Extrusion die rack with stripping mechanism

A mold base and stripping technology, which is applied in the field of extrusion mold bases with a stripping mechanism, can solve the problems of no stripping mechanism, troublesome use, complex structure design of extrusion mold bases, etc., to improve production efficiency and facilitate use , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

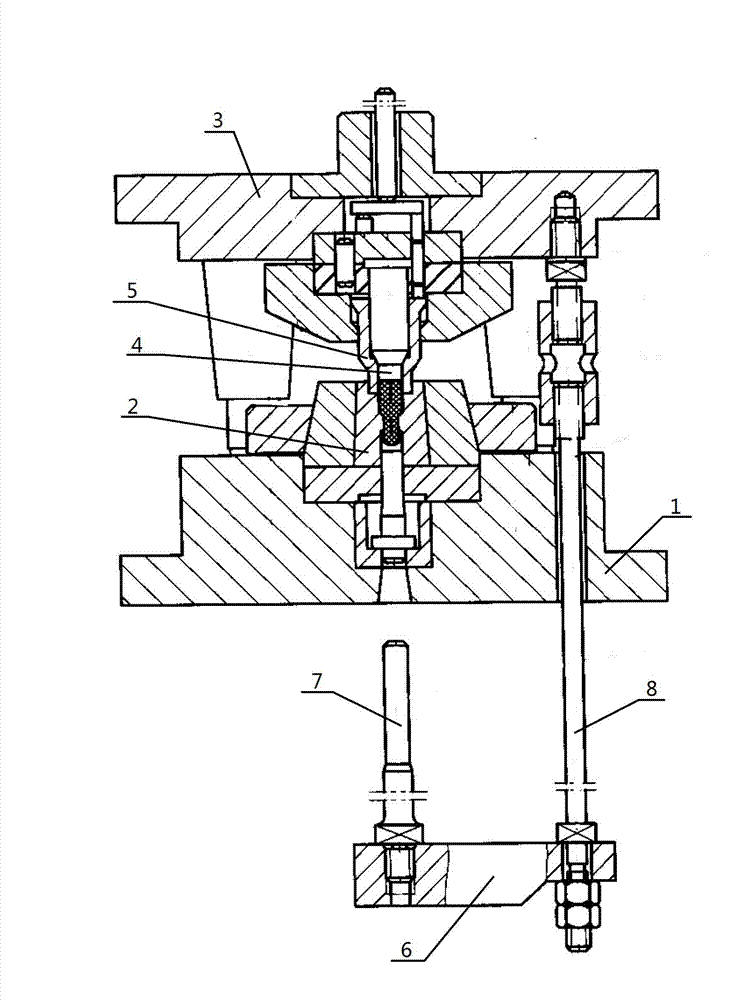

[0009] like figure 1 As shown, the present invention provides an extrusion die frame with a stripping mechanism, comprising a lower template 1 and an upper template 3, the lower template 1 is provided with a die 2; the upper template 3 is provided with a punch 4, and the punch 4 is covered with a convex die The mold cover 5 also includes a stripping mechanism. The stripping mechanism includes a top plate 6, a push rod 7 and a pull rod 8. One end of the top plate 6 is connected to the push rod 7, and the other end of the top plate 6 is detachably connected to the pull rod 8. The push rod 7 The center line coincides with the center line of the die 2 and the punch 4, and the free end of the tie rod 8 passes through the lower template 1 and is detachably connected with the upper template 3.

[0010] In this embodiment, the punch 4 is covered with a punch sleeve 5, the punch sleeve 5 can not only guide to ensure the smooth movement of the punch 4, prolong the life of the punch 4, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com