Hoop tube type air-free tire

A technology for free of pneumatic tires and hoops, which is applied to non-pneumatic tires, special tires, tire parts, etc. It can solve the problems of tires detaching from the rim, uneven tire force, and inappropriateness, so as to facilitate the installation and removal of tires , small rolling resistance, suitable for high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

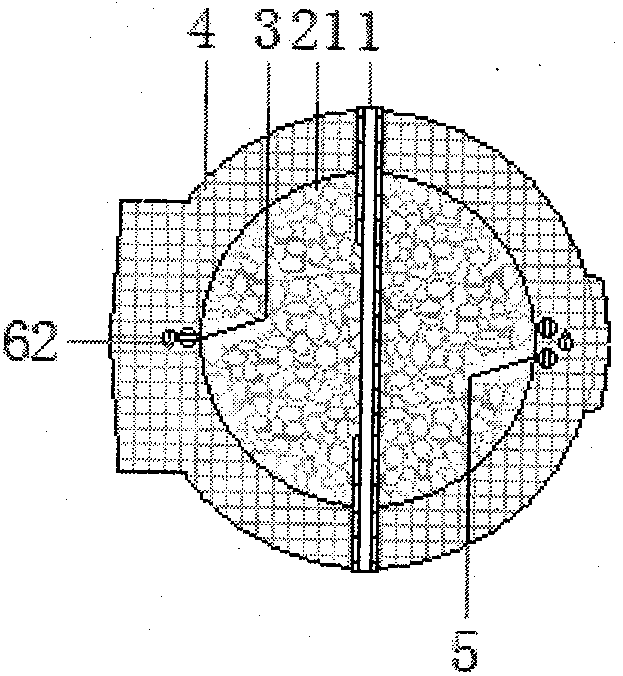

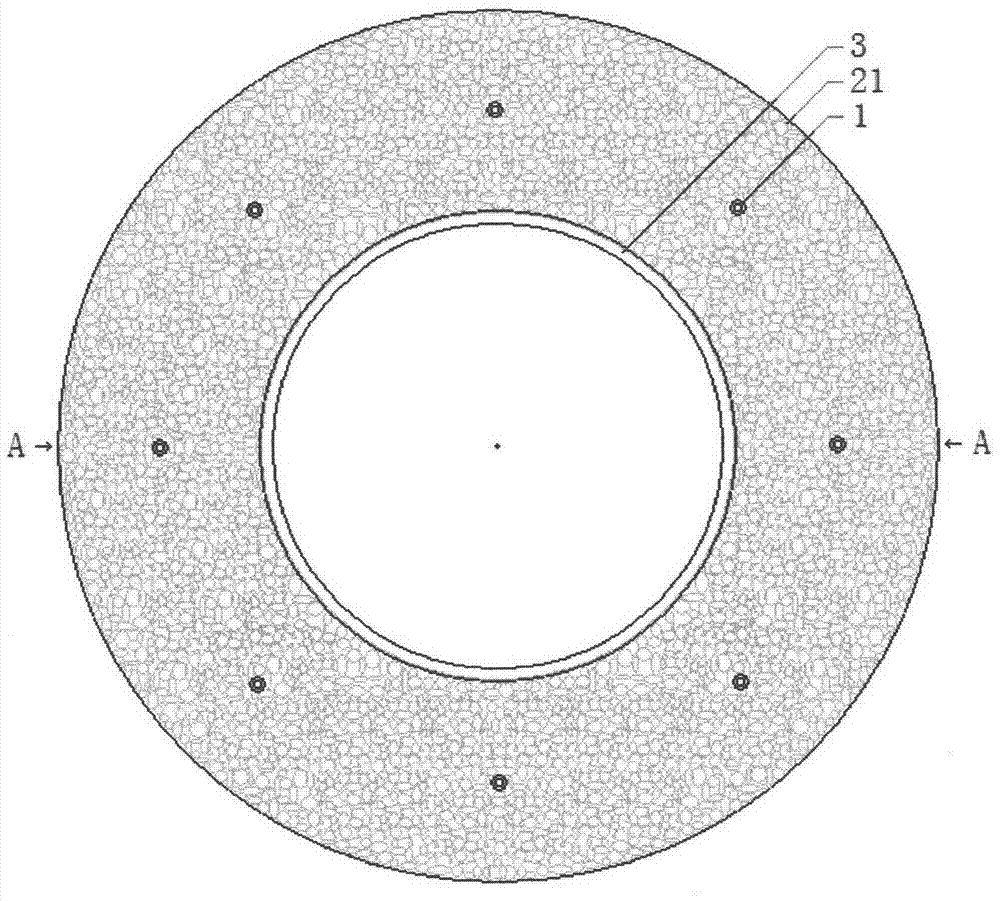

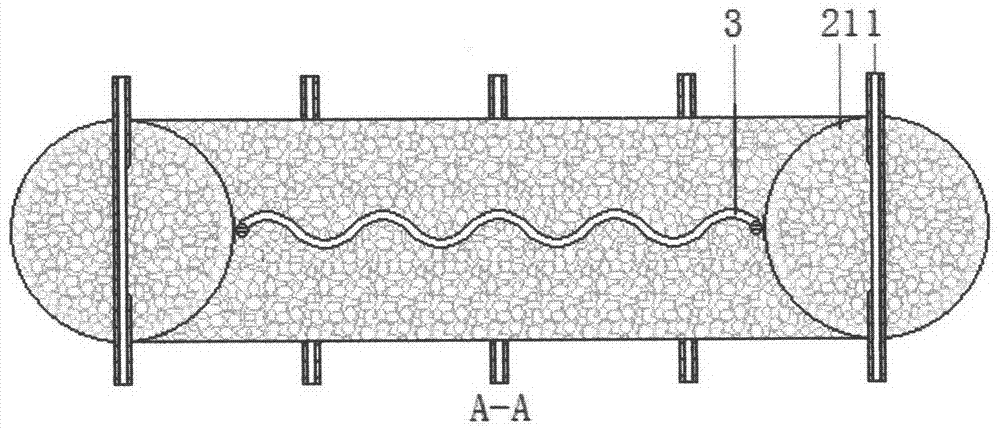

[0007] Embodiment one, such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 As shown, a bubble body ring tube 21 with a circular cross section has eight tire support tubes 1 across and fixed on both sides of the ring at equal intervals, and the two ends of each tire support tube 1 protrude from the bubble body. Outside the two sides of the ring of the circular pipe ring 21, a laterally wavy elastic hoop 3 is fixed on the inner side of the ring to form the inner tube of the hoop. On the ring side, the so-called weft hoop inner tube is formed, and the polymer material is poured into the mold cavity of the weft hoop inner tube supported by the two ends of each tire support tube 1 to form the connected outer tube 4, and the hoop inner tube type is obtained. Free air tires. The foam ring tube 21 is made of polymer material such as PU foam, and the surface can be made into a smooth arc, or can be made to match the grooves of the hoop and interconnected elastic parts....

Embodiment 2

[0008] Embodiment two, such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 8 As shown, at least three non-closed single elastic rings 61 are nested at equal intervals on the tube surface of the weft hoop inner tube of embodiment 1. Others are the same as in Embodiment 1.

Embodiment 3

[0009] Embodiment three, such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 9 As shown, a helical tube spring 62 is sheathed at equal pitches on the tube surface of the weft hoop inner tube of embodiment 1, and the connection at both ends is preferably clamped by inserting tube sections. Others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com