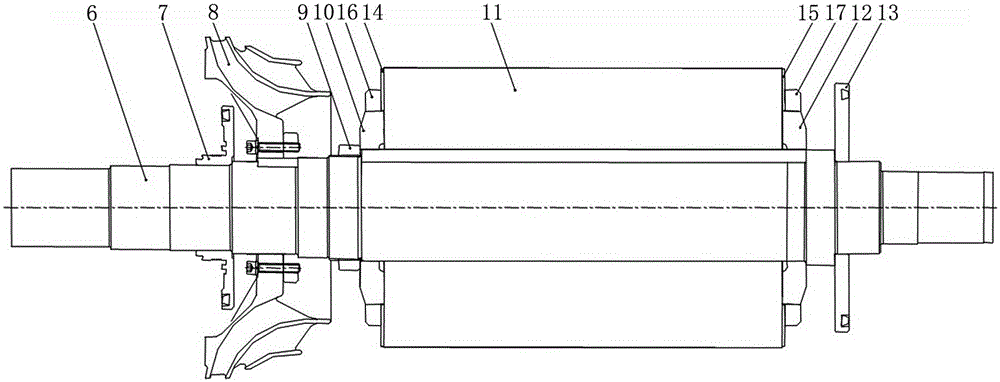

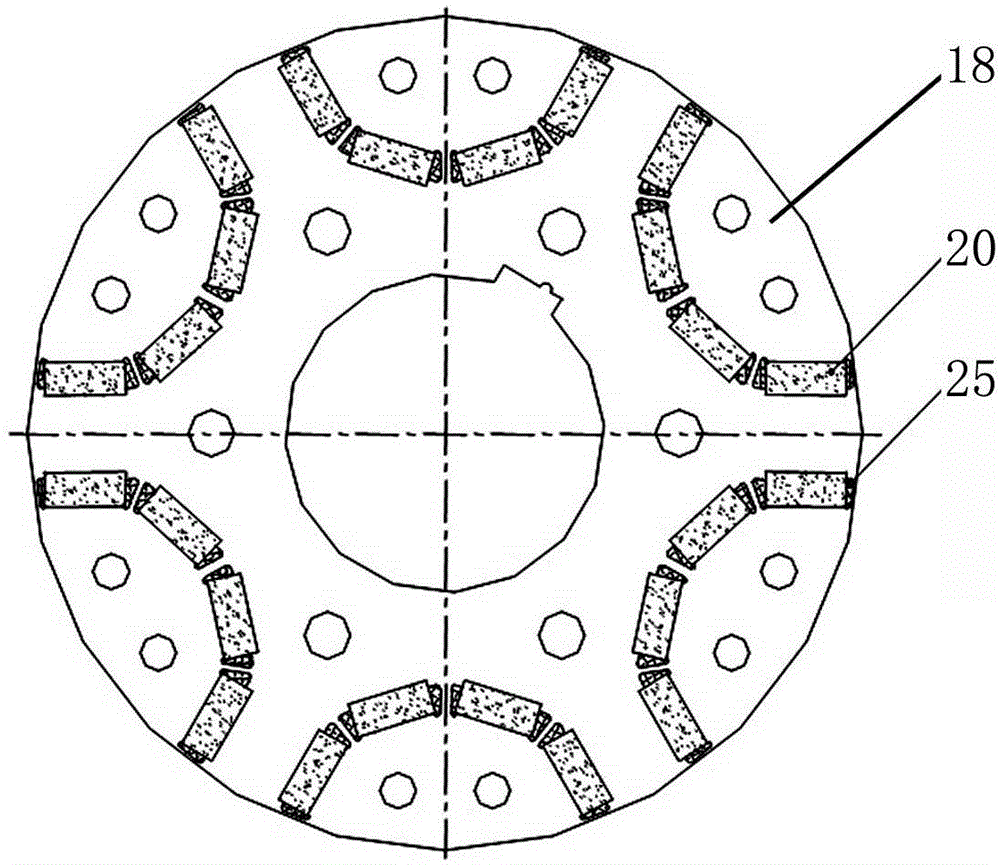

[0016] The rotor structure includes a rotating shaft 6, an inner sealing ring 7, a fan 8, a round nut 9, a first rotor pressure ring 10, a rotor core 11, a second rotor pressure ring 12, a balance plate 13; an inner sealing ring 7, a fan 8, The round nut 9, the first rotor pressure ring 10, the rotor core 11, the second rotor pressure ring 12, and the balance plate 13 are fixedly assembled on the outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com