Cylinder lubrication system

A lubrication system and cylinder technology, applied in the direction of timing lubrication, pressure lubricant, lubrication parts, etc., can solve the problem of not necessarily eliminating the lubrication of the upper cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

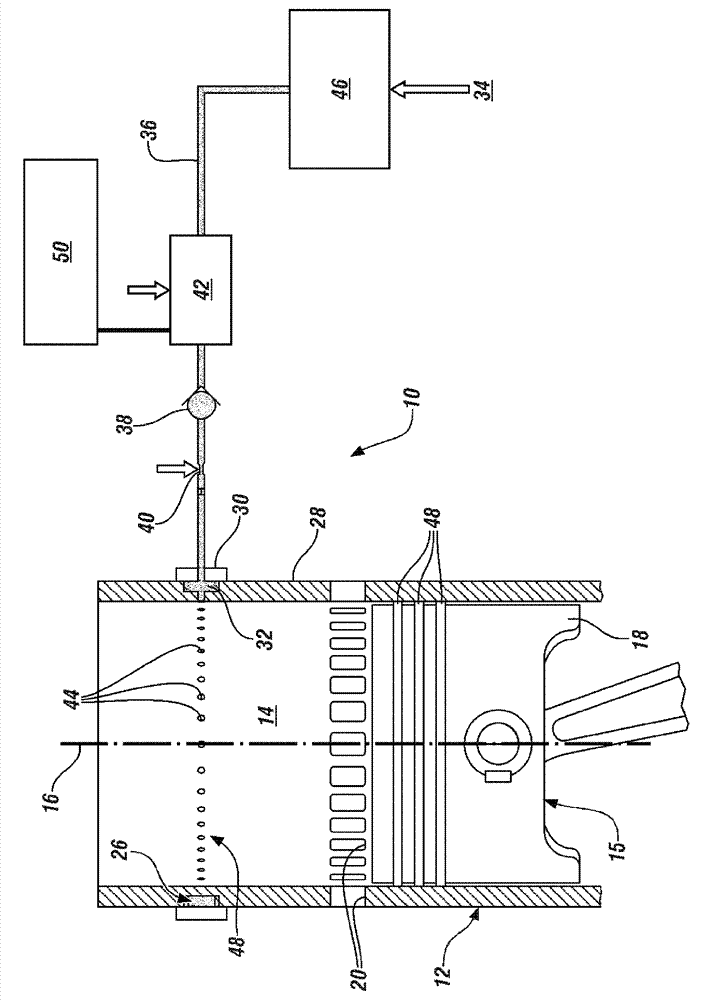

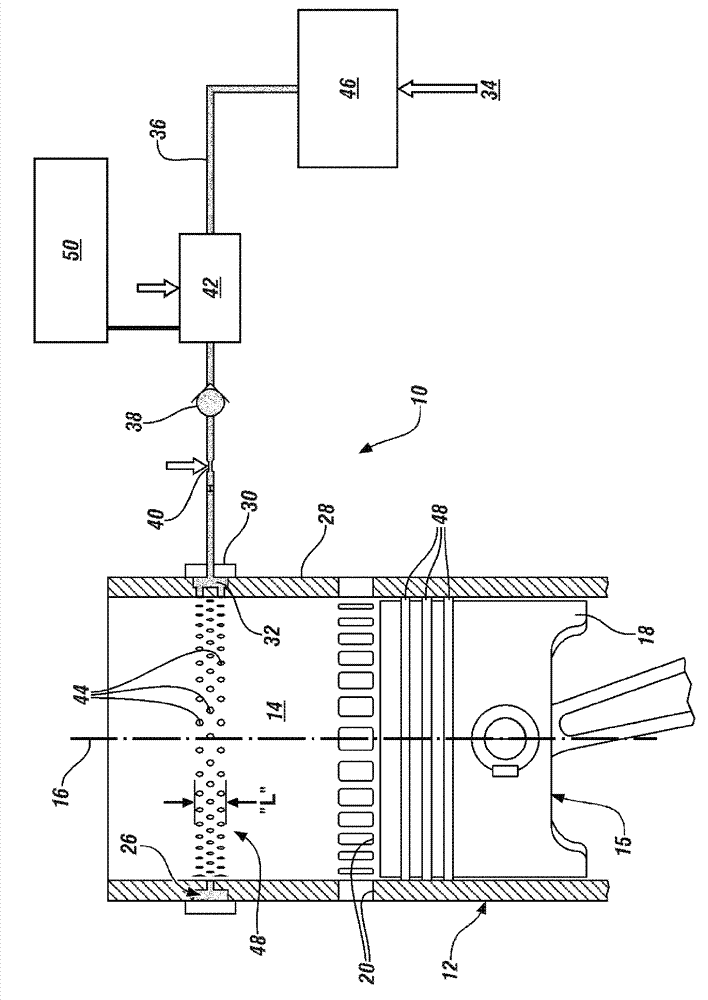

[0037] The following description is merely exemplary in nature, and is not intended to limit the disclosure, its application, or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts or features. As used herein, the term module or control module refers to an application-specific integrated circuit (ASIC), an electronic circuit, a processor (shared, dedicated, or grouped), and memory that executes one or more software or firmware programs, Combinational logic circuits and / or other suitable means of providing the desired functionality.

[0038] now refer to figure 1 , an exemplary embodiment involves a piston reciprocating within a cylinder (and in this exemplary embodiment, part of internal combustion engine 10 ). In this example, the internal combustion engine is a 2-stroke engine comprising a cylinder liner 12 containing a cylinder 14 having a piston 15 reciprocally mounted therein for axial travel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com