Method and apparatus for joining screen material for minimal optical distortion

A bonding material and minimization technology, applied in optics, thin material handling, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

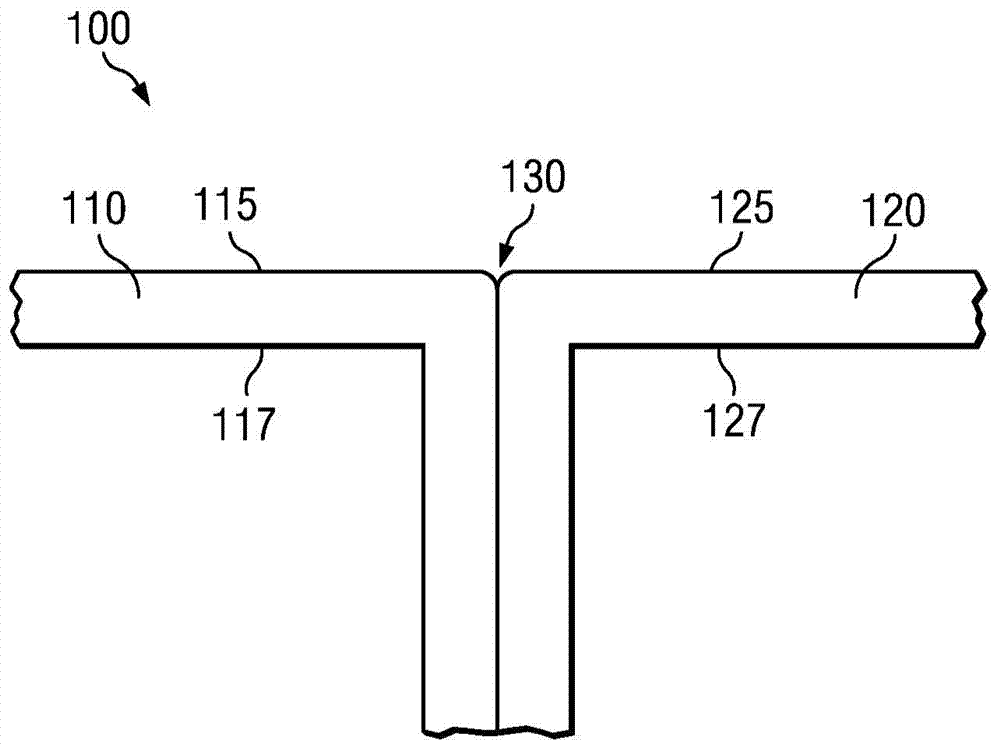

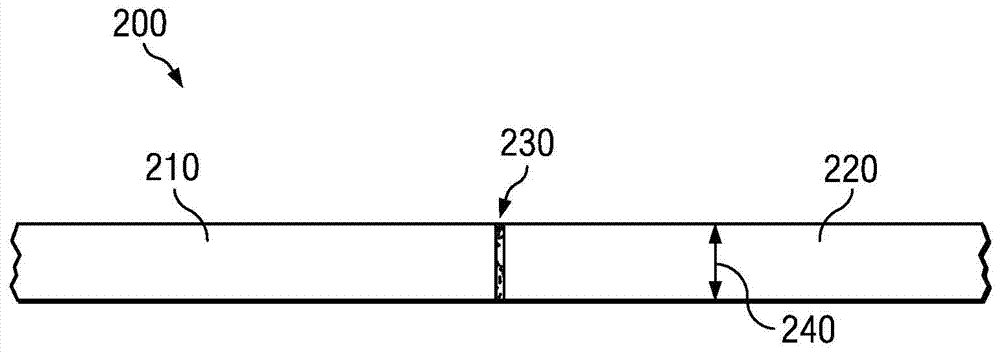

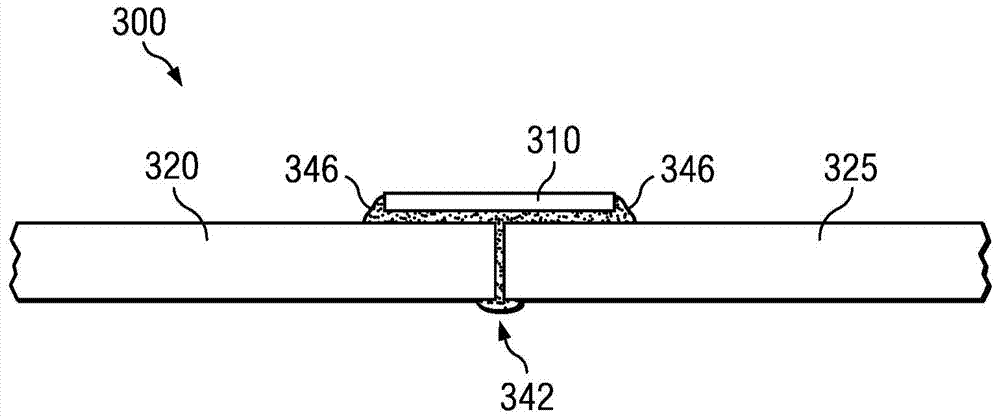

[0015] According to the present disclosure, a method for joining materials may include positioning a first edge of a first piece of material adjacent to a first edge of a second piece of material to create a seam, and positioning a first side of a third piece of material adjacent to The seam, wherein the optical impact of changes in local surface normals in the vicinity of the seam is substantially minimized. The first and second pieces of material may be substrates whose first side is covered with an optically functional material and may be substrates with a relatively high tensile modulus. The third piece of material may be adjacent to the seam and may be adhered to the seam by using an adhesive such as PSA, which may be a curable adhesive and in one embodiment, May be cured using UV radiation. Furthermore, a third piece of material may be adhered to the first and second pieces of material on a second side opposite to said first side covered with optically functional materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com