Dust suction pipe raising ring

A vacuum tube and height-adjusting technology, which is used in vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of reduced suction power and lack of flow of the vacuum tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

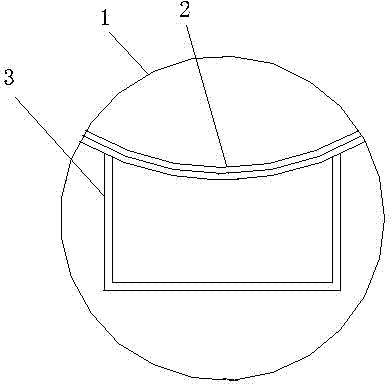

[0013] Such as figure 1 As shown, a vacuum pipe height adjustment ring, the dust suction pipe height adjustment ring includes an outer ring 1, a mesh plate 2, and a steel pipe 3, and the outer ring 1 is made of flat iron and has a circular structure. The screen plate 2 is made of Yuan Gang and is connected with the outer ring 1 and made into one body, and the steel pipe 3 is connected to the screen plate 2 and the outer ring 1 .

[0014] The above is only one of the specific embodiments of the present invention, but the scope of protection of the present invention is not limited thereto, and any person familiar with the art can think of it without creative work within the technical scope disclosed in the present invention. Changes or substitutions should fall within the protection scope of the present invention. Therefore, the protection scope of the present invention should be determined by the protection scope defined in the claims.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com