High speed air bearing ring

An air flotation and steel ring technology, applied in textiles and papermaking, etc., can solve the problems of yarn breakage, complex structure, and inability to control the rotation speed of the ring ring orbit, reducing friction, reducing mutual rotation, and air pressure. increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

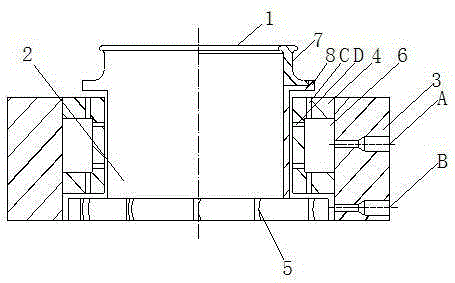

[0015] Such as figure 1 As shown, the high-speed air-floating steel ring of the present invention includes an upper ring ring 1, a lower ring seat 2, an outer ring 3, an inner bushing 4, and a fan blade 5 installed at the bottom of the lower ring seat;

[0016] Such as figure 1 As shown, the inner bushing 4 is in the shape of a ring, the diameter of the outer circle is the same as the diameter of the inner through hole of the outer ring 3, and the height is lower than that of the outer ring 3, and an annular air chamber 6 is arranged on the outer peripheral surface. The bushing 4 is fixedly mounted on the inner side of the outer ring 3, and the upper surfaces of the two are in the same plane; the outer ring 3 is drilled with a plurality of through holes A along the diameter direction in the part opposite to the air chamber 6, and in the part o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com