An assembly tolerance optimization design method based on cost objective optimization

A technique for assembly tolerance, target optimization, applied in computing, special data processing applications, instrumentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

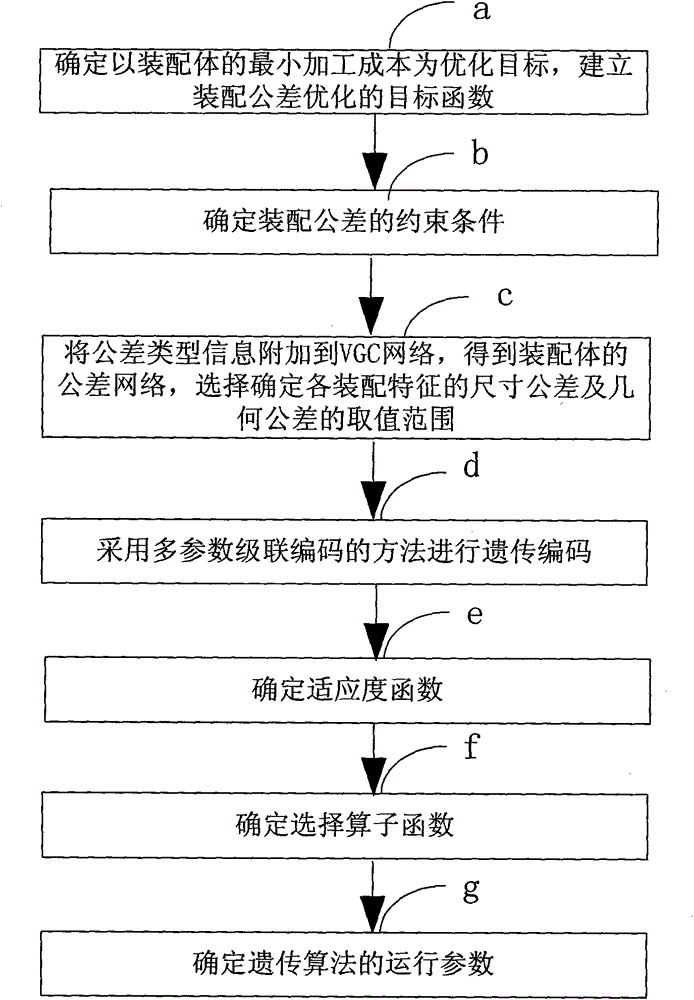

[0071] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

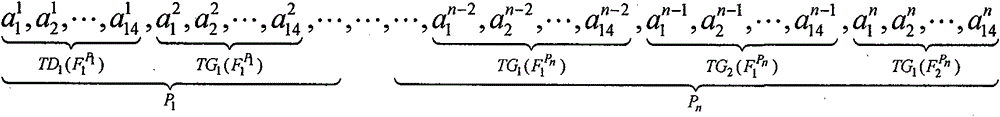

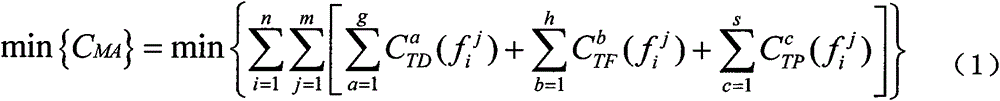

[0072] The invention takes the minimum processing cost as the optimization goal, comprehensively considers the size tolerance and shape tolerance, and establishes a new cost-tolerance model. The total tooling cost of an assembly consists of the tooling costs of all attached parts, and the tooling cost of a part consists of the tooling costs of all its feature faces. Not every feature face participates in the assembly of the part. Since the present invention mainly considers the optimization design of assembly size tolerance and shape tolerance size, only the processing cost of the assembly feature surface is considered.

[0073] see figure 1 As shown, it is a flow chart of the assembly tolerance optimization design method based on cost target optimization of the present invention.

[0074] The process i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com