Improvements to or relating to lawn maintenance equipment

A technology for maintaining equipment and lawns, which is used in the improvement of lawn maintenance equipment and the field of spring units, which can solve problems such as reducing the efficiency of cutting height components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

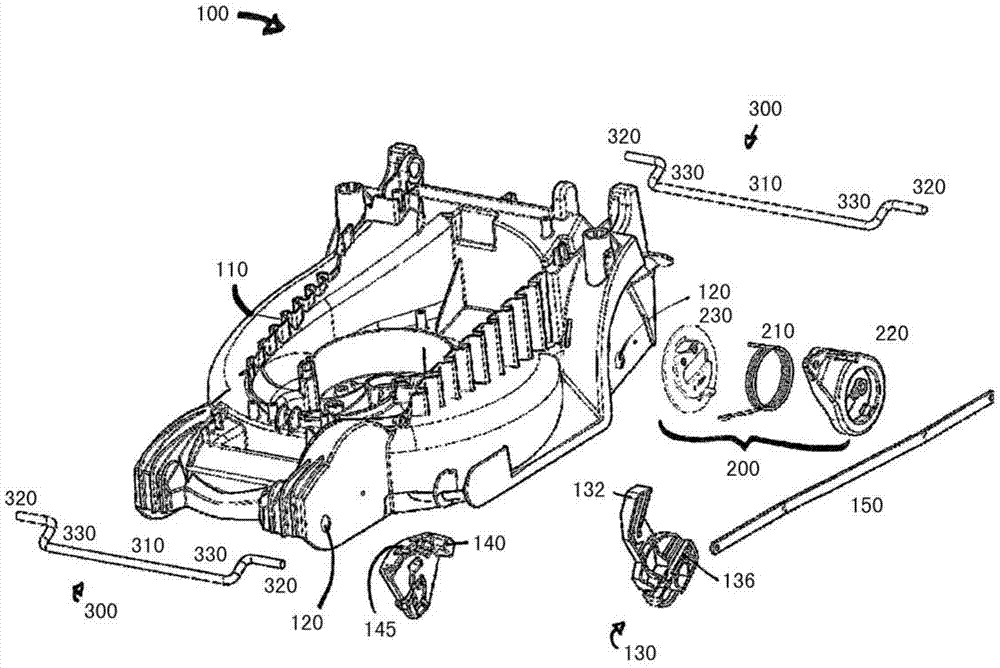

[0023] figure 1 Shown is a lawnmower chassis 110 equipped with a single point height of cut adjustment system that allows simultaneous adjustment of the relative height of each wheel (not shown) relative to chassis 110 using a single point mechanism . This is accomplished by using a crankshaft 300 between the two front wheels and between the two rear wheels so that rotation of the axle 300 causes the relative height of the wheels to the chassis 110 to rise or fall accordingly.

[0024] Crankshaft 300 is a shaft that includes an inner portion 310 and an outer portion 320 at each end of the crankshaft. The outer portion 320 of the crankshaft is parallel to, but not axially aligned with, the inner portion 310 of the crankshaft. The two outer portions 320 of the crankshaft 300 are aligned and parallel to each other. The inner portion 310 is partially connected to each outer portion 320 via an angled crank arm 330 . While crank arm 330 is typically at right angles to both the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com