Manufacturing method of multi-stage stamping device and middle mold included therein

A manufacturing method and intermediate die technology, which are applied to manufacturing tools, presses, casting and molding equipment, etc., can solve the problems of increased equipment costs, large-scale and height-influenced multi-stage stamping devices, etc., and achieve the effect of miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

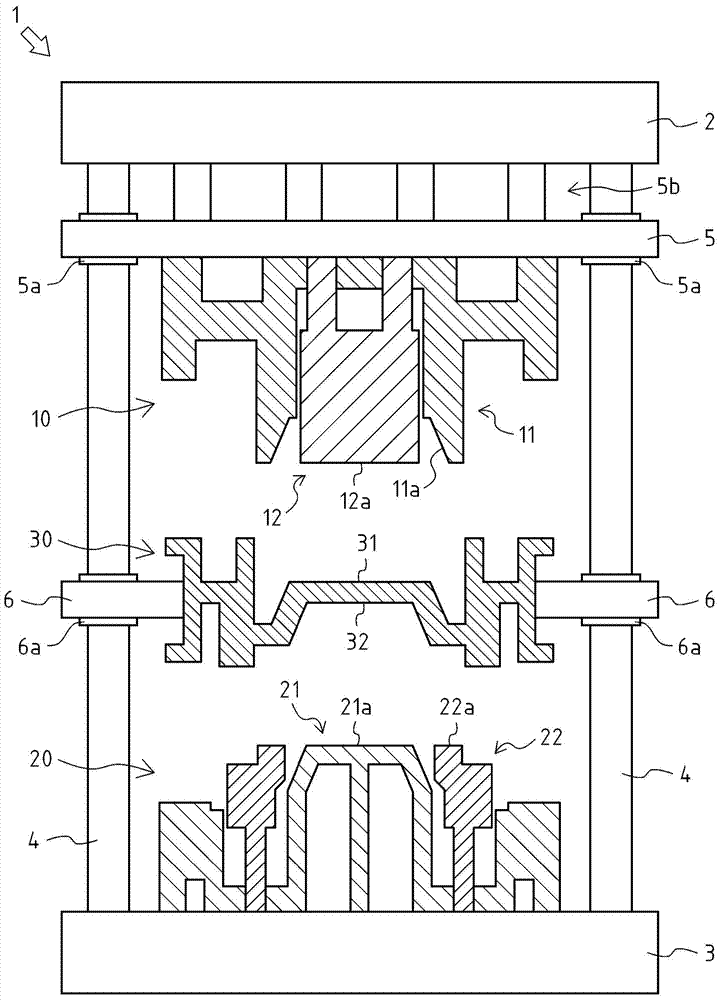

[0027] Below, refer to figure 1 , the multi-stage press device 1 in one embodiment of the multi-stage press device of the present invention will be described.

[0028] The multi-stage press device 1 is a press machine in which a plurality of (in this embodiment, two) processing sections for processing workpieces such as steel sheets are provided along the vertical direction, and the workpieces corresponding to each processing section are simultaneously Perform stamping.

[0029] It should be noted that, for the convenience of explanation, the figure 1 The up and down direction in is defined as the up and down direction of the multi-stage punching device 1 . The up-down direction of the multi-stage press device 1 coincides with the vertical direction.

[0030] Additionally, the figure 1 The left-right direction in the figure is defined as the left-right direction of the multi-stage press device 1 .

[0031] Such as figure 1 As shown, the multi-stage stamping device 1 has:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com